-

Conclusion

12/09/2021 at 01:39 • 0 commentsThat wraps up this project. I am very happy with how it turned out and its function. I successfully assembled a small run of 10 PCBs with 64 components per board using this SMD Vacuum without any issues. Utilizing the blunt needle tip along with one of the suction cup tips that came with the Weller WVP I was able to handle all the SMD parts for those PCBs. The smallest package size was 0603 and the largest package was a ESP-12F WiFi module. The SMD Vacuum had enough suction power to lift everything and made placement easy. Goodby tweezers, hello SMD Vacuum.

-

Nozzles

12/09/2021 at 01:38 • 0 commentsNozzles, you will need some. The Weller WVP comes with some nozzles and suction cup tips. You can also get these nozzle and cups with one of the cheap vacuum suction pens. These nozzles and suction cups are great for picking up larger SMD packages like microcontrollers and power MOSFETs but they are not useful for small packages such as 0603 resistors and capacitors. The suction cup gets in the way and grips the part so well that it will not release when suction is turned off. Removing the suction cup is not possible since the nozzle ID is large enough that a 0603 resistor can get sucked up it. Remember that filter, this is why it is installed before the shutoff valve.

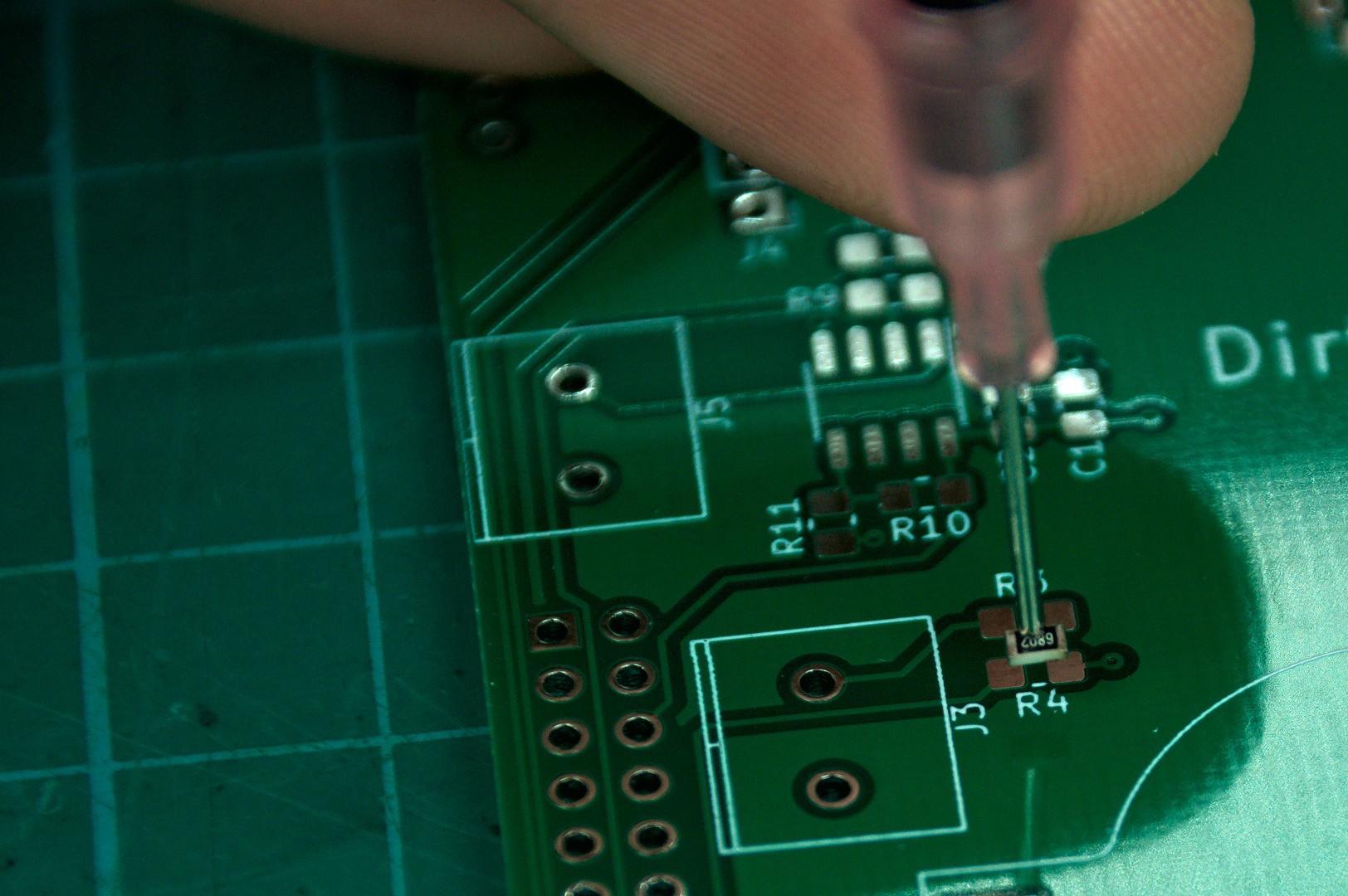

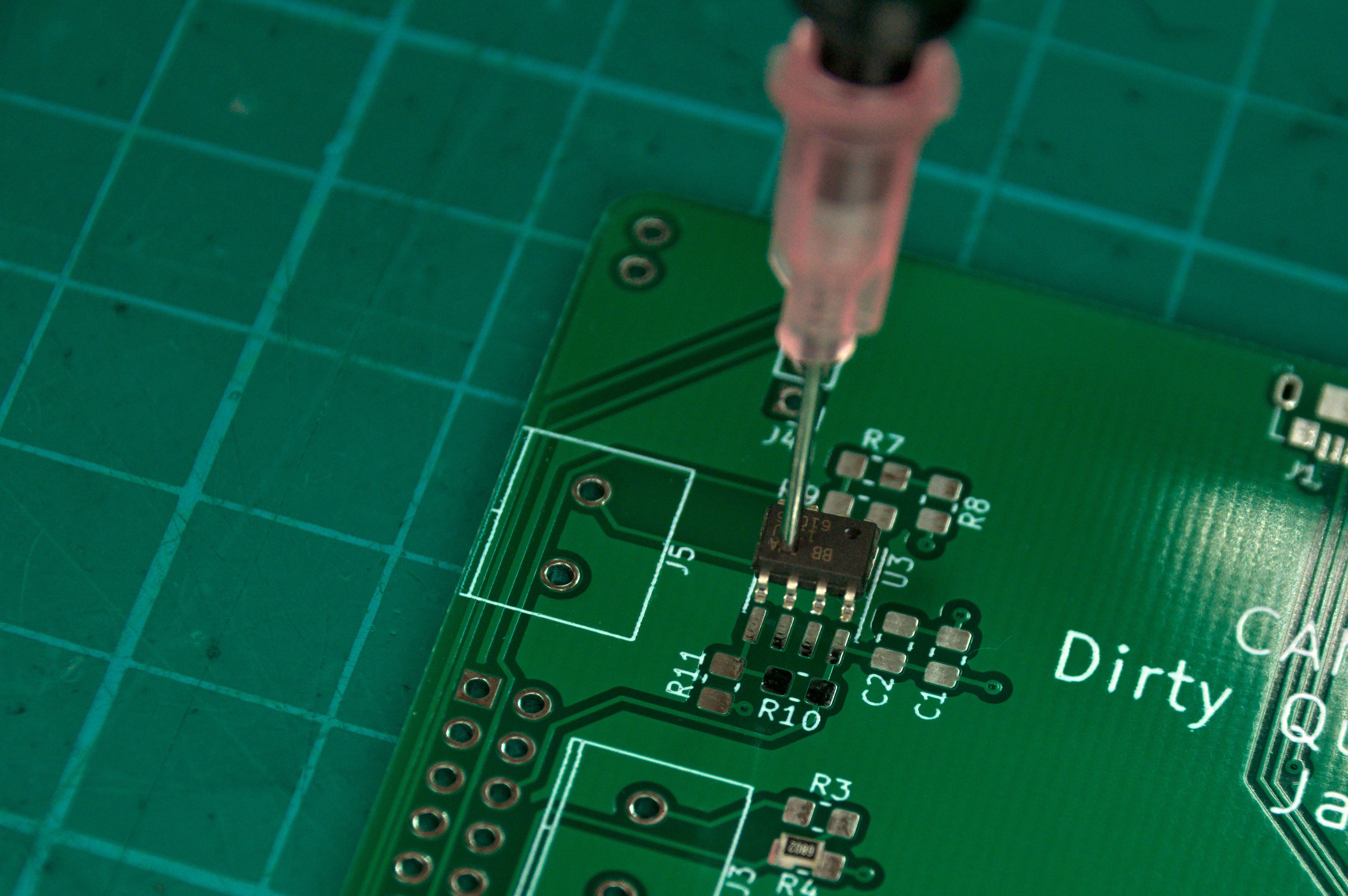

What I found that works great for these small packages is blunt tip needles for syringes. I got a variety pack with 14ga, 16ga, 18ga, 20ga, 22ga and 25ga needles along with some syringes. I found the 20ga needle (pink) to be the perfect size for picking up 0603 packages along with SOT-23 transistors and some larger packages. The part drops off as soon as suction is off and you can see the part while manipulating it. The only problem is that the nozzle requires you to work with the hand piece vertical since it does not have the angle on it like the nozzles that came with the Weller WVP. If I get adventurous I may try bending one someday but for now I found working vertical gave me better position control.

![]()

![]()

-

Hand piece

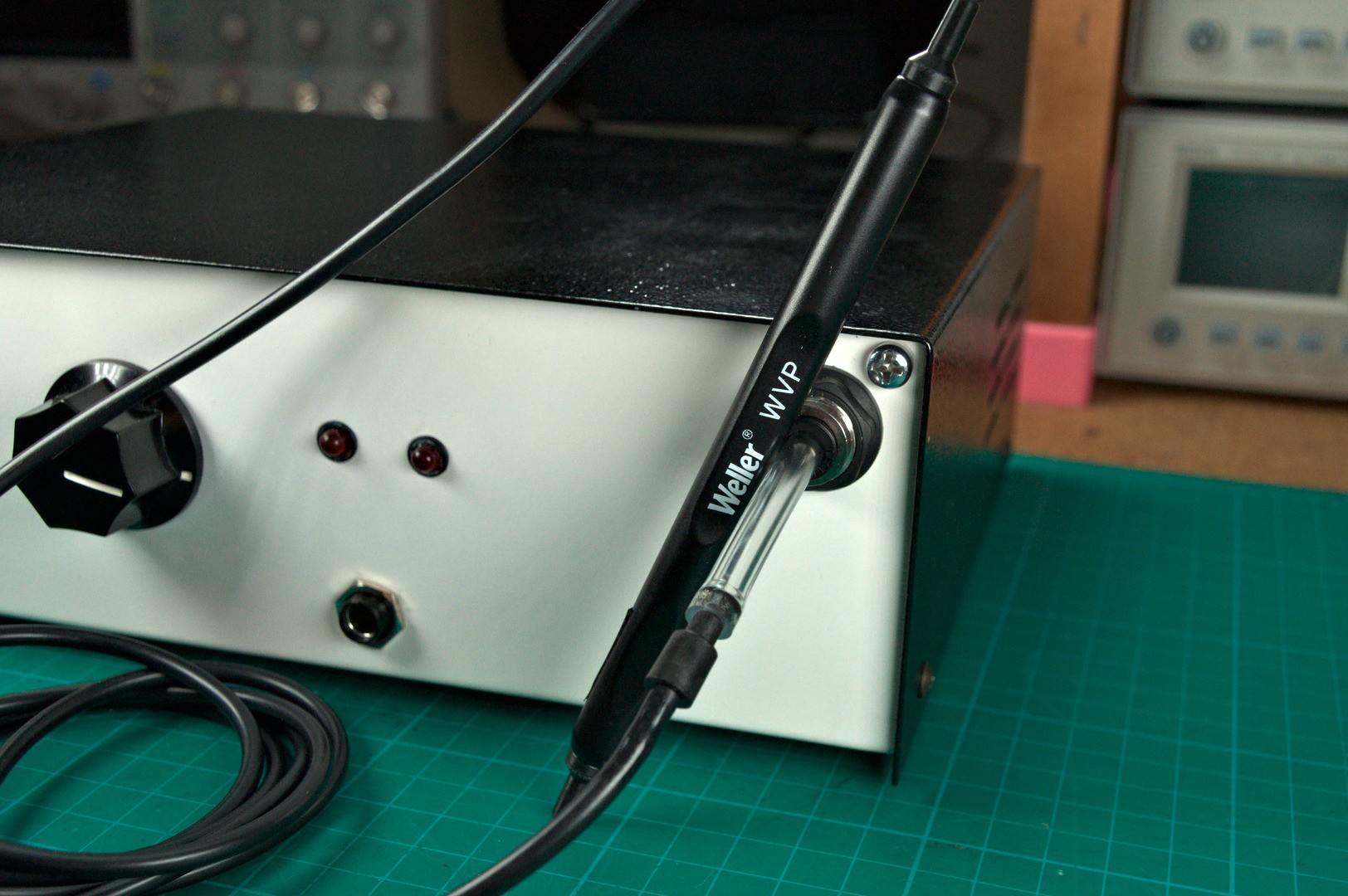

12/09/2021 at 01:36 • 0 commentsAside from the vacuum pump the second most important item for this build is the hand piece. This is the part that you hold and use to pickup SMD parts. I was able to find a used Weller WVP on eBay. I would suggest looking there or other used market places first since it is relatively expensive brand new for some reason. The part number to search for is T0052918499N or look for replacement parts for a Weller WR3M Station. DigiKey sells a new Weller WVP for $88. The Weller WVP is adapted to the SMD Vacuum by cutting a small section of the 1/4″ PVC tubing and inserting the plastic nozzle on the end of hand piece into the tubing as shown below. Finally block the hole on the side of the Weller WVP since we are using a foot pedal to control suction and not your finger.

![]()

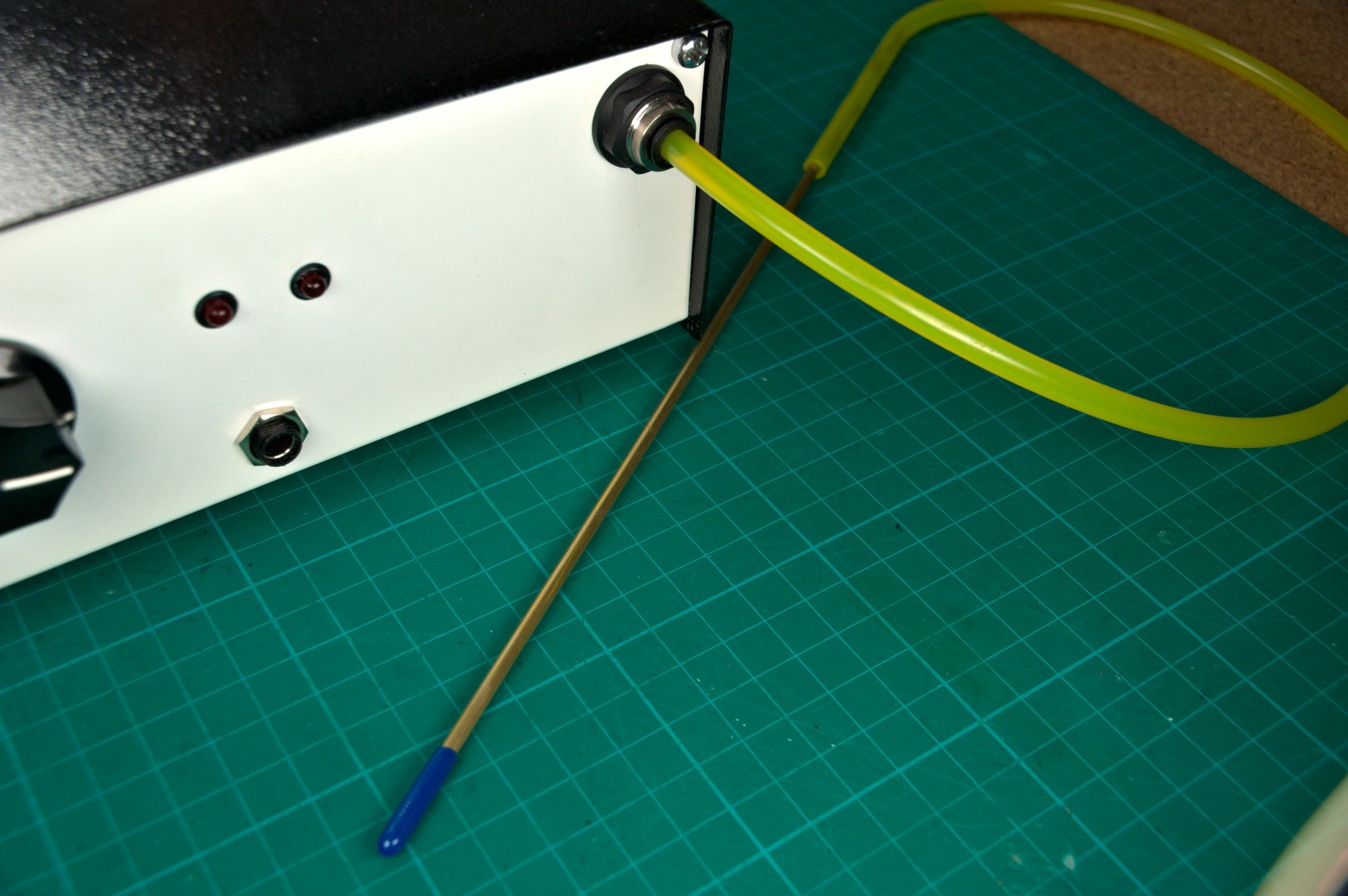

This hand piece feels really nice and works well for me. Having said that if you cannot find one for a decent price or feel like making your own hand piece I did do a little experimentation and found that it is possible to make something similar while not as well polished. I used a 1/8″ OD Brass Tube and connected it to the front port of the SMD Vacuum using 1/4″ OD Soft Tygon PVC Tubing. The clear PVC tubing used inside the SMD Vacuum is a little stiff for my liking and I found that Tygon tubing is slightly more pliant. The photos below show the rough setup I was experimenting with before I found the Weller WVP. My plan was to 3D print a case to go around the brass tube for gripping and to also 3D print adapters so that the nozzles could connect better to the brass tube. As pictured it works fine although not very ergonomic. For nozzles I used a rubber protective cover that comes on the engraving bits for the 3018 pro with a small hole that I drilled in the end. This setup was a rough prototype that I would have refined more had I not picked up a Weller WVP.

![]()

Manual Pick and Place SMD Vacuum

Foot pedal operated SMD Vacuum for manual placement of components. This upgrade from tweezers simplifies SMD placement during PCB assembly.

leumasyerrp

leumasyerrp