-

Qi charger 2

08/31/2023 at 07:12 • 0 comments![]()

![]()

![]()

![]()

![]()

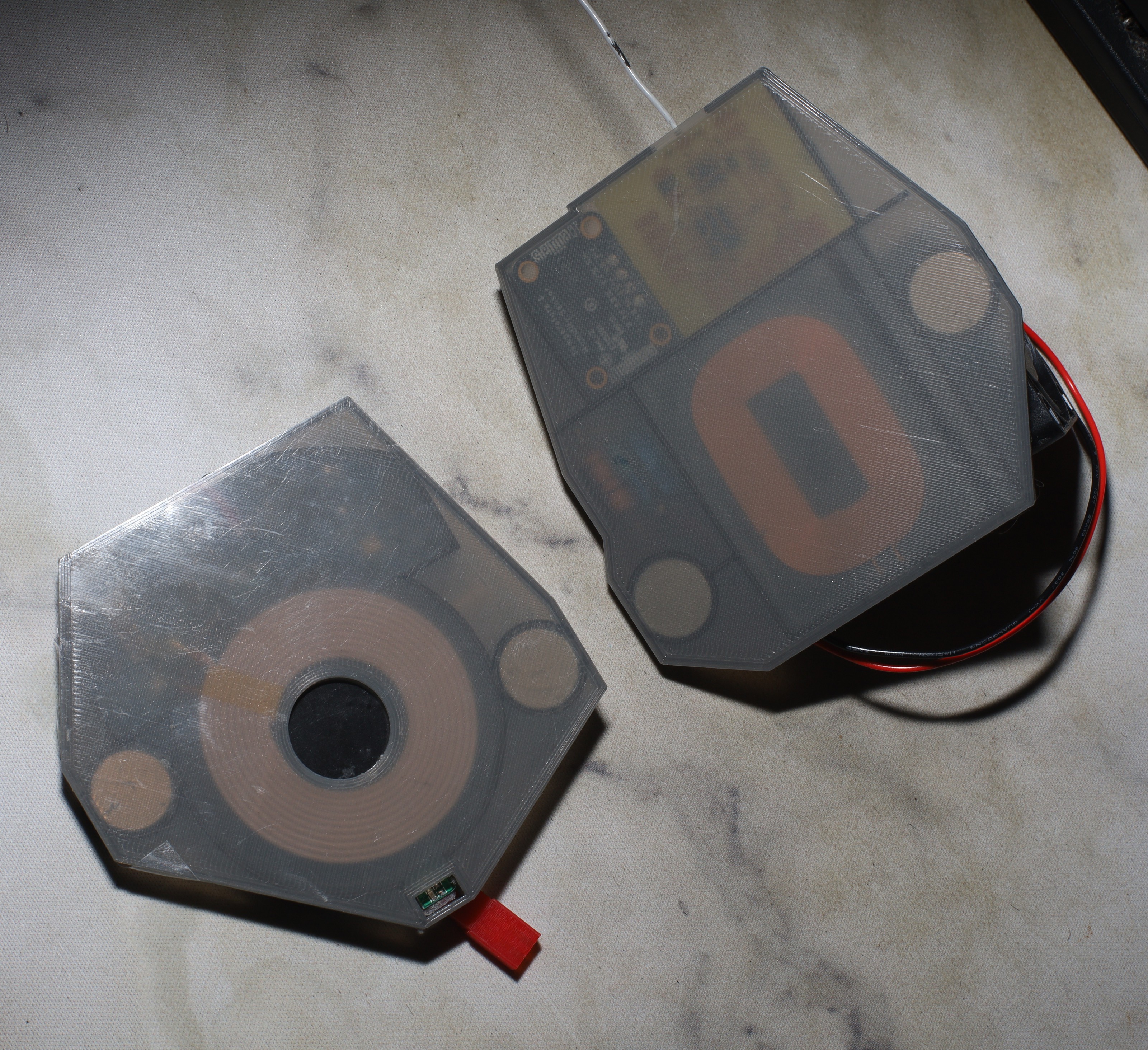

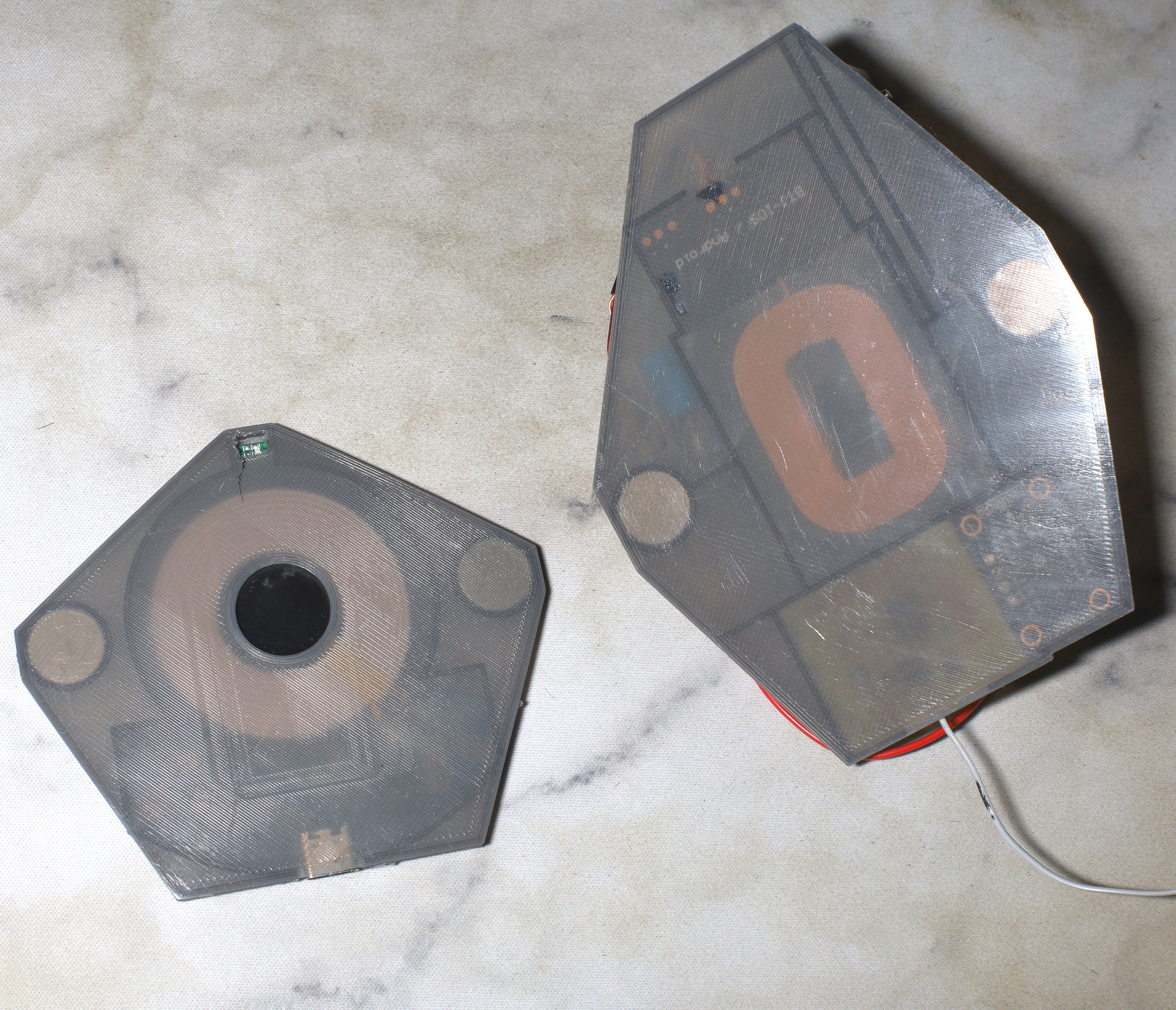

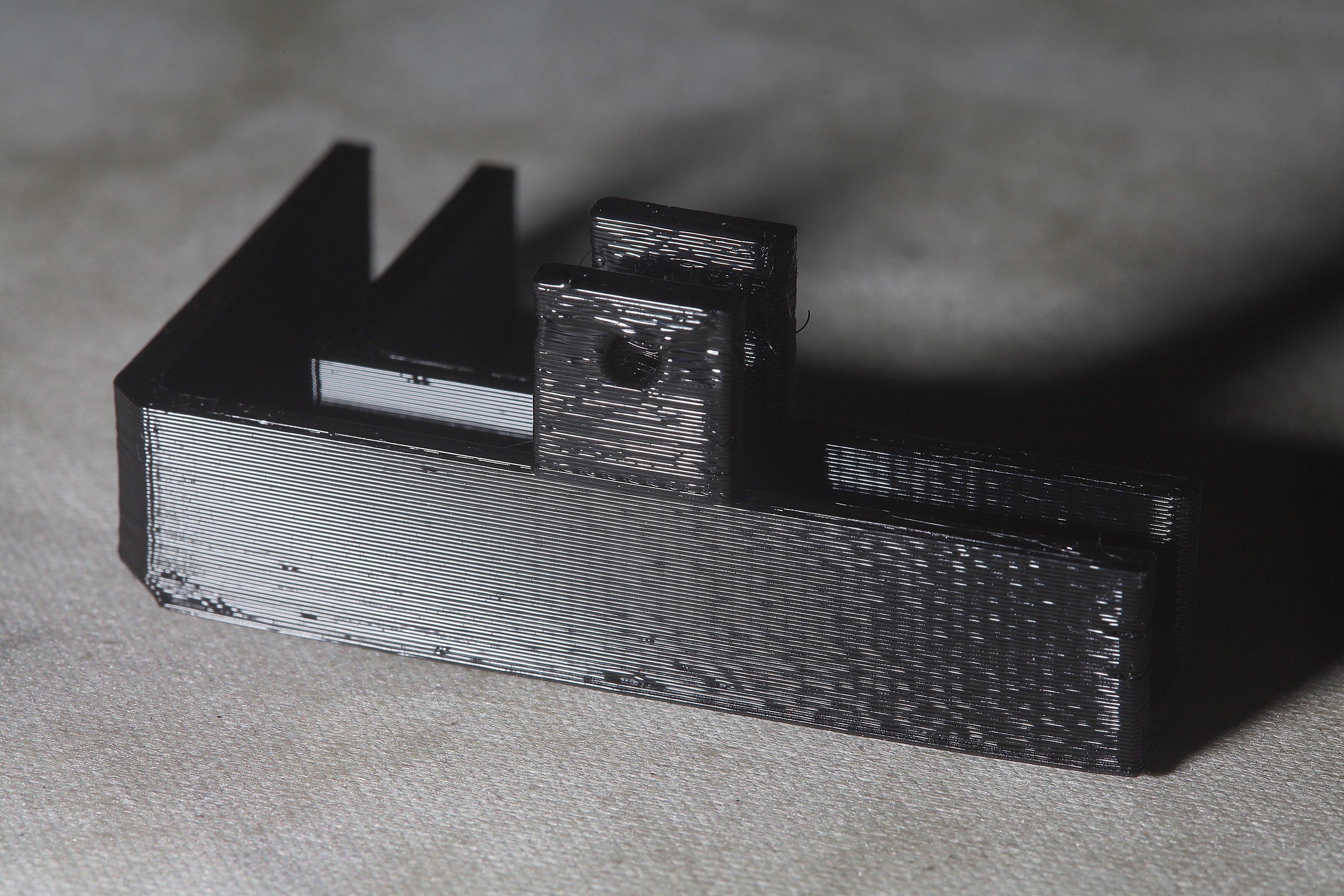

Another go with new PETG mounting plates didn't yield much. Maybe there could be separate panels for the power induction on the flat part & the loads on the corrugated part. Mounting on the corrugated part would still be tricky despite the lack of induction. Scotch has proven to degrade in the chamber. The circuit burns 150mA at the USB input.

Welding PETG manely works, but is very brittle & as hard to undo as welded PLA. It might require a temperature below 300C to avoid boiling off.

![]()

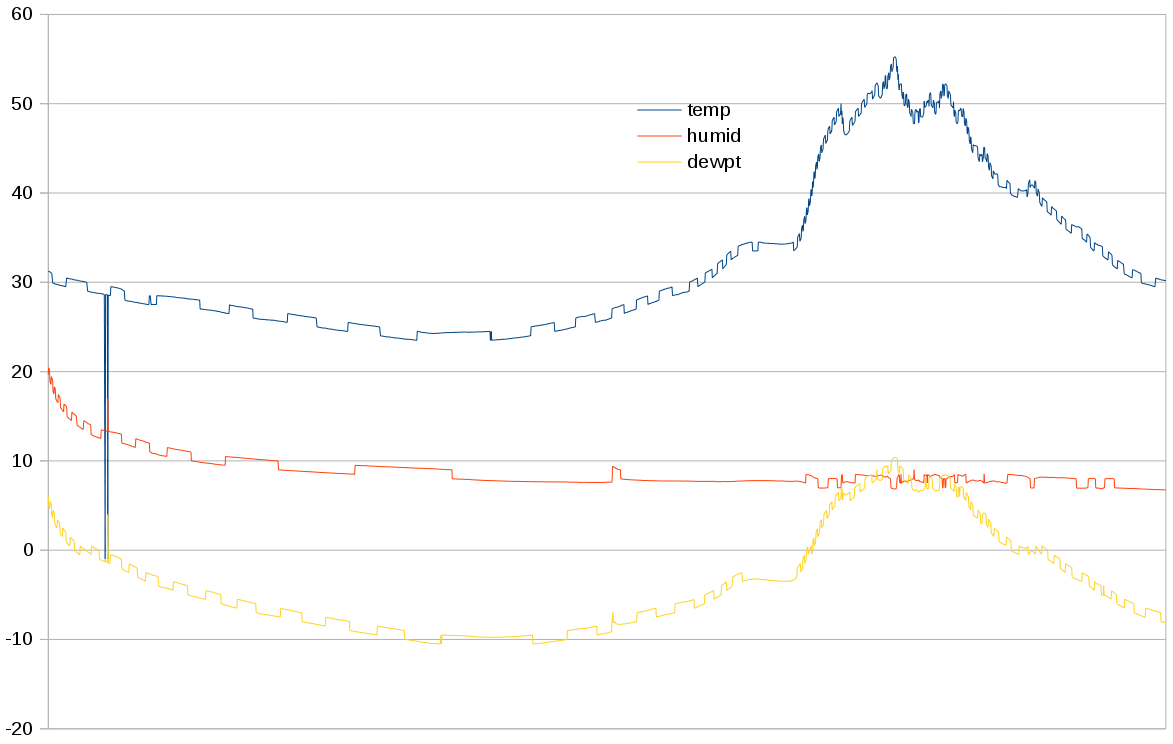

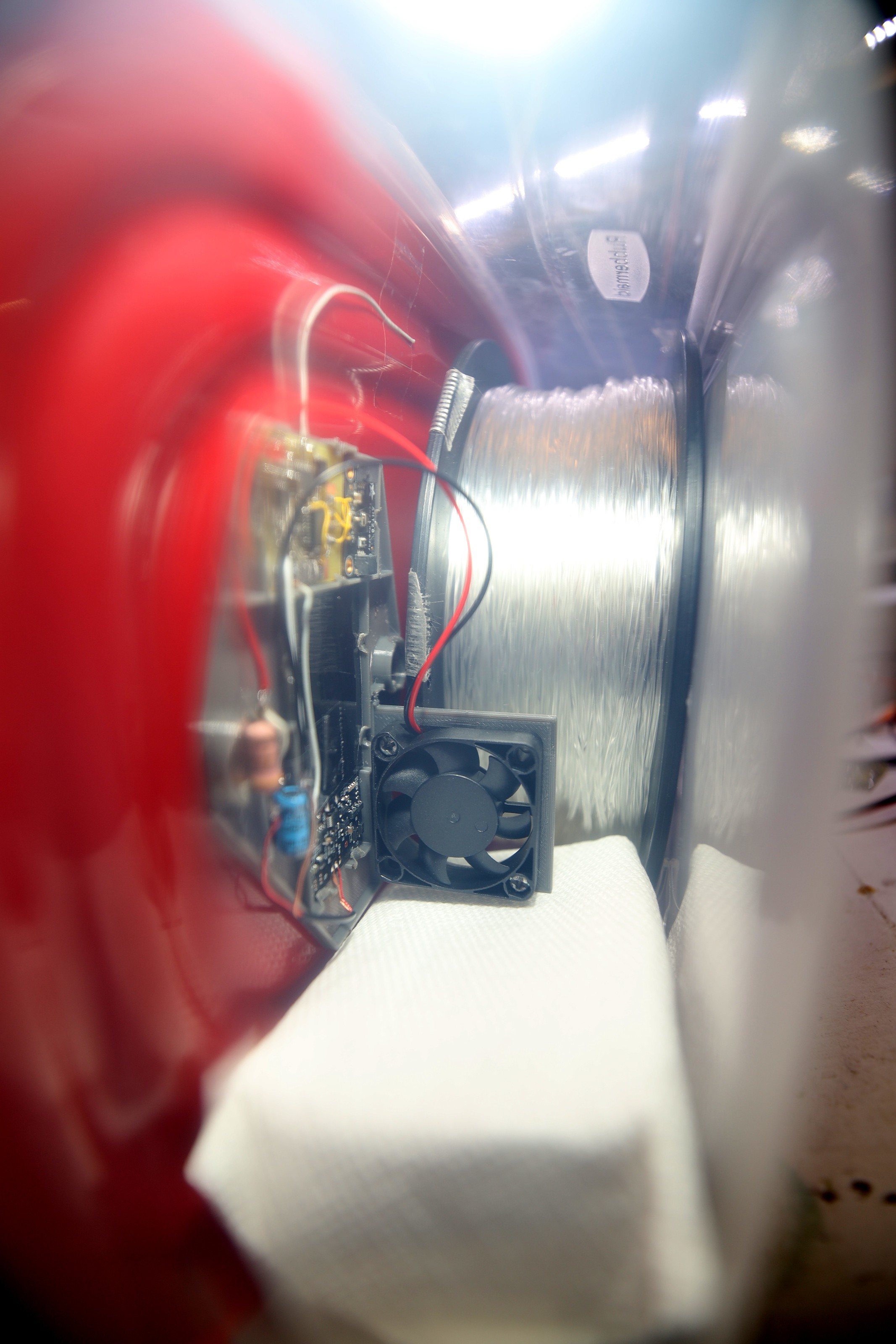

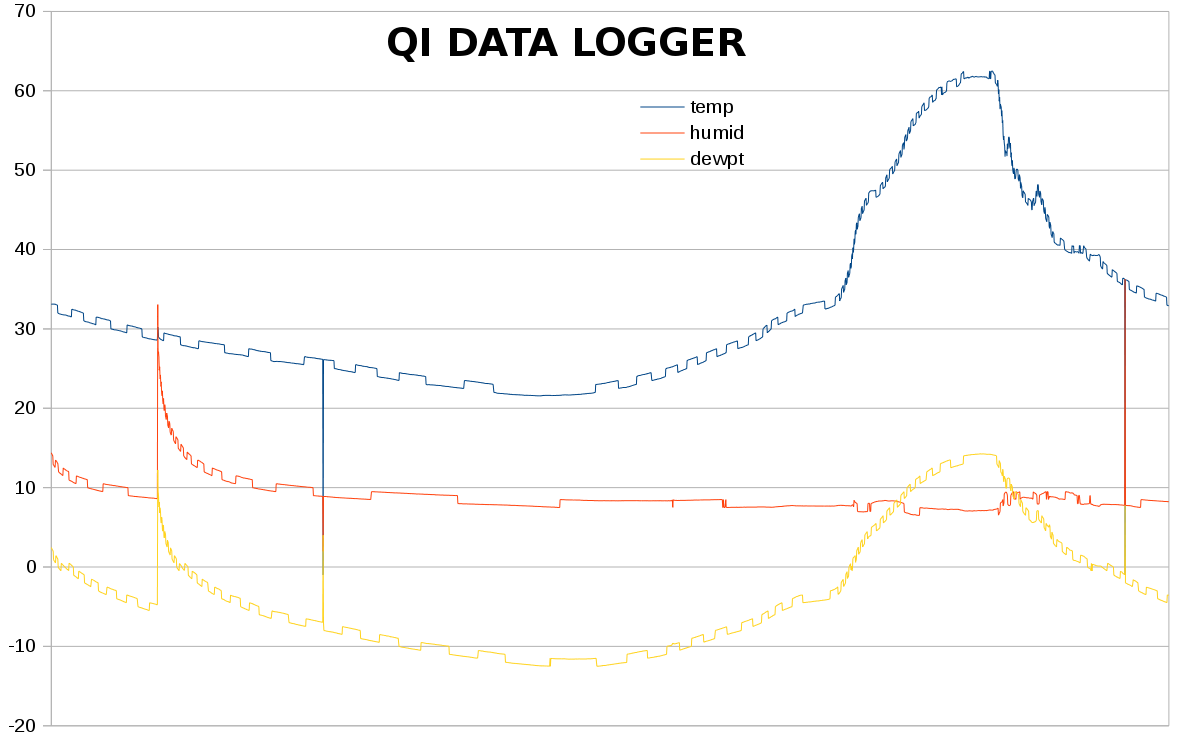

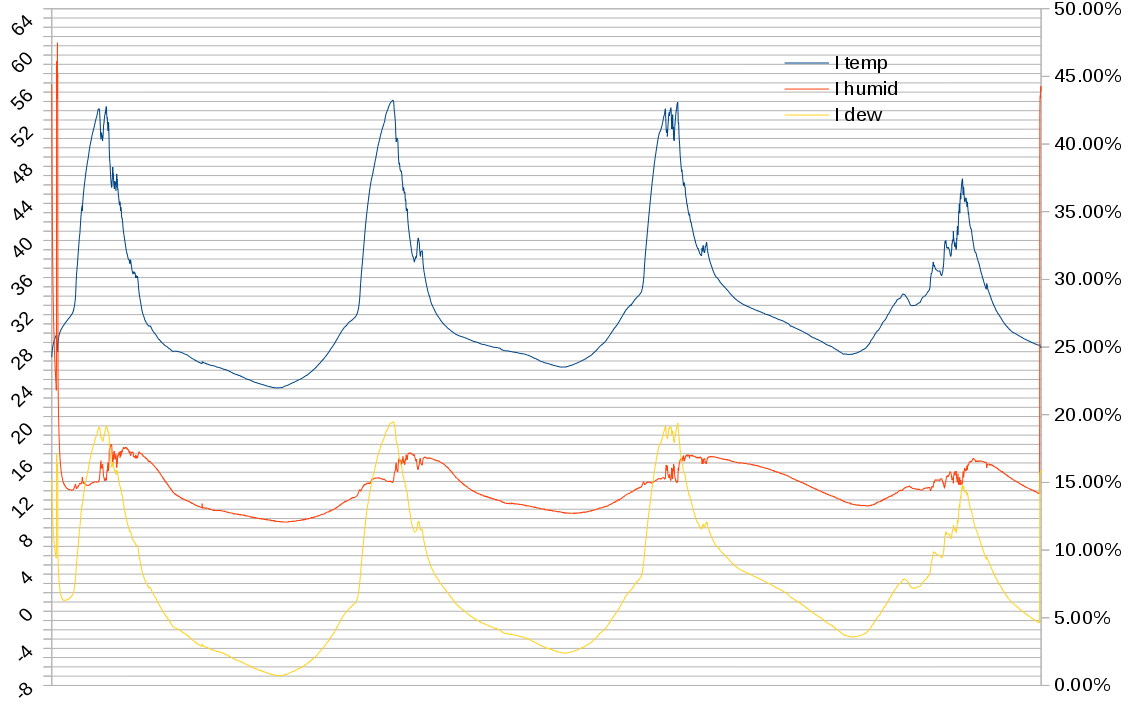

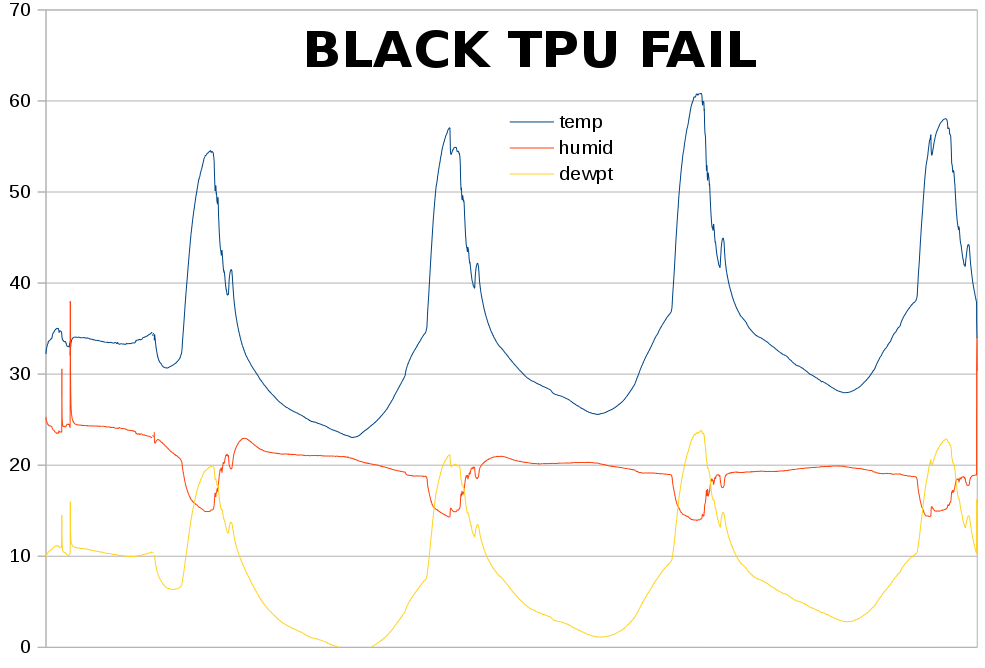

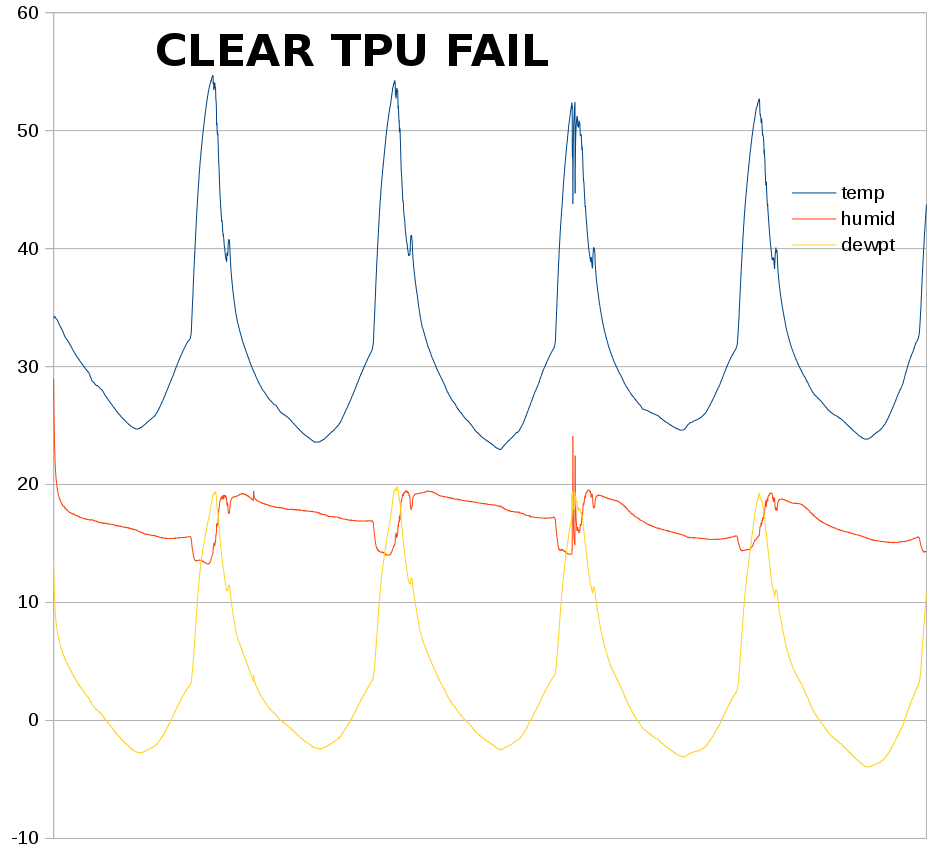

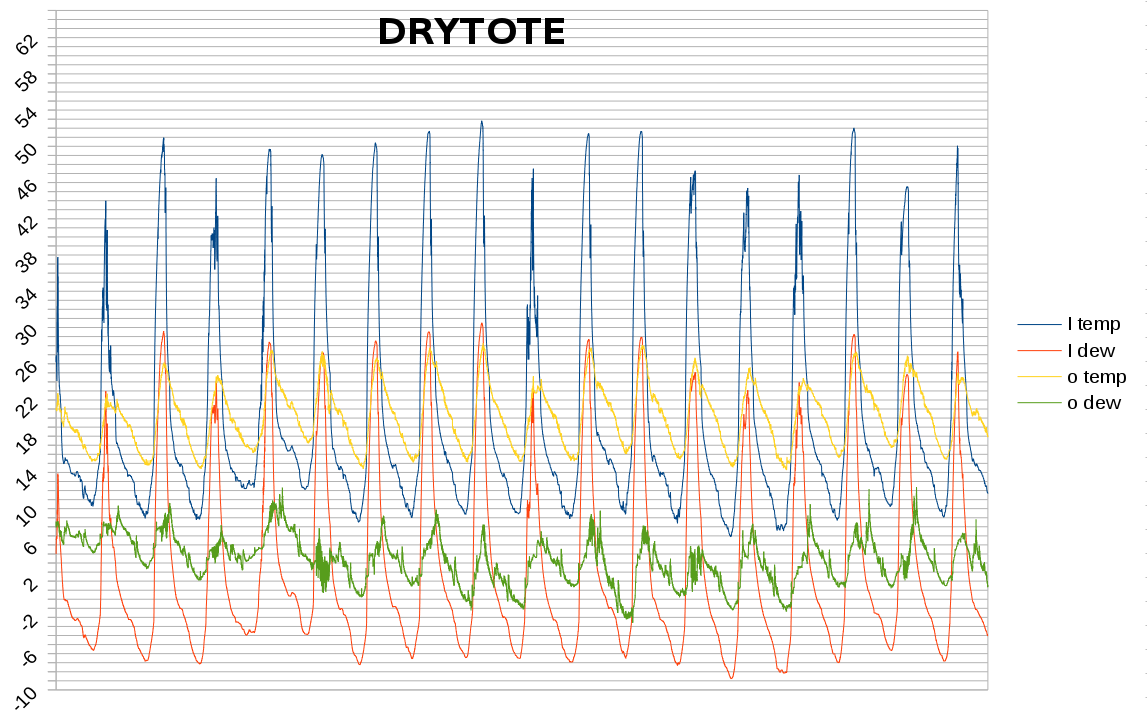

Lower starting humidity got it down to -10C dewpoint. The inductive solution is so obvious now, it's hard to believe it took so long. The only improvement might be stacking the fan on top of the radio, but it's going to be a miniscule improvement.

-

Data logging

08/26/2023 at 22:23 • 0 commentsReviewing the source code, it's hard to believe this journey began with a recycled inkjet vacuum pump, a fuse to prevent it from stalling, dual I2C drivers.

With the inductive power, there's no longer an easy way to measure external temperature & toggle the fan based on a temperature difference. The fan has to always run. All the brain is for is logging data. It's the only way to know if the container is leaking or the desiccant is dead. There are bluetooth sensors which would do the job with a lot less work.

https://www.adafruit.com/product/4881

But lions being what they are went ahead with a custom solution. It would send to the same apartment server that handles the desks & weather station. The success rate of any particular idea is so low, it actually ends up saving more than the cost of the commercial solution to build it out of bare chips.

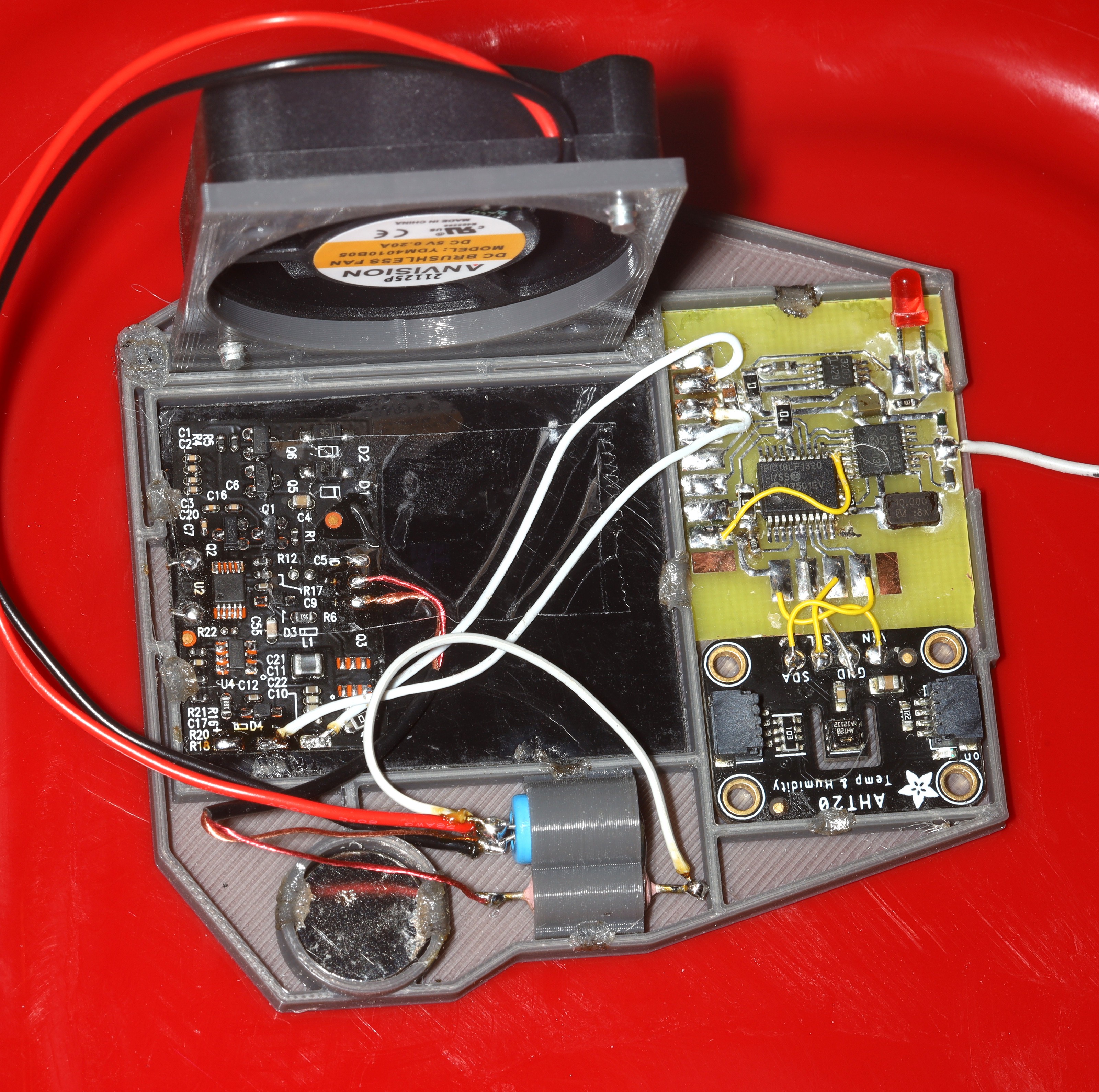

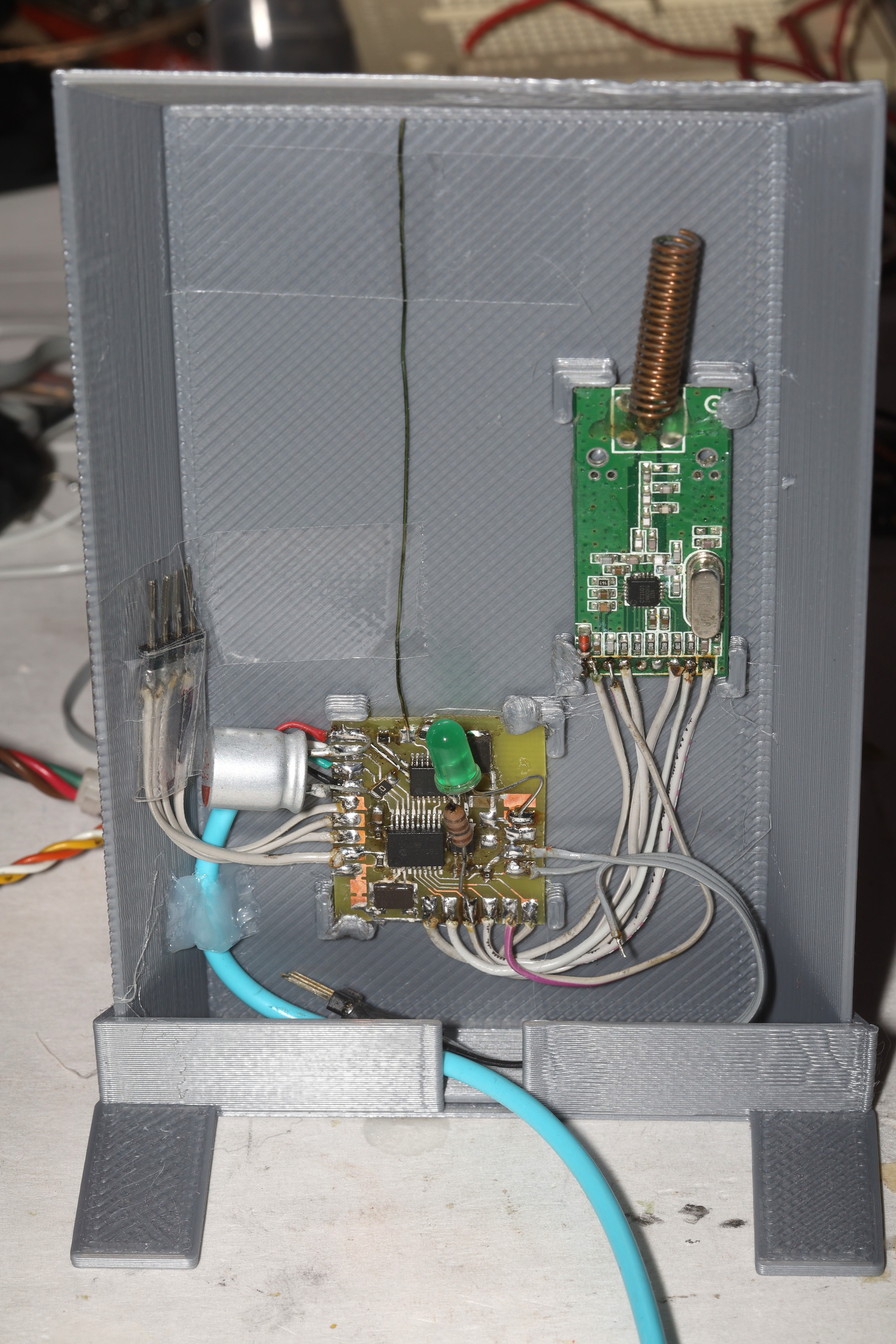

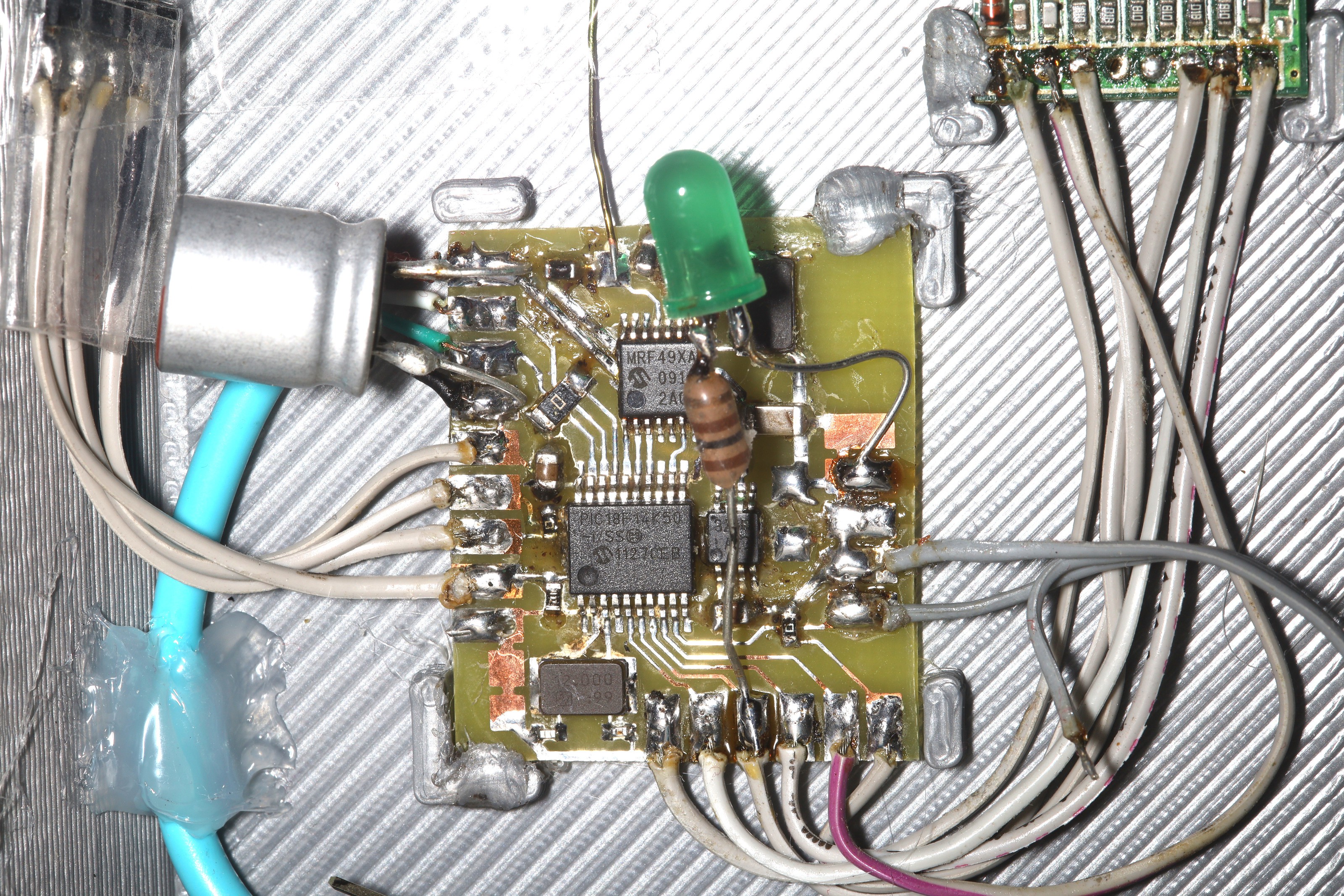

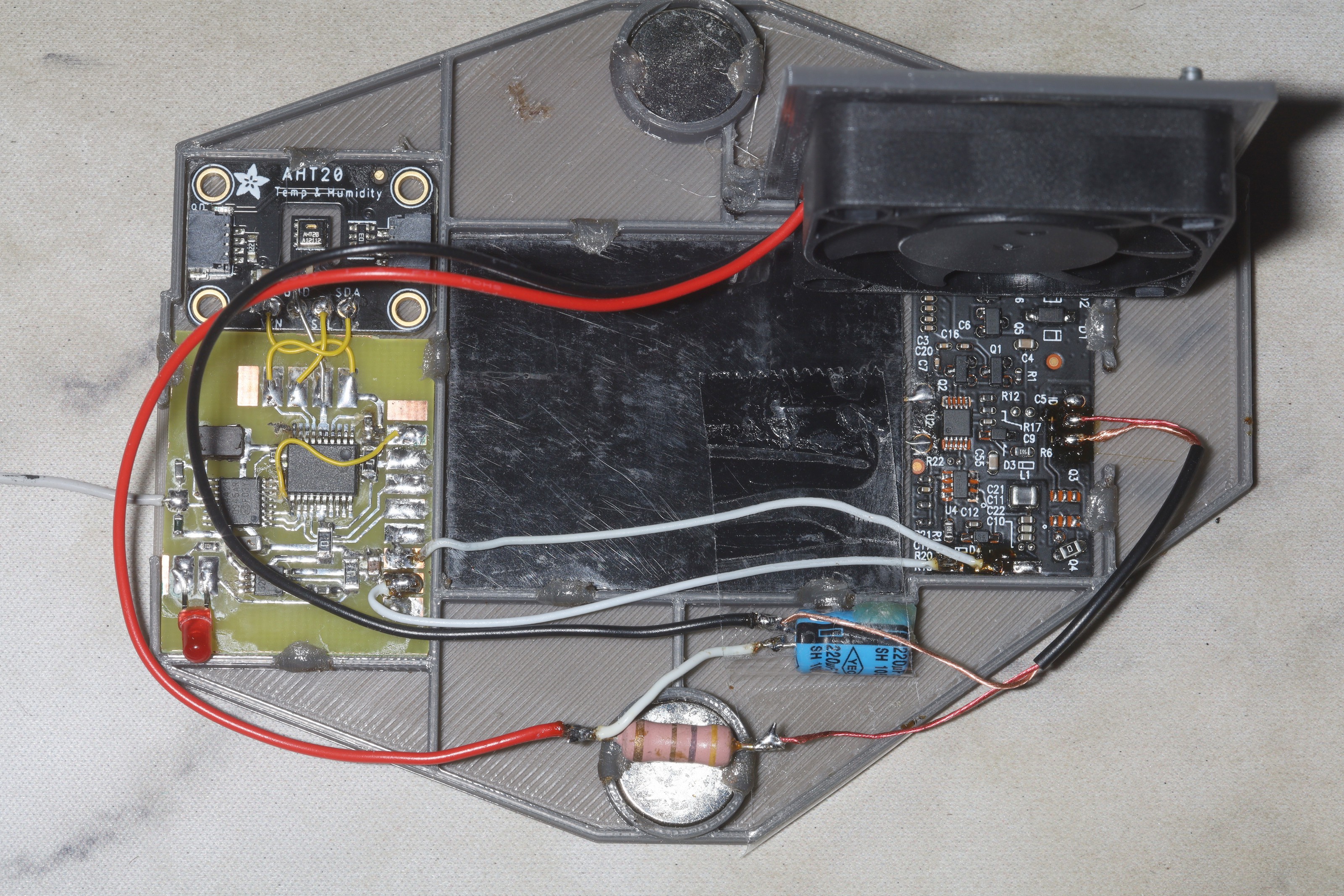

The very last 18LF1320 from 15 years ago went on a board. To stabilize the clockspeed in the heated container, it runs on the clock output from the Si4421. This ended up being a very janky operation. The 18LF1320 can't switch from its internal clock to an external clock.

The trick is if the Si4421 gets into a dead clock state, it needs a power cycle to reset. Then it generates a clock by default. Many retries are required to get the Si4421 out of a dead clock state. Another trap for young players on the 18LF1320 is the serial port receive pin can only be an input when the serial port is on. It's not independent of the TX pin. Finally, if the TX pin fights the radio because the radio is in receive mode, it pulls down the RX pin, copying the radio signal to the RX pin.

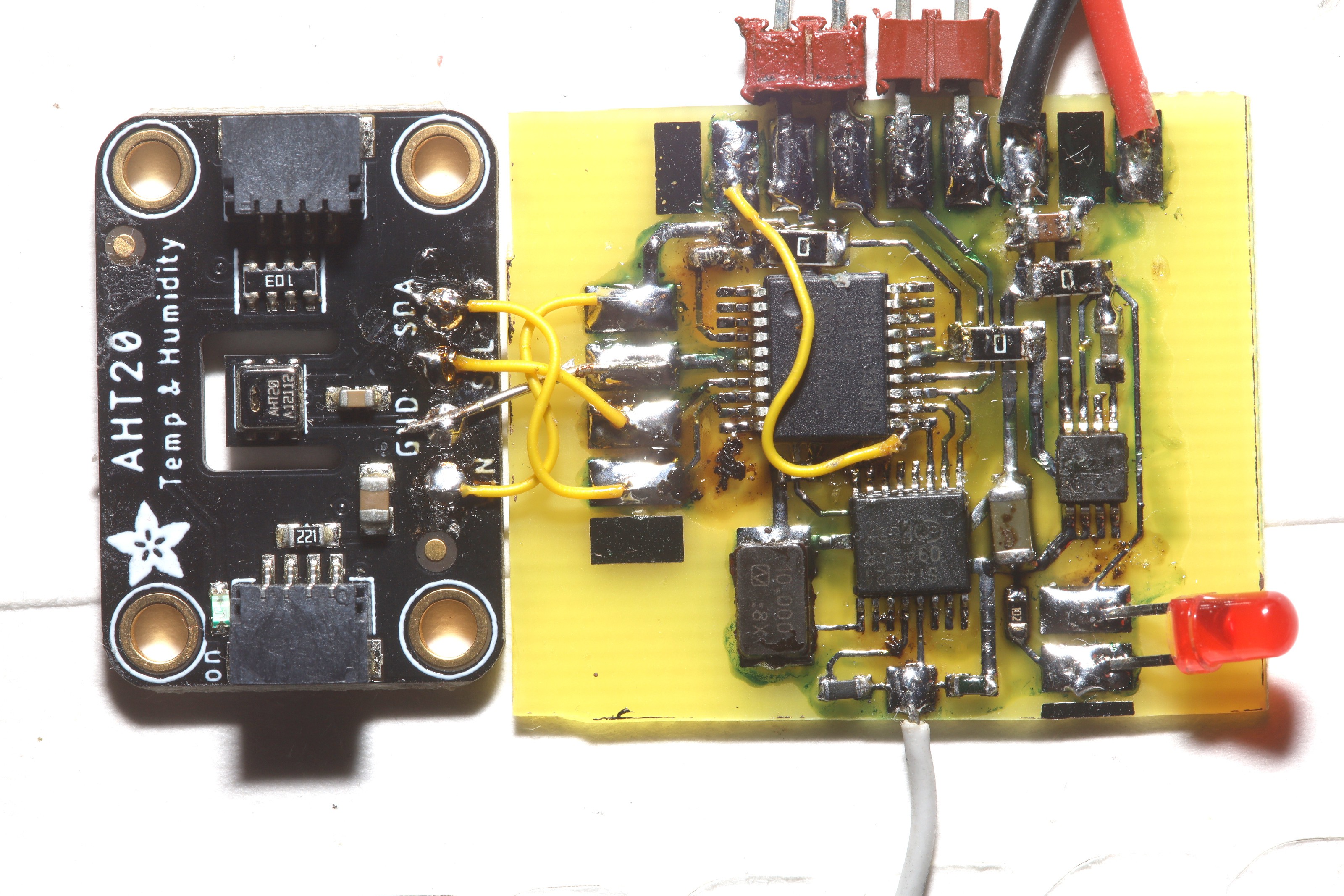

![]()

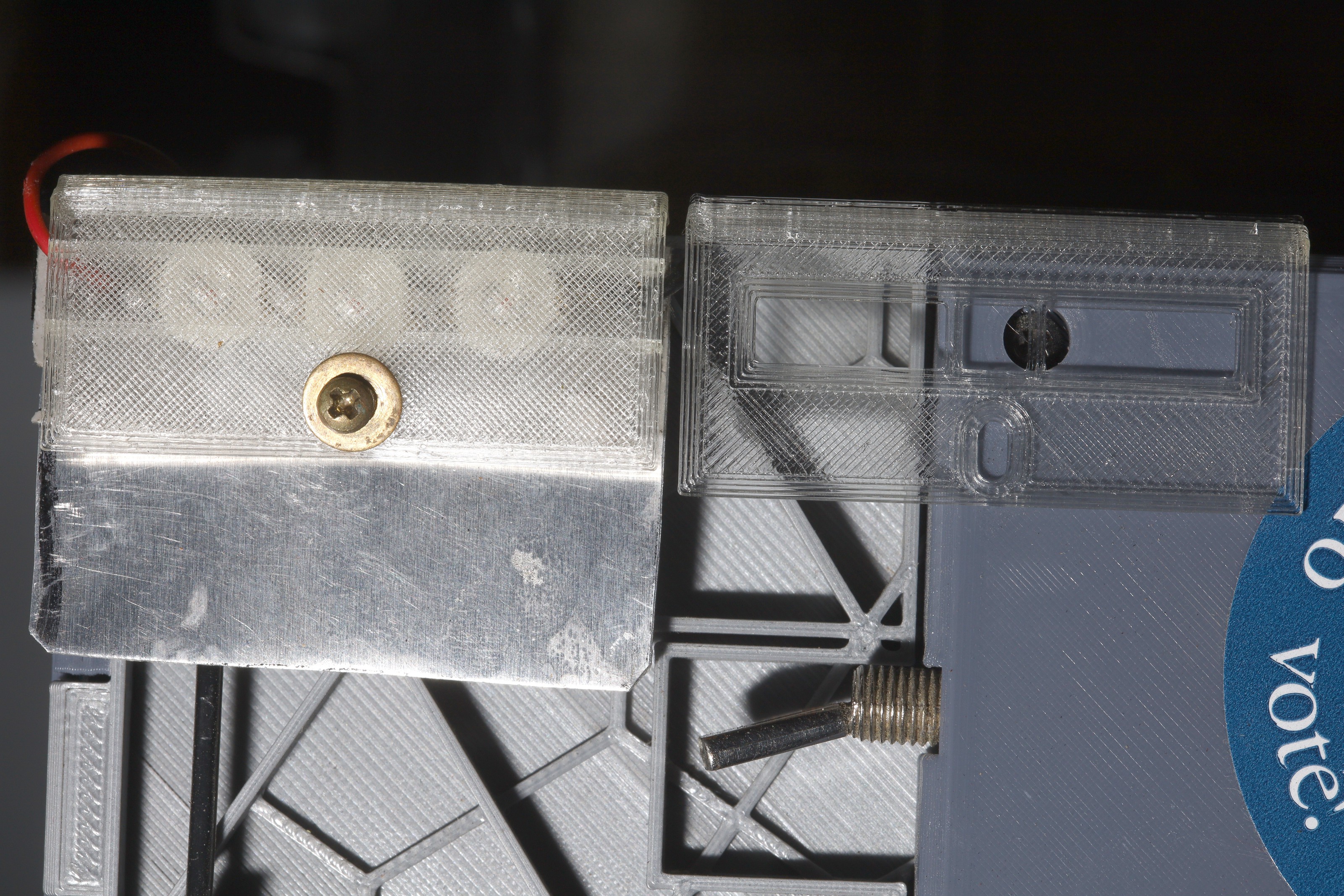

Would have been easier if the jumper wires were straight across, but mounting the AHT20 at a right angle would make it vulnerable to vibration.

![]()

![]()

The mane router upgrade was an LED for received desk code. It's suffering from extreme packet corruption but desk 1 also seems to miss a lot of wifi packets. It may require a 2nd microcontroller for just decoding the 433Mhz signal.

Adding filament drier data to the apartment server was a big job, it's remarkable that the exterior weather station still works, given its condition. There is a desire to upgrade all the radios to 100kbaud, but this would make it difficult to parse the 433Mhz signal in software.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

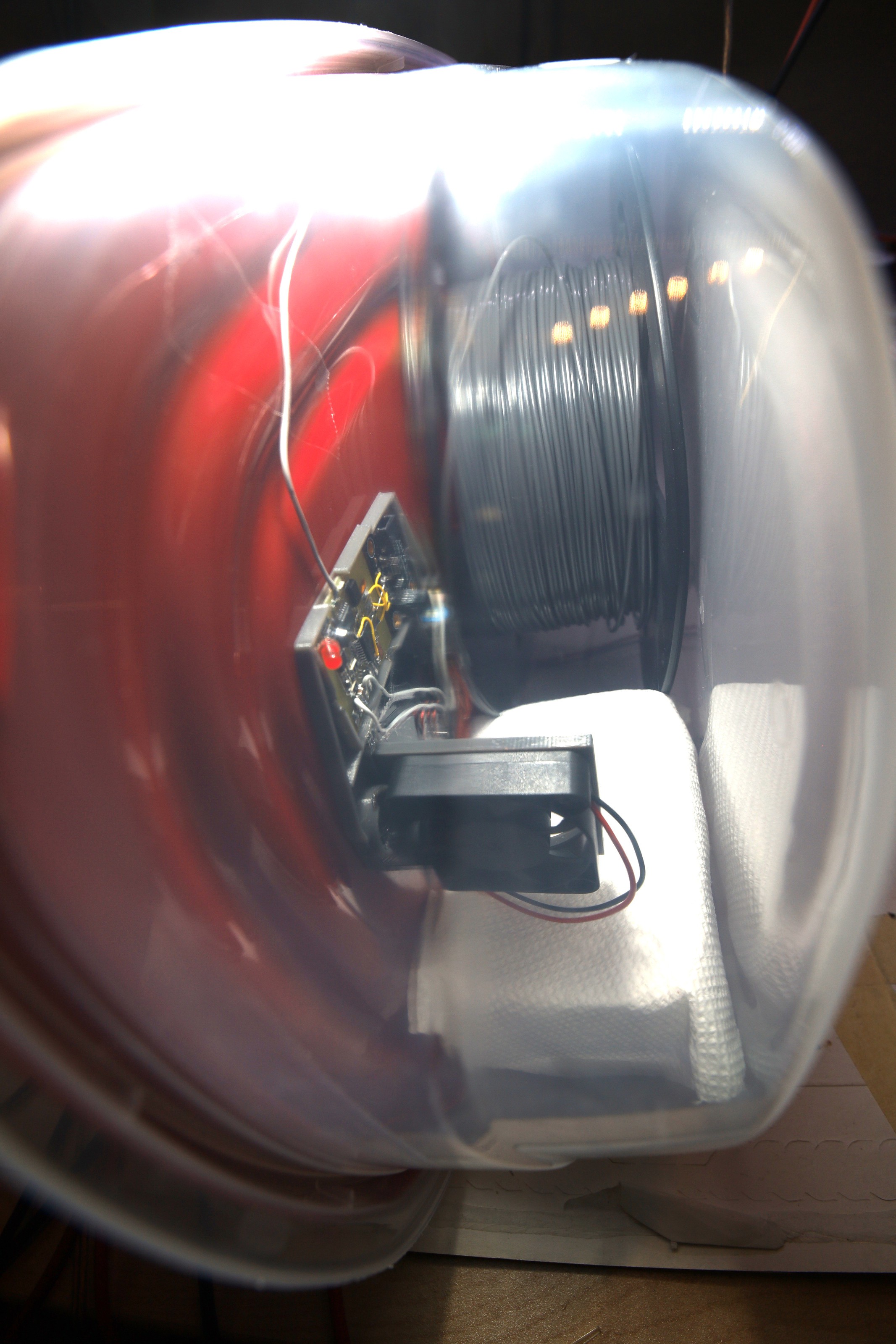

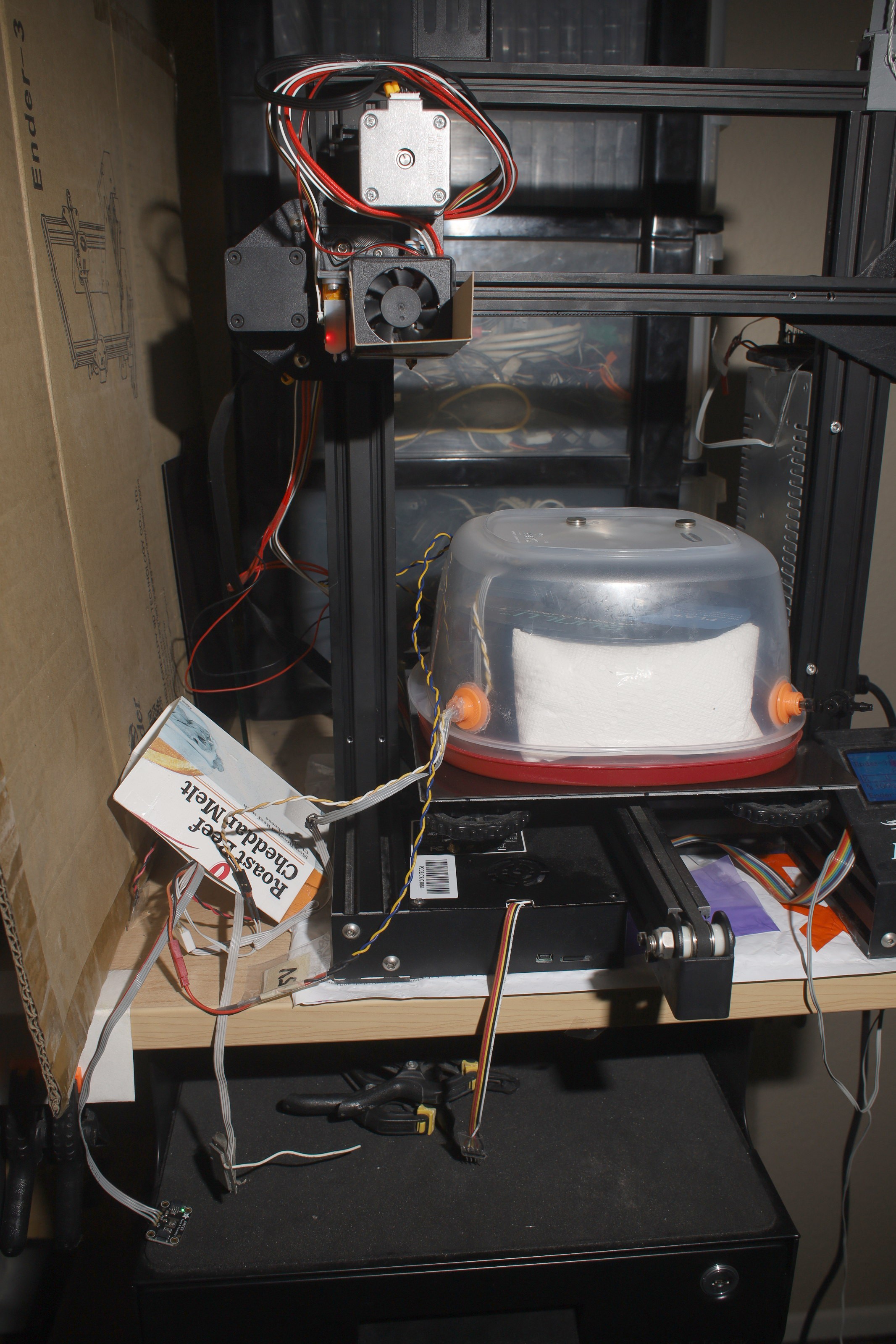

A few hours with this showed the new container getting a lot hotter than the old container. Less leaking & more exposed area got it to roast.

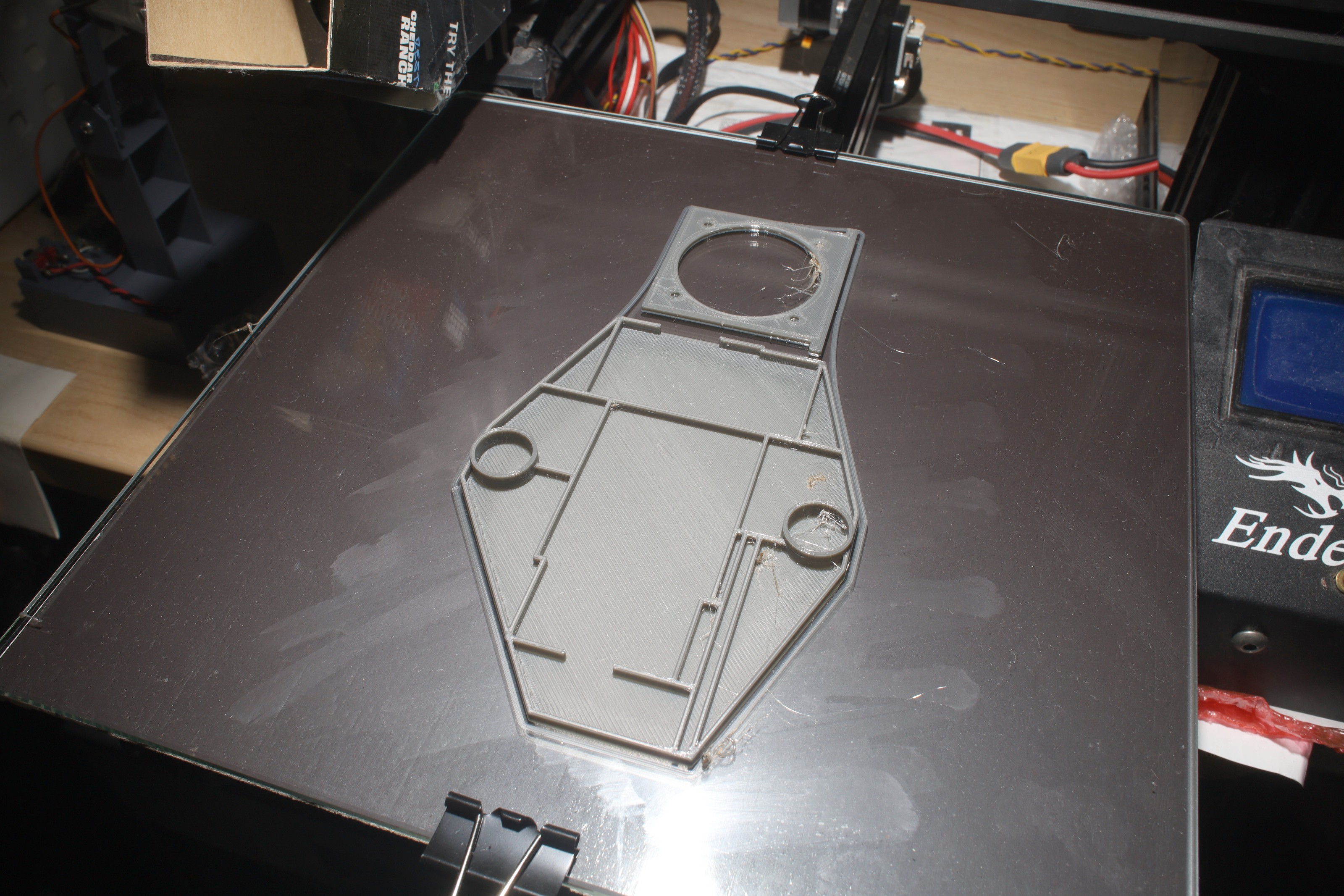

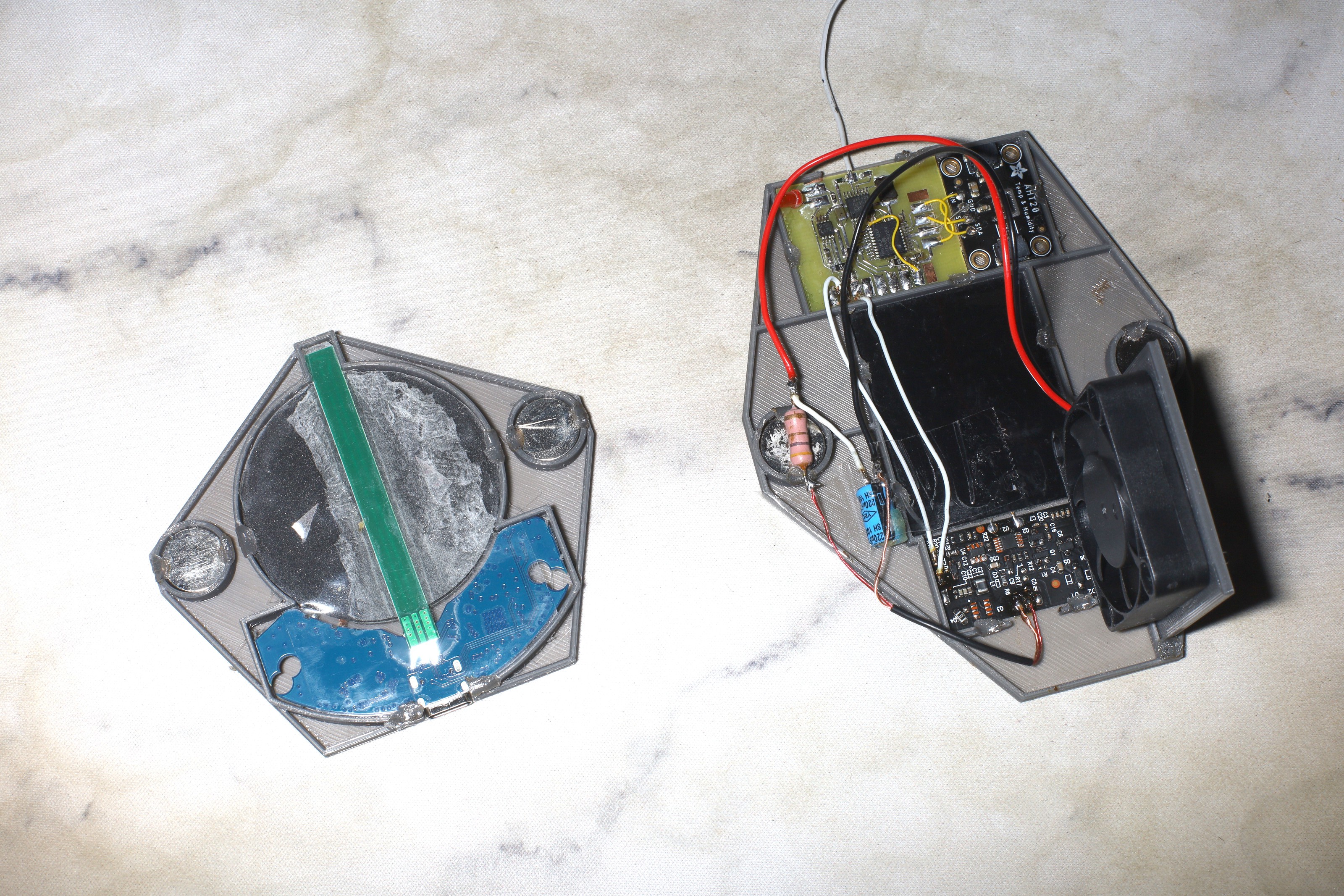

The 1st data logging attempt had a few problems. The mane problem is the lid not being flat. The only place for it is right next to the filament. The antenna can't be extended & the fan has to be right next to the filament. The signal still reaches the router.

The fan has to go in the middle on the opposite side. The magnets have to go right next to the charger coil & diagonally. The RC circuit needs some fixtures.

If the Qi receiver is folded over & double sided taped together, it should free up more space.

The Qi receiver still needed a 5 ohm, 220uF RC circuit to power the fan.

A big problem is the desiccant spilling everywhere despite being covered.

-

Wireless power experiments

08/24/2023 at 05:38 • 0 comments![]()

So the aquarium sealant on the previous container degraded & let air through. Powering a fan without penetrating the container was the great task.

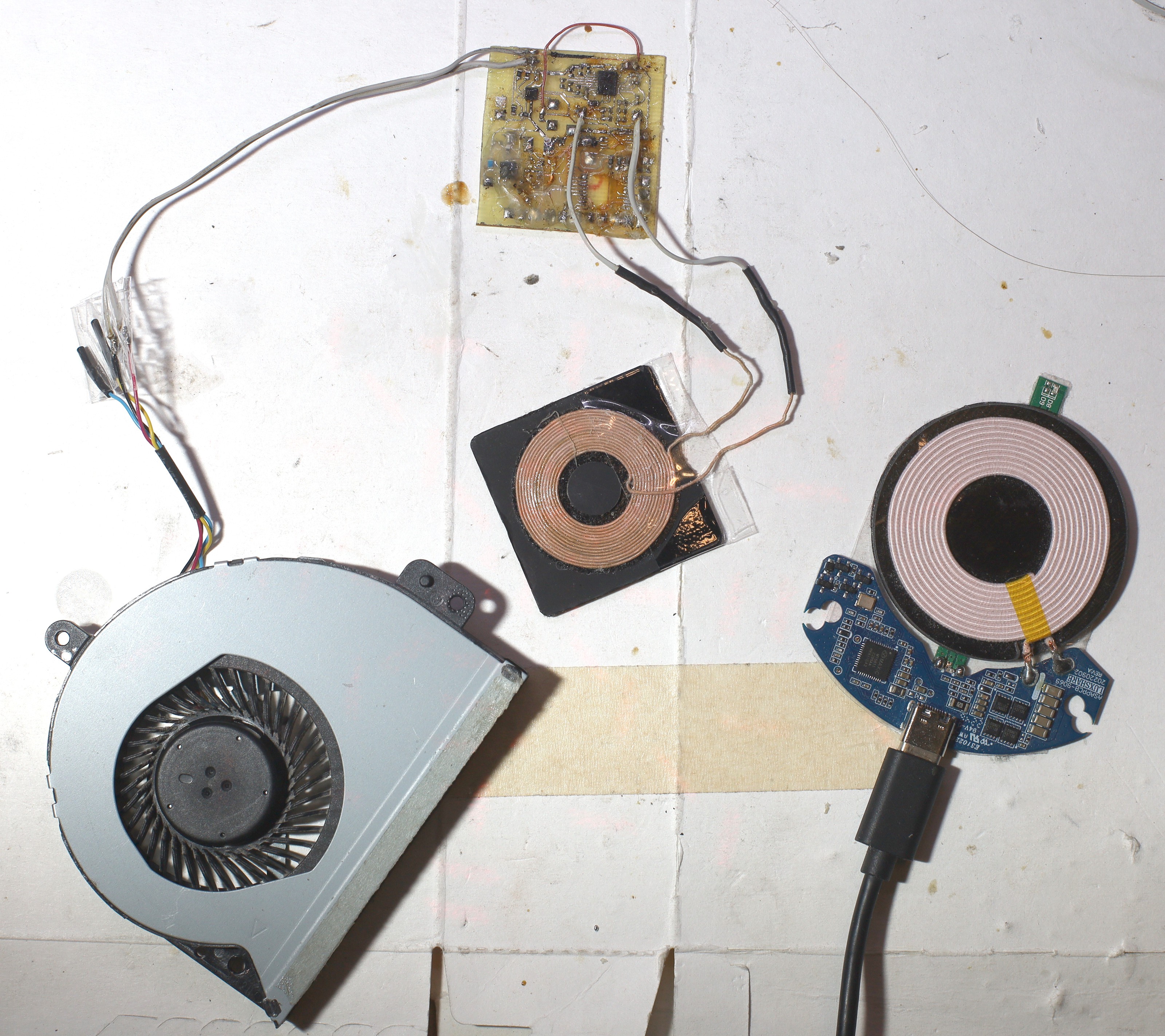

A quick test with a used Qi charger said fuggedaboudit. It couldn't power the inductive load of the .4A fan for any amount of time. The BQ51013 got to 4.4V, got hot & it constantly reset. There are BQ51013 breakout boards with better heat sinking, for a price.

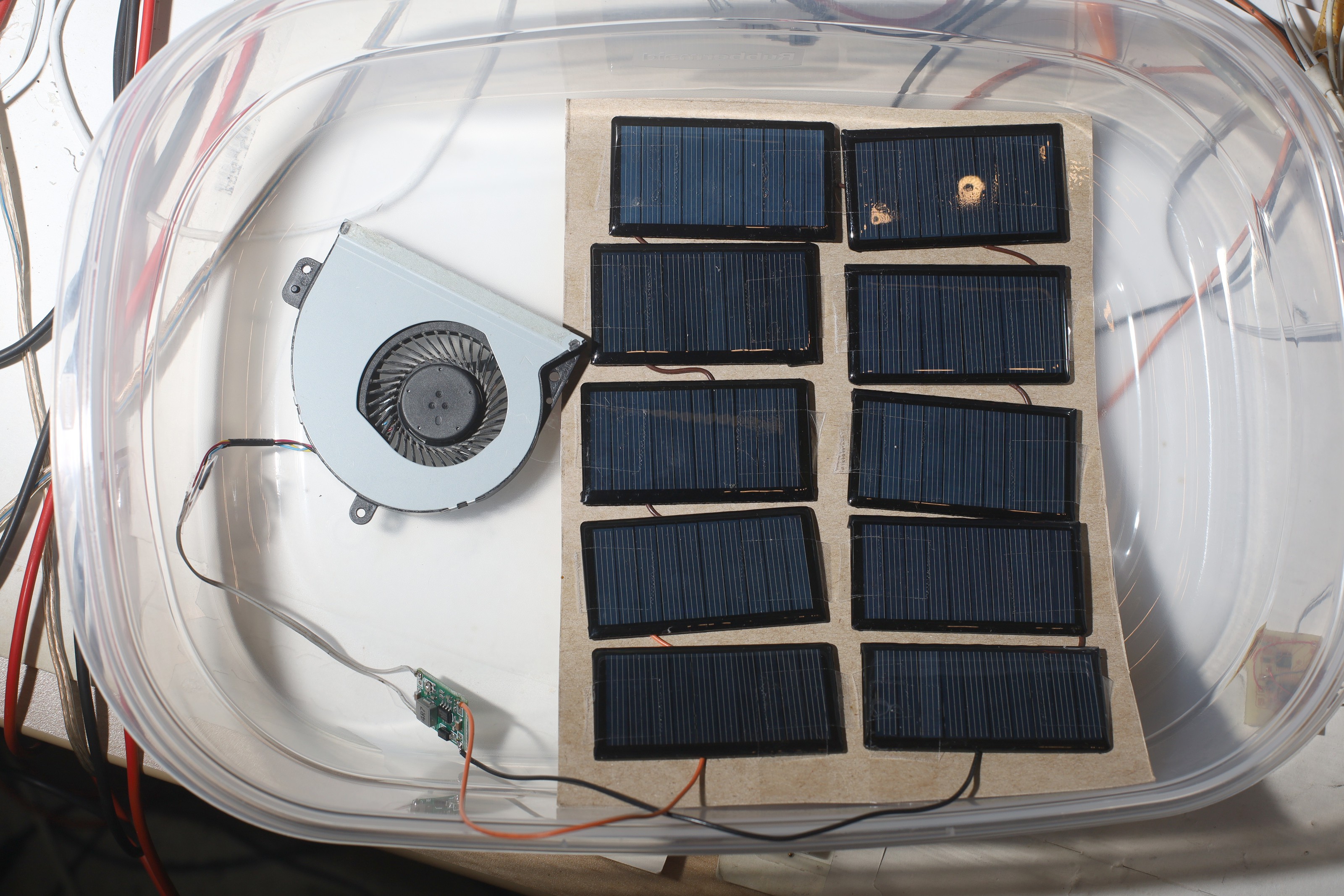

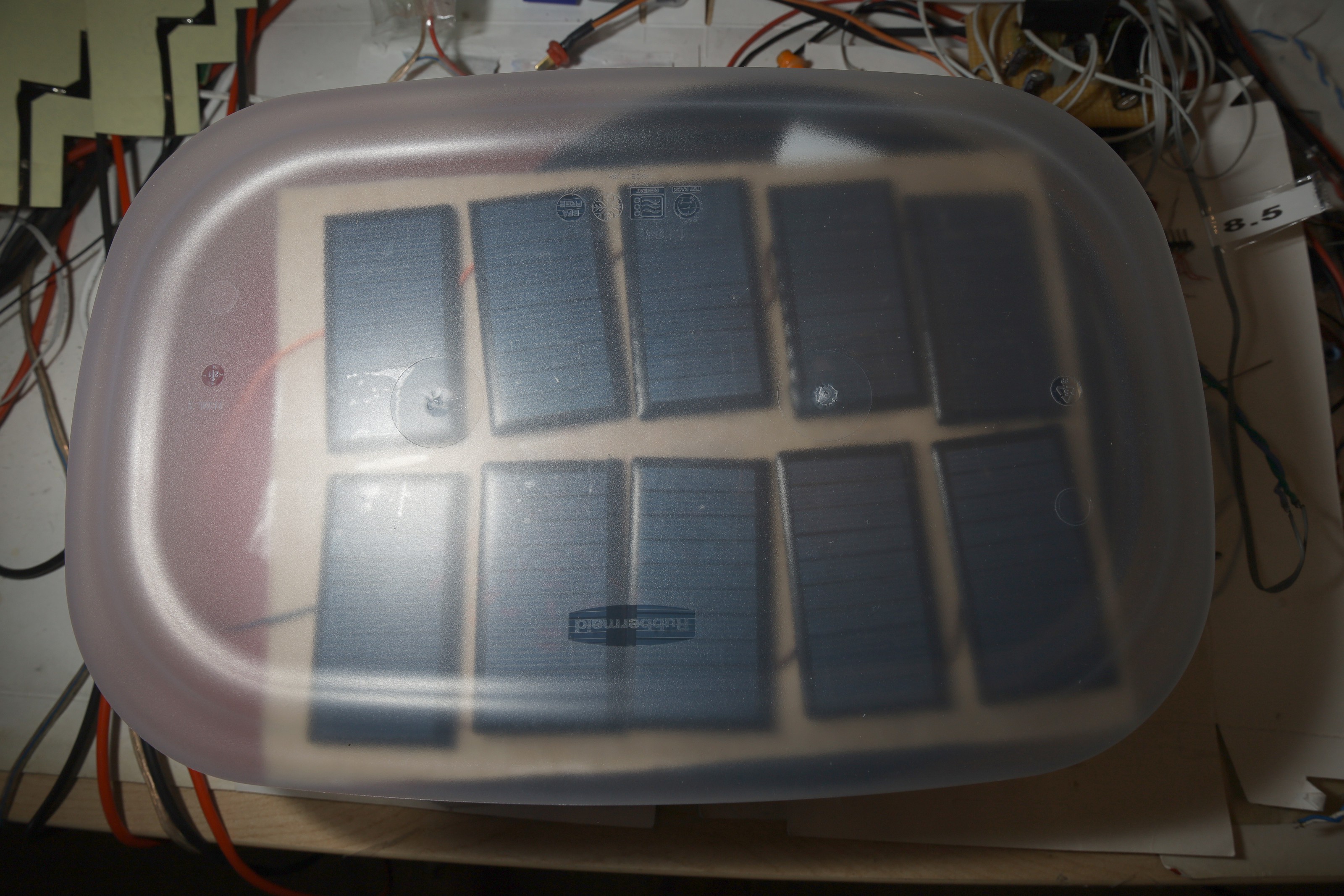

If it charged a battery which powered the fan, no battery would survive inside the heated chamber. Then of course, there's blocking out part of the chamber with solar panels. It would only work during the few hours of direct sunlight & it wouldn't get as hot. A double Qi charger might do the job but burn at least $20.

There's a chance solar panels wouldn't block too much heat & wouldn't always have to be in direct sunlight. The 1.1 gallon container probably gets too hot without solar panels. There is a chance of data logging only when the fan was on.

![]()

A quick test of the spare solar panels got the fan spinning but not fast enough to move any air in direct sunlight. This would fit in the container if it completely blocked all the sunlight. The container wouldn't get hot.

![]()

![]()

A .2A fan did slightly better. Putting the solar panels in parallel worked better. They're 5.5V max in parallel. Only 4 are needed to power the .2A fan.

A pulsed system which blew air & transmitted telemetry in pulses might work. It would need over 10,000uF, but a capacitor that big would have a hard time in the heat. A 105C nichicon might work. The inconsistency of solar power was still problematic.

An expendable battery powered data logger could reduce the problem to just the fan. Magnets outside the container could drive a fan inside the container.

There's always custom inductive power, with a big old electromagnet & brain on the outside. The last time lions invested so much in something that custom was 20 years ago.

A pulsed BQ51013 system is still the leading candidate. The brain would be continuously powered & send logging via 900Mhz. It would pulse a big old fan based on a capacitor charge. It might achieve 50% duty cycle. The internal menagerie would be farstened to the lid. The power cable & charger would stick to the outside via magnets.

Penetrating the container continues to be vastly simpler. If the container was penetrated by a big old ribbon cable instead of the twisted pair it used before, it might be air tight. The seal would have to be routinely replaced but would never be as good as the stock container.

Some fiddling with resistors showed a 10R + 4700uF could correct the phase enough to power the .2A fan off the BQ51013. It only gets 60mA, but it's just enough airflow. It can also run off a 5R & 80mA though this heats up the BQ51013 more. Suspect the heat sinking is the limiting factor & an off the shelf Qi receiver would go all the way to 1A. A commercial Qi receiver + small resistor + any 5V fan + radio should handle all the blowing & data logging.

-

Filament drying failure

08/22/2023 at 22:25 • 0 comments![]()

![]()

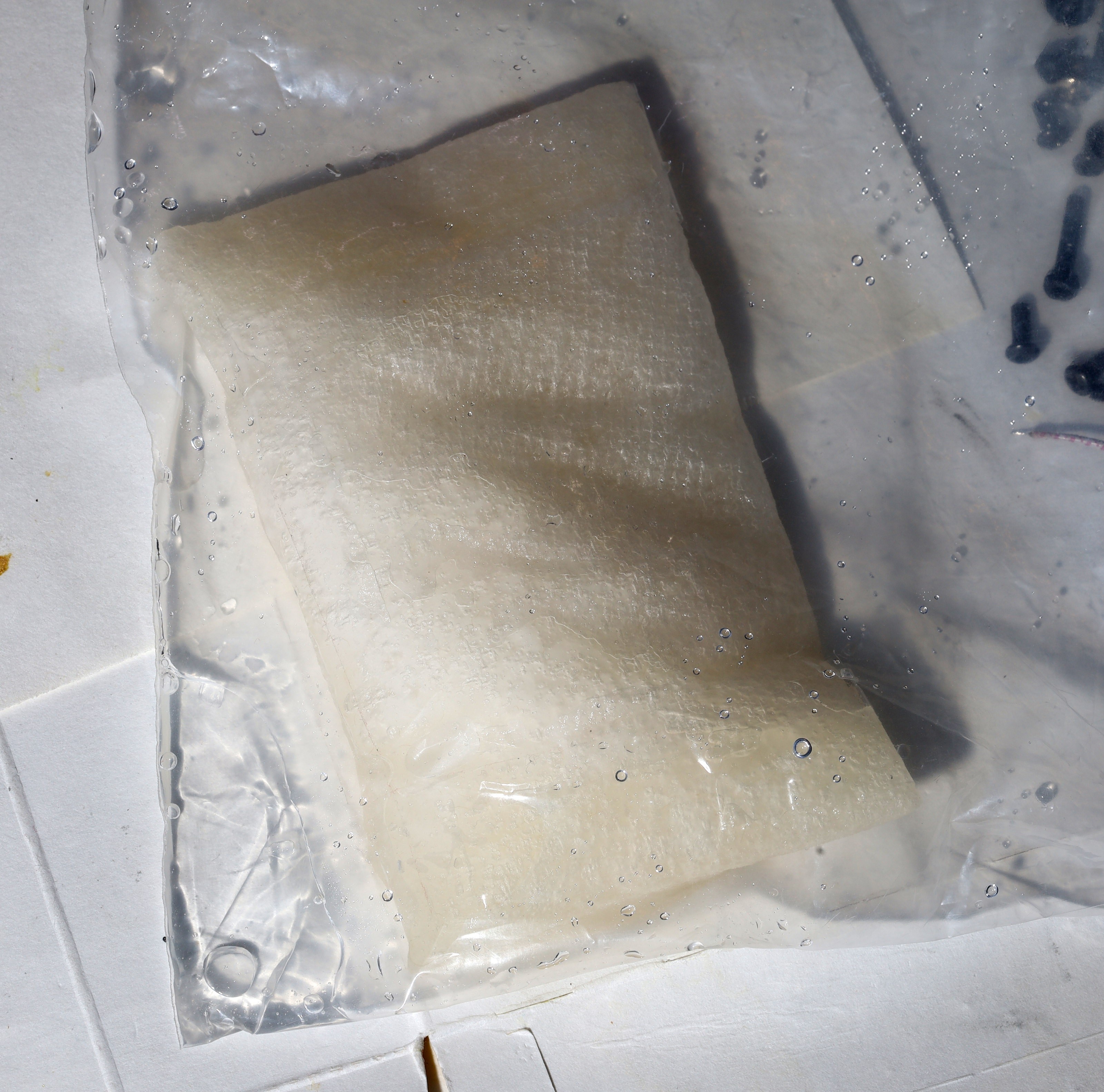

Desiccant placement has been a long time problem, but newly aggravated by more air leaking into the container than there used to be. Dumping it in made a mess after it got wet & the filament had no improvement in print quality after 4 days.

![]()

Humidity went up as the desiccant saturated. Lions noted the saturation of a column of desiccant goes 2cm deep & leaves everything else dry. The ideal container would be a tray with <2cm depth. A bottle is not the ideal container. A sphere would let wet desiccant leak out. It has to be water tight on the down & side facing sides. For the current solar container, it would have to be a rack of 2cm deep trays with air passing between the trays. It's a bit labor intensive so a better system is going to be a much wider than necessary container with enough room for a single desiccant tray & filament to be side by side.

For storage containers, lunch meat containers come to mind. Coroplastic things could elevate the filament over the desiccant tray.

The next step was just making a desiccant tray out of a very old tupperware with paper towel to keep it from spilling.

![]()

![]()

The optimum container for side by side placement was a 1.1 gallon Rubbermaid.

![]()

![]()

The bigger problem is the container longevity. Container longevity & getting signals in the container without creating holes is a super hard problem. There are concepts for inductive power, but getting enough power for the fan is tricky. For now, the fan & sensor were abandoned.

![]()

![]()

A few days of this yielded perfect parts. Results seem to take just 1 day in the sun with no fan.

-

Failed drying

08/09/2023 at 04:36 • 0 commentsIt seems the container began leaking or the desiccant got saturated.

![]()

This one only got pulled down to 15% briefly before popping back to 20% every night. The last successful drying in February stayed at a constant 9% in temperatures only reaching 58C while dew point went negative. The desiccant pack was wet but not mush like the truly expired ones. Surprising that the desiccant would saturate right when the filament went in the sun, but it might show how important heat is for drying filament.

Replacement desiccant continued to saturate in short order, with dewpoint not getting significantly below 0 & humidity not getting below 15%. The 3.3L rubbermaids were the most expensive, topping $7. Now they're $11.

![]()

Smaller desiccant containers which can be reconfigured for horizontal & vertical packing might be the best. They're not allowing the lid to seat securely so it might be time for a 2.5 gallon rubbermaid.

![]()

New desiccant improved it slightly, but still nowhere close to the -35C dewpoint it should reach.

Noted with the latest desiccant bottles, it gets saturated next to the paper while the rest of it stays dry. So there's always emptying it out every single day or going back to the pure paper towel bags. Emptying it out every day returns water to the container.

The ultimate desiccant trend is just dumping it in the bottom of the container. All the electronicals would have to be moved to the top. Experience has shown it's possible to manually keep the desiccant on the bottom of a ziploc bag separate from the filament.

![]()

![]()

![]()

All the scotch on the inside degraded.

The mane task is increasing the surface area of the desiccant.

-

Solar drying, PG&E edition

08/04/2023 at 08:18 • 0 commentsTPU got wet just from an extended period of printing. Keeping it dry in the last mile is unsolved.

To speed things up, the menagerie was moved to the good old print bed at 60C.

![]()

It became highly desirable to turn off the extruder fan & save on dust. A JST connector would do it.

After a few hours pulsing in 240W to keep the bed at 60C, the chamber reached an equilibrium it couldn't leave. 34C & 23% humidity on the inside was the best it could do. Merely opening the container sent the humidity up & the temperature down. This practice of drying filament on top of the print bed, in an open container was obviously a waste.

After throwing it back in the sun, it popped to 54C 15%. The sun was definitely capable of more heat with a lot less effort, but during far shorter periods. $3000 doesn't buy a back yard with constant sunlight. It may also be a problem of the desiccant releasing water when it's hot & more heat being transferred to the desiccant than the filament when it's on the print bed. A bigger container might allow better placement of the desiccant & better air circulation. A container that's wider than taller would allow more air circulation & a bigger fan, but consume more precious rent.

The best performance would come from keeping the desiccant cold & the filament hot, with air as a working fluid transferring water. There might even be a peltier cooler for the desiccant.

-

Wishlist

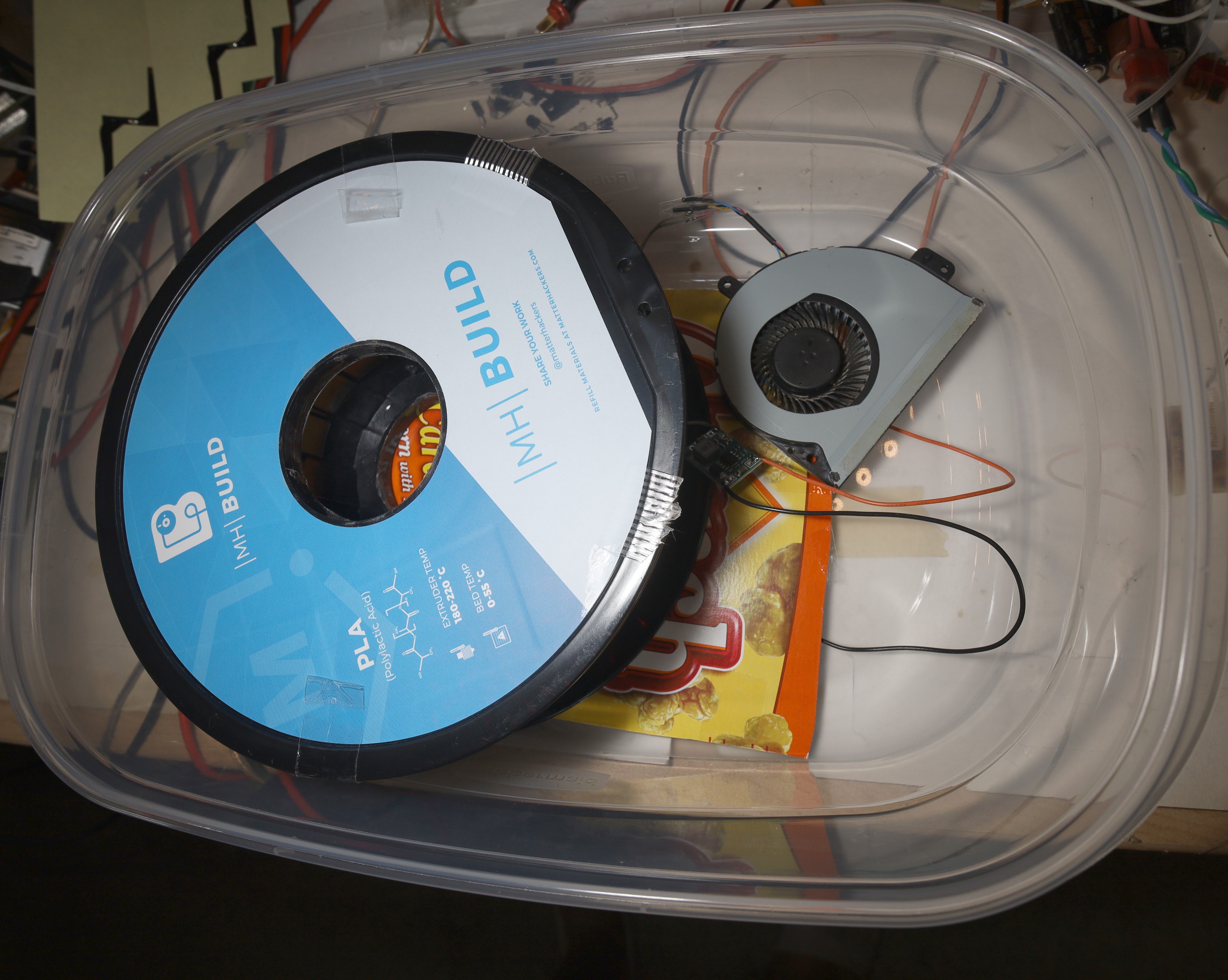

07/23/2023 at 23:12 • 0 commentsThe solar drier got no use after February since no more filament got wet & no more filament came from a factory in a hydrated state. This created a real need to use the container for long term storage as well as solar drying. It's not as air tight as the long term storage but it could be air tight enough.

The ideal solution would be completely wireless to avoid puncturing the container. There would be a self contained board with radio, sensor, fan controller. This would be inductively powered from the outside. An off the shelf charger might do the job. The boards would stick together with magnets. The fan would run continuously while the sensor & radio would just provide monitoring.

The mane problem is the container has to be vertical for solar drying & horizontal for long term storage.

![]()

The home made desiccant bags failed while leading candidates have moved to acrylic cups which have to be upright. There has to be a way to monitor the desiccant & it has to be in a waterproof container because it liquefies suddenly. A paper towel lid might be good enough to transport it, but it can't be stored sideways. Some PETG lids could be tested to find the maximum hole size.

It almost needs different desiccant containers for horizontal storage & vertical drying. The only room for desiccant & place where it won't fall over is the filament hole. The only acrylic in the right size might be pipe stock. It would need a waterproof end cap. Even then, the hole isn't always going to be right side up.

-

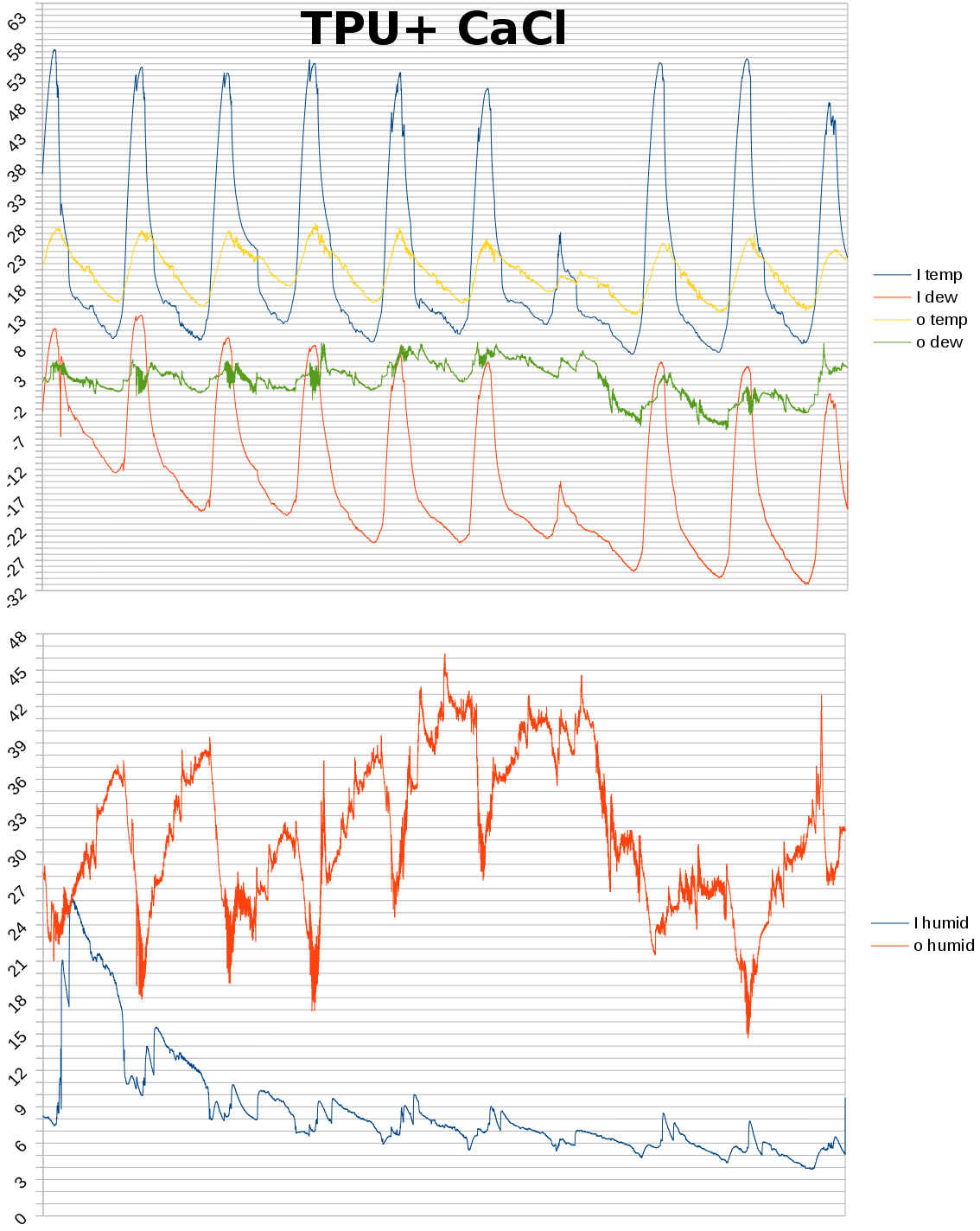

Clear TPU + CaCl

02/02/2023 at 03:45 • 0 comments![]()

This one once again had a progressive drying over several weeks. The trick is leaving it in until humidity levels off or the next rain cycle arrives. It needs direct sunlight to get the required heating.

![]()

![]()

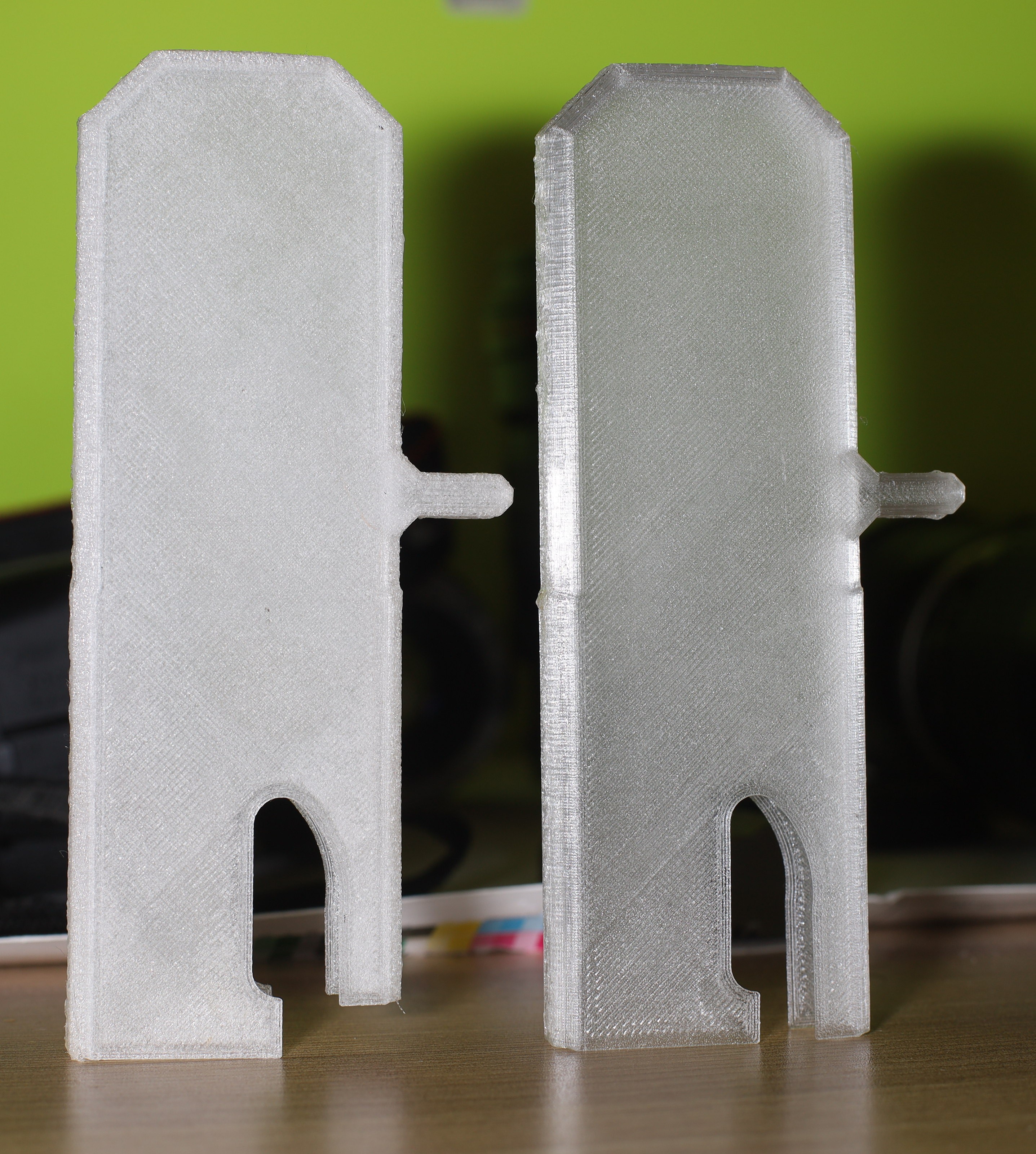

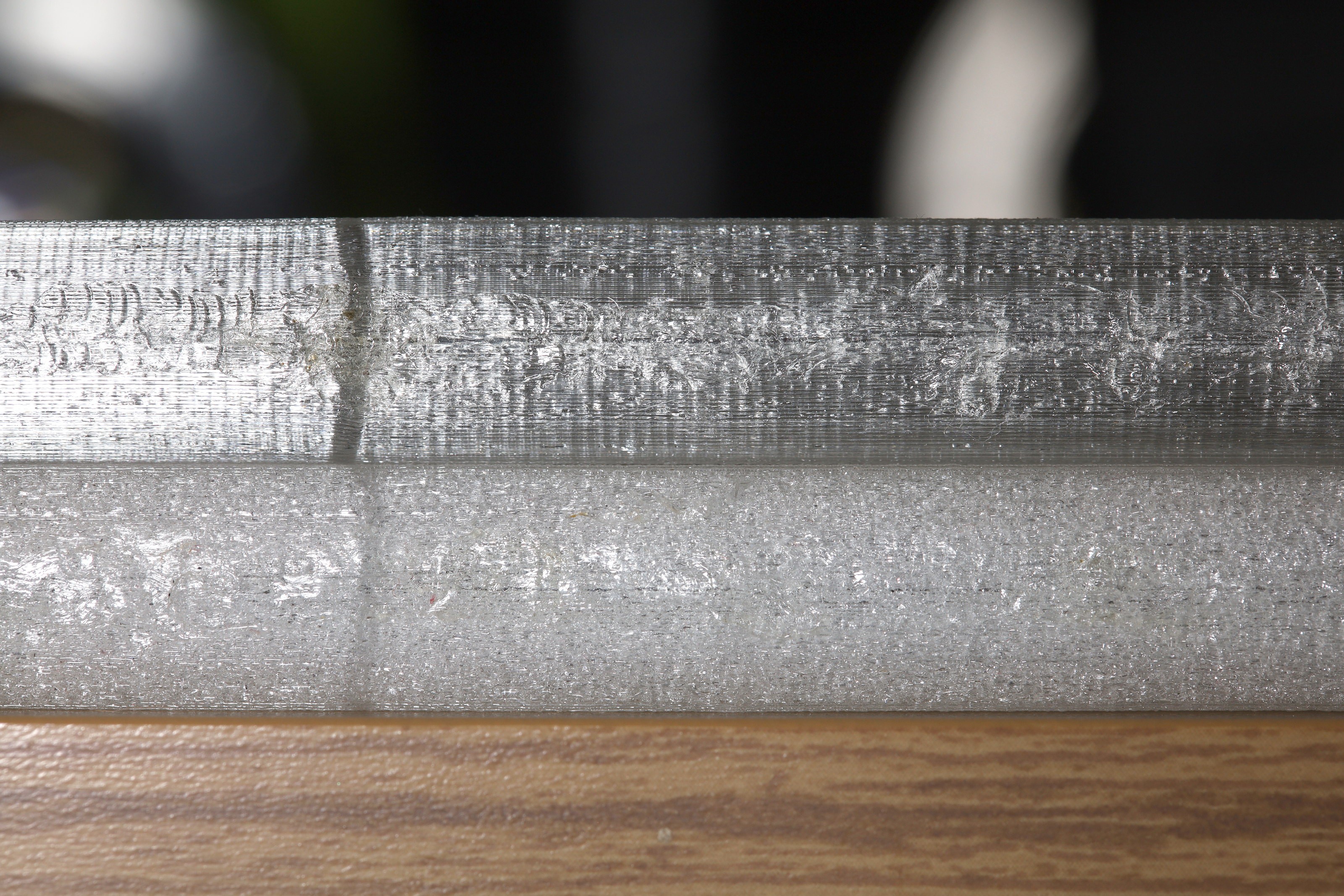

Not so easy convey the difference on camera without a lighting angle that over emphasizes the difference, but there's a big difference between stock & dried. The difference is manely from the side.

-

Drytote test

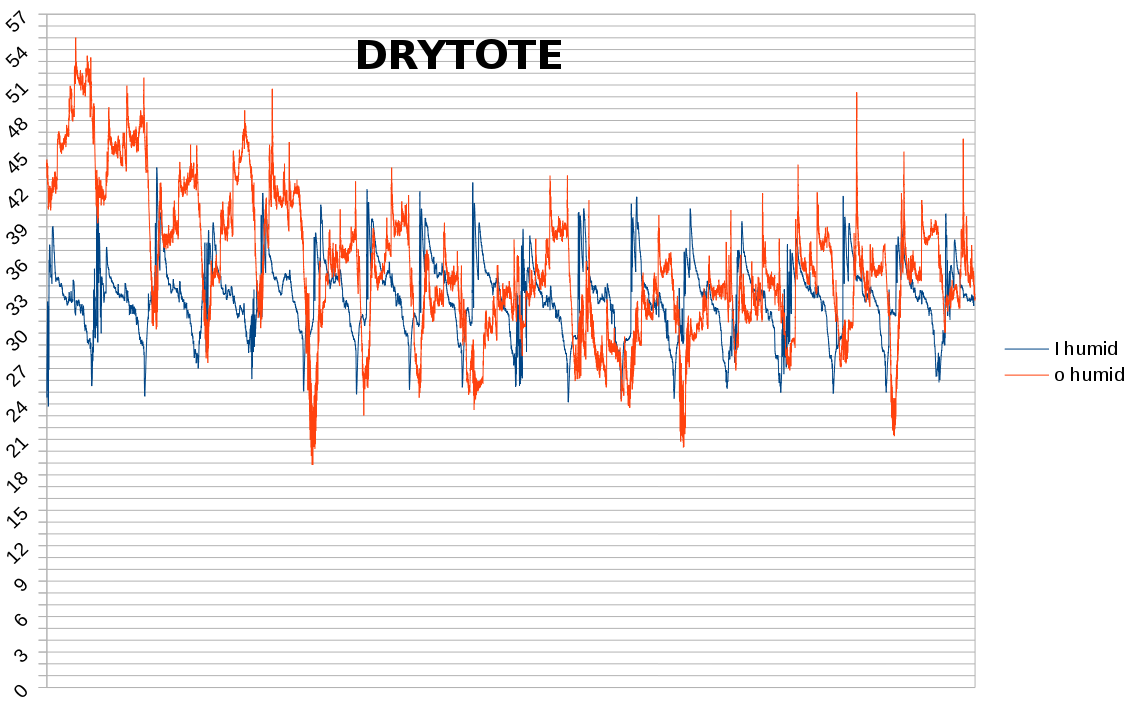

12/05/2022 at 19:29 • 0 commentsAfter a bag with drytote yielded wet filament, the decision was made to test drytote in the solar drier with the circulation fan & no filament.

![]()

![]()

Over several weeks, it didn't do anything despite the indicator being blue. The leading theory is the silica gel has to be cold to absorb water while filament has to be hot to release water. The solar drier is just going to release the water from the silica gel & the filament every day without anyone doing a net absorption. You need a desiccant which absorbs at high temperature.

![]()

![]()

The blue dot stayed blue up to 40%, which is where filament degrades.

Solar filament drier

How to keep filament dry while being too poor to afford electricity.

lion mclionhead

lion mclionhead