-

1Step 1: Prepare transparent top layer

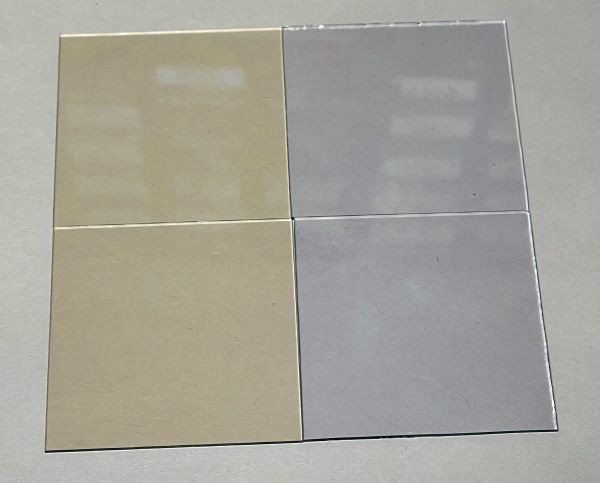

ITO glass is the best solution for top plate. I use glass 50x50mm or 100x100mm with conductive layer 10-20 Om resistance

![]()

Кinse the glass thoroughly

-

2Step 2: Prepare back conductive layer

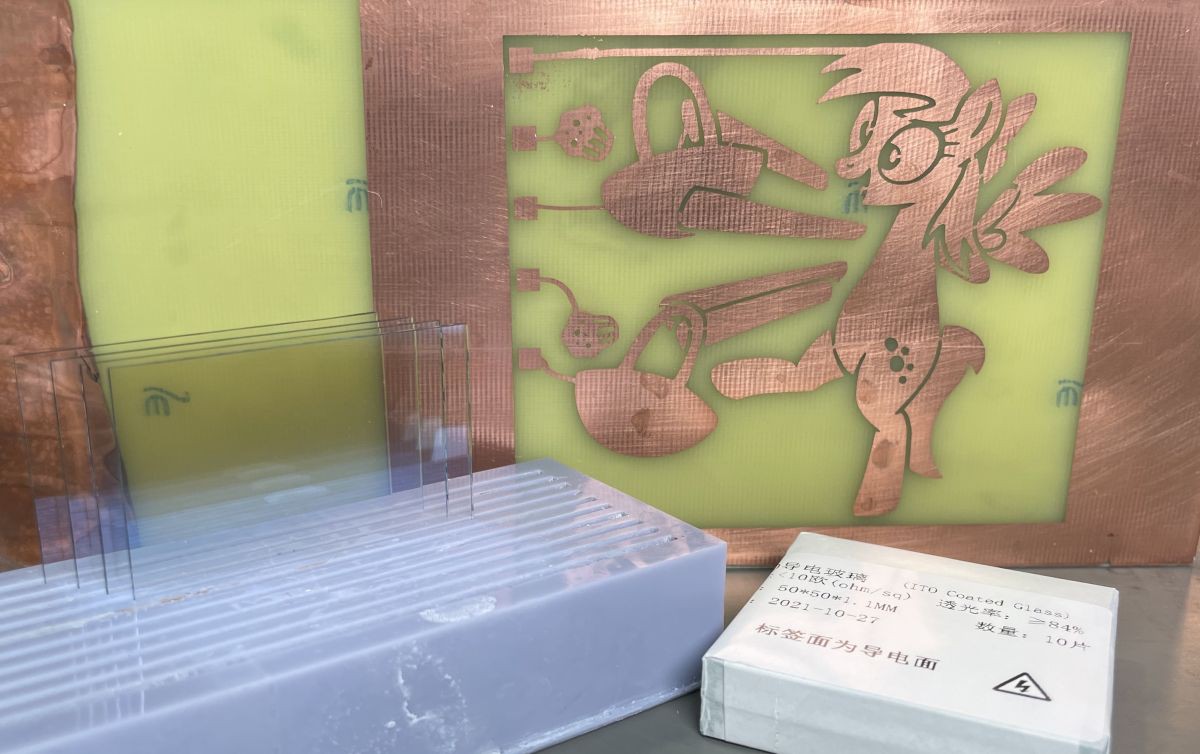

PCB with proper etched image - is the best solution for back plate. Double-side is better, but single-side is also ok - but you need to apply mask when fill emitting layer.

Use immersion gold instead of lead or HASL - to avoid any interactions between EL powder and pcb coating

![]()

-

3Step 3: Apply emitting layer

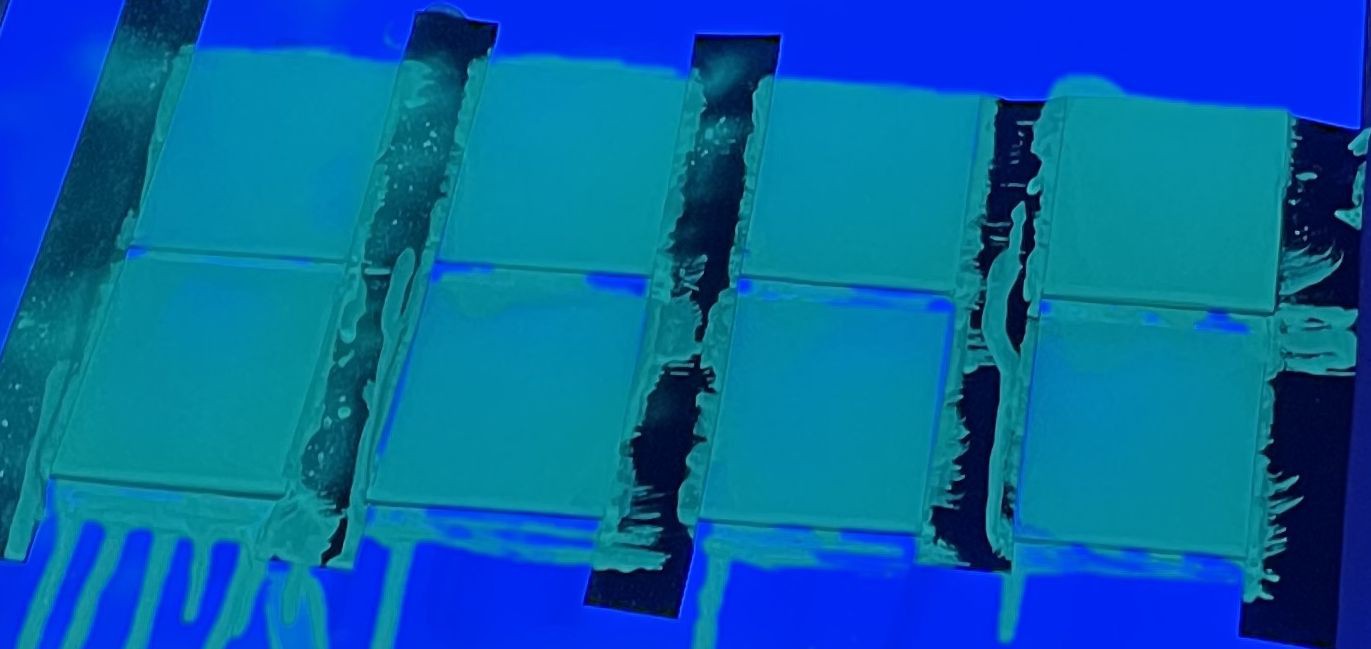

Mix the electroluminescence phosphor in epoxy resin in a ratio of 1.5: 1

You can use ZnS phosphor or Zn2[SiO4]

Epoxy resin must be two-component and has the dielectric constant from 7 to 10. Higher is better. two-component Polyurethane also show good results.

Apply thin layer of the mix to conductive glass. Good thickness is 50-70um

![]()

applied emitting layer under UV light

-

4Step 4: Glue the packet

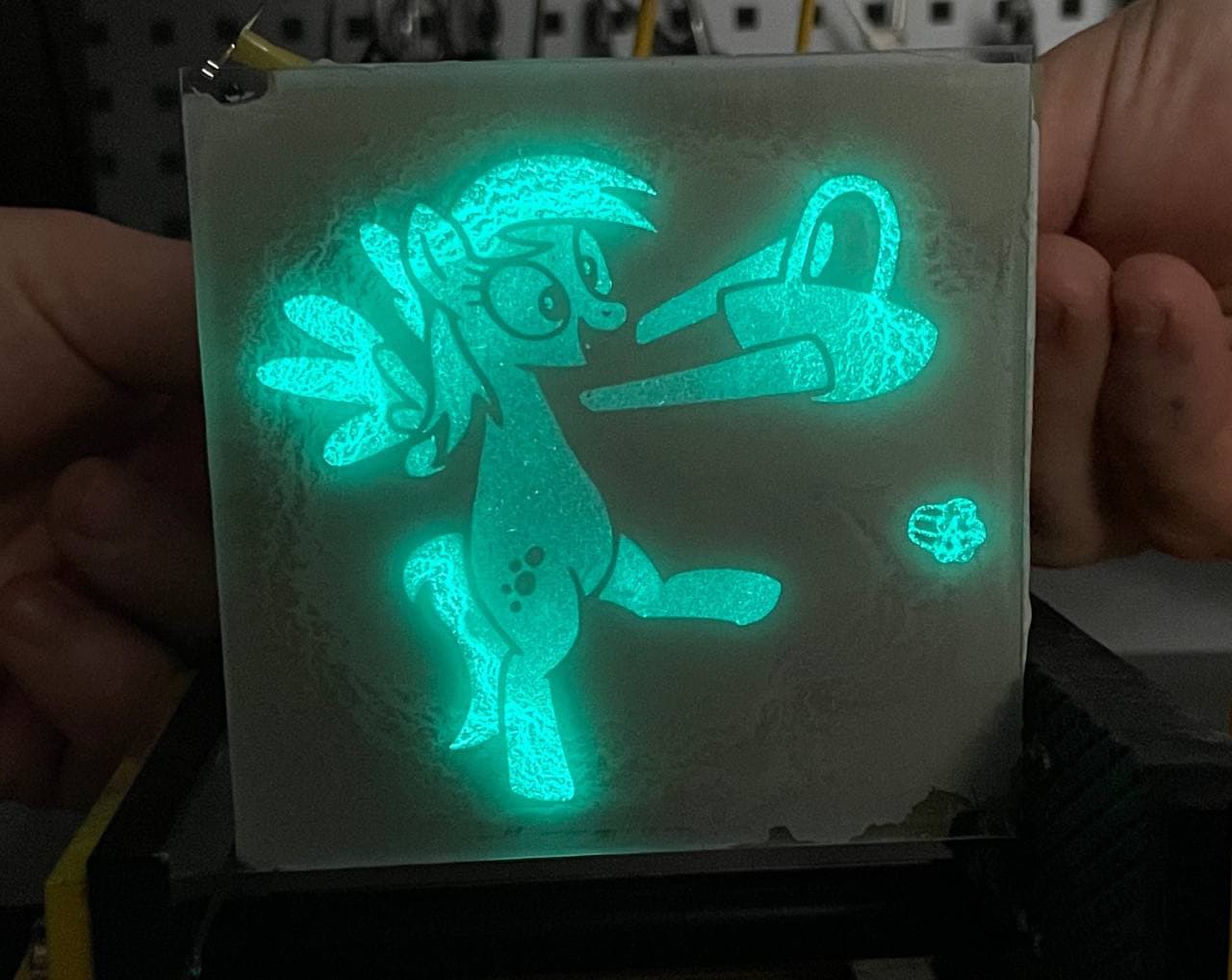

Mix the BaTiO in two-componentepoxy resin in a ratio of 1: 1 and glue the packet with this composition and apply some pressure

![]()

-

5Step 5: Connect EL panel to AC power supply

New EL panel require 100-300V 400-1200Hz

![]()

Self-made EL segment displays

How to make your own display with almost any configuration just using a paintbrush

Artem Kashkanov

Artem Kashkanov

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Where did you order the phosphor?

Are you sure? yes | no