-

Video

11/30/2024 at 05:42 • 0 commentsThe project is done!

-

Gauge and final assembly

11/26/2024 at 03:29 • 0 comments![]()

![]()

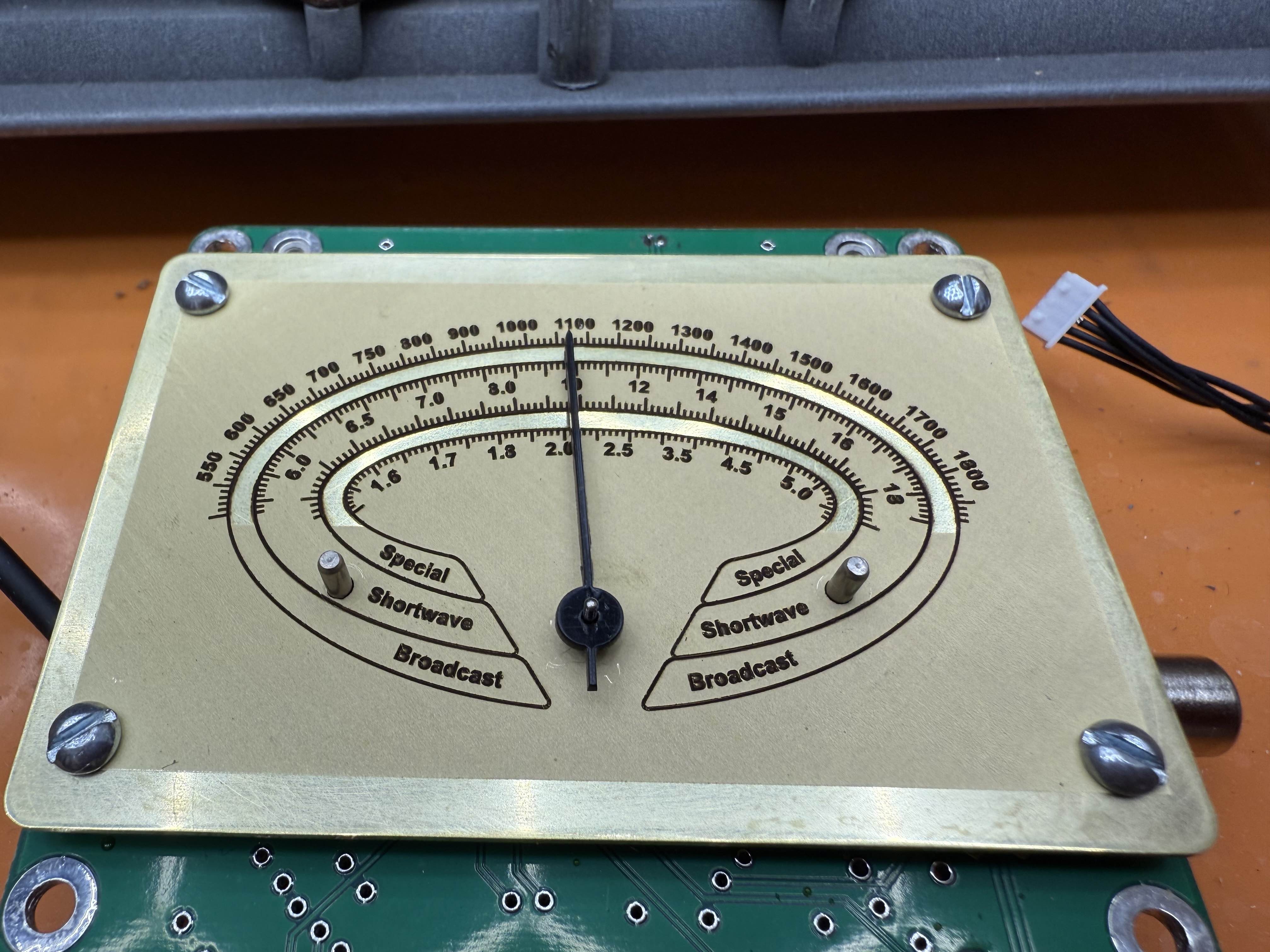

As one of the final steps of the project I laser etched the brass gauge face. First I had to polish the the plate, such that the area between the numbers stays with a mirror finish, and the rest is made matte by the laser. It also does the blackening all in one 6 minute etch by a fiber laser.

![]()

![]()

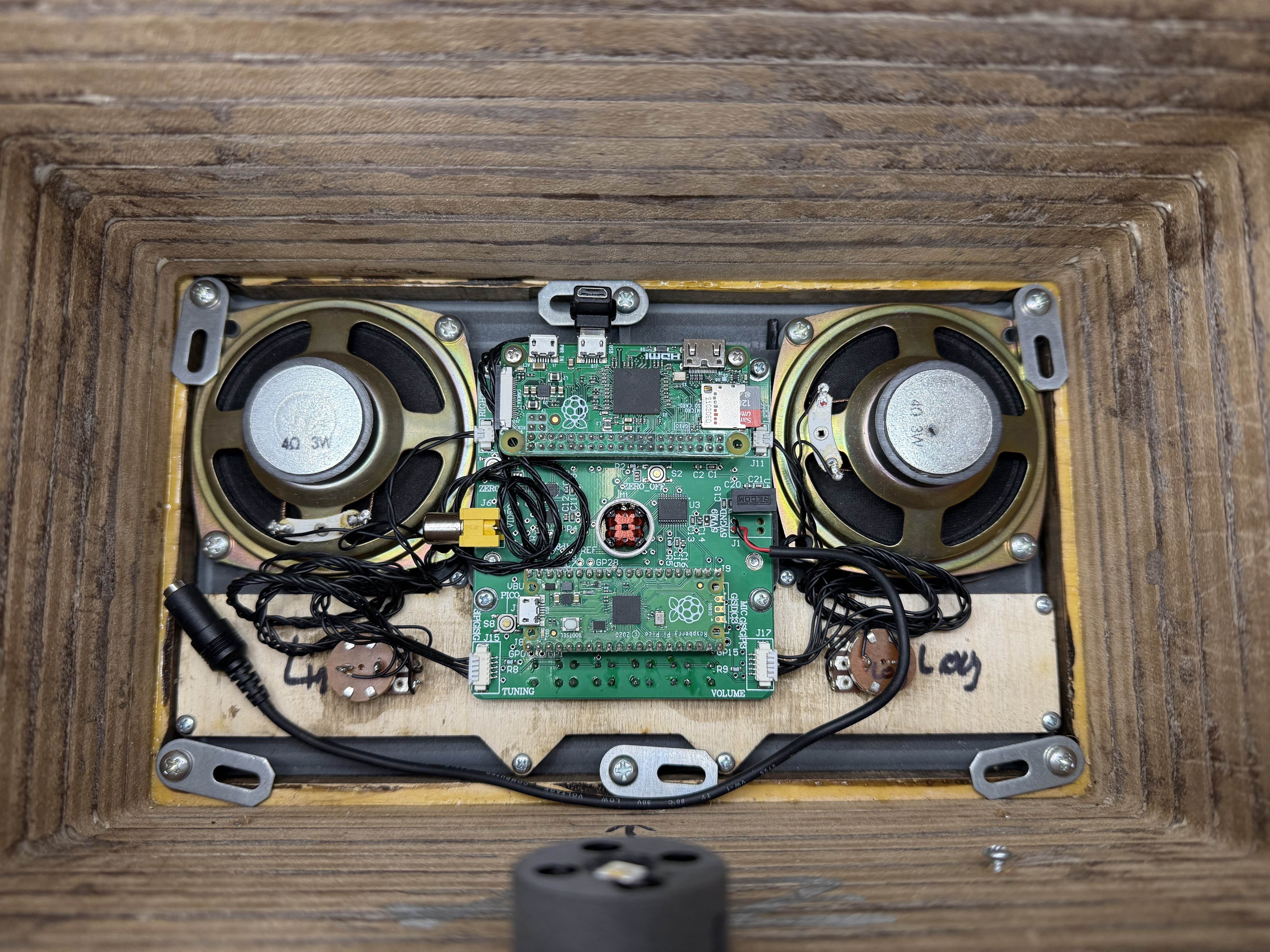

This is the electronics as they sit before final assembly. I should have spent some time to shorten the wires, but I was too lazy.

Not shown is the AC to DC supply.![]()

![]()

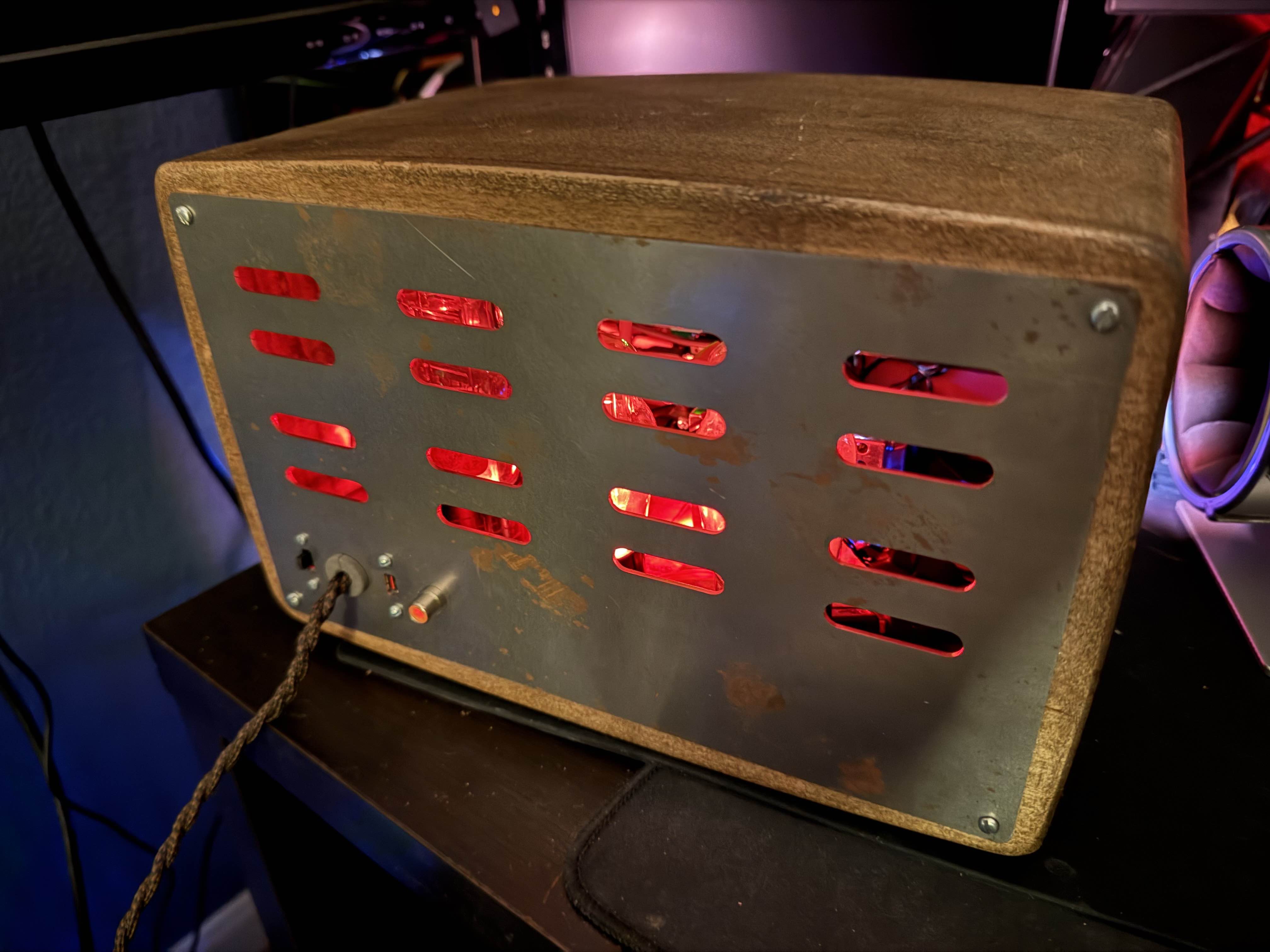

I have three neopixels inside 3D printed vacuum tube socket. Yes, these are real fake tubes. But they look great when you look inside the back of the radio.

![]()

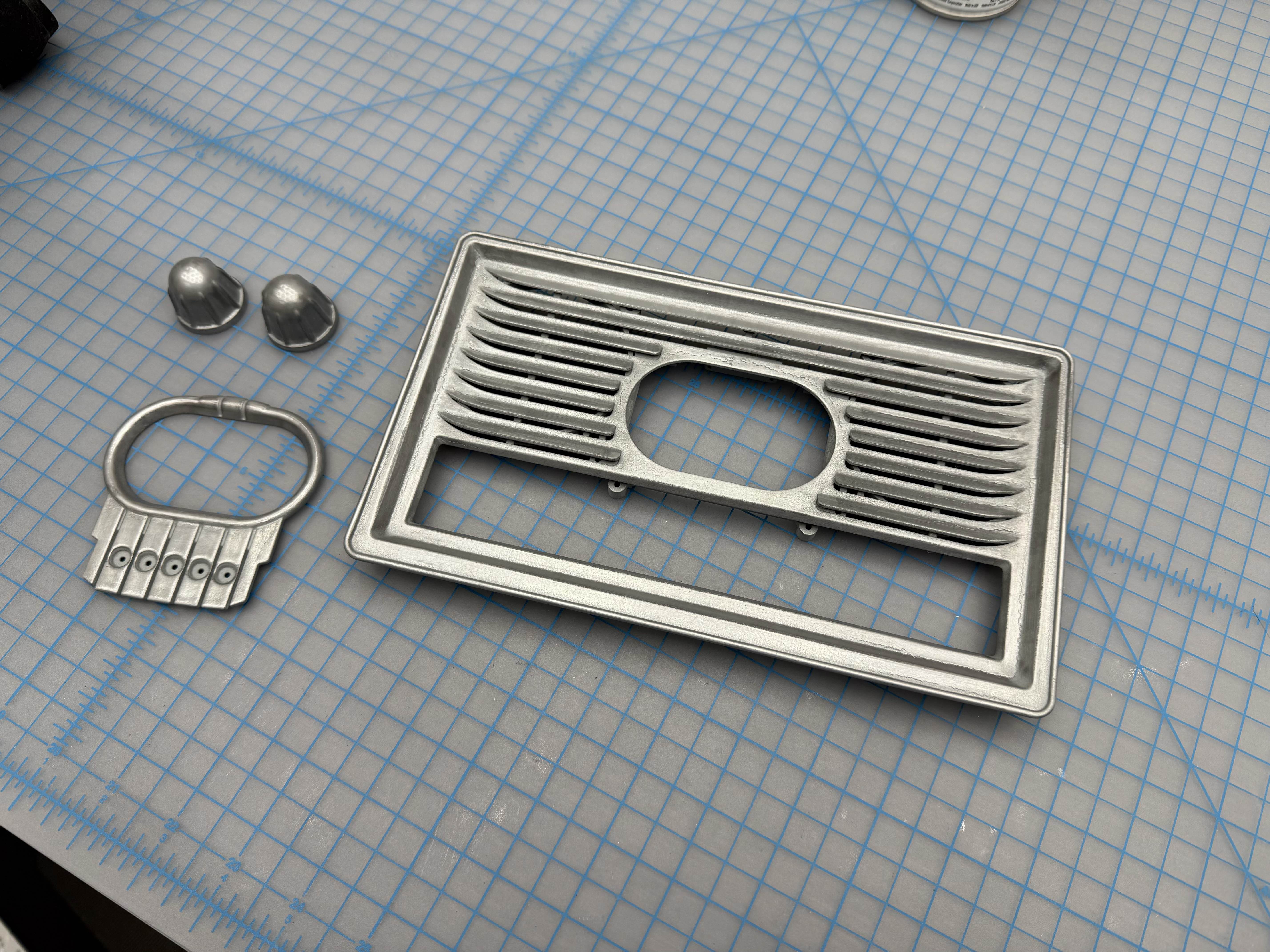

The very last step (which I will probably redo) was to make the Radiation King badge as reflective as possible. For this I actually used silver gilding leaf. This was the best of 6 attempts, I am not sure if I want to redo it, or leave it a bit rough as the rest of the radio is that way anyways.

I also finally have the code done. I added a few new features that make it just work smoother. -

Faceplate

11/13/2024 at 15:06 • 0 comments![]()

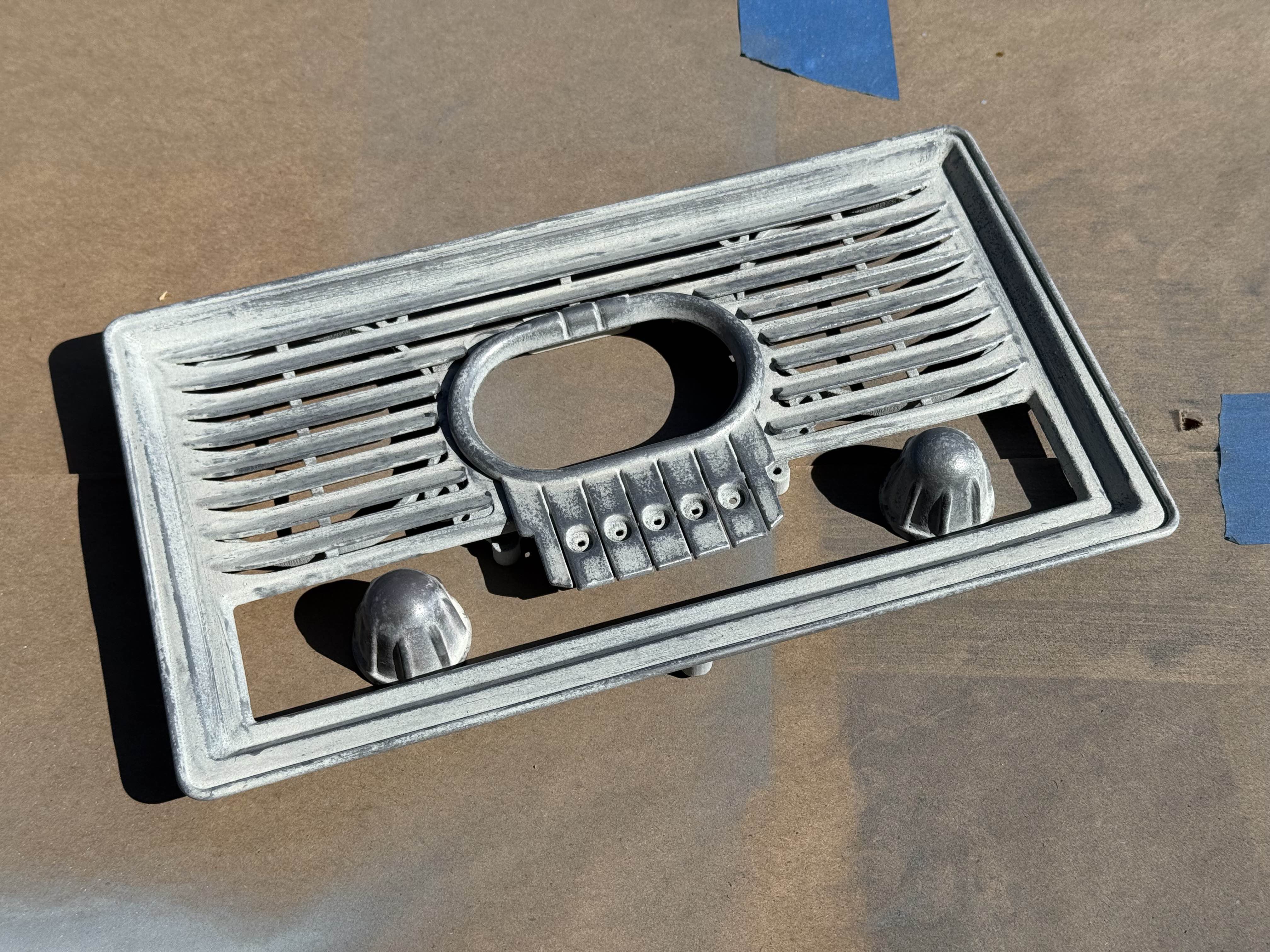

I wanted the front bezel to look like metal. So I used a technique I saw somewhere on the RPF: Zinc Galvanizing Spray.

![]()

This is a paint with lots of zinc metal in the paint. It goes on grey, but then can be shined up using steel wool.

However, after polishing the whole face, it did look like metal, but also very boring and monotone.![]()

I had purchased some cream colored paint to try as an alternative, but then had an idea: Use both!

I sprayed a very light coat of the cream colored paint over the zinc. I then polished away the paint. It really looks very nice in person. The zinc shows up as glints of metal, and the paint makes it look like the radio has been around for a hundred years. The coolest part is any more wear over time will just make it look more authentic. Later I added some washes to break up the two color finish with a bit of very light rust.![]()

I SLA 3D printed the logo, and small buttons. Then used a molotow chrome pen to make them silver, aging them similarly.

![]()

I did another test assembly of the radio, and it looks (and sounds) like it was taken right out of the game.

![]()

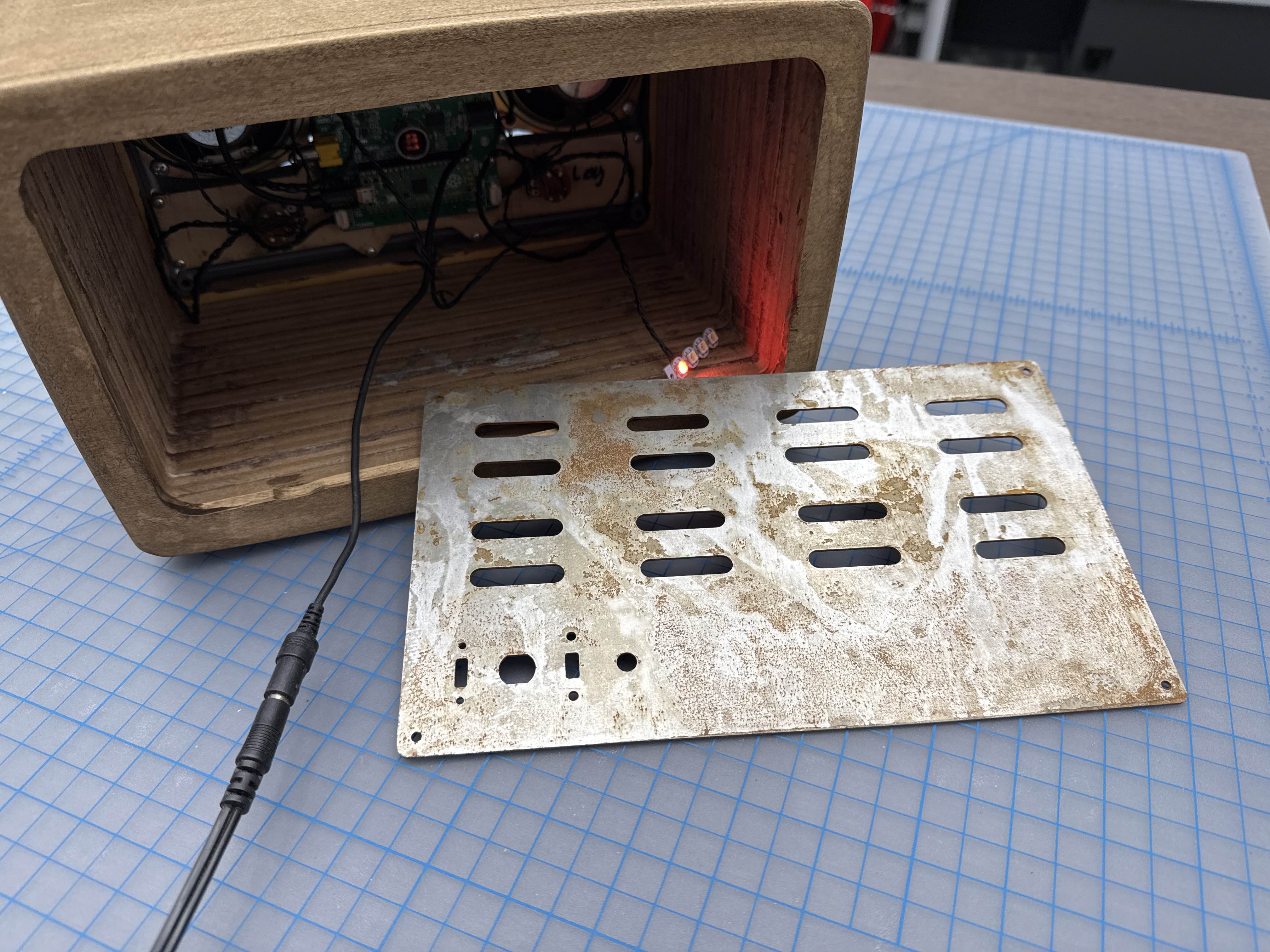

There are still a few more things to do. The gauge is currently paper, and it needs to be replaced with laser etched brass.

I have some fake vacuum tubes to add to the interior, along with LEDs to illuminate them.

Then everything gets wired to the rear panel, which has authentic rust on the steel plate.I have a few electronic bugs to work out. The major one being that the Pi Pico doesn't want to show up on the Raspberry Pi at a fresh boot. I have to physically remove the Pico from the PCB, reset it, and then plug it back into the board with USB still attached.

-

Woodworking

11/13/2024 at 15:00 • 0 comments

![]()

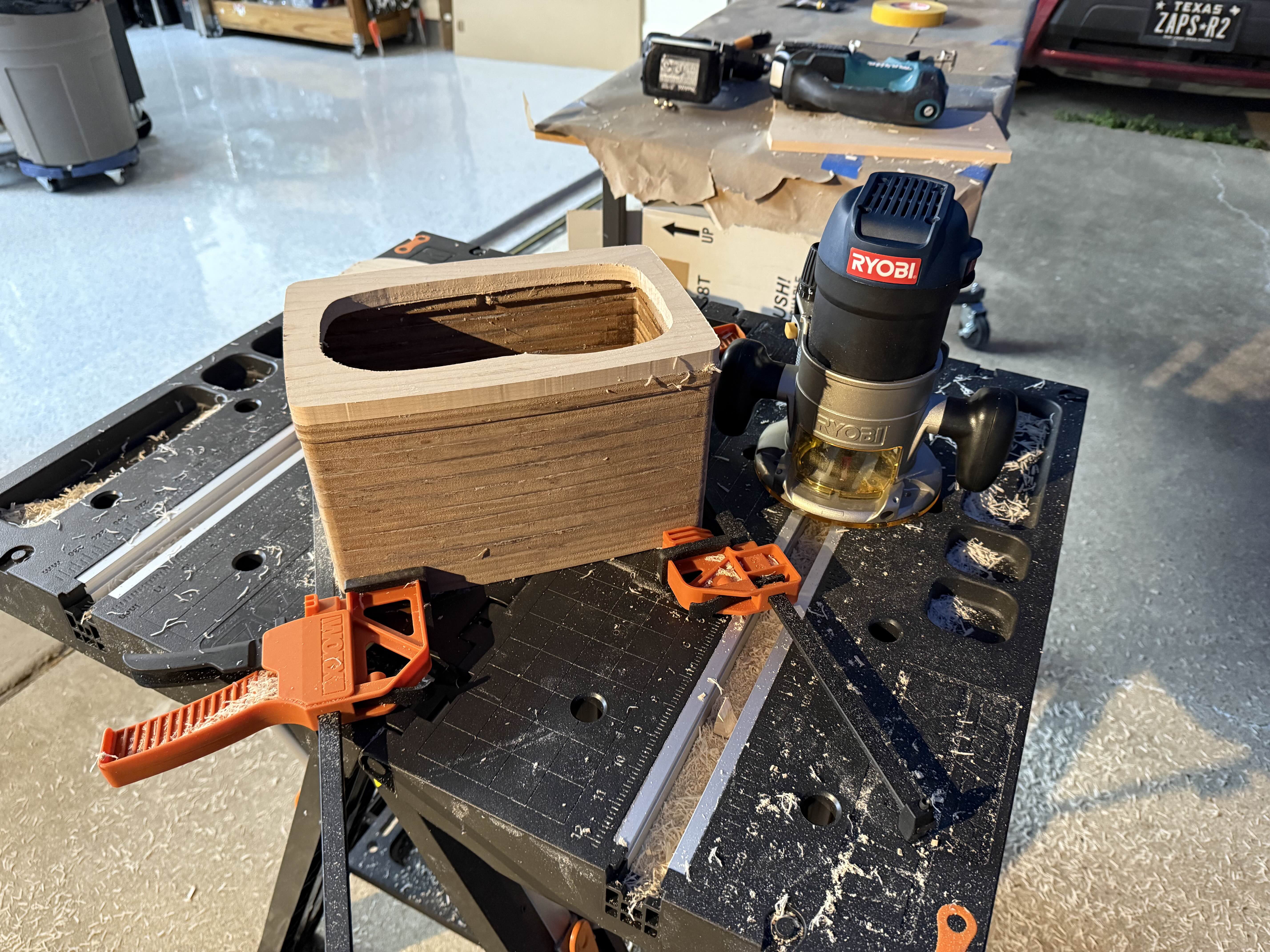

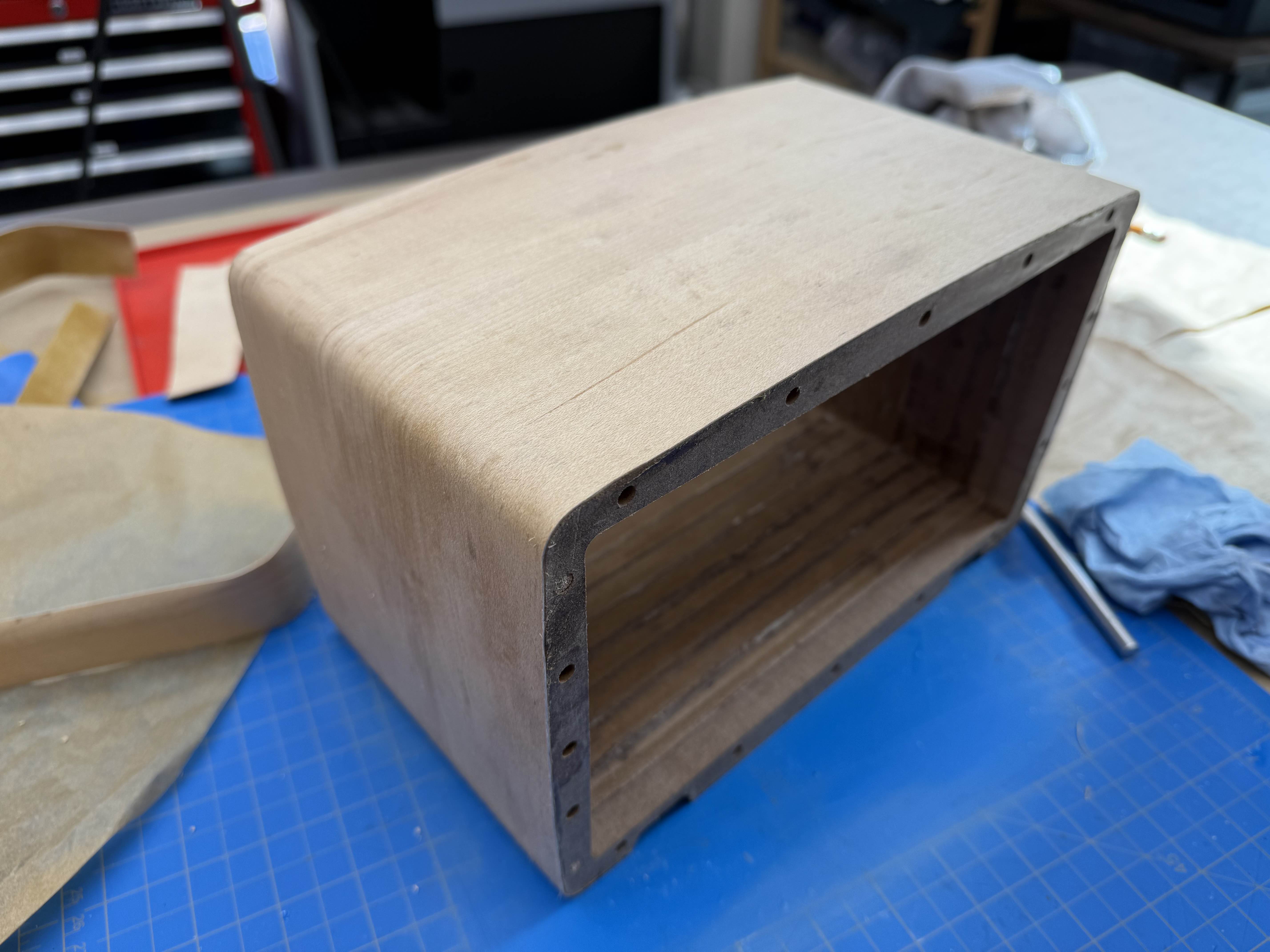

So I had some motivation this weekend and got a whole lot done on the radio. First I glued up my 12 layers of MDF. The 12 layer was supposed to be a routing template for the front panel, but I accidently included it in the stack. I used a trim router bit to carve the 1/2" thick maple front, and then the 1/4" maple back panel.

![]()

To cover the MDF, I am using 1mm thick maple veneer. Before I glue it though, I pre-formed it to the MDF by steaming the wood and then wrapping it with ratchet straps.

![]()

I then used contact adhesive to bond the veneer to the MDF, and trimmed the excess.

![]()

I glued on the front and rear maple panels. Later I applied a rustic wood stain to the whole thing. -

Boards from PCBway

09/22/2022 at 14:36 • 0 commentsMy circuit boards have arrived!

I have to give a special thinks to PCBWay for these. They gave me a good discount on getting these boards made, and they even sourced and populated the SMT parts for me. They even were able to get the motor driver IC that is out of stock at all the US suppliers.

All I need to do is add the though-hole components. They were so far, I am actually still waiting on some of the parts to arrive before I build up the board.

The board itself is four layers, with more time and a less symmetrical layout I could probably get it down to two layers. I designed it in CircuitMaker. You can get the design file here.

--------------------------------------

So I decided on a method for my enclosure construction. I wanted something that didn't require me to sand the whole curve into the enclosure, and I wanted something that folks to reproduce. I debated trying to use a wood CNC, but most of the software I could find did inaccurate 2 .5D etching, or charge huge amounts for true 3D sculpting.

What I ended up settling on was to use lots of layers of laser-cut plywood with dowels to make the main structure. This section will be covered with a thin real wood veneer.

The front will be made from 1/2" of maple, and the back will be a 1/4" piece of maple., both with rounded edges.

-----------------------

It took a few hours to glue up the 45+ layers together. If I were to do it again I would use 6mm (1/4") plywood to save on the total number of layers.

-------------------

I then waited 24 hours to the glue to fully cure. I used a belt sander to remove all the glue and the laser burnt edges. I then slathered the surface in wood filler (I smoothed and removed most of it after taking this photo)

Once that fully sets I will sand and paint the surface with a filler primer. This will then become the base that gets wrapped with the veneer. -

Video logs

02/14/2022 at 19:53 • 0 commentsFull text log here:

https://www.therpf.com/forums/threads/zaps-fallout-radiation-king-radio.304867/

Radiation King Radio

A Pi based music player with simulated live station playback, analog controls, and a 1950s era ultrasonic remote.

zapwizard

zapwizard