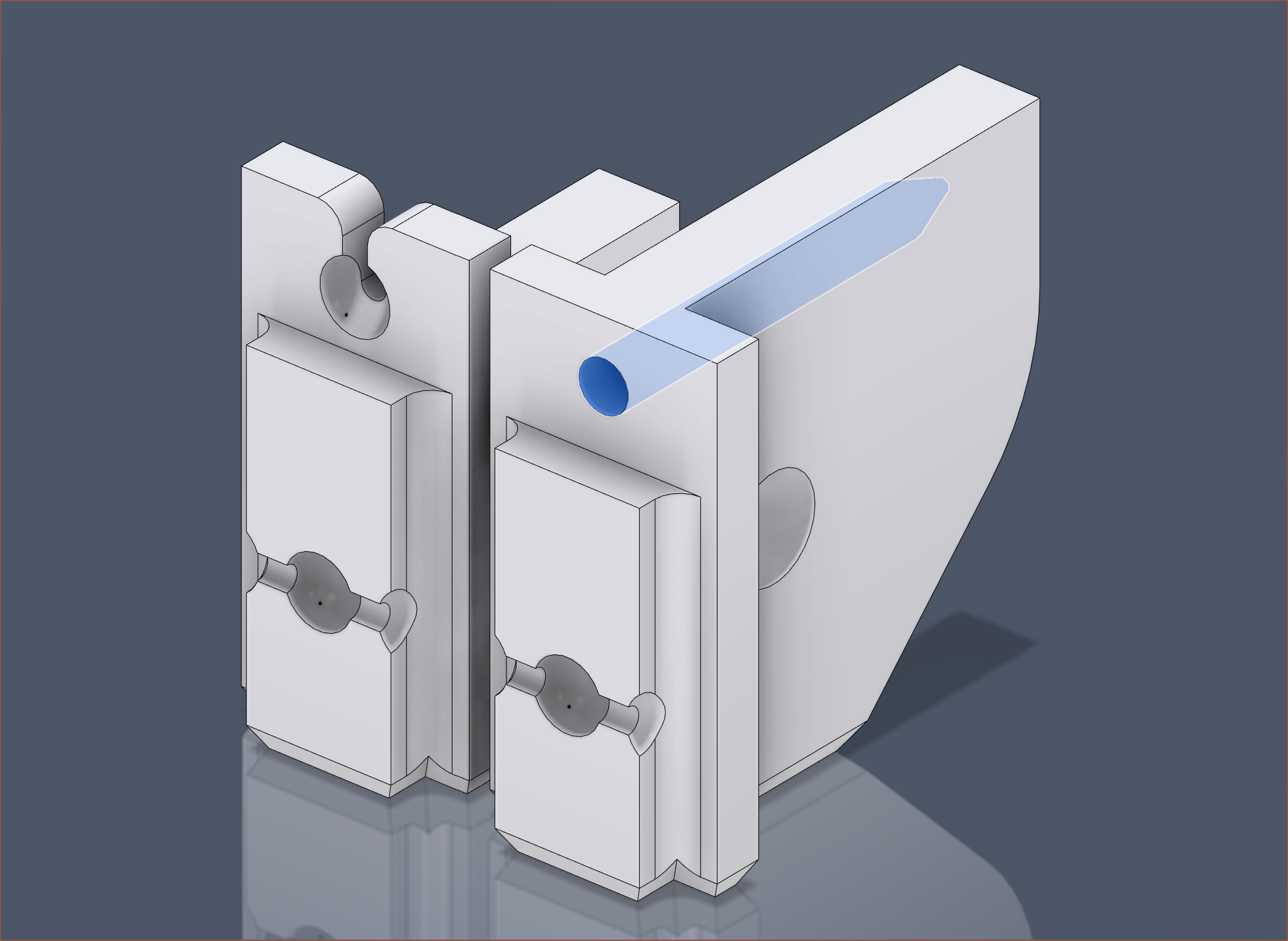

So I attempted to print out a set of jaws, following myinitial idea a dozen logs ago. Long story short, it doesn't work because the ball tilts when the spike goes into it.

Changes I had to make after my initial design:

- Change the spike hole from 2.2 to 2.4mm so that the spike could actually fit in the hole, even though the spike itself is only 1.99mm.

- Increase the side bolt hole size from 4.5 to 4.8mm

- Swap which side of the slot had the ball cutout.

- I originally had it on the other side, but that allowed the ball that was being stabbed to slide even more than in the configuration seen in the topmost image.

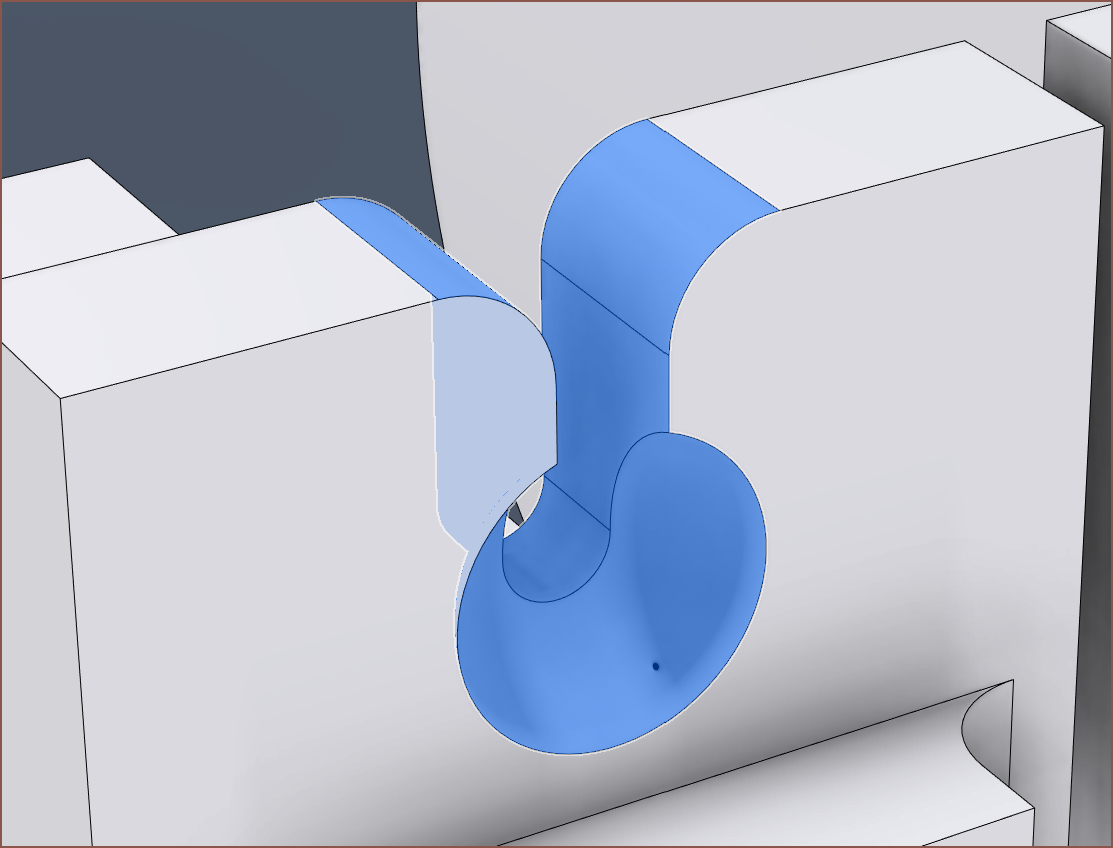

- Add cutouts of subsequent balls to the ball reformer mould

- Originally, it was just the one single spherical cavity. Now there's 2 more partial cavities on the left and right of it because the next ball in the chain isn't actually that far away from the one being reformed.

- Add a 0.6mm by 60 degree chamfer (using the distance and angle option in Fusion 360) because elephants foot was preventing the jaws from even going into the SN-28B.

- Change the width of the large rear wall (the one that has the side bolt hole) from 4.0 to 3.9mm.

- Moved the slot end so that it was slightly closer to the hinge end of the jaws than the spike.

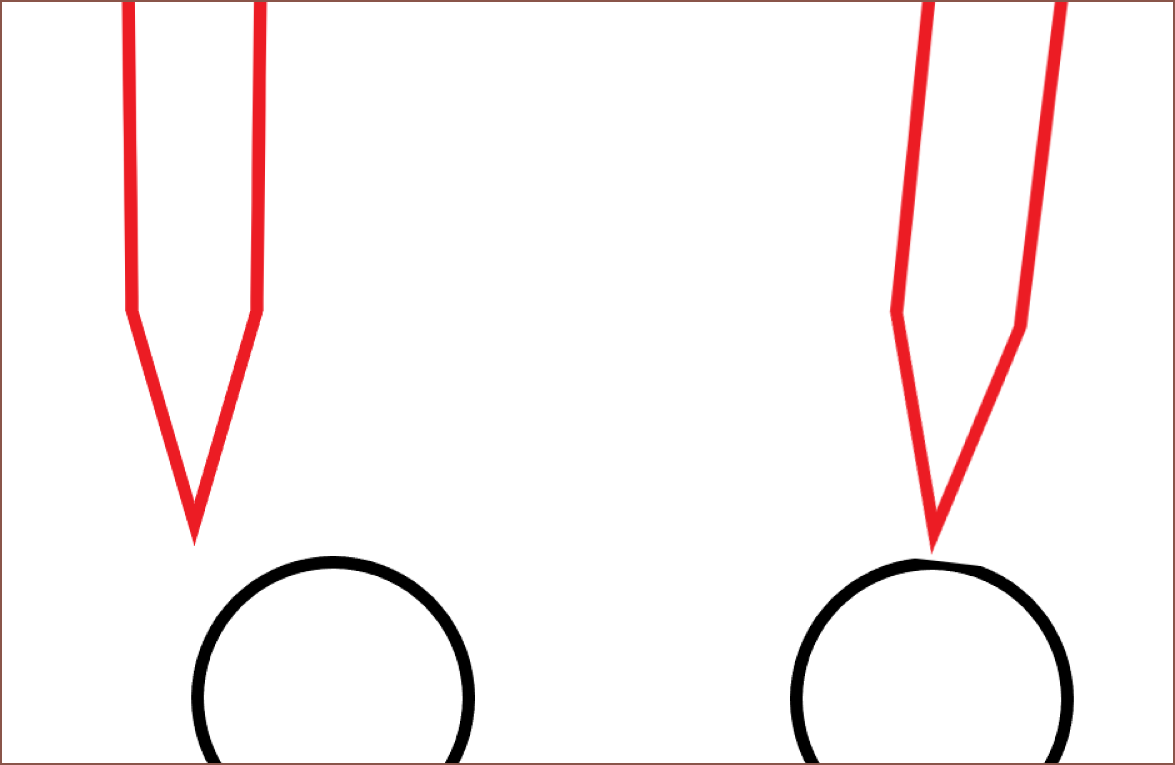

- This was an attempt to eliminate the asymmetrical ball opening that I'll talk about shortly. The left is how it's modelled in CAD, and the right is what happens in the real world, taking the slight rotation of the jaws into account as they close.

Basically, what I'm trying to say here is that I'm not a fan of the manufacturing stage because, like anyone in manufacturing would tell you, it's just as much of a grind as actually designing the thing in the first place. I don't have high hopes that I'd be getting #Tetent [gd0090] built anytime soon, and why I'm not even bothering with #SecSavr Suspense [gd0105] until after Tetent, since I'd most likely have to revise things a "Hey, there's Big Ben, Parliment" amount of times.

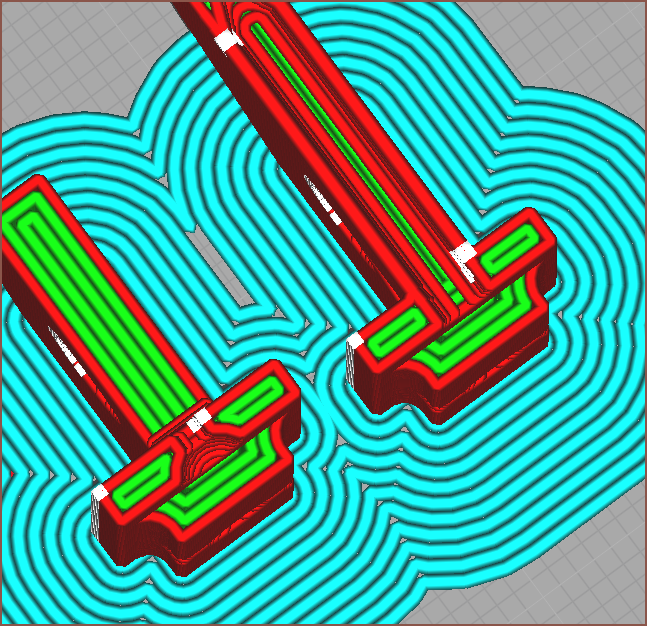

Anyway, this is the result:

The balls seemed to bend assymetrically; instead of evently splitting apart, the top hole would open loads and the bottom wouldn't open at all, and instead the sides would skew as seen above. Additionally, the jaw already broke after just 1 attempt:

It was printed solid (see below) so there's not much more I can do:

Oh, and actually cutting the chain left these voids in my nice cutters (that I mainly use for part cleanup). My long nose pliers fared much better for this task.

Speaking of these, I also tried using them in place of the 3D printed slot (see below), but I still got the asymmetrical seperation.

I'm tempted to buy a "Used, Like New" commercial tool to see if this is an issue with my design or if I've just got uncooperative balls.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.