-

[M] Clamp 161

05/06/2022 at 17:56 • 0 comments![]()

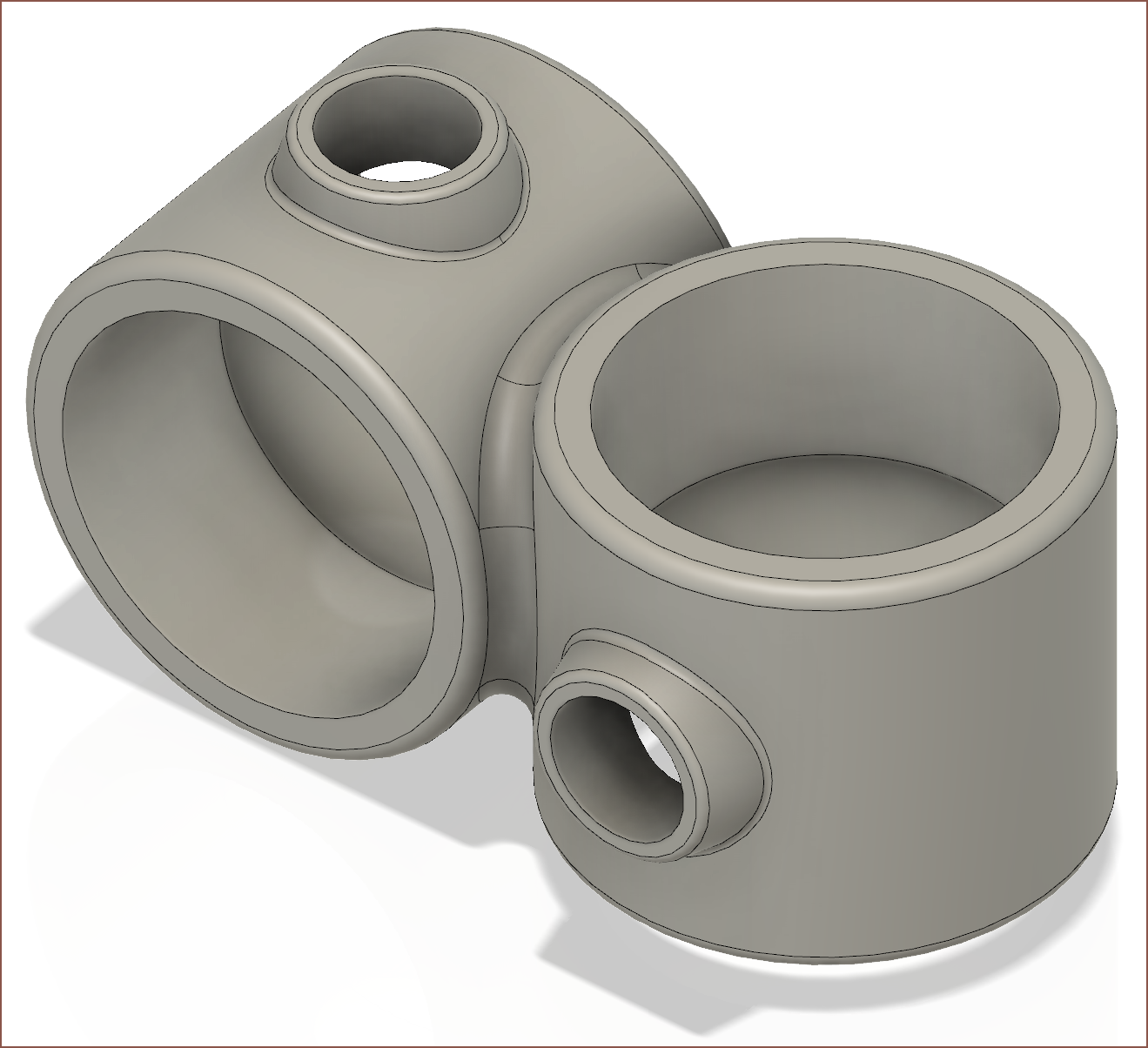

I was thinking about how I was going to do the window sections and thought that I should model and add these clamps on before I create a design that would intersect where these need to go.

-

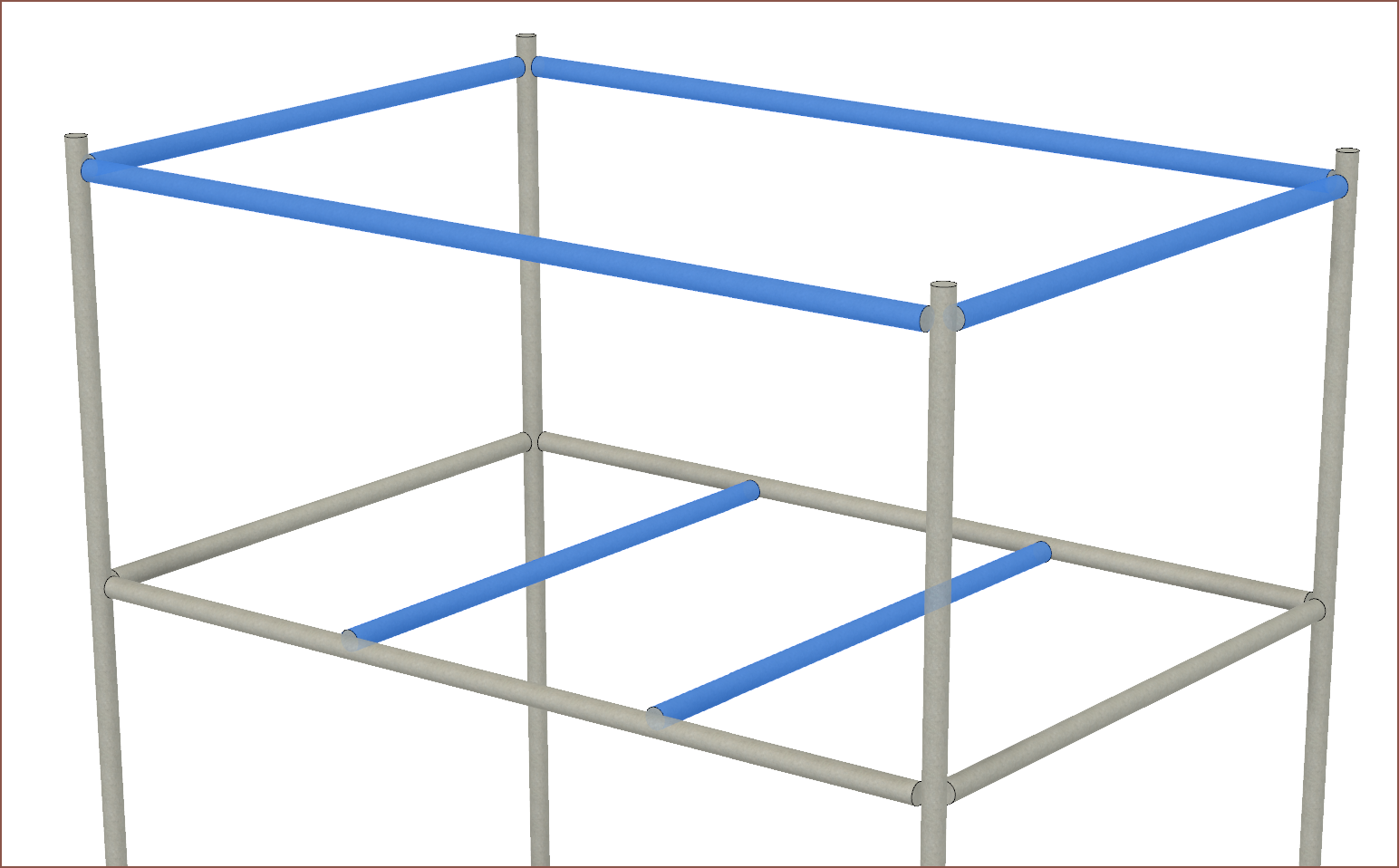

[M] Bed and start of frame

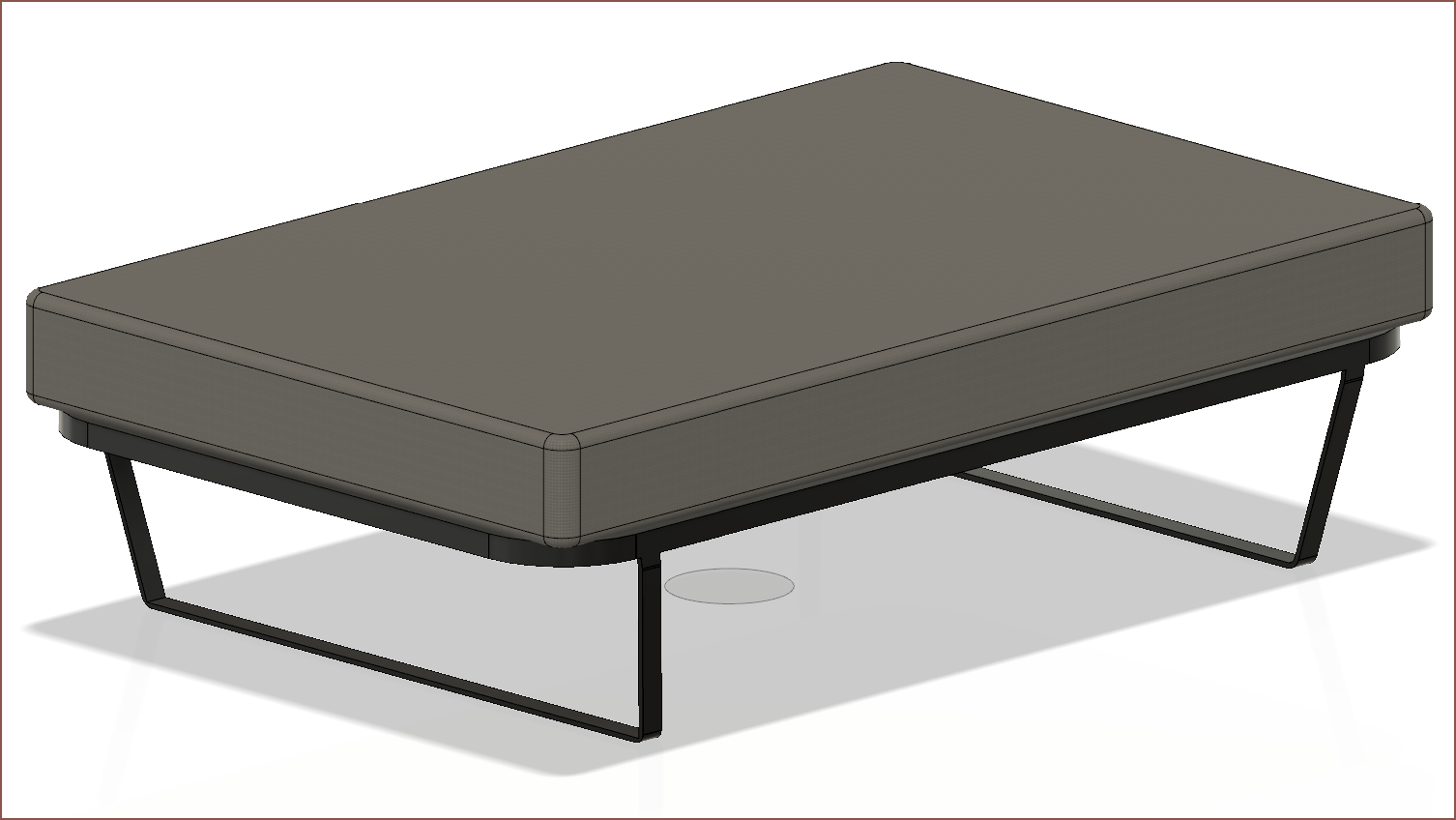

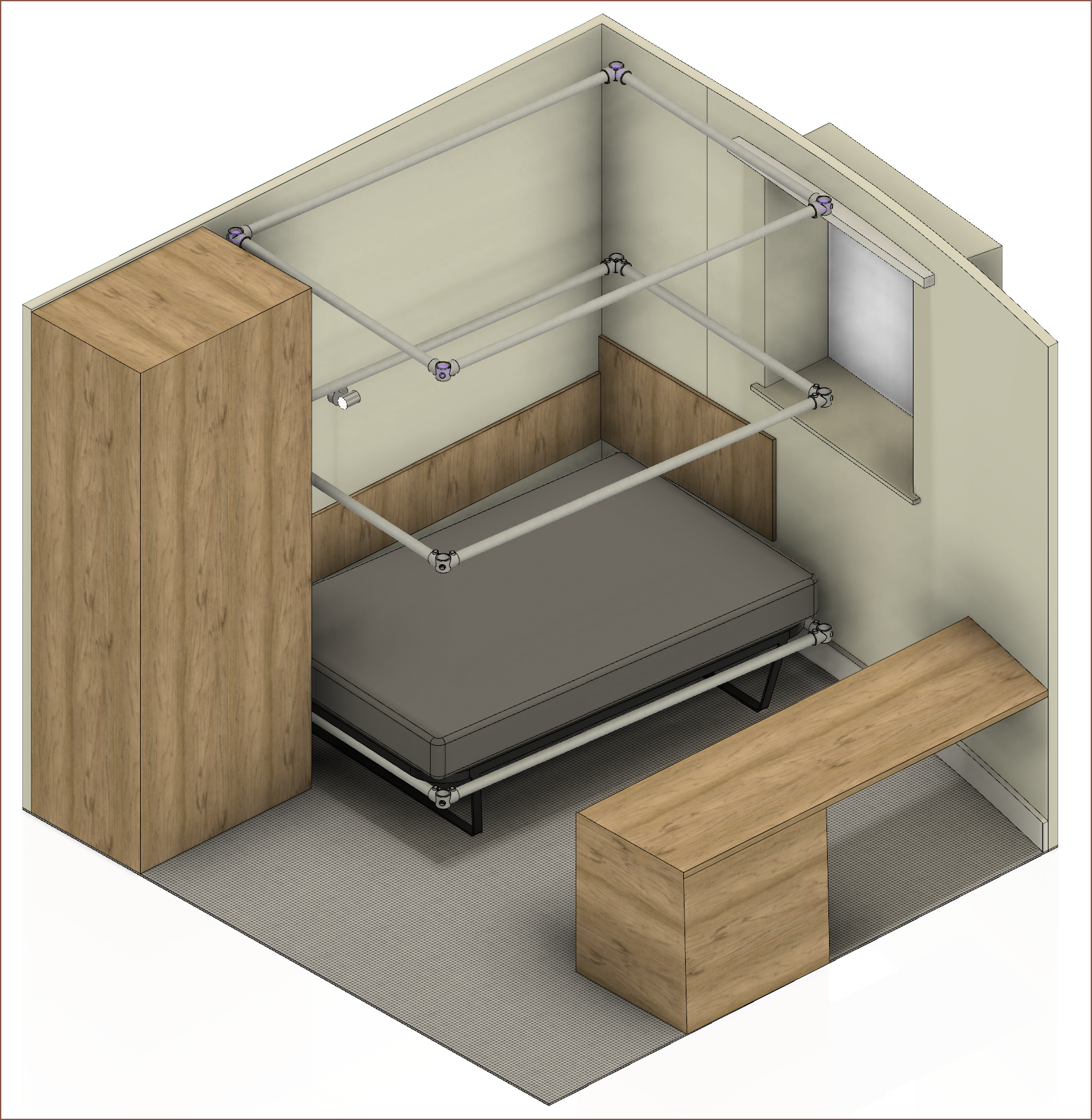

05/06/2022 at 16:11 • 0 comments![]() Today's modelling began with the small double bed, which is a 1.9m by 1.2m large mattress. A normal double is 1.37m wide.

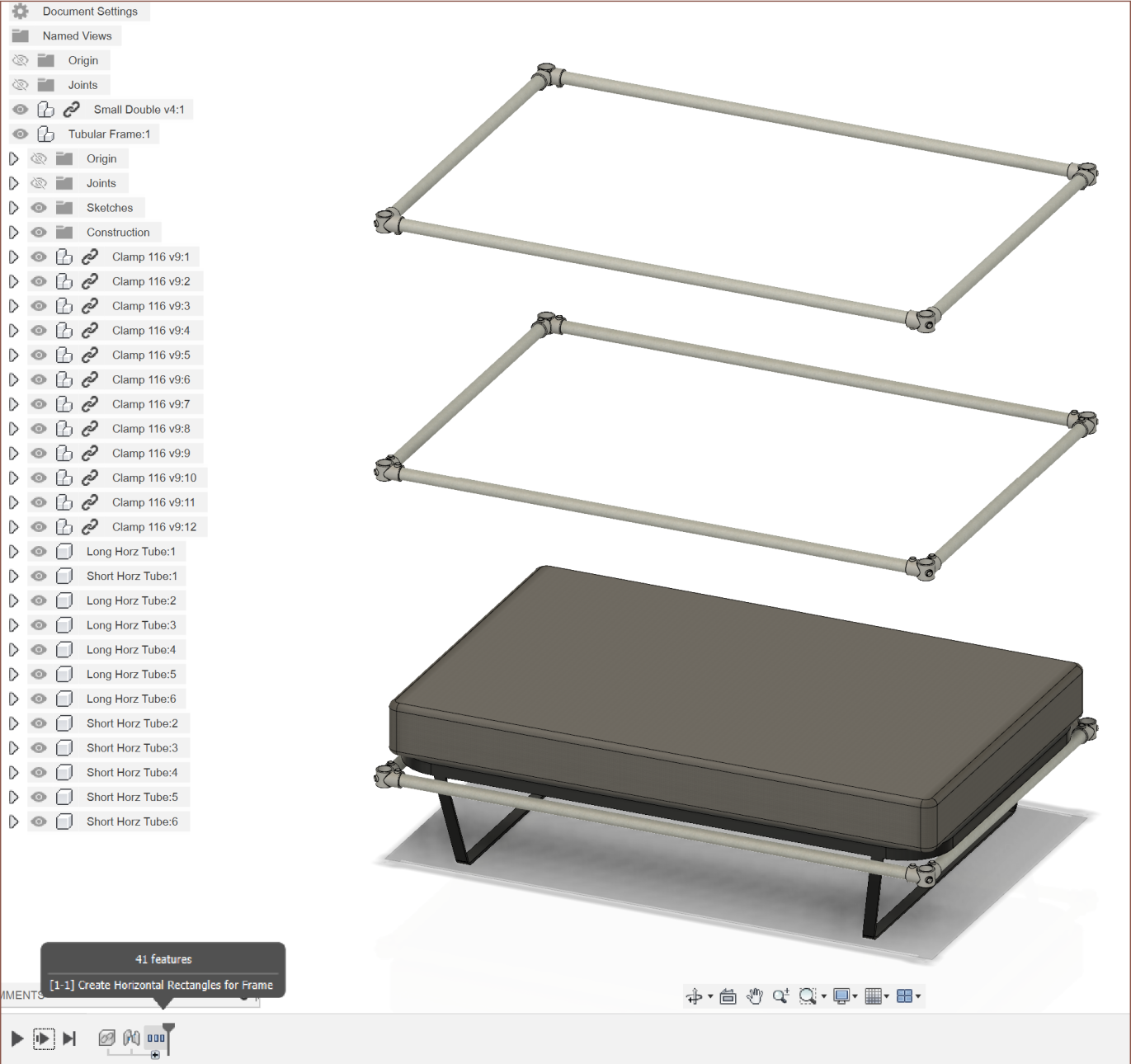

Today's modelling began with the small double bed, which is a 1.9m by 1.2m large mattress. A normal double is 1.37m wide.![]() I then did all the modelling and joining of the horizontal rectangles, only to realise I could've streamlined the whole featuregroup after I named the group.

I then did all the modelling and joining of the horizontal rectangles, only to realise I could've streamlined the whole featuregroup after I named the group.![]() Thus, I modelled it all over again so that I don't have to constantly think "man I should've refactored this" for weeks. Took an additional 20 mins.

Thus, I modelled it all over again so that I don't have to constantly think "man I should've refactored this" for weeks. Took an additional 20 mins.Here's the current model in my room's virtual twin:

![]()

Modelling time: Approx 2hrs 50mins

-

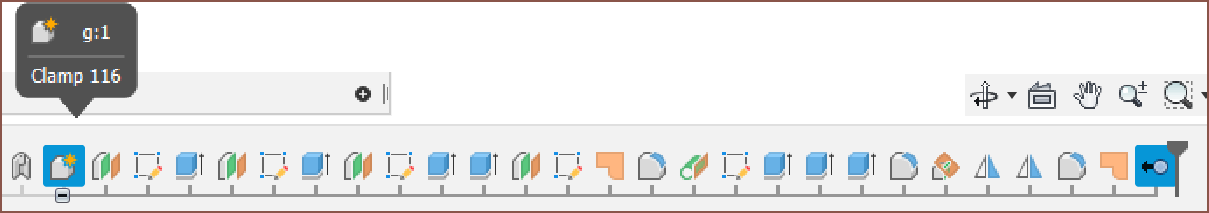

[M] Clamp 116 and Fusion 360 Housekeeping

05/05/2022 at 19:16 • 0 comments![]()

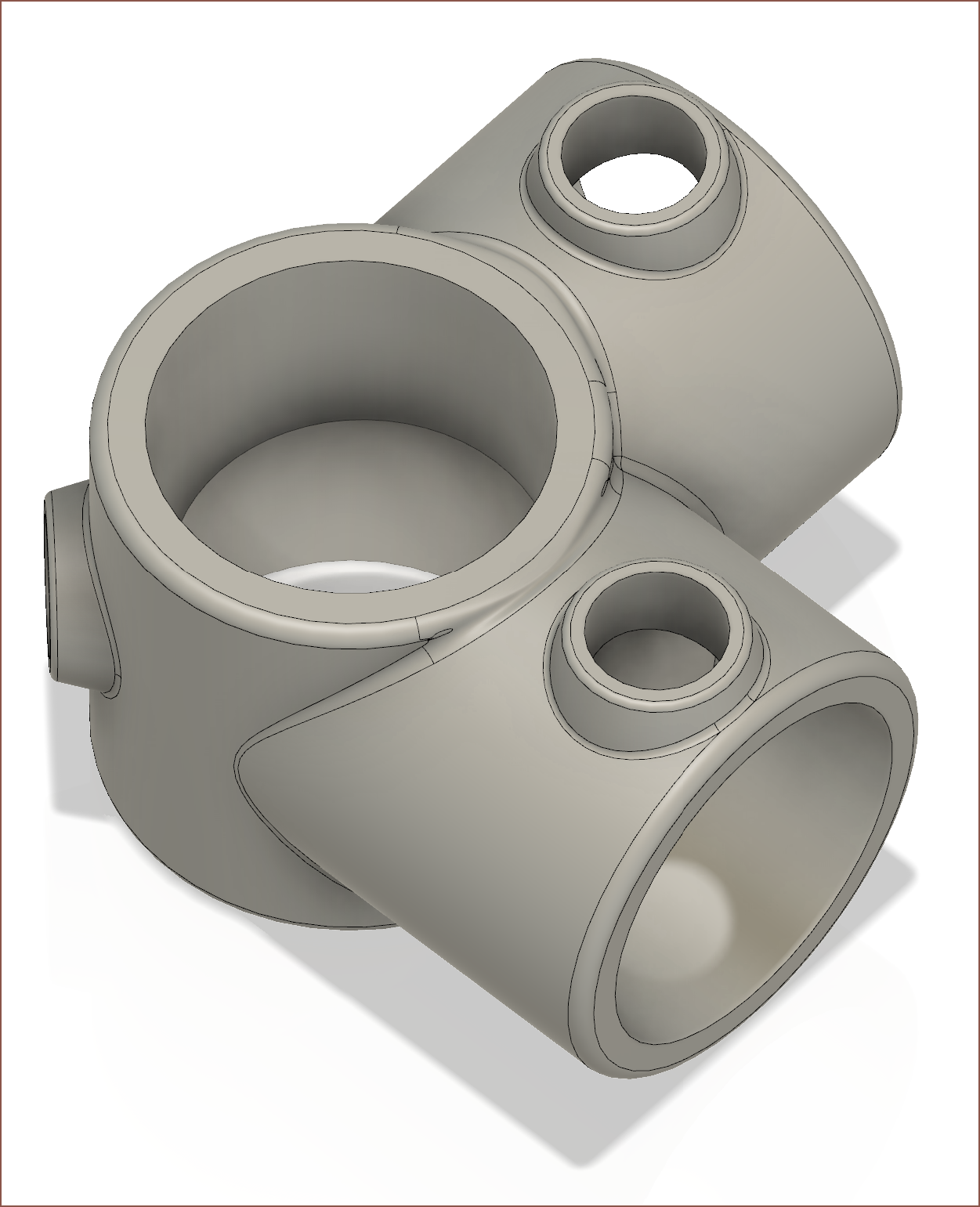

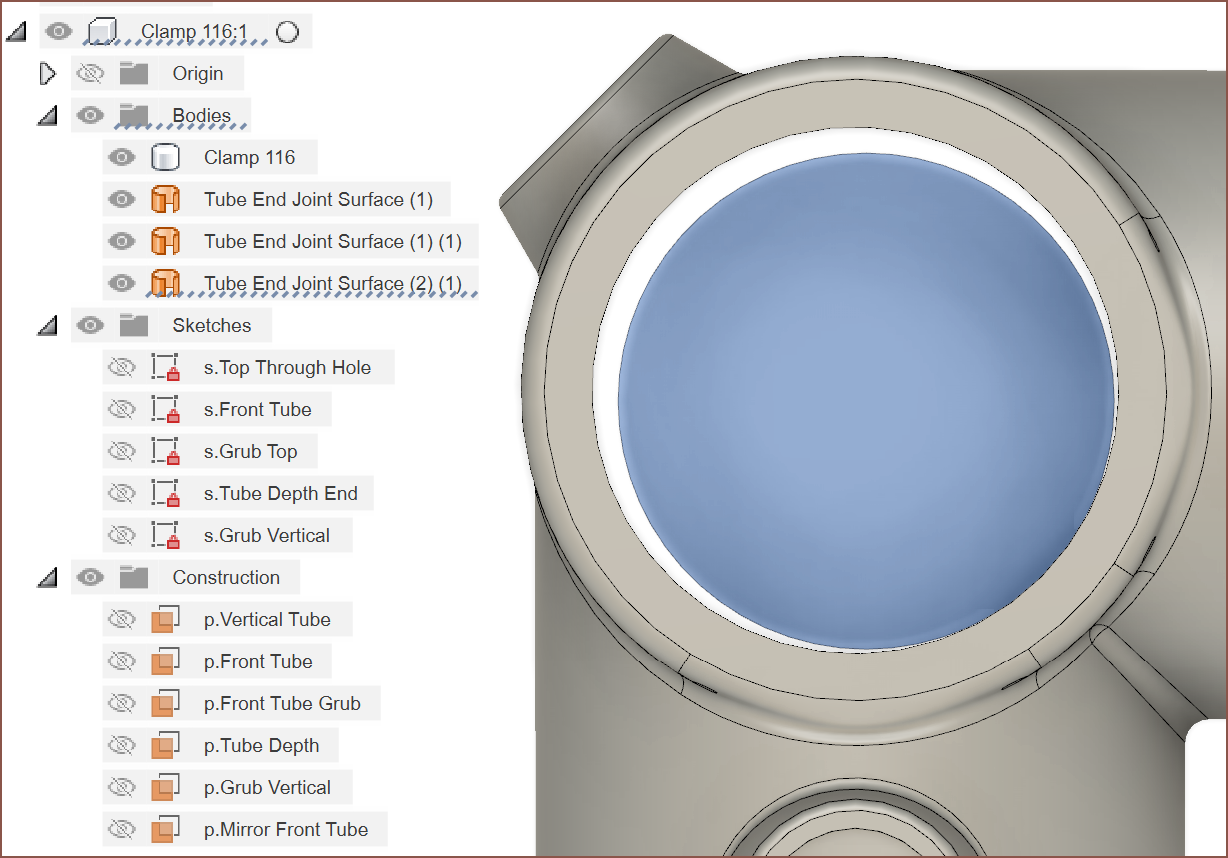

So far, I've modelled one out of the three key clamps that will be used in the frame. The other two are 161 and 179. I used this opportunity to get aquanted with the conventions I want to use to make files easier to maintain and adapt.

![]()

For sketches, I've decided to give them their own 0 offset plane instead of working directly on the origin or other faces. This stems from the time consuming process of fixing a model after the reference plane is lost. For projections, I just have to relink the reference geometry, but geometry from the face will become fixed, green lines. Another alternative would be toggling the setting off to automatically create face-related geometry. Either way, offset planes give a bit more flexibility anyway.

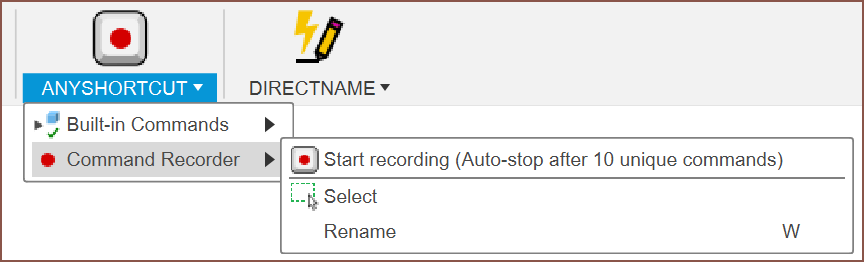

For naming, joints, sketches and construction will start with a letter and dot, and then a somewhat descriptive name. For example, Rigids are "r.", planes are "p." and sketches are "s.". Features that would only show in the timeline would keep their full name, unless another is more descriptive like "Cut" instead of "Extrude" on a cut extrude feature. Naming is made easy with DirectName. For files created before now, some kind of bulk feature renaming would be welcomed (as in, being able to have all the features in a menu, skipping the context menus), but now that I think about it as I type, AnyShortcut may have already solved it by allowing the command to be keybindable. Wait...

![]()

This QOL add-in could change everything. Save as Mesh? Keybind. Activate Component? Keybind. Wait! Isolate and Unisolate All?! Keybindable!! Put the keys next to each other and I can Active Component then Isolate!! 🤯. Aww but I can't do Edit Sketch and Edit Feature.

Achem. Anyway, surfaces have been created specifically for jointing other components. I'll likely move the bodies into their own subcomponent if it starts to get out of hand in Bodies.

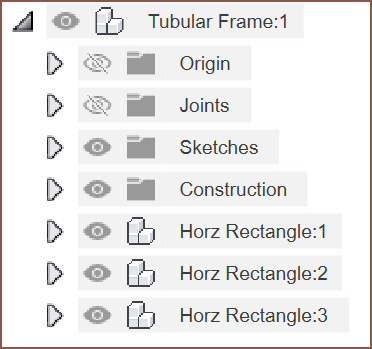

![]() Lastly, I make a component called "g" to denounce the start of a group, and removal of the same component to end it. This is because the group feature is somewhat underbaked and doesn't have the ability to add stuff to the start or the end of the group without recreating it.

Lastly, I make a component called "g" to denounce the start of a group, and removal of the same component to end it. This is because the group feature is somewhat underbaked and doesn't have the ability to add stuff to the start or the end of the group without recreating it. ![]()

I'm thinking I'm going to keep my timeline group naming since, to my knowledge, Fusion still doesn't have an easy way to share parameters between files. I hoped that the new Driven Dimension Parameter feature was going to open up a workaround, but it fell short.

-

[R] Searching GitHub

05/05/2022 at 11:01 • 0 commentsSome github repositories I found while searching. These could be related to SecSavr or subprojects like #SecSavr Sol^2 [gd0045] .

- (5 Axis) Gcode Viewer

- Belt Balance System

- Klipper toolchanging

- Octoprint web GUI for managing multiple printers

- I thought the STL naming convention of this project was nice.

- Using NixOS for Klipper

- I thought this printer looked cool, with its filament drybox running Windows 10

- I believe this is a slicer for printing a single, continuous line of filament to print a part

- Some idea of what 3D printer firmware could be doing under the hood

-

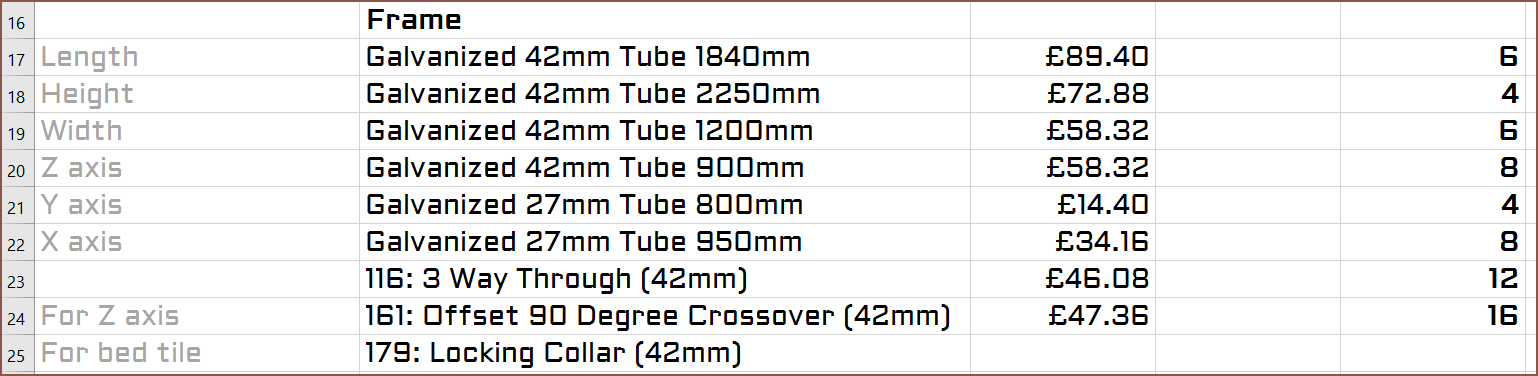

[T] Frame BOM

05/03/2022 at 13:47 • 0 comments![]()

So I've decided to remove the 2 middle tubes, move the 4 topmost tubes up so that I have more area to apply force to the ceiling (using printed parts) instead of the 4 points at the top of the vertical tubes and change the Y axis from 42mm to 27mm pipe, saving almost 2kg of mass and almost halving the cost.

![]()

I'm also planning to use clamp 179 as a base for the part that holds up each tile for each SecSavr Slab (I'm still thinking of a name for each gantry/bay/core/etc).

-

[T] SleepCinema design

05/02/2022 at 22:05 • 0 commentsToday, I've been thinking about the SleepCinema design. I intended to actually model sometihng, but I didn't exactly know what to model.

- First was TV research.

- My plan was to have a projector, but then I put the width of 1.2m into an aspect ratio calculator and it gave me around 54 inches IIRC.

- Thus, I looked to see what kind of TV's you can get these days. Seems that getting a 50 inch 4K TV under £300 is doable these days, so I'll keep that option in mind.

- I also thought all the TVs in this range (and above) had trash energy ratings, but it turns out that there's a new energy rating system and so all those A+++++'s are out.

- I'm thinking it might be better than the loud and low rez dirt cheap projector I was planning on, but only because 4K Tv's are silent and I can still use it as a work monitor.

- Yeah, I know it's a bad idea to work and sleep in the exact same area, but I need reasons grounded in "solid fundementals" to show to my client, Future Me.

- My concern with the TV (and projector to an extent) is the minimum brightness level

- All the manufacturers obviously talk about their top brightnesses and HDR, but never mention the minimum brightness for all those late night TV watchers.

- I might just put a filter on it to reduce the brightness.

- All the manufacturers obviously talk about their top brightnesses and HDR, but never mention the minimum brightness for all those late night TV watchers.

- Looking at my helper file of a virtual twin of my room, I prioritized making sure that the long sides were as short as possible. In the model, I have 30mm of clearance.

- I'm thinking of a design that goes around the inside C of the tube and has the outside arc of the tube exposed so that the printed parts can stay flush with the outermost part of the pipe.

- Then I spent a good amount of time thinking of the design while messing around with the pipe clamps I bought months ago.

- The Q Clamp 116 I have doesn't seem to want to clamp such that the vertical tube is plumb, so I'll have to keep that in mind. I probably should've gotten an Interclamp with the test order to see if the difference is more than just aesthetic.

- It turns out that you can make them look really nice with a bit of polish.

- I'll have to keep the possibility in inaccuracies in mind, though I'd like to have faith that these scaffold systems are designed so that getting them square, plumb and level is straightforward.

- The door was the other thing to think about.

- Whilst designing the Hexadecibel, the door was one of the trickiest things that I had to think about.

- The requirement of these 3 sets of doors was that it had to hang off the side (partially due to SpaceApp, partially due to looking cool and inspiring) and have a sound-tight seal when closed. Oh and symmetrical.

- The second one is kind of tricky, since I need to be able to slide the door without binding but have a seal when it closes. Thus, I was thinking of various sliding tracks and perhaps magnets to pull the door towards a gasket seal when in the closed position.

- The symmetrical requirement caused some issues with the placement of the outside handles. I've got a design solution for that which is to make the handle look flush with the rest of the front design.

- The Q Clamp 116 I have doesn't seem to want to clamp such that the vertical tube is plumb, so I'll have to keep that in mind. I probably should've gotten an Interclamp with the test order to see if the difference is more than just aesthetic.

- I think I've got a good idea now of how I want the SleepCinema to be constructed and look, and will hopefully model it soon. The galvanised clamps are still a worry point.

- I feel like my filament reserves are going to get consumed very quickly though. I hope Sunlu's white PETG looks like Yousu's because it doesn't seem like I can get the latter of ebay.co.uk anymore.

On another note, I was expecting this log to be like 3 sentences. Truly no progress is too small to log.

- First was TV research.

-

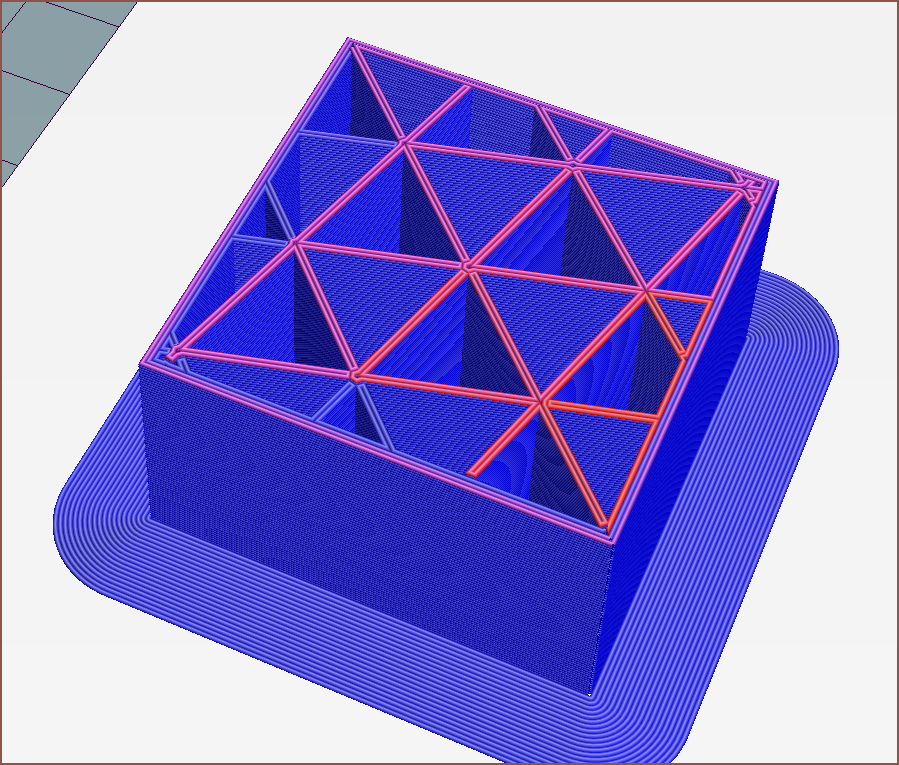

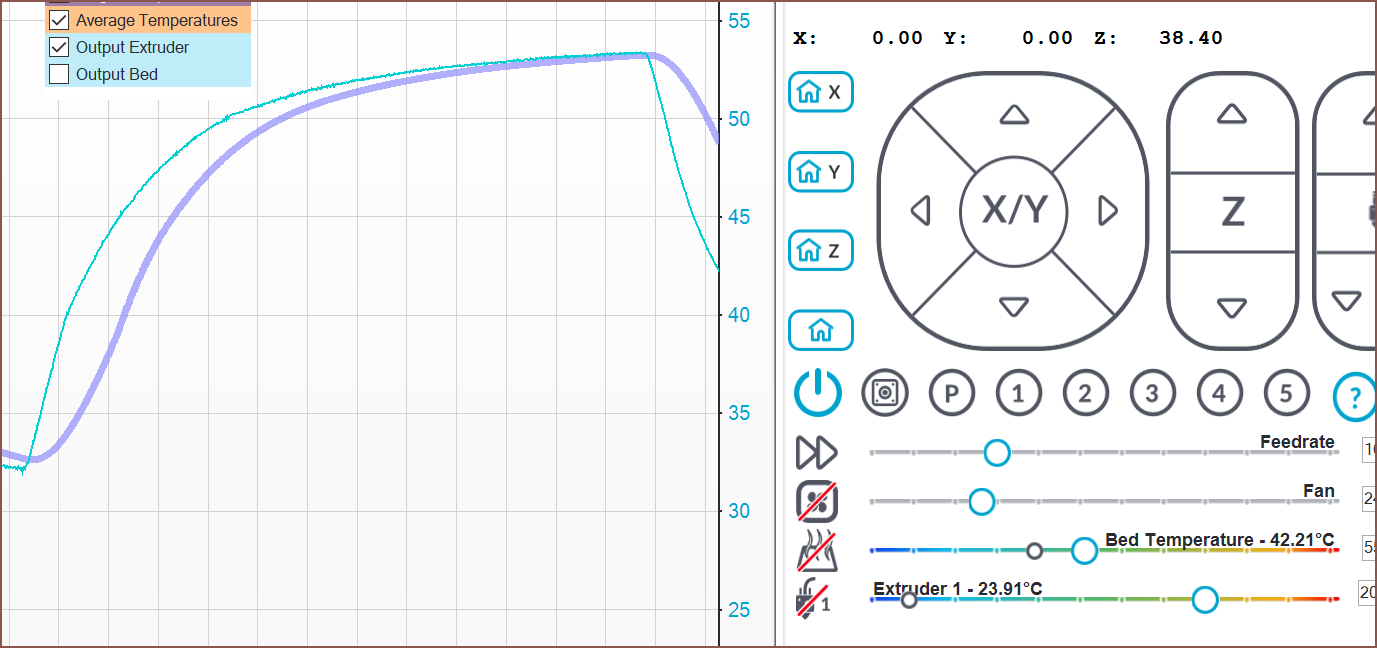

[E2] Initial extruder tests

04/20/2022 at 15:22 • 0 comments![]()

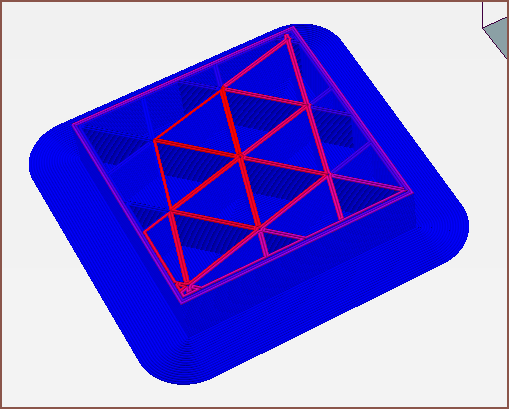

So I turned off the minimum extrusion temperature so that I can send over a print without heating up the hotend first. It didn't seem like the extruder wanted to move at the start of the print at all until I tried spreadcycle mode.

![]()

The peak was 53.3C and the S6609 cools down fast, so it makes sense why it would be somewhat cold by the time I was able to open up the DP2 and put my finger on them. The cooling rate could be increased due to the heatsink. This test print was performed with a motor current of 800mA.

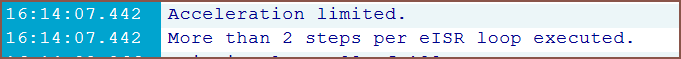

I tried 0.01 linear advance and it sounded horrible while I got these messages:

![]()

[16:54] Reading this, I enabled Square Wave Stepping in Marlin and now spreadcycle is much quieter. Stealthcop still doesn't work and linear advance still sounds like a screaming skittle, but I no longer hear each individual line of infill. It's more like a slight rattle (likely slack in the metal BMG).

![]()

[17:07] So it looked like at 800mA (actually 795 according to M122) was going to converge to 55C. Changed the current to 600mA (581) and temperature dropped to 47C. I might keep a thermistor in the box just so that I can test stepper driver temperatures, because I wasn't expecting an 8C drop from a 200mA power cut.

-

[E2] Extruder issues

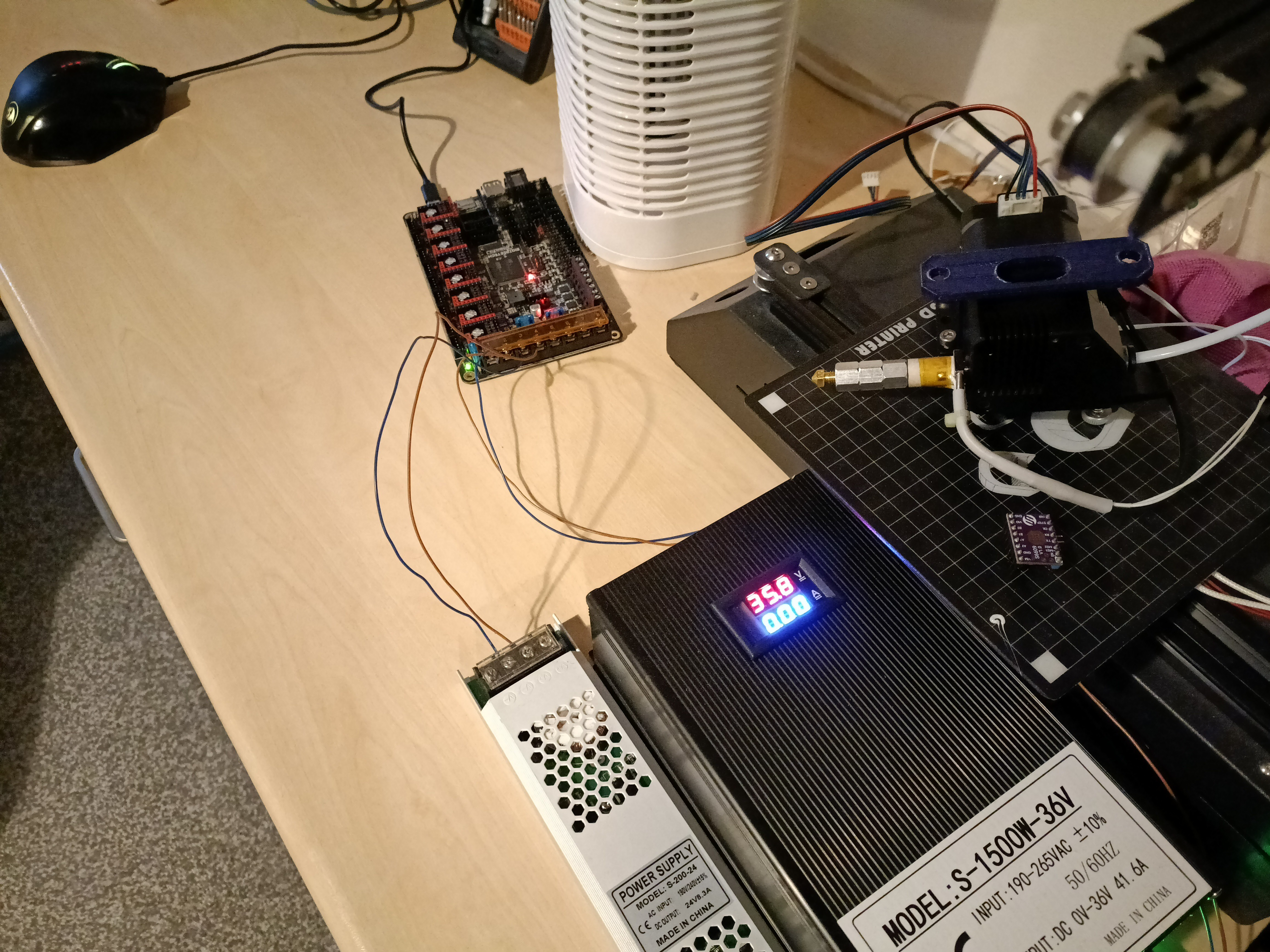

04/20/2022 at 10:25 • 3 comments![]()

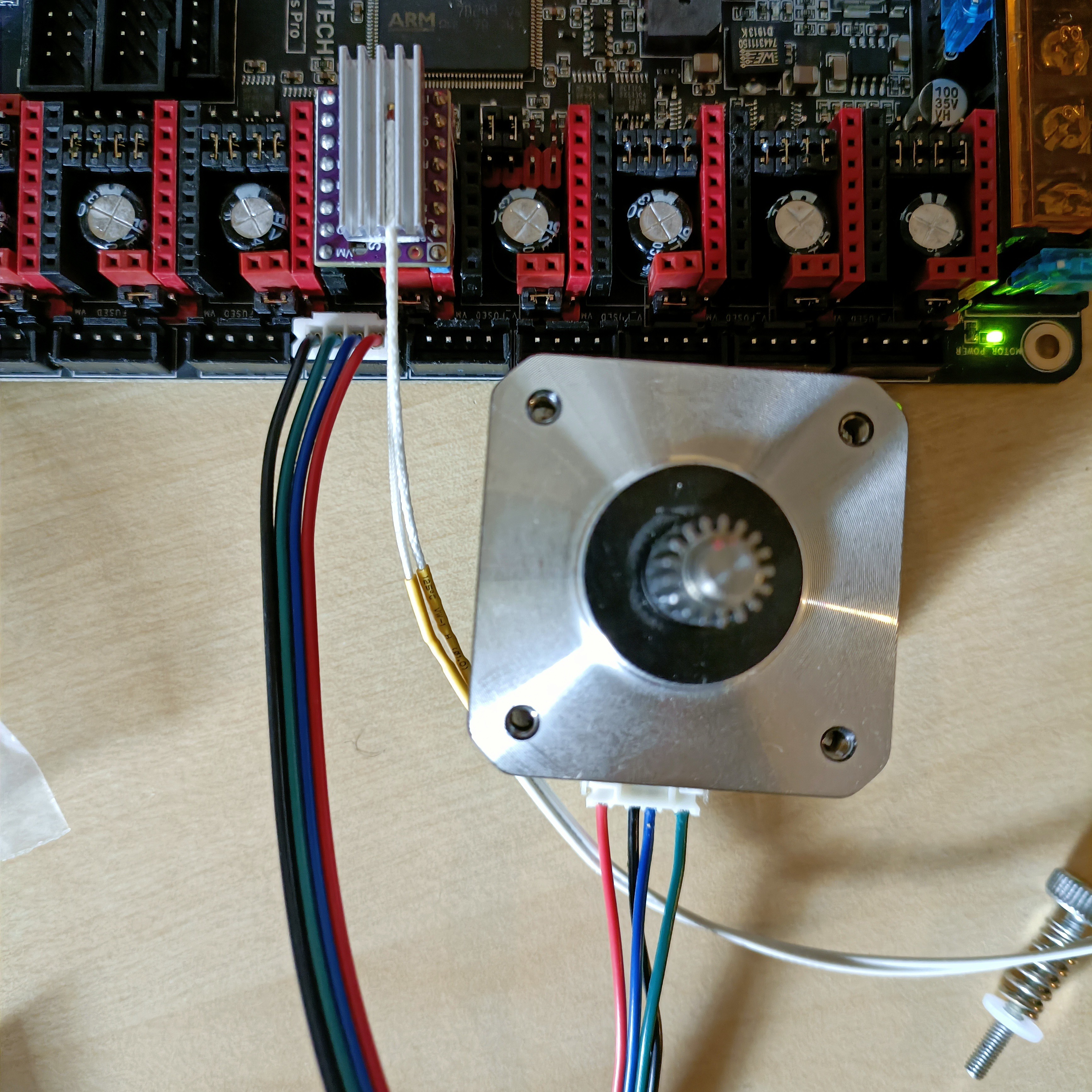

So I connected power and nothing broke so that was a good sign. Thus, I connected the extruder wires and heated up the nozzle. As you can see by the title of this log, the extruder motor didin't turn when I commanded a retraction.

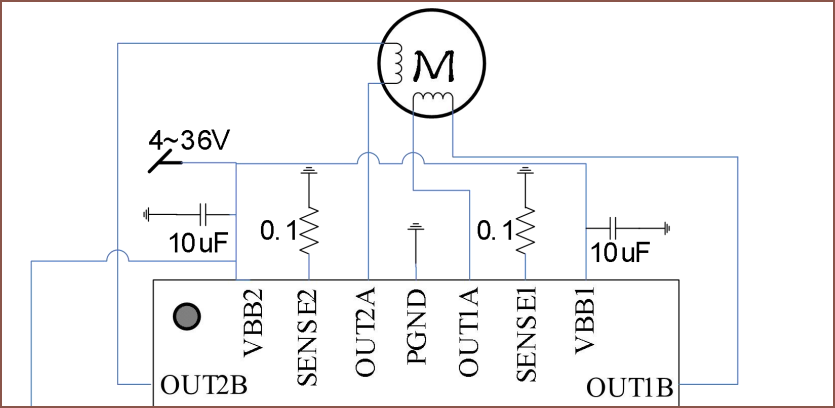

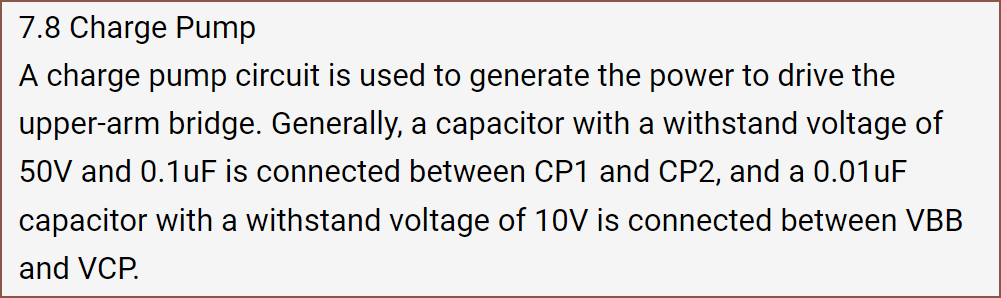

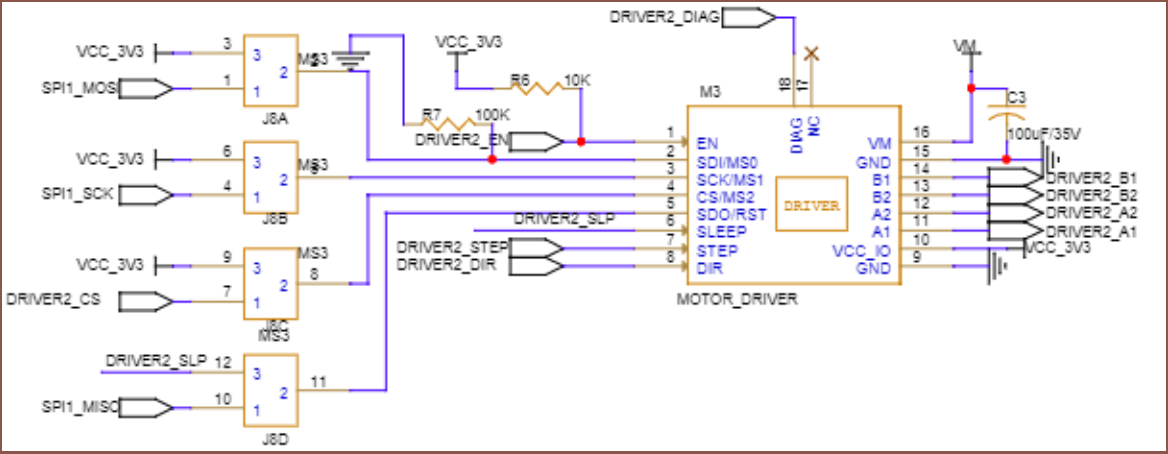

So I got out a multimeter and swapped the wires around so that it matched up with this diagram in the S6609 datasheet:

![]()

Still nothing. Oh and while I'm on the subject of the datasheet, it's specified that a 50V capacitor is recommended so I don't really know why FysetC is using 35V in their schematic.

![]()

Then I found out from here that Marlin has the first extruder on Motor4 by defaut.

Good news: Something happens when I extruder / retract now. Bad news: The motor sounds the same as when the Z axis crashes into the bed or something. Perhaps I've got the polarity on one of the coils backwards so I'll try that now. Also, I'm testing on 24V first and then moving to 36V.

[12:26] Swapping the wires only made the chatter sound different.

I looked in the schematic and found out that BTT has addressed the issue caused by some stepper drivers when their Rx and CK pins are shorted together.

![]()

As you might be able to see (I know it's low res), the connection between pin 6 and 7 is now the 4th jumper pin. Thus, I tried UART mode to see if I could get a connection to the S6609 without cutting off the CK pin, and it worked!v Excellent stuff. That's 32 pins I no longer have to worry about snipping.

[14:52] Thank you Me In The Past for taking a picture of the electronics in the DP2. Got out a new cable, matched the colours exactly to the DP2 one and now I've got a slippery silent stepper!

![]()

As you might also notice, I'm using one of the heatsinks to hold in the thermistor so that I can get actual temperature values instead of "almost too hot to touch but actually no it's fine" claims. Ambient is 24C and before I got the stepper working, the highest I saw was 35C on the readout.

-

[T] Electronic bed levelling

04/15/2022 at 22:02 • 0 commentsRight, so my plan was to level the various beds using the good old fashioned manual way.

Now, because

- 3D reliability is actually really important,

- I want to further flex-tape my features,

- (bragging rights if this isn't a standard feature by the time SecSavr is working)

- the beds are planned to be swapped out often,

- some bed segment orientations would make accessibility difficult,

- the max supported bed segments would technically be 6, thus 12 levelling points, and

- the W axis needs to be very accurate or taller 5-axis parts could be out of alignment,

I am going to start looking into an automated bed levelling solution. Maybe automated bed tramming is the word? I'm talking about the bed moving to make sure its surface normal is aligned with the main Z axis.

I'm assuming I'll be using a multiplexer to make this happen. It's not like the electronic levelling has to be particularly fast. It still would likely be faster than me doing it.

-

Enclosure: SecSavr SleepCinema [gd0099]

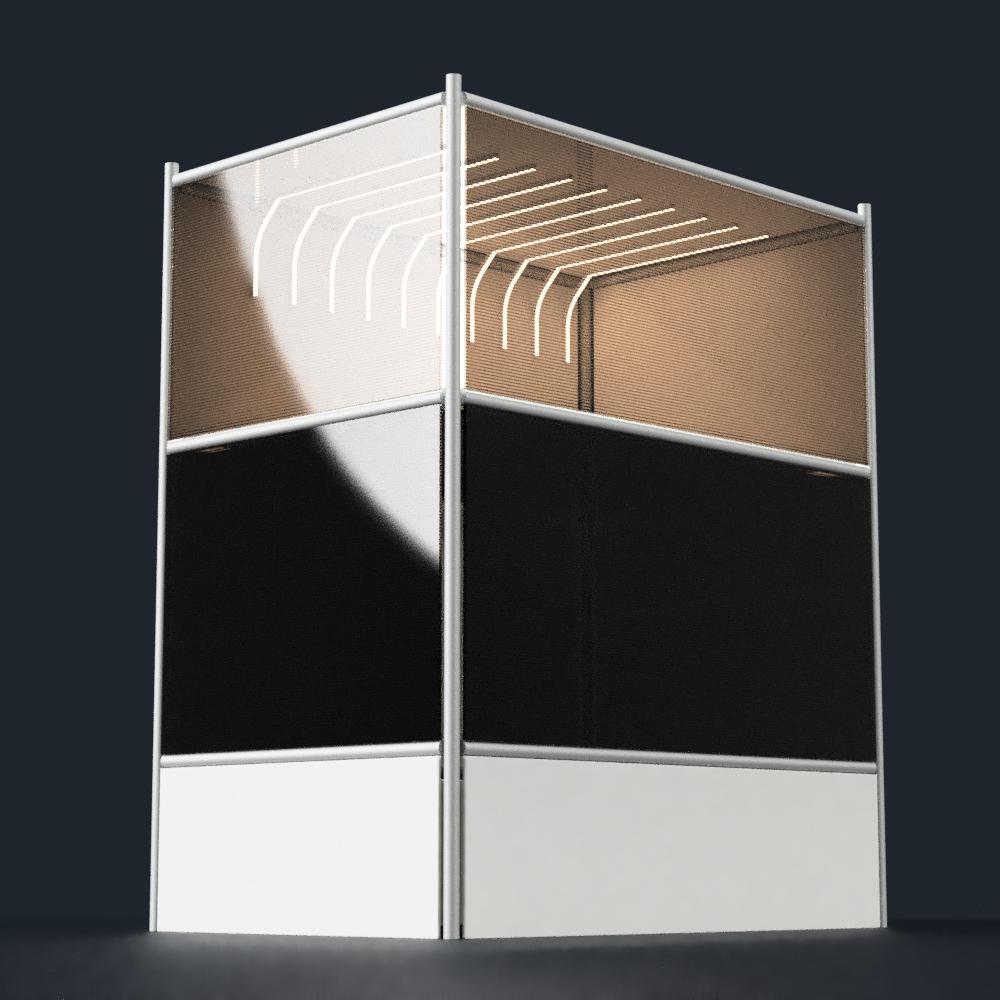

04/12/2022 at 11:09 • 0 commentsI'm thinking that SecSavr is really just a motion system and enclosure agnostic enough to justify having a name (and subproject for), just like the main effector SecSavr Slime [gd0088], filament selector #SecSavr Select [gd0091] , extruder SecSavr Slight [gd0091] and the Hexadecibel.

![]()

The reason why the above enclosure configuration is called the SleepCinema is because this printer is designed to fit around a small double bed (120*190cm) and have a projector installed which will cast on the short wall furthest away from the camera. There's supposed to be light in that section so that you can see it, but the fusion 360 renderer didn't co-operate. Thus, the middle section looks like a black panel, even though it's the same as the bronze panel above.

Due to space constraints (which I reffer to as The SpaceApp), I'm expecting the doors to slide open and hang off to the side. There are 3 other constraints -- CostApp, PowerApp and CanDoTheTaskApp -- that all need to pass to obtain a solution.

SecSavr Sublime [gd0036]

An FDM 3D printer that I described as "The FULL Coverage, Extended X, Pro Max, Ultramatrix Solution".

kelvinA

kelvinA

Today's modelling began with the small double bed, which is a 1.9m by 1.2m large mattress. A normal double is 1.37m wide.

Today's modelling began with the small double bed, which is a 1.9m by 1.2m large mattress. A normal double is 1.37m wide. I then did all the modelling and joining of the horizontal rectangles, only to realise I could've streamlined the whole featuregroup after I named the group.

I then did all the modelling and joining of the horizontal rectangles, only to realise I could've streamlined the whole featuregroup after I named the group. Thus, I modelled it all over again so that I don't have to constantly think "man I should've refactored this" for weeks. Took an additional 20 mins.

Thus, I modelled it all over again so that I don't have to constantly think "man I should've refactored this" for weeks. Took an additional 20 mins.

Lastly, I make a component called "g" to denounce the start of a group, and removal of the same component to end it. This is because the group feature is somewhat underbaked and doesn't have the ability to add stuff to the start or the end of the group without recreating it.

Lastly, I make a component called "g" to denounce the start of a group, and removal of the same component to end it. This is because the group feature is somewhat underbaked and doesn't have the ability to add stuff to the start or the end of the group without recreating it.