-

[T] Print Material?

03/12/2022 at 21:51 • 0 commentsI don't like the idea of printing ££ of PETG just to get to a stage where some other material can be printed, which looking at today's UK market is £££. Seems that even the days of sub £10 ABS are long in the past. I'm expecting that the SecSavr and its sealed enclosure is going to take around 10kg so I'd likely reluctantly get this 10pcs pack for £125.

It also seems that the seller I found that was selling the PBT pellets has vanished, so even if I got that to work, I'd be back to my long search of finding a supplier. The PET pellets haven't gone anywhere though, so it's an option if I can get around the filament brittleness, considering the working temperature is similar to ABS and so would hopefully survive enclosure temps. 10kg is £28. Throw in £10 worth of masterbatch and it could be a viable solution to keep costs down... well at least for me and those that have a filament extruder.

-

[M] - Enclosure Initial Concept

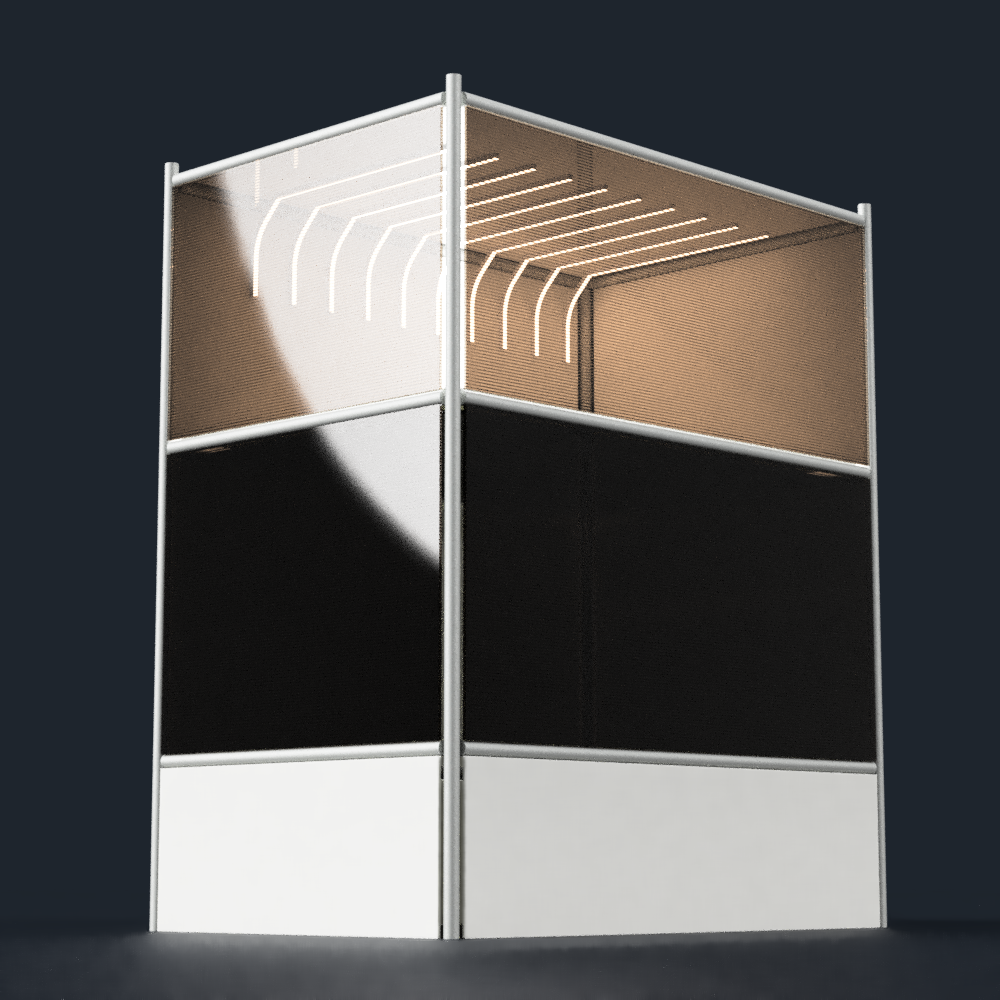

03/11/2022 at 23:32 • 0 commentsI should be sleeping, but I've been meaning to model out a basic concept of the frame and enclosure for the SecSavr so that I could get a clue on what it looked like and what panel colours looked the best.

![]()

The LED arrangement was a cool idea in my mind, but now I'm concerned that it'll hit the XYZ gantry when it homes. At the same time, just lines on the ceiling would probably be bland.

The middle section is still the same bronze polycarb as the top, it's just that I haven't modelled in any lighting yet. The bottom , as well as all the panels that are not the visible 4 bronze, are Opal.

-

Tube Linear Carriage Success

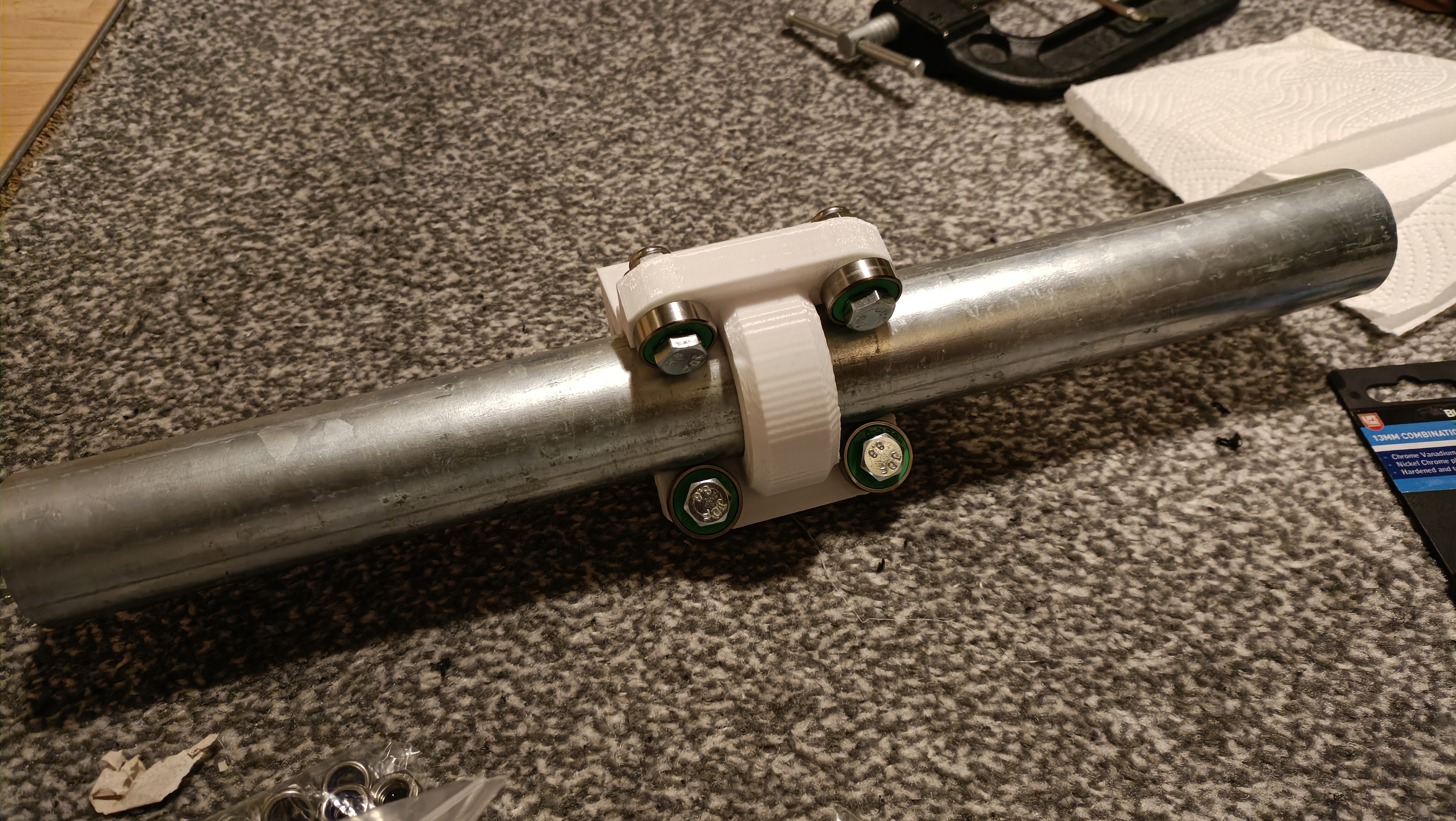

03/11/2022 at 21:35 • 0 comments![]()

Seems that 42.35mm was a great first estimate to use for this part. Slides ok and very rigid. I'm going to need to improve my supports settings a tad though, as I had to use pliers, a file and a stanley knife to clean up the part.

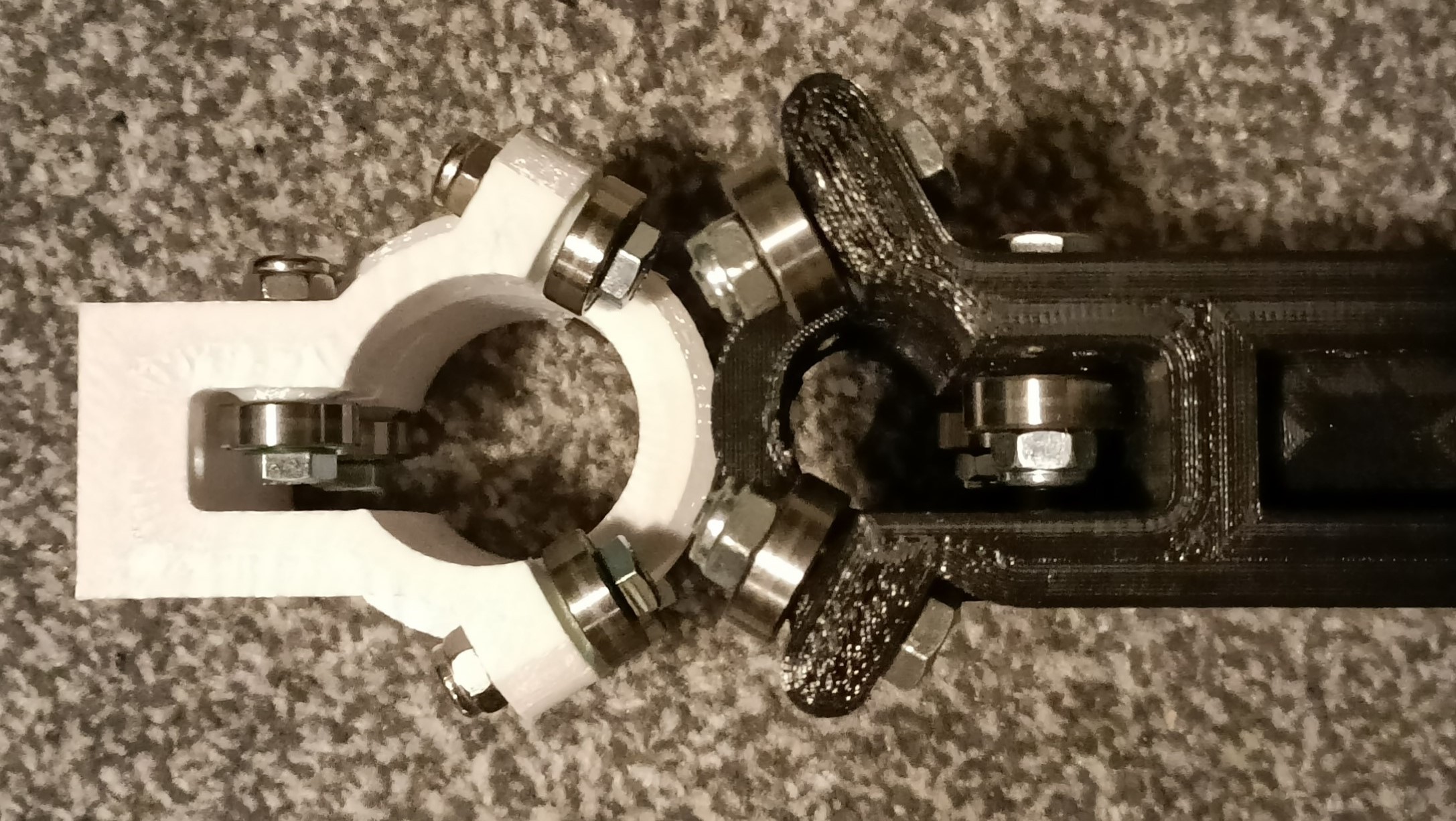

![]() It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space.

It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space.![]() Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second)

Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second)Lastly, I tried packaging tape on one of the matte tubes and there's a slight improvement in noise. Friction seems to have slightly increased too.

Oh and I tried detergent, wet wipes, iso alchohol and hand sanitizer to get rid of the oil that's on the bearings. A bit of it came off, but just rolling the bearings on the tube got it off. Now the bearings aren't sticky and move pretty nicely.

-

[M] - Test linear carriage

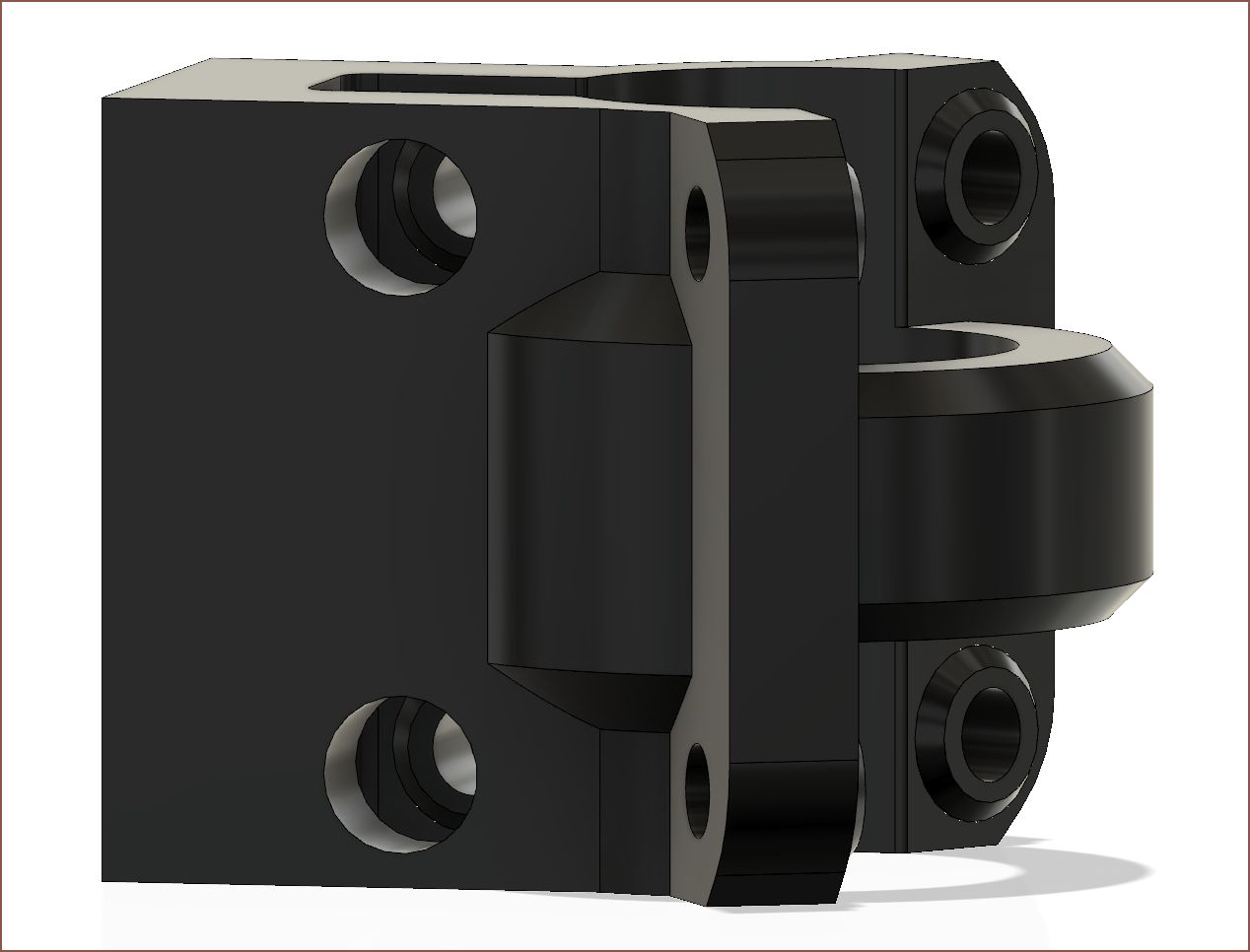

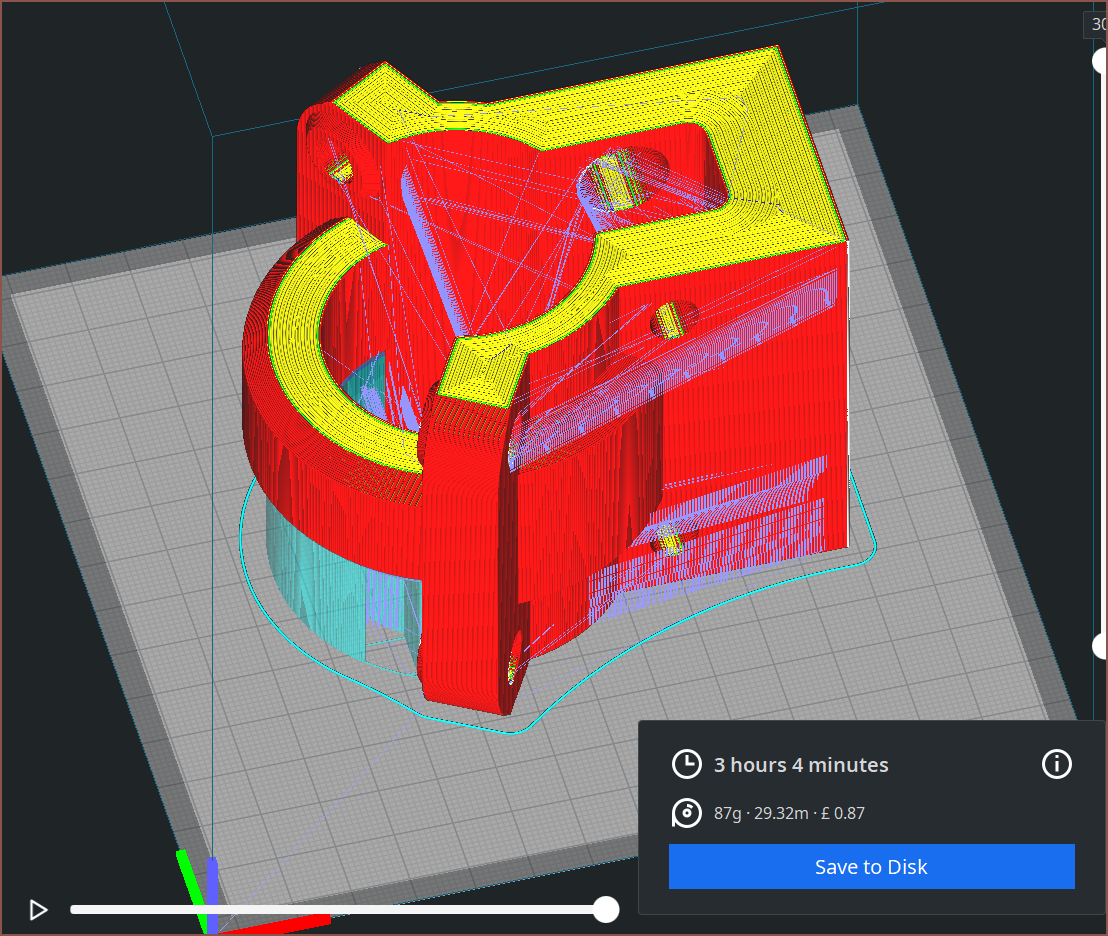

03/11/2022 at 17:03 • 0 commentsFollowing the arrival of the nuts and bolts, I've just designed and have started printing the carraige that uses 608 bearings to slide on the 42.4mm tube.

![]() I've added an arc to mitigate flex from PETG, which was the material I was going to print components out of until I started hearing the issues that people building Vorons were having. Ideally, I'd want to print in PBT, but that's a whole other project so I may have to look into other materials.

I've added an arc to mitigate flex from PETG, which was the material I was going to print components out of until I started hearing the issues that people building Vorons were having. Ideally, I'd want to print in PBT, but that's a whole other project so I may have to look into other materials.![]() Hopefully the DP2 can print this without issues, considering this is the first time I'm trying out supports.

Hopefully the DP2 can print this without issues, considering this is the first time I'm trying out supports. -

[P]

03/11/2022 at 16:54 • 0 commentsM8 Zinc Bolts and self locking nuts

![]()

My order of 150 nuts and bolts have arrived. I tried to find bolts that used allen keys, but they were drastically more expensive. Instead, I looked for bolts that were only partially threaded, which should give more usable life than if the bearings were pressing on threads.

![]() [first bolts I bought on left, new in centre, bearing location on the screw is simulated on the right]

[first bolts I bought on left, new in centre, bearing location on the screw is simulated on the right] -

[R] Similar Project Research

03/10/2022 at 20:34 • 0 commentsWoah! This project is disorientingly on the same page as the SecSavr Space which evolved into this printer that I'm working on right now! I wonder if this is the taste of the feeling someone gets when they see their doubleganger.

-

[R] Toolchanging printers with shared extruder motors

03/10/2022 at 19:01 • 0 comments -

[R - E1] Multiwall Polycarbonate

03/10/2022 at 14:53 • 5 commentsI've stumbled on this listing that has much more useful information.

- The double edged news is that 10mm and 16mm have the same sound blocking of 20dB.

- That's great because 10mm is cheaper, but unfortunate that 16mm doesn't get any better.

- I still wonder if something like 2 10mm panels will have an even greater effect. Looking at how 35mm only increases the soundproofing by 2dB, perhaps 6 or 8mm could be an option as the sound blocking seems to be around the 20dB area.

- It sounds like it's got a good fire rating.

[E[number] = Edit added]

Edit 1

I've found this printer that uses multi-wall polycarb for the enclosure while just searching around on Hackaday. Most enclosures I found for CNC's were made from MDF and I believe most 3D printer enclosures are acrylic, so it's nice to see what this materal looks like when enclosing a printer.

- The double edged news is that 10mm and 16mm have the same sound blocking of 20dB.

-

Enclosure material considerations so far

03/08/2022 at 20:34 • 0 commentsSince I'm most likely not going to be around the machine when it's working, I've also got to consider material fire safety into the mix. It's still good practice to consider fire safety regardless.

From my research, it seems that:

- solid polycarb > multiwall polycarb > acrylic >> untreated corrugated plastic

- I'm just not sure if solid acrylic is better or worse than multiwall polycarb

Due to that, and not liking wood for some reason, that crosses out MDF and drywall (which I think in the UK is called plasterboard). I also don't like the idea of large panes of glass.

Soundproofing research says that I want to look for heavy, non resonating materials, thus thin sheets of metal are probably not up for the task. The research also says that I want sealed gaps of air inbetween.

Sounds like 16mm polycarb multiwall is the best option so far, but I haven't seen what 6mm solid polycarb prices are though. Anyway, for the annoyingly large printer section, my estimates are around £260. I also want to make the bottom part of the SecSavr some kind of soundproof home cinema pod instead of just where my bed is (I'm a uni student with limited space), bringing that estimate closer to the £500 area. 😬

If I do go with polycarb, it's likely going to be Opal for the printer section and Bronze for the cinema section so that I can wake up feeling like I'm already in the future. I might do a bronze door so that I can see the printer (but mainly the addressable LEDs I plan to install) but I can imagine that the whole build would look tacky. Hopefully I can get to modelling soon so that I can try different configurations out.

- solid polycarb > multiwall polycarb > acrylic >> untreated corrugated plastic

-

[P]

03/08/2022 at 13:43 • 2 comments![]()

I got an Aliexpress package, and obviously I'm trying to feel inside (like trying to figure out what's in a present), and it turns out that there's a bunch of packages that's been shipped as one. Efficient.

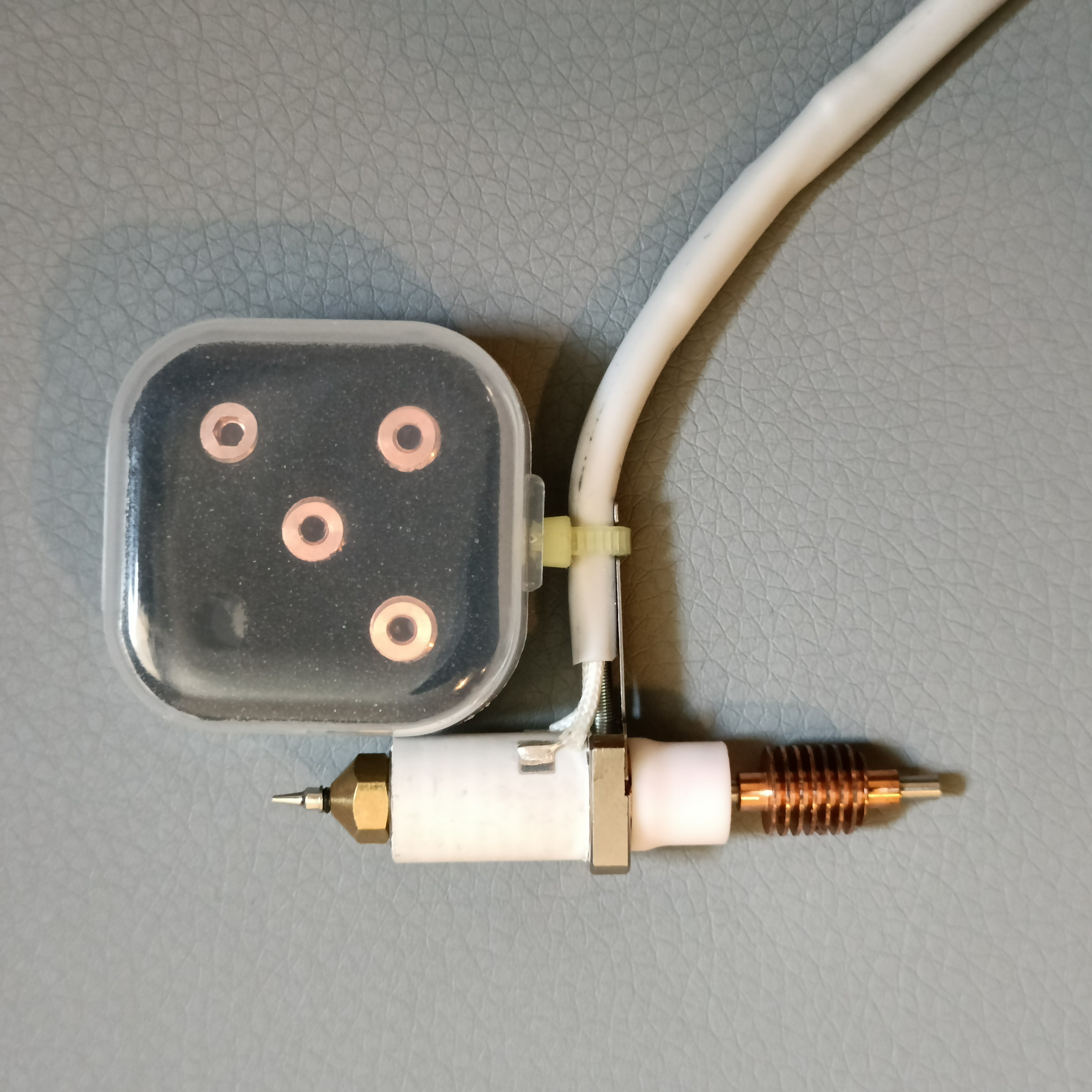

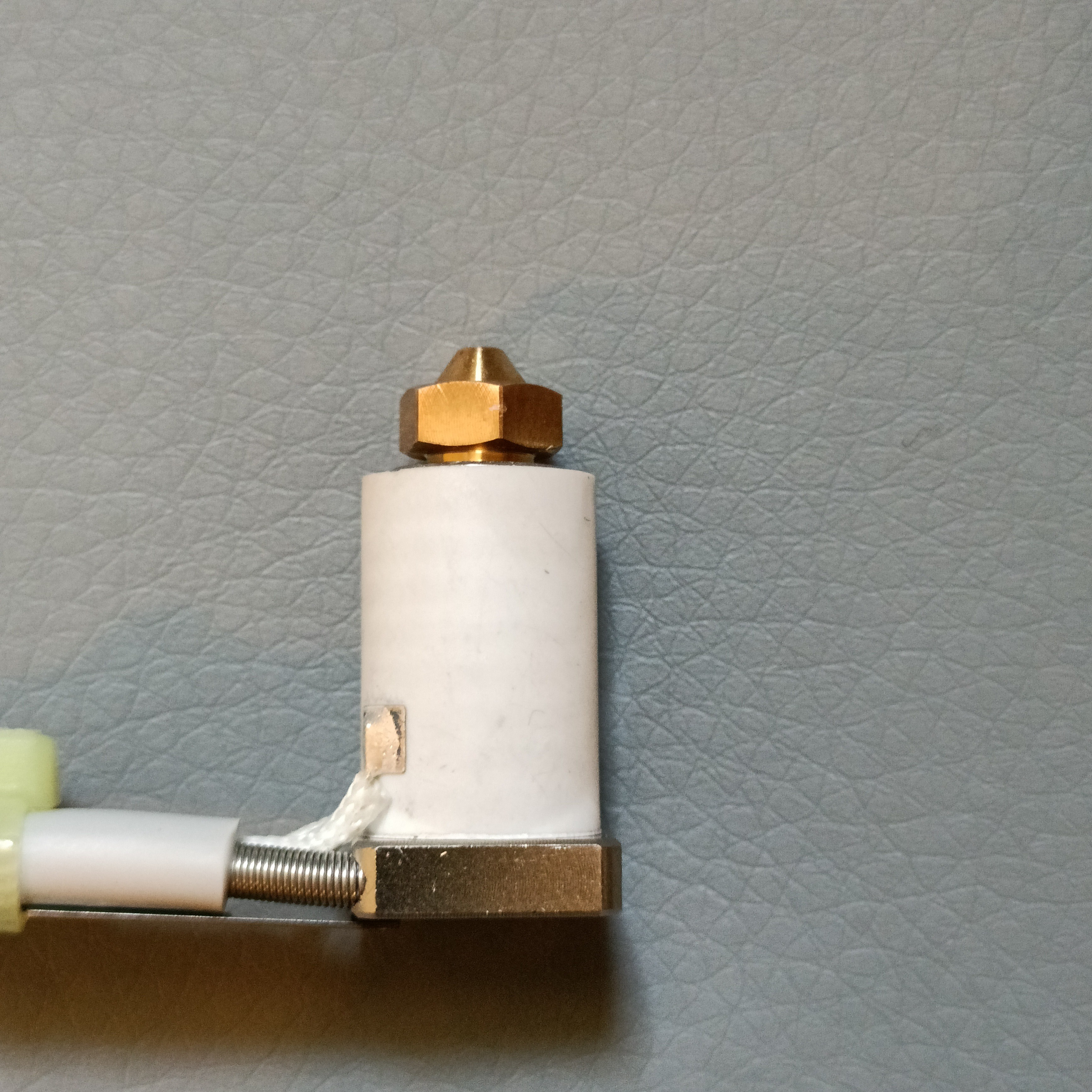

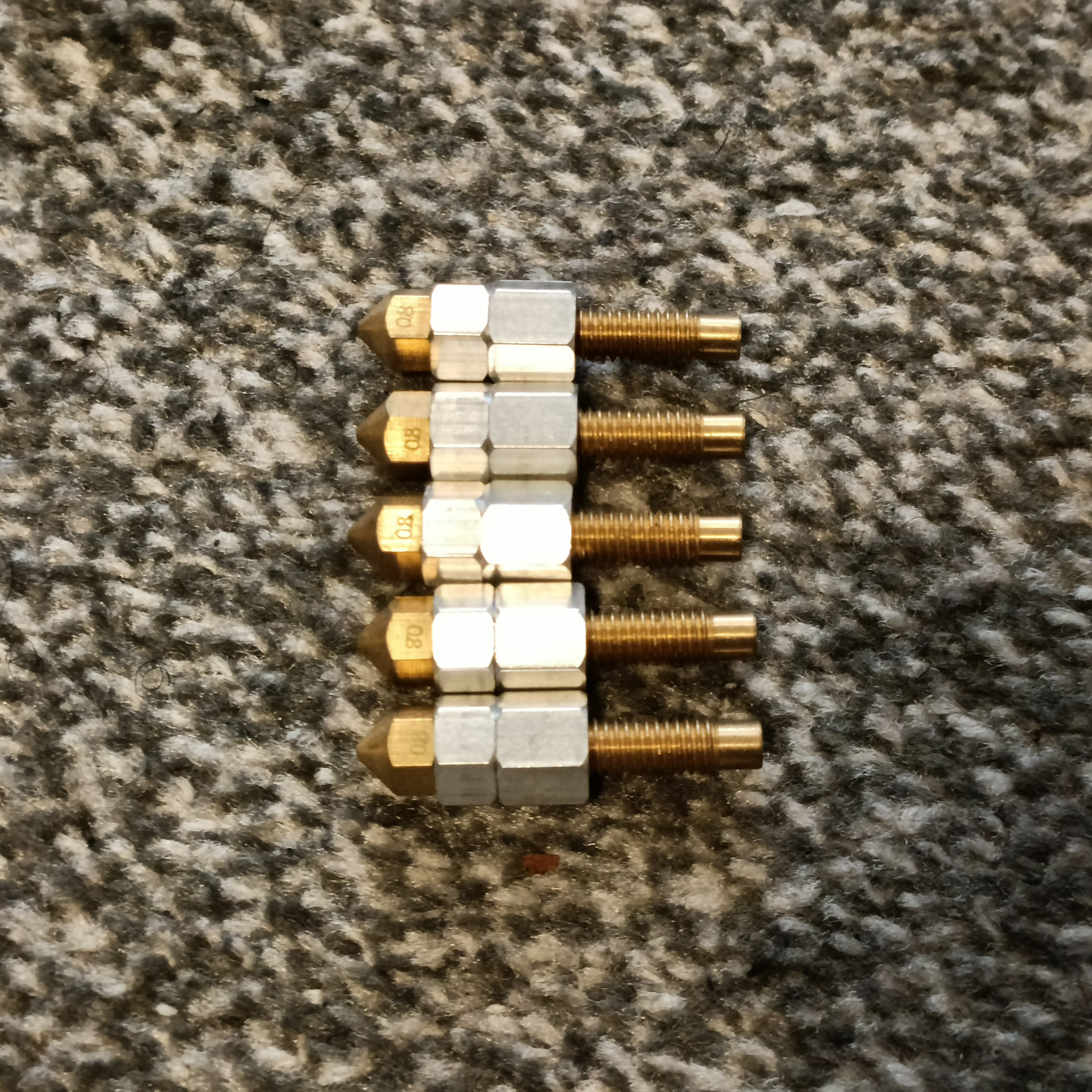

"Lengthen" nozzles

![]()

These nozzles are 40mm in length, and I'm assuming it was one of those old 3D printer parts that AliExpress sellers just have stock of because nobody really needs them these days. I'm using them along with the aluminium spacers, which I'll talk about below.

![]()

Mysterious purple stepper drivers

![]()

From the same Aliexpress seller, I got these GC6609 stepper drivers. 8 of them. Other than the schematic on the and [this video], I couldn't find much about these drivers. However, the video told me all I needed to know -- they're actually as quiet as they claim. Translating the description and comments, it sounds like they follow the same protocol as, and work like, a TMC2209 without sensorless homing. That could possibly mean a better 2208 that costs less and requires less cooling, assuming pressure advance actually works. These 6609s have the same max working voltage of 36V but has a 2A RMS, 3A peak output compared to the 2208s 1.4A and 2A respectively. The steppers I'll be using take up to 3A RMS, but I feel like driving them with 2A 36V should suffice. The fancy CC PSU I bought years ago (but unfortunately can no longer find) allows me to test both 24V and 36V to see if there's a useful benefit, especially for high speed motors like the V, W and the SecSavr Select motors. (V = axis inside Slime, W = axis rotating bed)

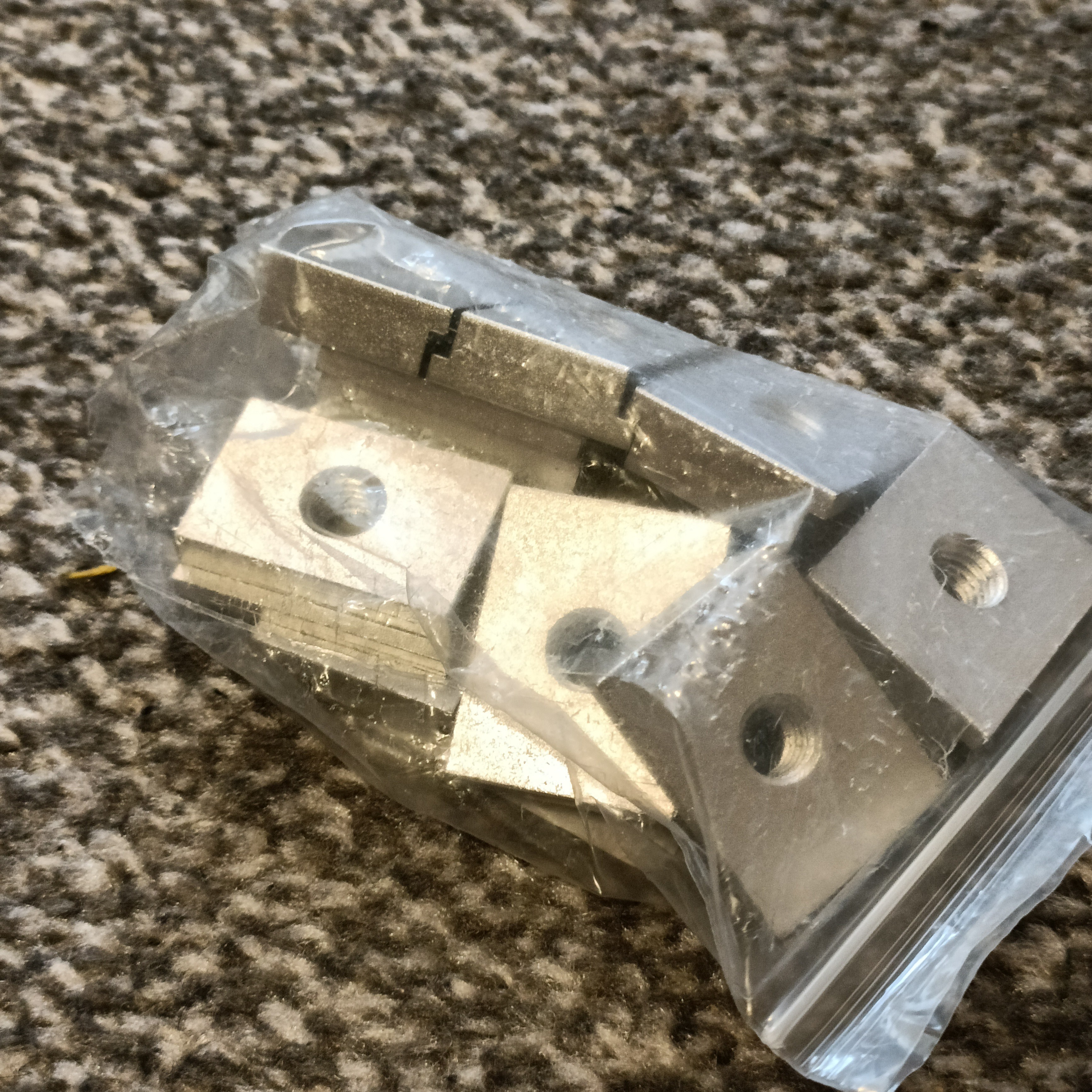

M8 T Slots

![]()

I wasn't expecting the sides to be anodized, instead thinking it would just be a saw cut or something similar, going off their product page images:

![]()

These are planned to hold the bed plates similar to the Anycubic Kossel. I'm just unsure if it'll be effective.

Volcano nozzle adapters

![]()

The packaging looks pretty fancy for some "defective" parts. What's more interesting (and hilarious) is actually the newspaper themed product catalouge that shipped with it.

![]()

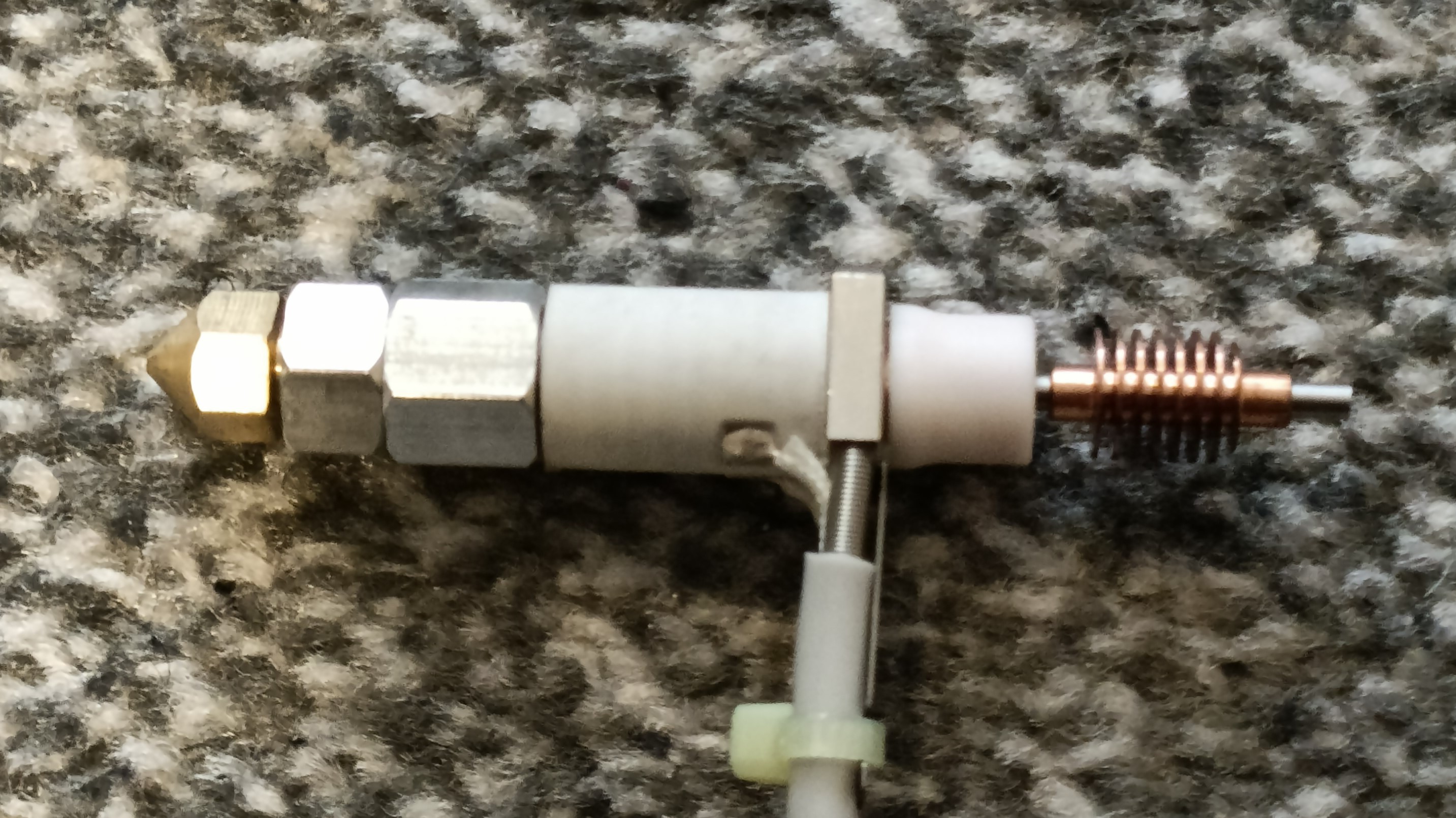

Melt zone extenders, otherwise known as aluminium spacers

![]()

After seeing the Rapido hotend, I set out to find something that could work as the melt zone extender. I didn't think TL would sell it at the price I wanted, and I was right. Eventually, I found these aluminium spacers.

It's so strange how light these spacers are, but it's very nice that the ends have a lot of flat surface area to allow thermal conduction. Speaking about thermals, I wonder how thermal expansion is going to play out.

![]() Aluminium Nema 17 holders

Aluminium Nema 17 holders![]()

These are going to be the plates for the tools. They look a lot better than I was expecting for sub 80p each. Also strangely light.

Springs

![]() These small springs are intended to be used with the Slight extruder.

These small springs are intended to be used with the Slight extruder.Magnets

![]()

These came later in the day and have quite the copious amount of packaging surrounding them.

![]()

They're D15 x 15mm in size, and they seem pretty strong. Strong enough to hold a spindle for plastic and PCB cutting? I'll have to find out.

Issues

![]()

Firstly, the 30mm alu spacers were really hard to screw in. I'm currently talking with the seller about it, but I had to clamp it and use a bolt to see if it was possible to screw it all the way in. it worked, but it didn't make screwing in the supervolcano nozzle any wasier. The 9mm and 6 also had noticable resistance when I was first screwing the 40mm nozzles on, and I was thinking it was the nozzles considering the thread didn't look that great.

Secondly, I tried the volcano adapters with the airbrush nozzles and it bottomed out. I then found out that the volcano nozzle that I tried with the CHC initially actually stops screwing in before its head.

![]()

![]()

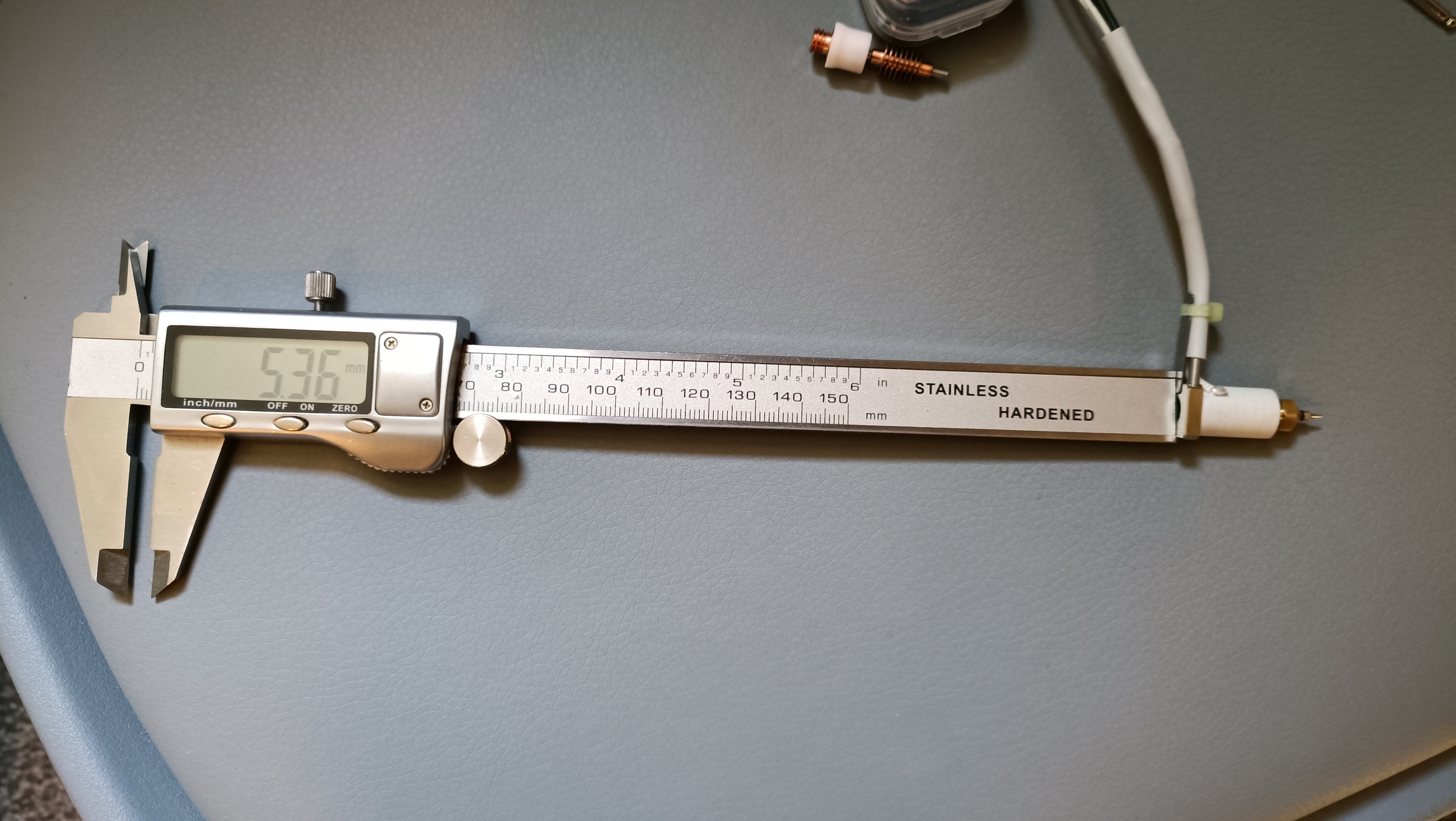

Measuring, the thread of the heatbreak into the CHC is 1mm short, as expected considering I did a scale drawing from the product image. However, it seemed like I still had enough space in the CAD model.

![]()

![]()

[I forgot to 0 the calipers (it's 0.24mm shorter than displayed) but the 1.2mm difference would be the same]

SecSavr Sublime [gd0036]

An FDM 3D printer that I described as "The FULL Coverage, Extended X, Pro Max, Ultramatrix Solution".

kelvinA

kelvinA

It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space.

It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space. Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second)

Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second) I've added an arc to mitigate flex from PETG, which was the material I was going to print components out of until I started hearing the issues that people building Vorons were having. Ideally, I'd want to print in PBT, but that's a whole

I've added an arc to mitigate flex from PETG, which was the material I was going to print components out of until I started hearing the issues that people building Vorons were having. Ideally, I'd want to print in PBT, but that's a whole  Hopefully the

Hopefully the

[first bolts I bought on left, new in centre, bearing location on the screw is simulated on the right]

[first bolts I bought on left, new in centre, bearing location on the screw is simulated on the right]

Aluminium Nema 17 holders

Aluminium Nema 17 holders