If you're wondering why I'm thinking of all the optimistic possibilities in the future when I don't even have a printer working right now (Suspense or otherwise), it's because I want to know what features I can "flyby" on the way to a solution. Unlike what I desire for #enSweepen [gd0096], CAD in general is a bit like the waterfall model in computing where you don't really want to be making drastic specification changes when further into the design. I'm still looking at what Sublime feature could be ported over

Anyway, imagine this. A UV curable, not-a-resistor conductive resin comes along. Now for standard, single material SLA printers across the globe, this resin is near useless, thus it's unlikely to be made. Enter the completed Suspense, which can use multiple, viscous resins to print with. Now there can be a conductive and non conductive material (or several) in the print, with features probably 2 or 3 pixels thick (3 or 5 mils).

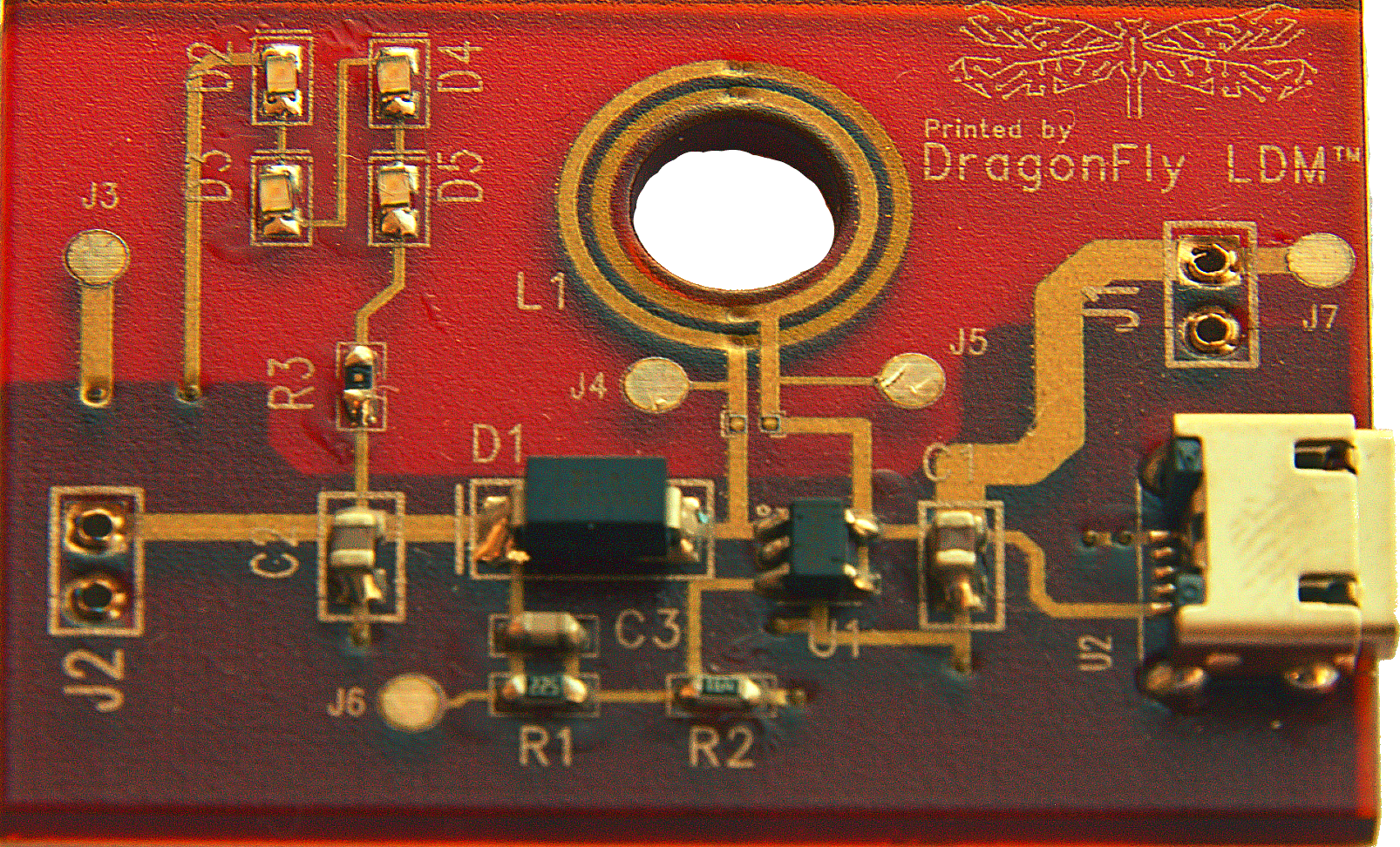

Tracks. Vias. 3D tracks. Variable layers. Pads. Solder masks. Silkscreen. Coils for motors. We could be Nano-Dimensioning out here instead of worrying about fiberglass dust or very hazardous chemicals.

And for the traditional flat PCB, I think I could fit a (solderpaste and) pick and place attachment under the continuous fibre attachment where its X axis is on top of the arm instead of below it for the fibre attachment. It could be like JLPCB's single-sided SMD service. If 180 degree was implemented over the easier to implement 90 degree shoulder joint, the Suspense could probably populate a 100% keyboard PCB.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

*Reads research on conductive UV resins*

"up to 1000 S/m electrical conductivity without sintering"

*researches electrical conductivity of elements (https://periodictable.com/Properties/A/ElectricalConductivity.an.html)*

"Copper: 5.9×10^7 S/m"

Me: Ok let's damper expectations. No motor coils. Silicon is 1000 S/m though so that's nice to know.

Are you sure? yes | no