Yikes this took ages to compute.

Yikes this took ages to compute.

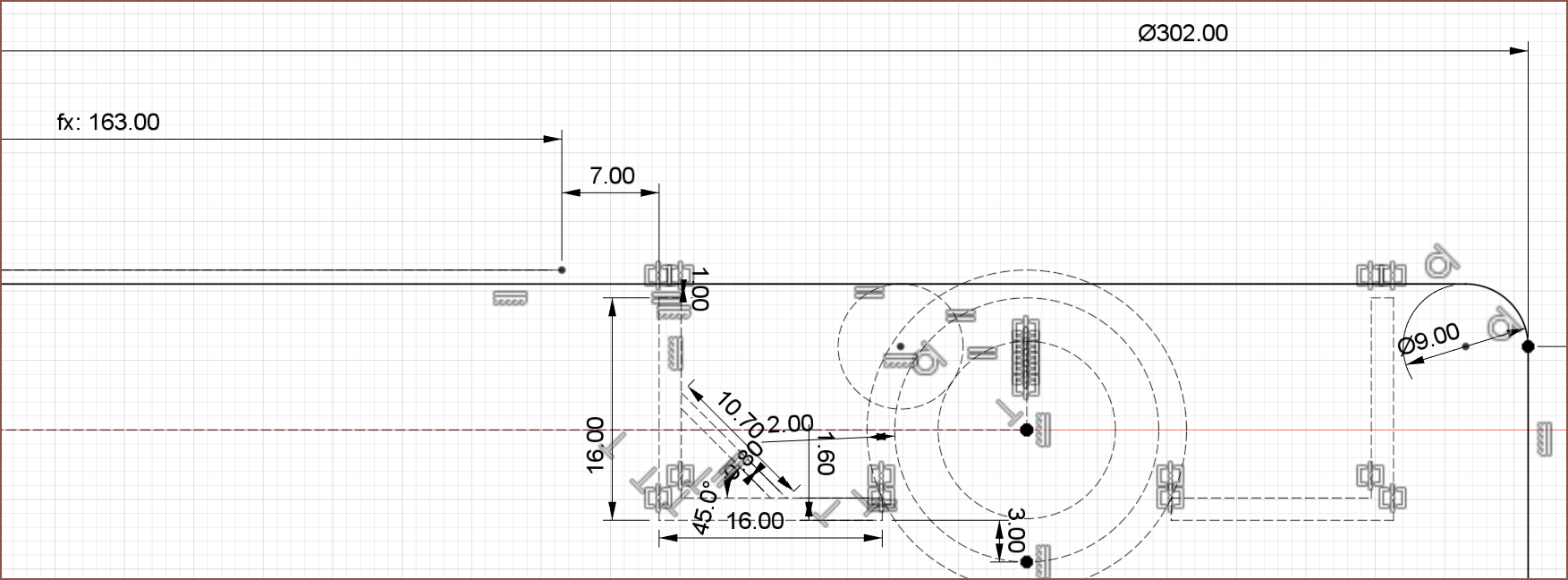

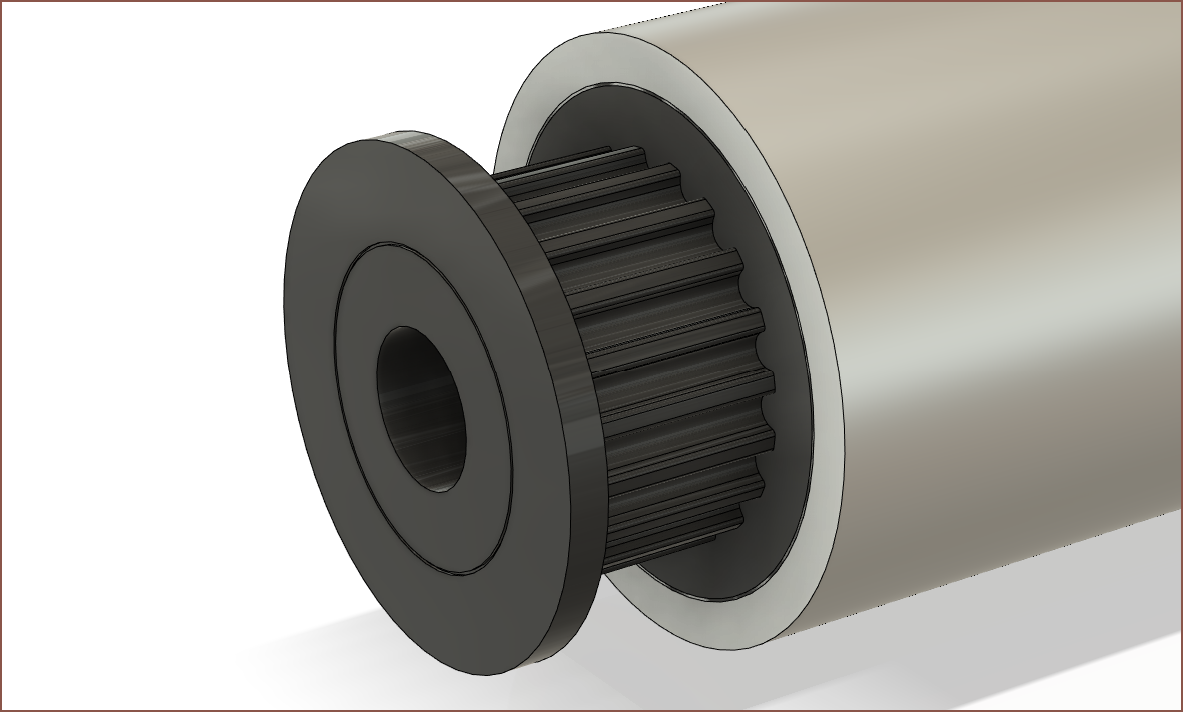

For starters, the idea is to have a 16mm OD pulley squeeze into a 19mm polished aluminium tube with a 1.6mm wall (so 15.8mm inner diameter. Not sure if that's going to work out.)

Then I decided to go with dual LEDs instead of dual roller as I wouldn't have to worry about both rollers having the exact same Z height. I then looked all over ebay for a 16mm aluminium anodised angle but could only find 15. I remembered about the aluminium LED profiles and how one was a 16mm square angle and plan to use that in the design. It's also more likely to be available in different markets around the globe and might even allow me to put a LED strip in the channel to cure the resin that hits the string.

Then I decided to go with dual LEDs instead of dual roller as I wouldn't have to worry about both rollers having the exact same Z height. I then looked all over ebay for a 16mm aluminium anodised angle but could only find 15. I remembered about the aluminium LED profiles and how one was a 16mm square angle and plan to use that in the design. It's also more likely to be available in different markets around the globe and might even allow me to put a LED strip in the channel to cure the resin that hits the string.Speaking of LEDs, I'm thinking of using the waterproof version so that any resin dropplets can be wiped off and the coating should make it easier to apply a professional looking finish.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Obviously it's time to get a lathe.

(Only partially tongue in cheek. You'd be able to customize parts for things like this, but it's a bit of a commitment.)

Are you sure? yes | no

I can't imagine what parts I'd use a lathe for. A drill press attachment is higher on the "tools I should buy one of these days" list.

Are you sure? yes | no

Lathes are basically *the* tool for precisely dimensioning round parts. So you could bring that 16mm OD part down to 15.8 (or maybe just a hair under, depending on how tight you need the fit).

But yeah, it's fairly niche.

Are you sure? yes | no

Yeah... but what about a heat gun to expand the 19mm pipe? Or a printed sander tool to file down the inside? I might just play it safe and go with the next size up (22mm) *checks file again and realizes I won't have space* or not...

Are you sure? yes | no

Heat guns do expand and can let parts slip in. I'm not actually sure how MUCH it expands and if you're in the right range. Worth at least research.

Are you sure? yes | no