The BOM has been rather stable, with the only thing that I wasn't sure about being the laser. I was considering a 5W 0.08*0.08mm spot laser for the #SecSavr Soapavr [gd0146], but more research shows that a 20W laser with a sufficient spot size is the way to go.

Firstly, I was looking at the cutting depth of stainless steel with these kinds of wattages, and it seems that 0.08mm thick is possible so that's good enough for me:

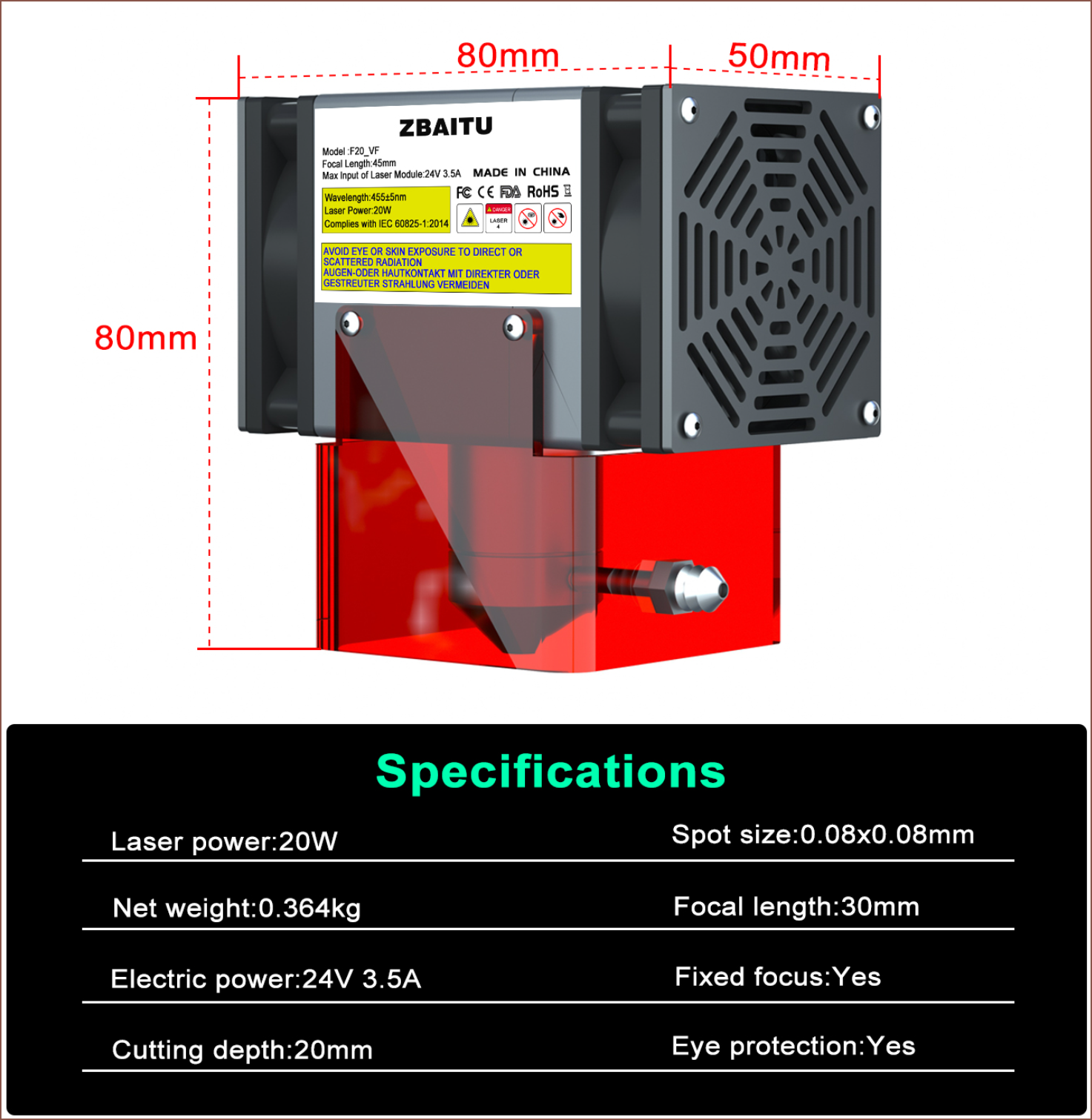

Then, I was looking at the recently announced 30 - 48W lasers. Unfortunately, there's some issues. Some of them have spot sizes that are 0.1*0.15mm or larger, meaning that the kW/mm^2 is still at around 20W laser levels. Most of them are 750g or heaver, as well as having dimensions exceeding 60x60x130mm. All of them are near or over 2X the price of the ZBAITU VF20 that is possible to get under £300 on sale.

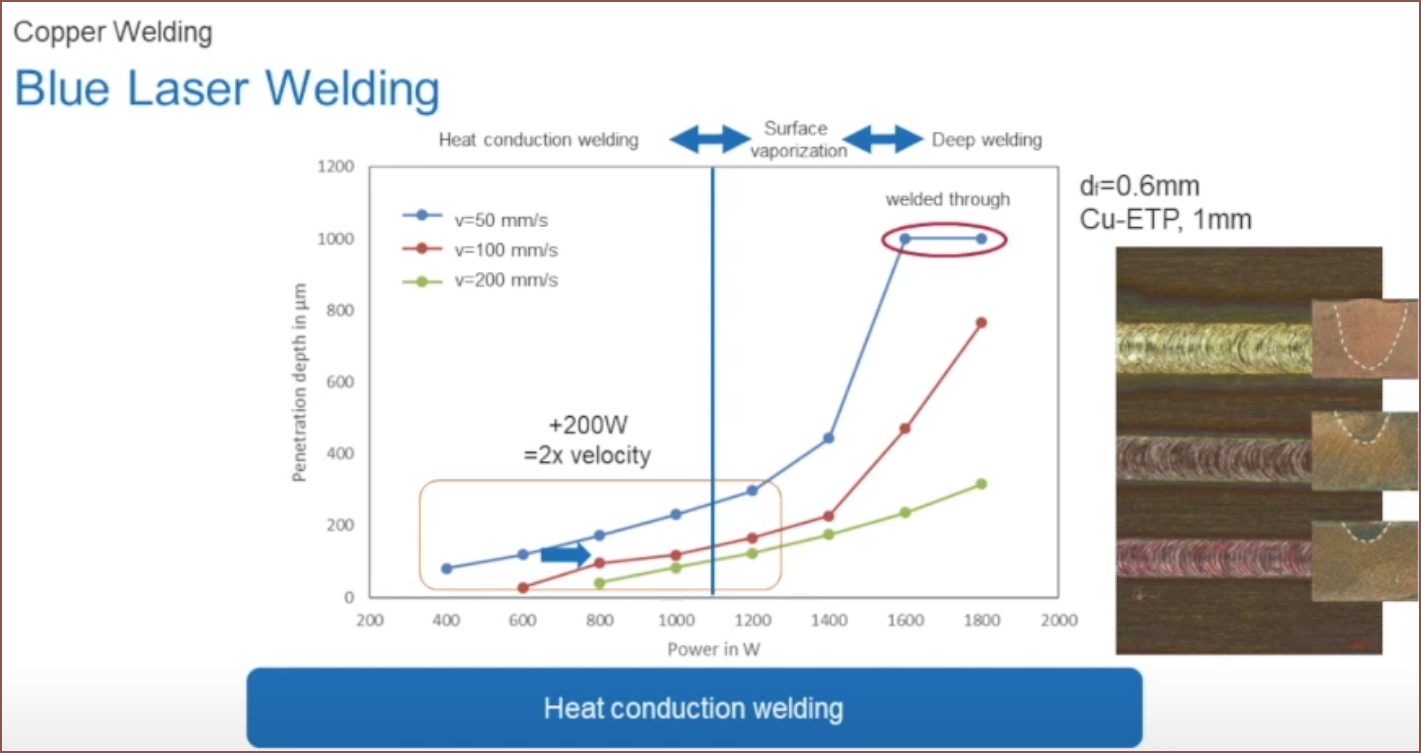

The next video I saw was about copper laser welding, which is essentially what I'm trying to do here.

One of the cool things is that the tests were done without shielding gas. Anyway, the below slide is important:

The 450nm laser used has a dot diameter of 0.6mm. Thus, for a 1kW laser, the power density is 3.5kW/mm^2. As you can also see from the graph, 100um depth is achieved at 600W, or 2.12kW/mm^2, for a travel velocity of 50mm/s.

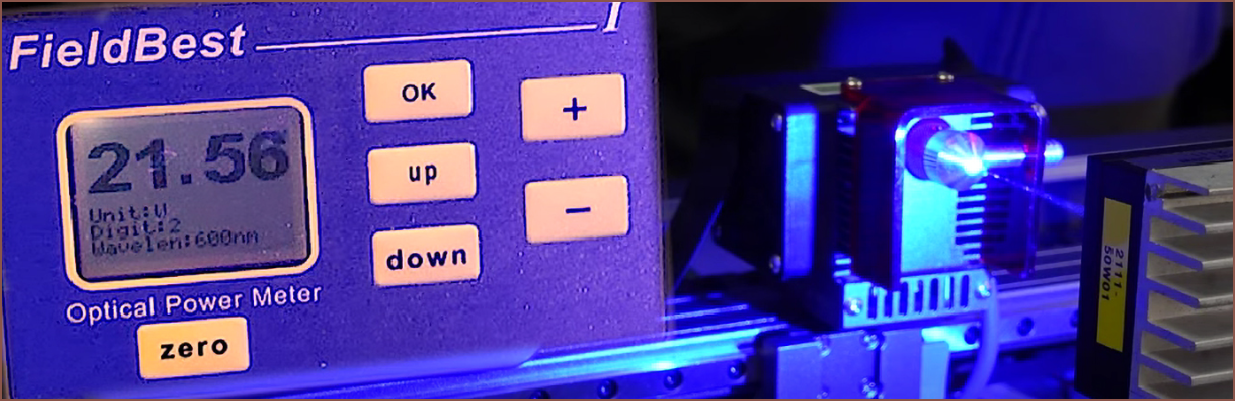

The VF20 has been measured to output 21.5W, though the meter also says "Wavelength: 600nm" even though this is a 445nm laser:

The listing on Aliexpress says that the spot is 0.1*0.08mm, but their website says 0.08*0.08. I know that, when it released, the spot was the former, and it's possible that, after almost a year of making these modules, they've been able to shrink the spot size to 0.08*0.08mm.

They've also got a similarly priced XF20 that has a 0.08*0.08mm spot size claimed in some listings and 0.06*0.08mm claimed in others. While I find the flame detection and laser crosshair useful, it's height of 130mm with the air assist inlet on the top (meaning I need even more height clearance) and weight of 700g makes it harder to integrate compared to the 80mm tall, 364g VF20. The XF30 also shares the same build as the XF20.

Power densities of the options:

| Power (W) | Spot Size (mm*0.08mm) | Power Density (kW/mm^2) |

| 20 | 0.10 0.08 0.06 | 2.5 3.125 4.166 |

| 21.6 | 0.10 0.08 0.06 | 2.7 3.375 4.5 |

| 30 | 0.08 0.06 | 4.688 6.25 |

| 32.4* | 0.08 0.06 | 5.062 6.75 |

*Assuming 5.5W diodes output 5.4W of power

Conclusions

- Obviously, the main conclusion I can take from this is that anything under 20W is unlikely to work. It also makes a bit of sense, since 10W and 5W lasers have existed for a while and yet there are no 3D printers that use them to sinter copper, but these 20W+ lasers are very recent and so it's possible that printers that use them are still in development.

- It does seem like the spot size really affects the power density.

- Coming in at about £575, it's unlikely that I opt for the 30W laser.

[9 Jun: Edit 1]

I'm just going to assume that the below specs are accurate:

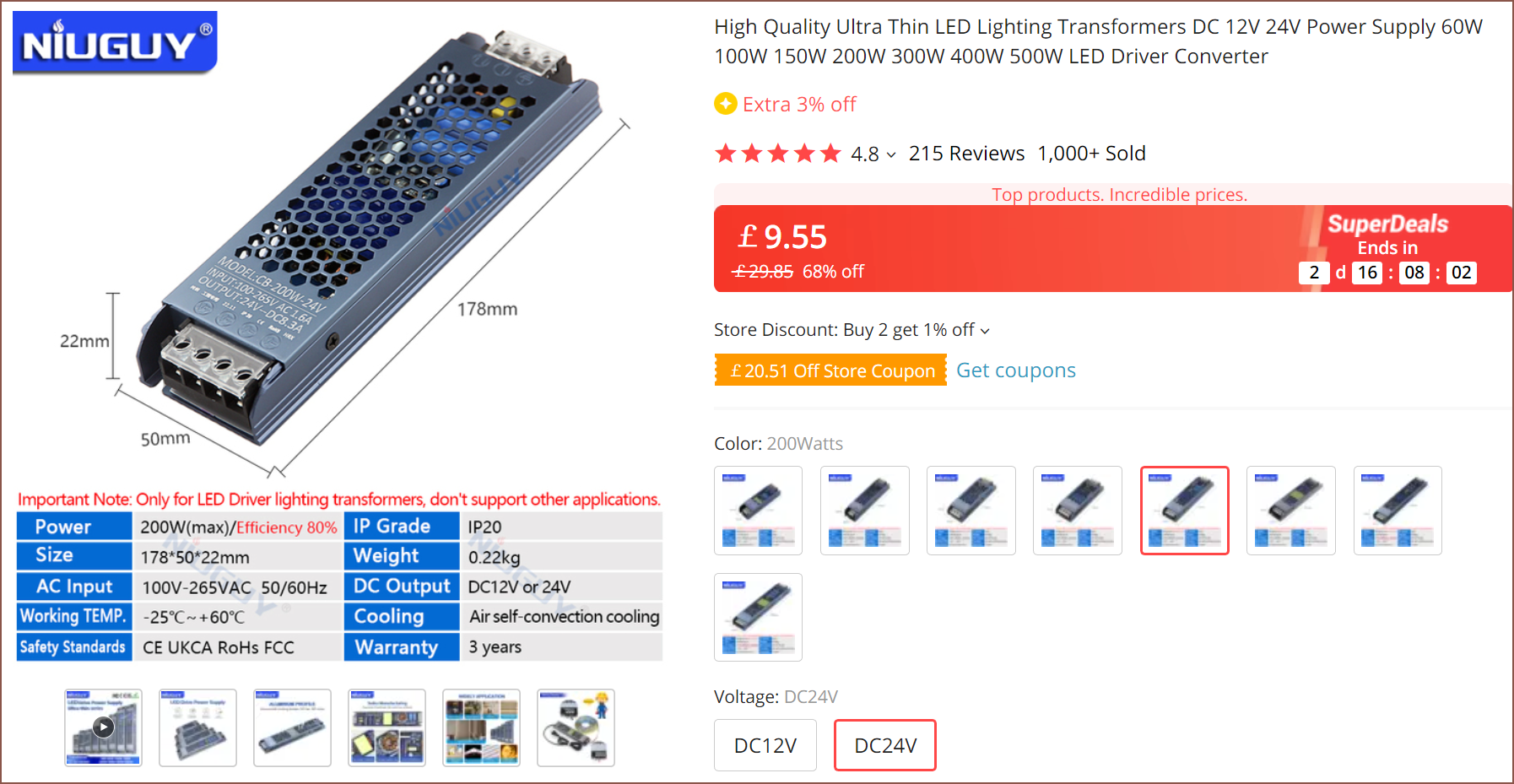

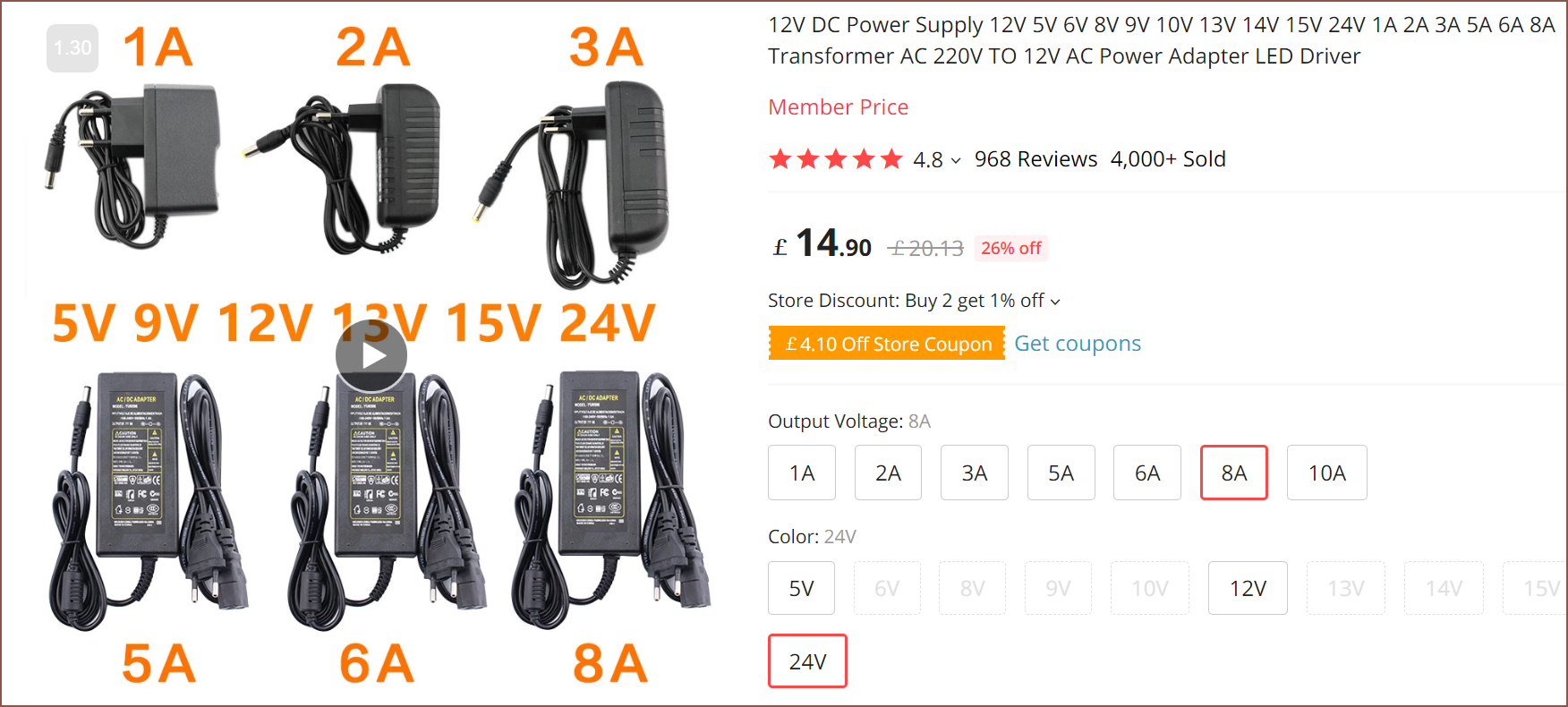

This is a 84W laser, the same as the 84W UV LED I'm planning to use for the #SecSavr Soapavr [gd0146]. I wonder if I should try powering the system on the 24V 5A (120W) power supply this comes with. Then again, since both L^3 SecSavrs have more things to power than a typical laser cutter, I should stick with a 200W PSU.

Then again, it could be benefitial to go with an external PSU, meaning that DIYers don't need to deal with mains connections at all (even if it's just screwing 3 terminal blocks).

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.