Navigation

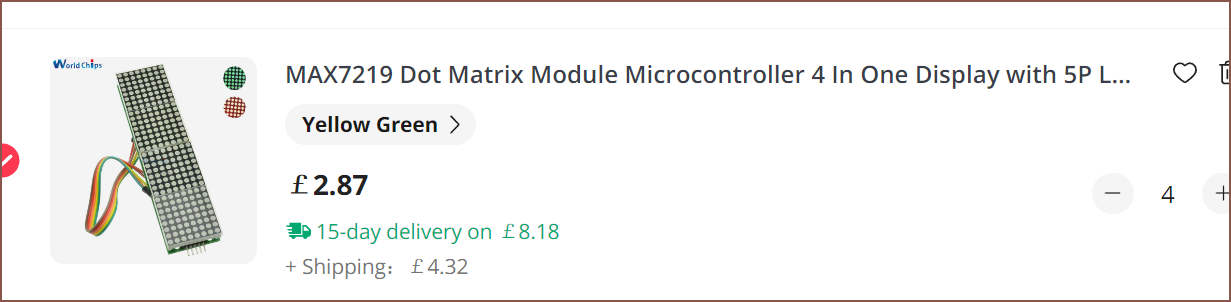

The title tag system is explained here, and the table is updated when a change occurs. Notable logs have bold L# text.

Preface

[2024 - Aug 2]

I underwent some surface-level research into soap and saw a few mentions to alkalis, so I thought soap + alkali = SecSavr Soapali. It emphasises the need that this solution has to be much cleaner than the current hobbyist MSLA workflows, and the "ali" sounds like "ally" so the name, overall, sounds more approachable and domestic. I've spelt it "alai" to reduce pronunciation ambiguity with "alee".

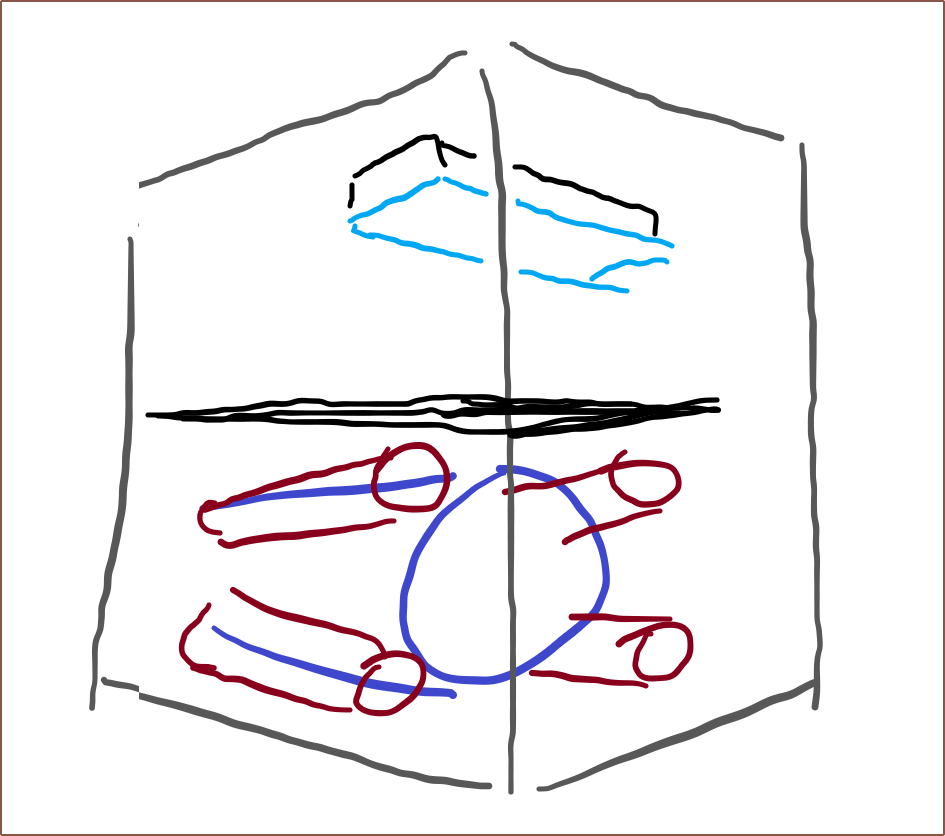

The minimum goal for this 3D printer is to be able to produce the 3D equivalent of a B+W toner printer, allowing for prints spanning from photorealistic PNGs to "3D colouring book".

I do acknowledge the risky-finish goal (Trackmania-speak) is to integrate a 20W-output blue laser that has a 0.08mm square dot size, allowing for sintering powder-infused photopolymers. My sights are set on copper to be able to fabricate 3DPCBs with at least 0.16mm traces and spacing. For context, the integrated circuit chips in QFN packages I've seen need 0.2mm traces and spacing.

[2023 - May 7]

I've done the research in #SecSavr Suspense [gd0105]. This project is to clean up my some of my concerns and pave the way to a solution, hence the name "Soapavr".

kelvinA

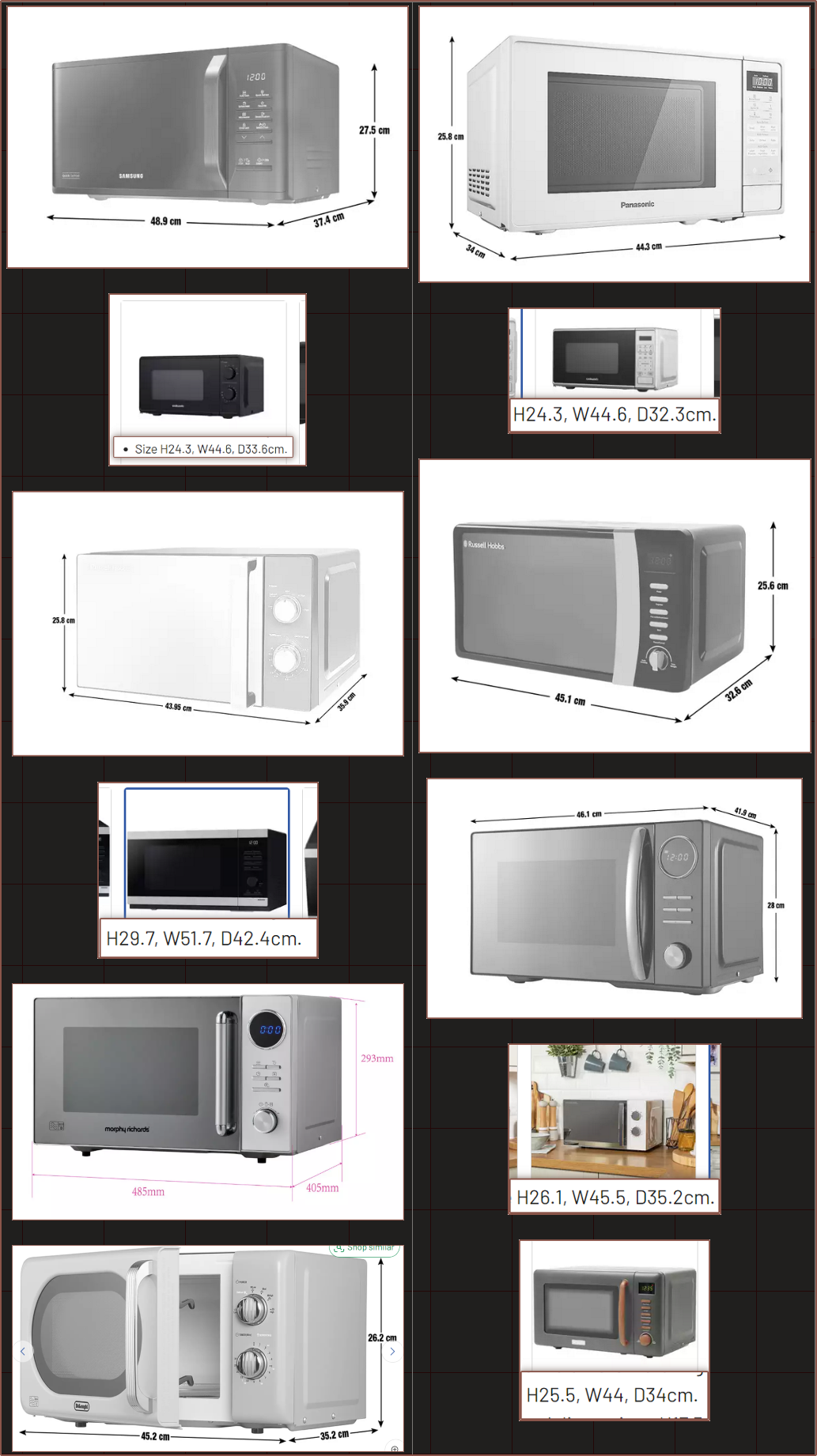

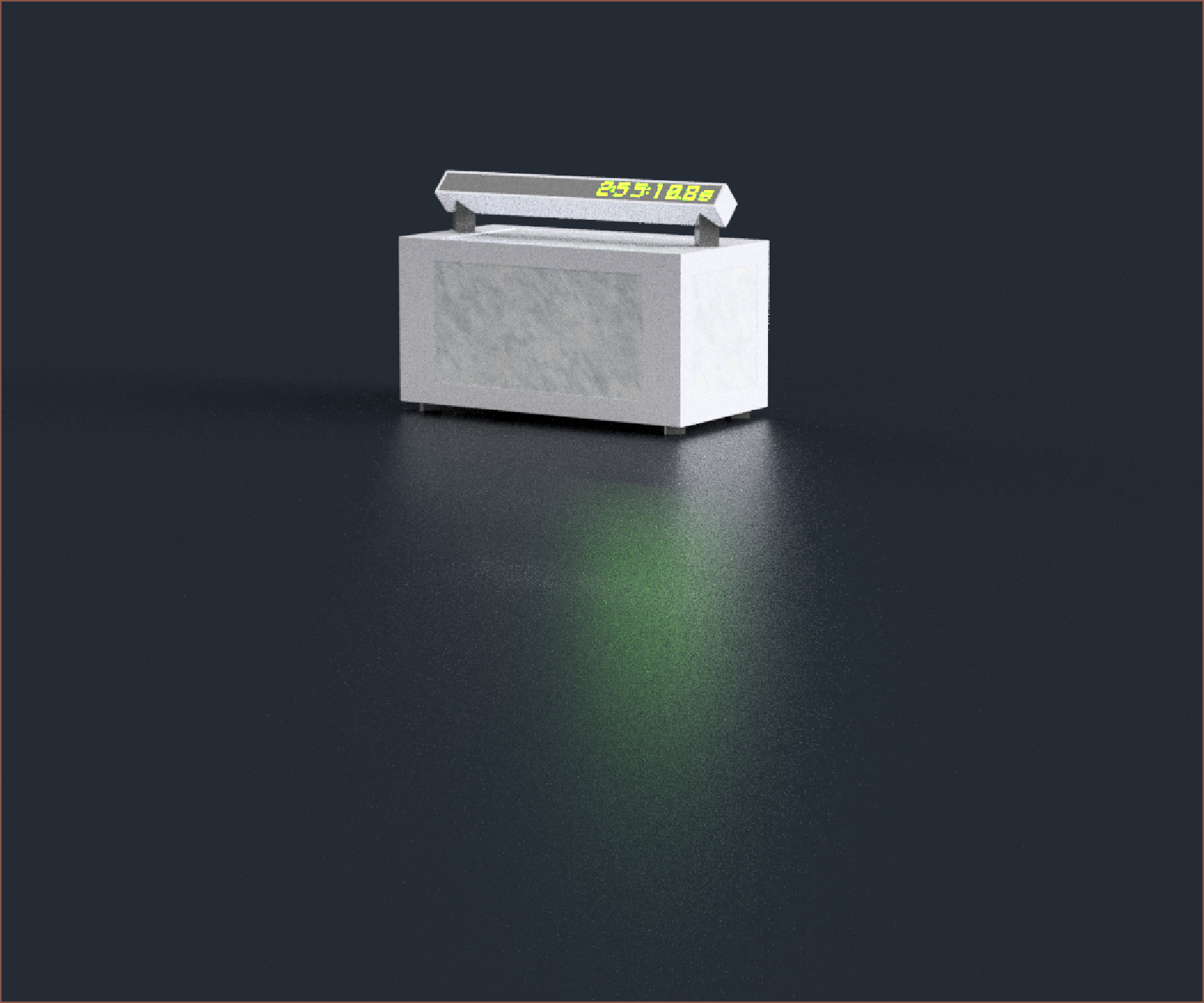

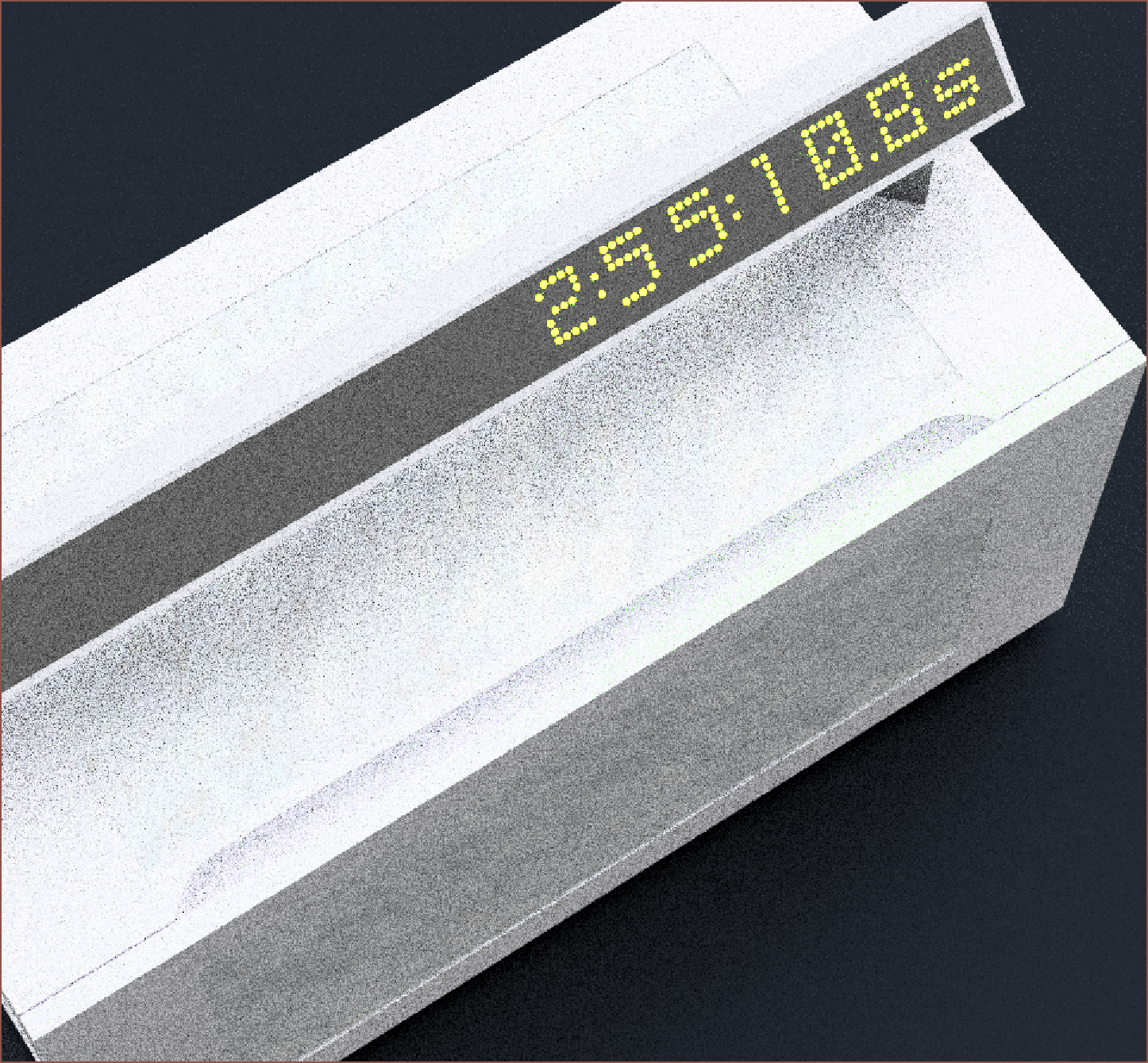

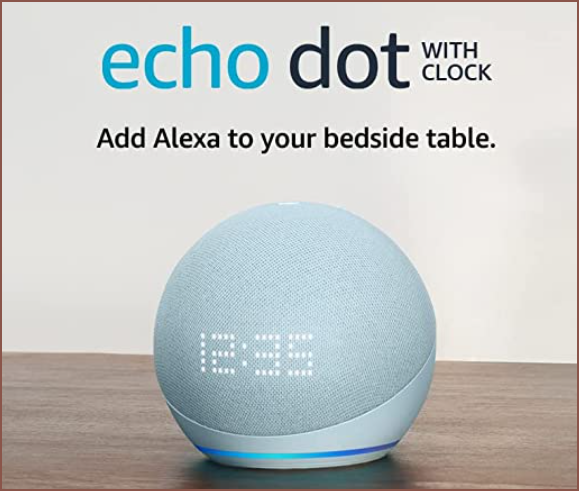

kelvinA I've just looked through the online Argos.co.uk catalogue of microwaves since they and Brother printers have the kind of aesthetic and user experience that I want to emulate. Microwaves especially are good sources of inspiration, especially since they also use glass plates in air-filled enclosures.

I've just looked through the online Argos.co.uk catalogue of microwaves since they and Brother printers have the kind of aesthetic and user experience that I want to emulate. Microwaves especially are good sources of inspiration, especially since they also use glass plates in air-filled enclosures.

I'd like to have something like a 215 x 430 mm build area so that it was also possible to print half of an A3 poster.

I'd like to have something like a 215 x 430 mm build area so that it was also possible to print half of an A3 poster.

Michael

Michael