Unless cylindrical active-carbon / active-charcoal products use the kind that can corrode metal, I'm planning to use it as the main internal filter for the printer. As mentioned in #SecSavr Suspense [gd0105], the plan is for an airtight enclosure so that, once the print is done, the air can go through multiple cycles of the carbon filtration to scrub out VOCs before the doors are unlocked.

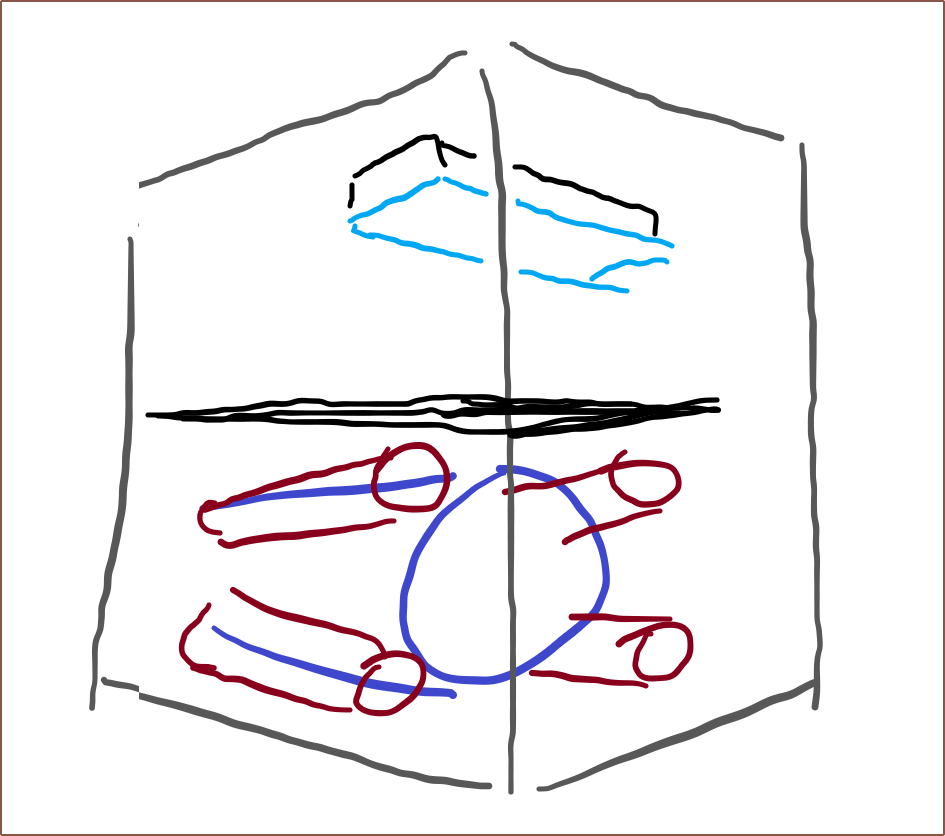

Below is a rough sketch of how I plan for things to be laid out. The bottom half contains the carbon filter surrounded by 4 tubes which contain photopolymer. The top half is where the usual print things such as the LCD and printbed are.

Something I know is important is that, like with a microwave, oven or fridge, things need to be accessible from the front of the machine. While it's not ideal to have to disconnect 2 polymer cartridges and the carbon filter to have access to the rear two cartridges, I believe it's still better than requiring side- or back-access of the machine. A possible compromise could be to make the front cartridges swivel so that the filter can be easily removed to gain access to the rear two, reducing more things that have to be dis/reconnected.

I believe that, since the machine is somewhat long, it shouldn't take much diameter to contain 1 - 2 litres of photopolymer. At the same time, I have to remember that the particular liquid is viscous and so I probably actually need to treat them like syringes (as used in clay/chocolate printers) as well as consider options on making sure air bubbles don't impede the quality of laminating the next layer, as this is probably one of the only printer technologies that needs "extruding" to be a 2-way system.

A more space-efficient solution could be something like a large toothpaste tube. Obviously, companies can get paste into the tube and consumers can get paste out so there should be a solution somewhere.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.