-

New New Backing Pump

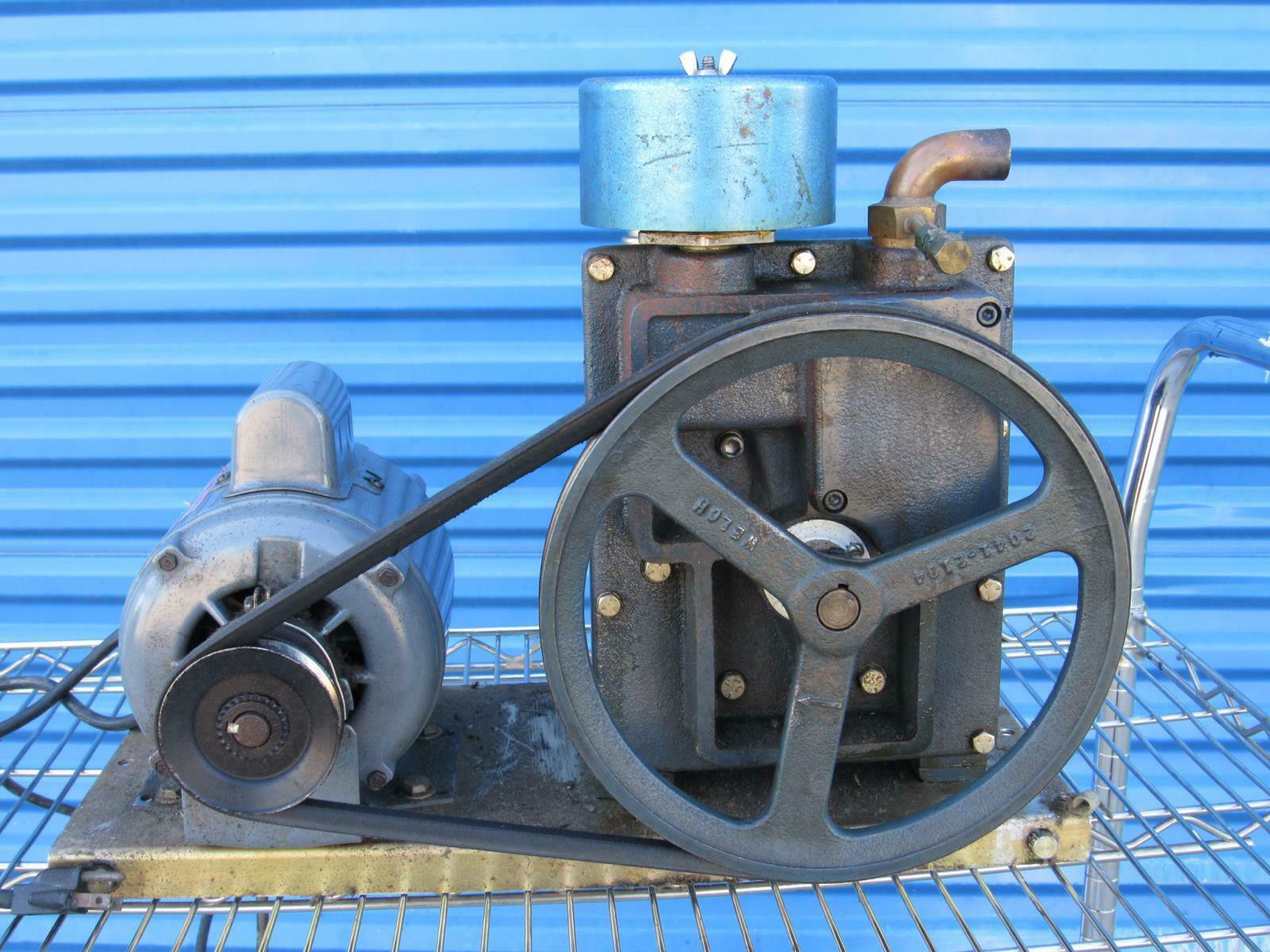

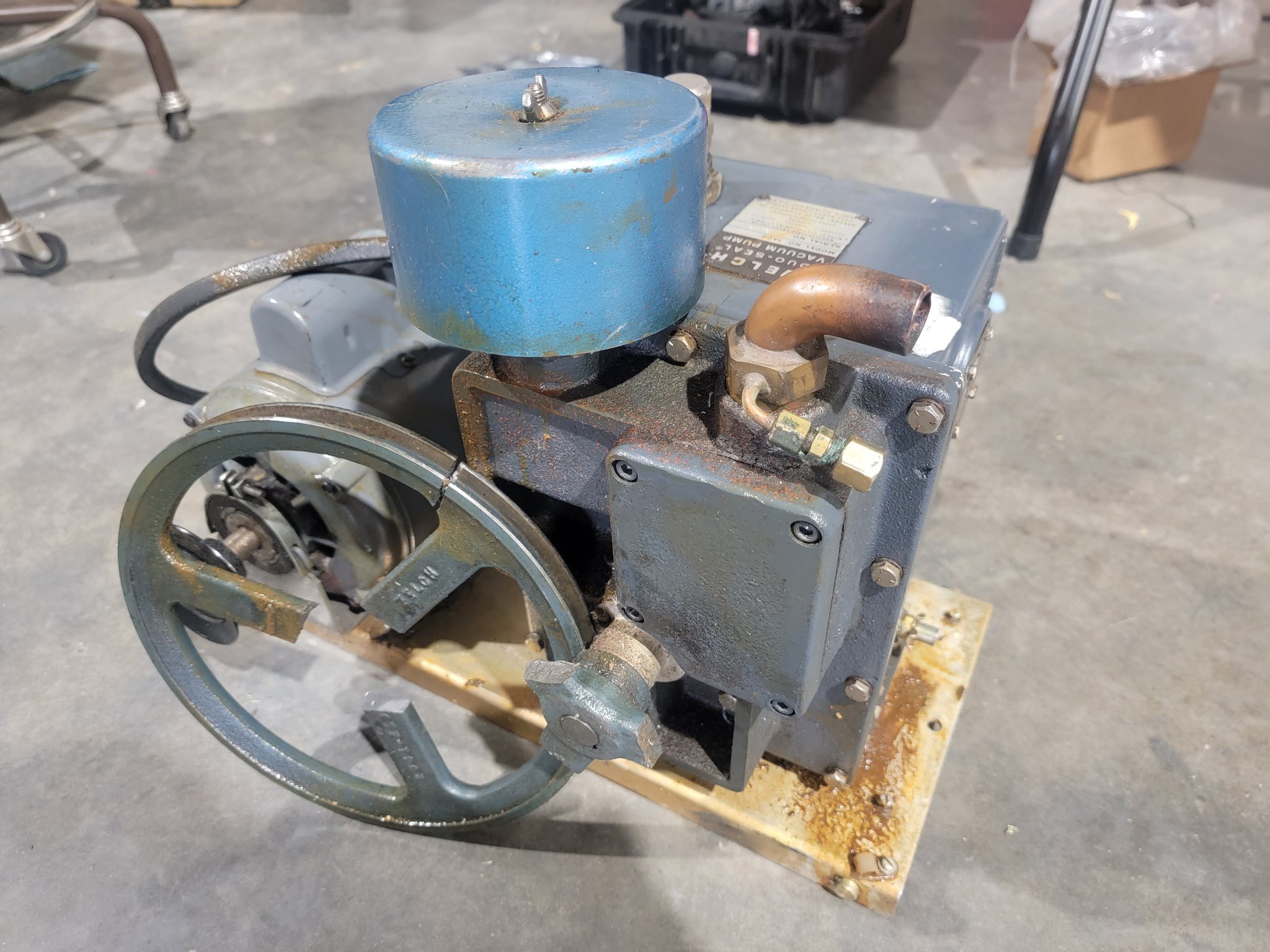

05/26/2022 at 02:28 • 1 commentI let the vacuum geeks talk me into a real backing pump and got this Welch 1402 for a good deal on eBay. The seller didn't know whether it worked, or what condition it was in. All they could say is that the motor runs and the pump feels like it pulls a vacuum. It looks good.

![]()

Well... it looked good, until UPS got their hands on it...

![]()

Luckily, the damage appears to be limited to the pulley and the oil mist filter. The seller offered to buy me a replacement pulley and so I found a used pulley of the same vintage and we got it sorted out. The new pulley arrives tomorrow.

Before we can get this hitched to the turbo, we'll need to do a few things:

- Flush the oil a few times and refill with fresh vacuum oil

- Replace the pulley

- Replace the belt

- Adapt the inlet to KF25

- Replace oil mist filter element and fix the cup or adapt the outlet to KF25 and replace with an Alcatel-style oil mist eliminator

As soon as all of these things are done, I'll post an update. This should improve both our pump-down speed and ultimate vacuum, so it's worth the effort.

-

New Backing Pump and Turbo Pump Test

05/09/2022 at 20:19 • 0 commentsI finally acquired a TC gauge that would allow me to evaluate the roughing pump candidates and did some testing over the weekend. The diaphragm pumps that I have hoped to use were only able to achieve an ultimate vacuum of about 6 Torr.

![]()

This is not horrible performance for a diaphragm pump, and it's also within the safe operating range for the Edwards EXT255H compound turbo pump, but there are a few reasons I'm not happy with it. Firstly, there just isn't much margin and working with such a high backing pressure will put more wear on the turbo pump than is necessary. Secondly, the Pirani gauges that I planned on using for monitoring rough-down and process control just don't operate at pressures that high. It would be much better to achieve a foreline pressure of at least 0.5 Torr so that the Pirani gauges can register it. To that end, I bought a Harbor Freight refrigeration service pump to act as my backing pump. I had hoped to keep the system entirely oil-free, but with some basic precautions, it should be very difficult for pump oil from the roughing pump to contaminate the rest of the system.

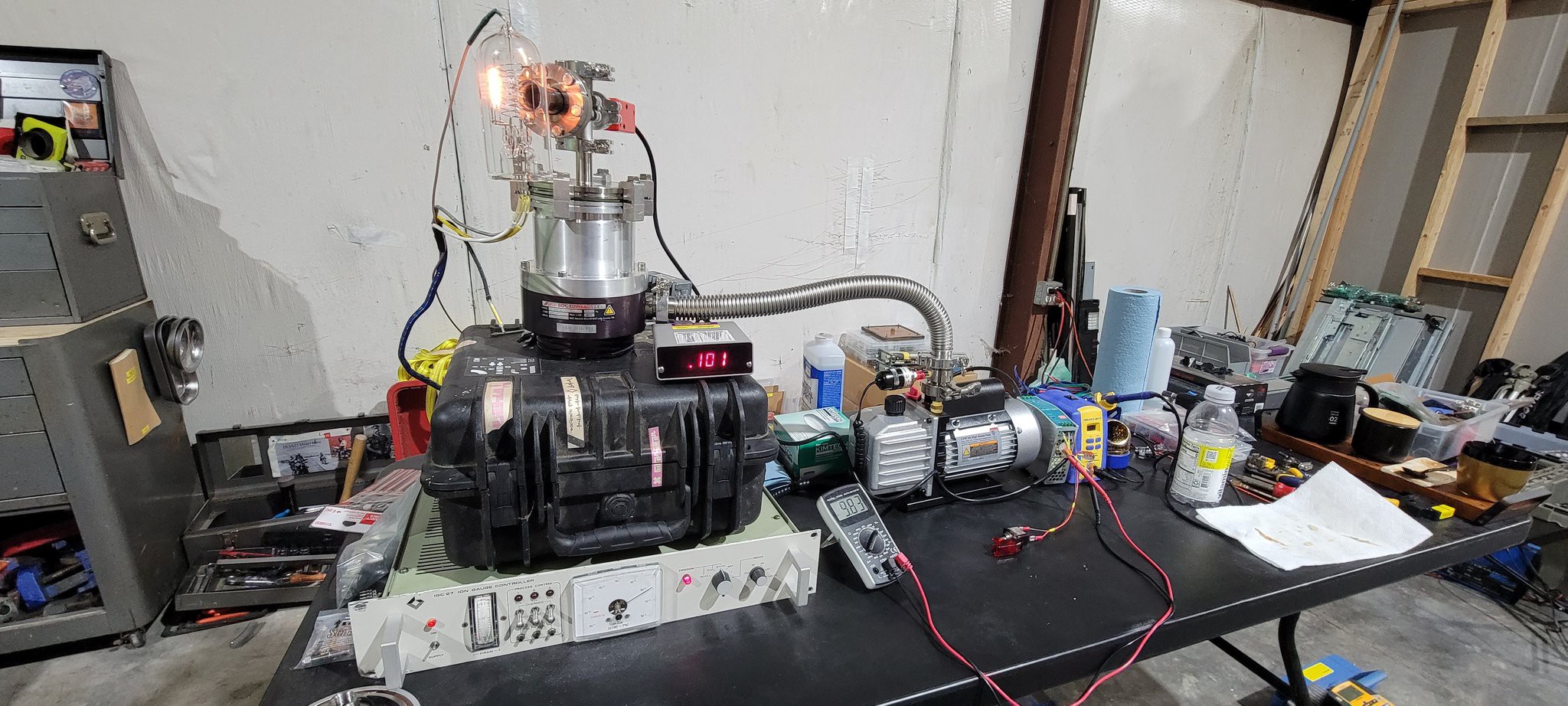

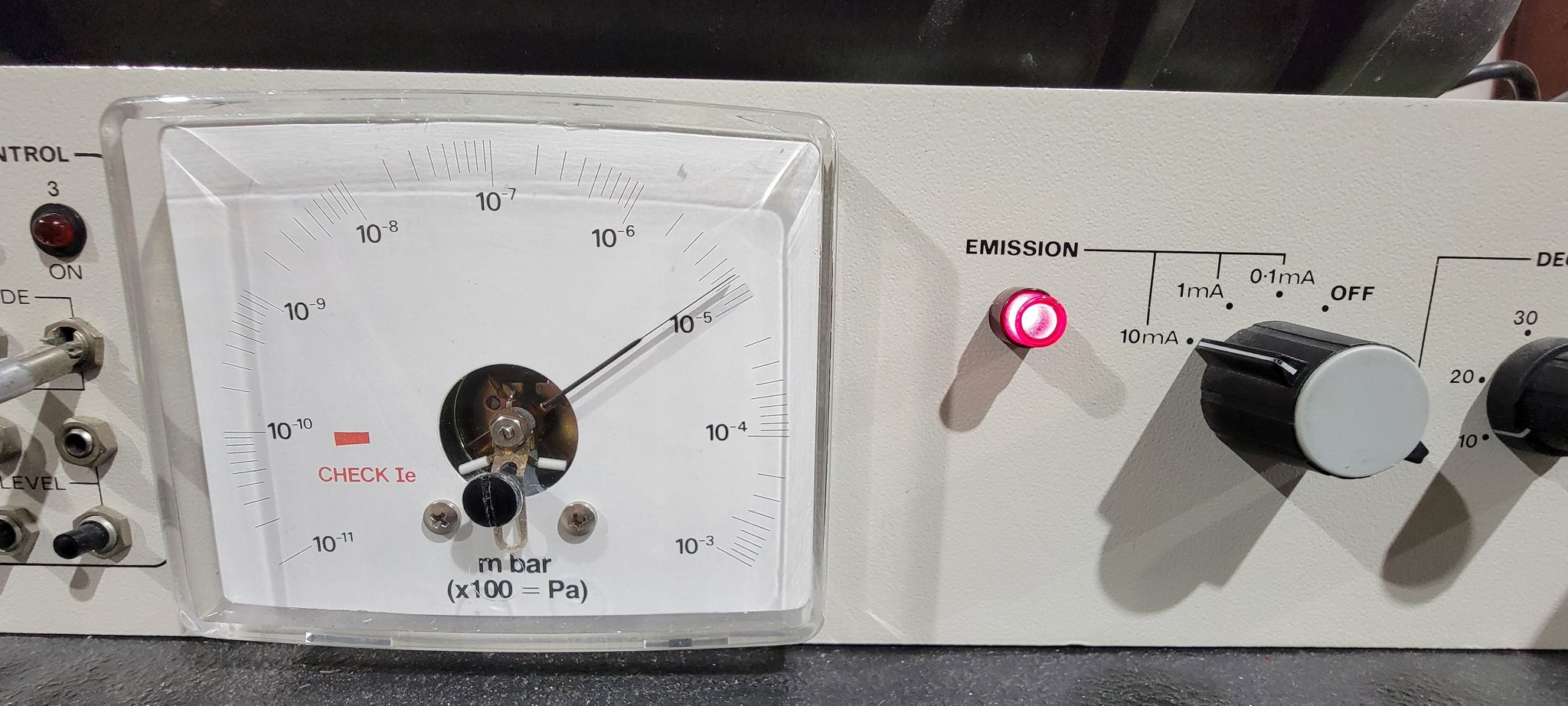

With the test manifold assembled, I fired up the new roughing pump and within a few minutes got the foreline pressure down below 0.1 Torr which is a massive improvement. With that settled, I wired up the Turbo and ion gauge, tightened everything down, and ran the whole system down for the first time.![]()

As you can tell from the glowing ion gauge, the system pumped down just fine and within about 20 minutes we were moving down through 10⁻⁵ mbar!

![]()

That's good enough. More performance can be squeezed out here by properly cleaning and drying the whole system and putting some Faraday Wax over the damaged purge valve port on the side of the turbo, but even if we never get into the 10⁻⁷ territory, a getter material in the sealed tubes will clean up the rest. -

Gearing Up to Pump Down

04/25/2022 at 20:12 • 0 commentsThese Solar Converters are only a small diversion in the larger project of experimenting with vacuum tube devices at home. To that end, I'm already in the process of building a high vacuum system that will be more than capable of pulling these tubes down to the levels of vacuum required to work. I'm also putting together the glass-working tools that will be needed to fabricate the envelopes and feedthroughs. I thought it would be nice to post some pictures of my growing stack of vacuum equipment here!

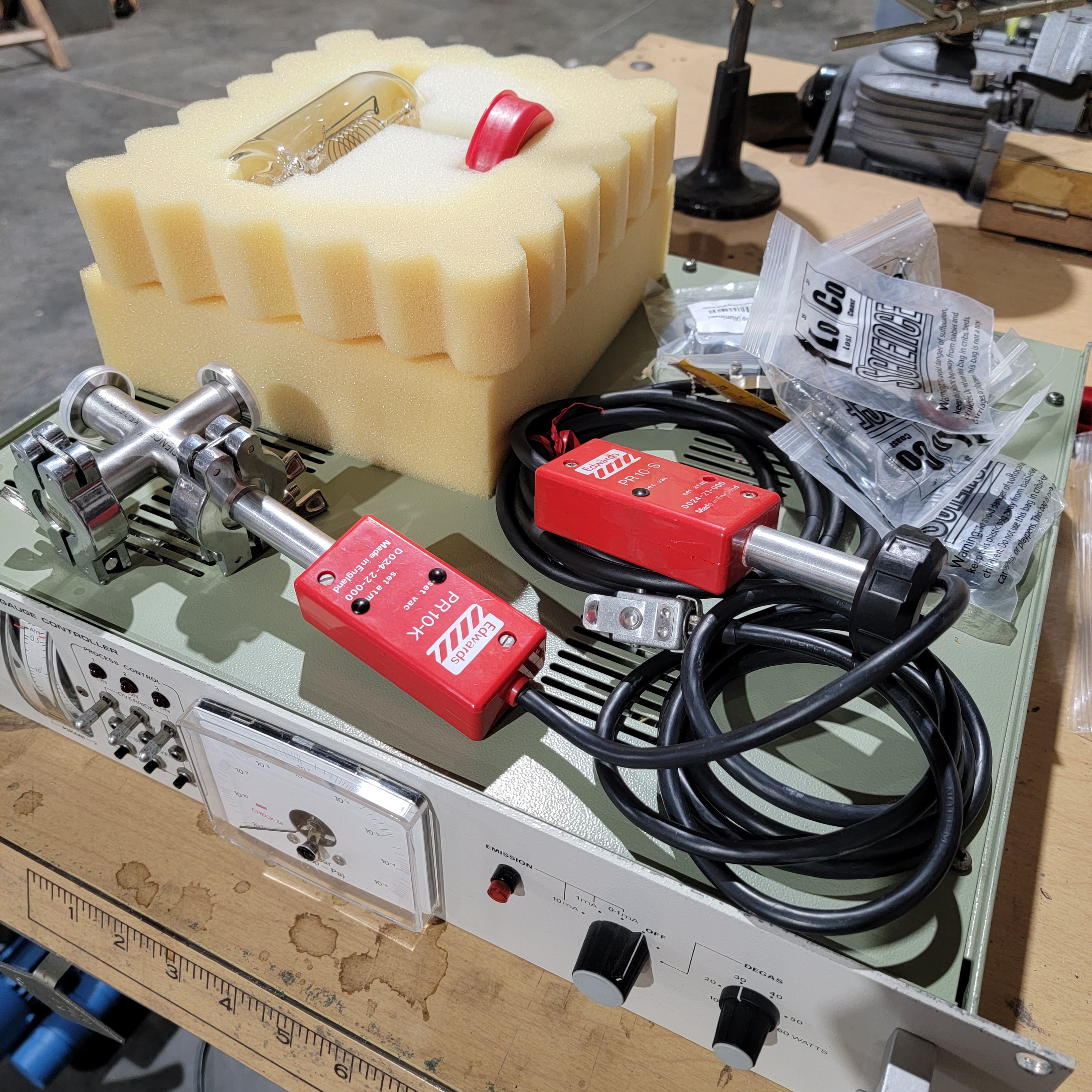

![]()

Here you can see my gauge controller and a number of vacuum gauges: two Edwards Pirani gauge heads and a Duniway Stockroom ion gauge. I've also put together a bunch of vacuum plumbing, although like any good plumbing project, I'm still missing some fittings. In the lower left, you can get a small peek of the mechanical vacuum pump that I planned to use. Unfortunately, even though it was sold to me as possibly being a Pfeiffer MVP series pump, it appears to be a Vacuubrand MZ, which I might get away with because of my choice of turbo pump (more on that in a second) but I'm also waiting on another pump to arrive which should reach much more convincing levels of backing pressure.

![]()

The big succboy is an Edwards EX255H compound pump which was pulled from a working mass spectrometer. It came with the controller, so I just need to provide it with 24V and it will do the rest. It has all of the modern self-protection features and tolerates a continuous working foreline pressure up to 5 mbar(!) although I hope to be able to achieve better than that.

I'll post another project log when we achieve first pump-down. Right now the main hold-up is an ISO-K 100 to KF16 reducer that I had to order from China. In the meantime, I'll be sorting out my roughing pump and plumbing.

-

Proof of Concept Pt.2

04/21/2022 at 00:25 • 1 commentSo we know that we can get some open circuit voltage by heating the cathode, but can it do any work?

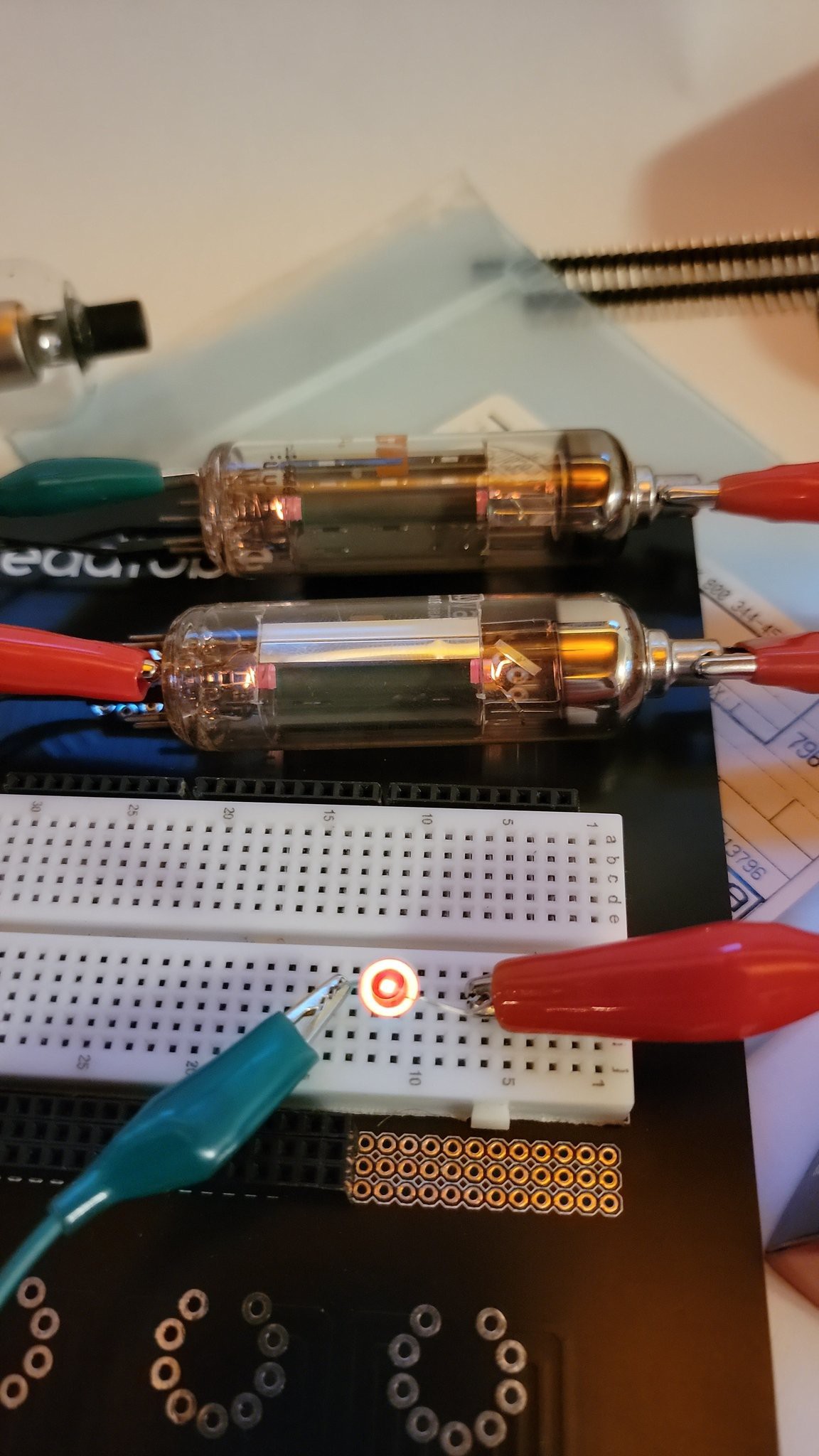

Here, two 6v3a diodes in series light an LED with their filaments at full tilt. The LED is drawing 7.5uA at 1.7v (LEDs are incredible)

![]()

Rough napkin math puts these diodes at about a 0.00012% conversion efficiency. That's between 5 and 6 orders of magnitude worse than a commercial PV cell. That said, these diodes are obviously not designed as thermionic converters.

As a demonstration, it feels a little "so what" until you unplug the power and the LED keeps shining until the cathodes cool down. That's neat.

-

Proof of Concept?

04/20/2022 at 18:22 • 0 commentsPlease enjoy this short video of me going ham on this poor 6v3a diode tube

In this video I'm using a large double-convex lens to heat up the cathode of a 6v3a diode to stimulate emission. Because these were designed to be heated from inside with a filament, the cathode doesn't really have line-of-sight to the outside of the envelope, but there is enough protruding through the top mica that I was able to get a bead on it. Considering this tube is not optimized for conversion, half a volt of open-circuit voltage is more than I was expecting. Of course there's almost no current available, and if you were to leave it this way it would eventually fail as the anode heated up and began emitting (or the envelope would eventually shatter) because there's no cooling.

That said, there it is, glass tube solar thermionic conversion! -

A niche within a niche

04/20/2022 at 18:15 • 0 commentsAs I'm gearing up to make more traditional styles of vacuum tubes (diodes, triodes, VFDs) I'm going to have all of the equipment I need to build, evacuate, and test my own Solar Thermionic Conversion tubes. I know that they'll never be as efficient as silicon-based photovoltaics, but they have their own advantages. The fact that you can build them with a torch, a vacuum pump, and a spot welder (more or less) means that these are extremely accessible devices. There's no need to get your hands on doped silicon wafers or exotic dyes or spin-coating equipment (although, there are some great demonstrations of homemade silicon photovoltaic cells out there!) So it's possible for remote communities to manufacture these devices themselves.

I'm going to enter this into the Hackaday Prize running and if it gets any attention, I plan to build some functional units, test them, and make the method and construction open source. My focus won't be so much on efficiency as simplicity of production. Yes, I'd like to see how well this technology works when pushed to the limits of my lab, but once we have a working device, I want to see "how low can we go?" Can you build working converters with just a blowtorch and an old HVAC pump? Maybe not, but... maybe?

Glass Tube Solar Thermionic Converters

Thermionic energy conversion isn't very efficient (it's also nothing new) but they *are* photovoltaic devices you can build with a torch

Nick Poole

Nick Poole