-

Chiller with the wifi switch

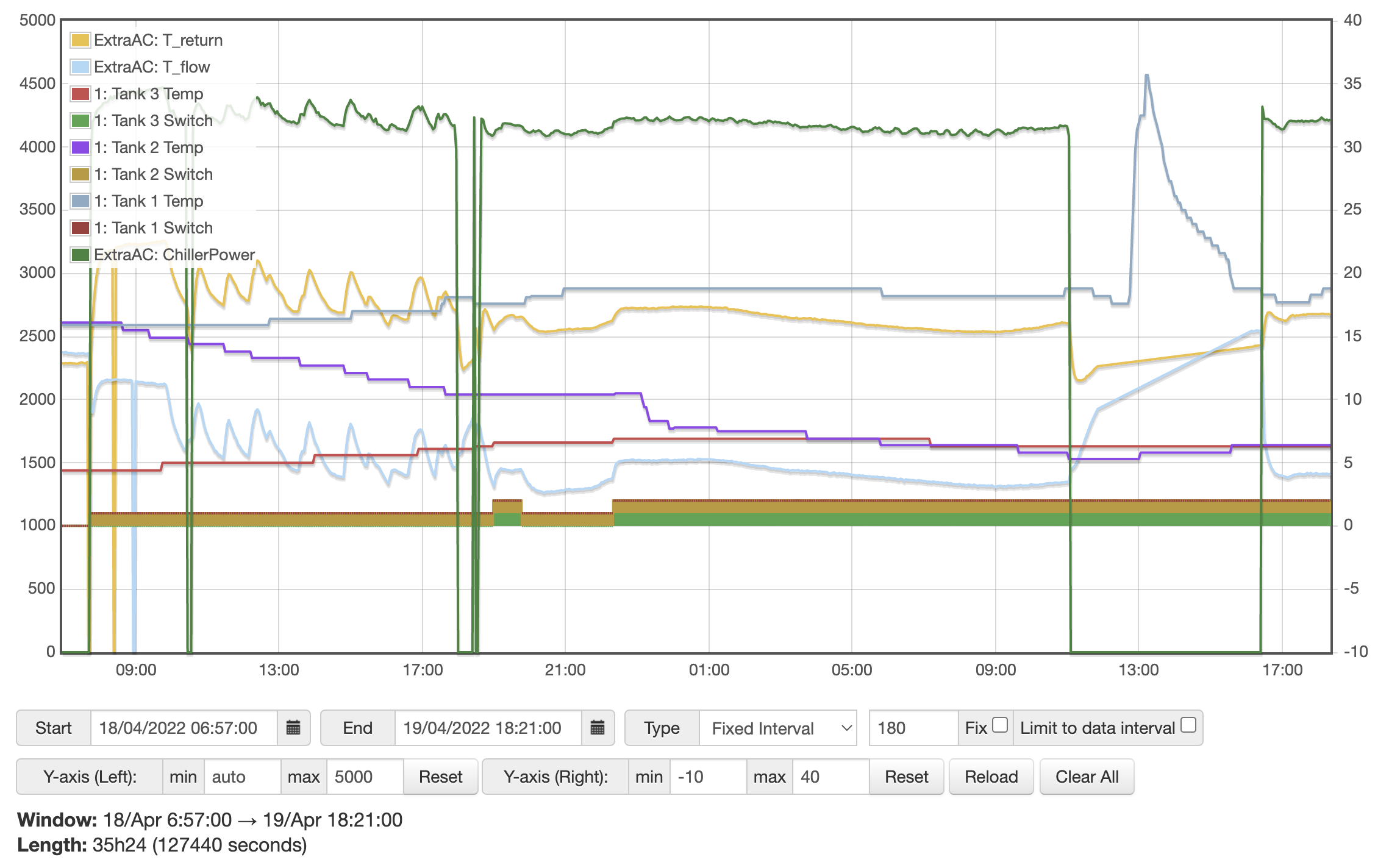

04/28/2022 at 20:21 • 0 commentsBelow we can see the chiller control turning off the chiller during the late morning and afternoon of the 2nd day 11:00 - 16:30, with only a small rise in tank temperature (Tanks 2 and 3) during that period. The tanks do not change temperature very fast - this is energy storage in action, and what allows us to turn off the chiller for this time. (Tank 1 is empty and is not being chilled)

Controlling the chiller via the wifi switch has allowed us to save 30% of our chiller electricity use, which is 5-10% of our total electricity use.

We added tank temperature monitor / controllers so we could monitor the tank temperatures from off-site, to verify that our tanks did not change temperature too much when the chiller is turned off. We used the Sonoff TH16 ($27).

Tracking tank temperatures has helped us get some numbers about the rate of tank temperature change at the cidery. Our 1500 gallon tanks can be cooled at a rate of 1.5F/hour. They self heat, during fermentation, at a rate of 0.25 - 0.5F/hour in our ambient temperatures.

By watching the tank temperatures, we can turn the chiller off when we want to, and then back on when the tanks start getting too warm. This is a manual process but we are learning how long the chiller can be left off without materially affecting the ferment process.

Sometimes the wifi temperature controllers get stuck reporting the same (incorrect) temperature. For example the purple Tank 2 temperature reported below at day 1 hour 17:30 - 23:30 is shown as a flat line when we know the temperature was actually going down following the trend. This may be a problem with the eWeLink cloud, our HA installation, or a poor wifi signal.

As we develop this system it needs to degrade gracefully in the absence of local wifi, or the internet, or the dependence on the third-party cloud.

-

Chiller monitoring before adding wifi switch

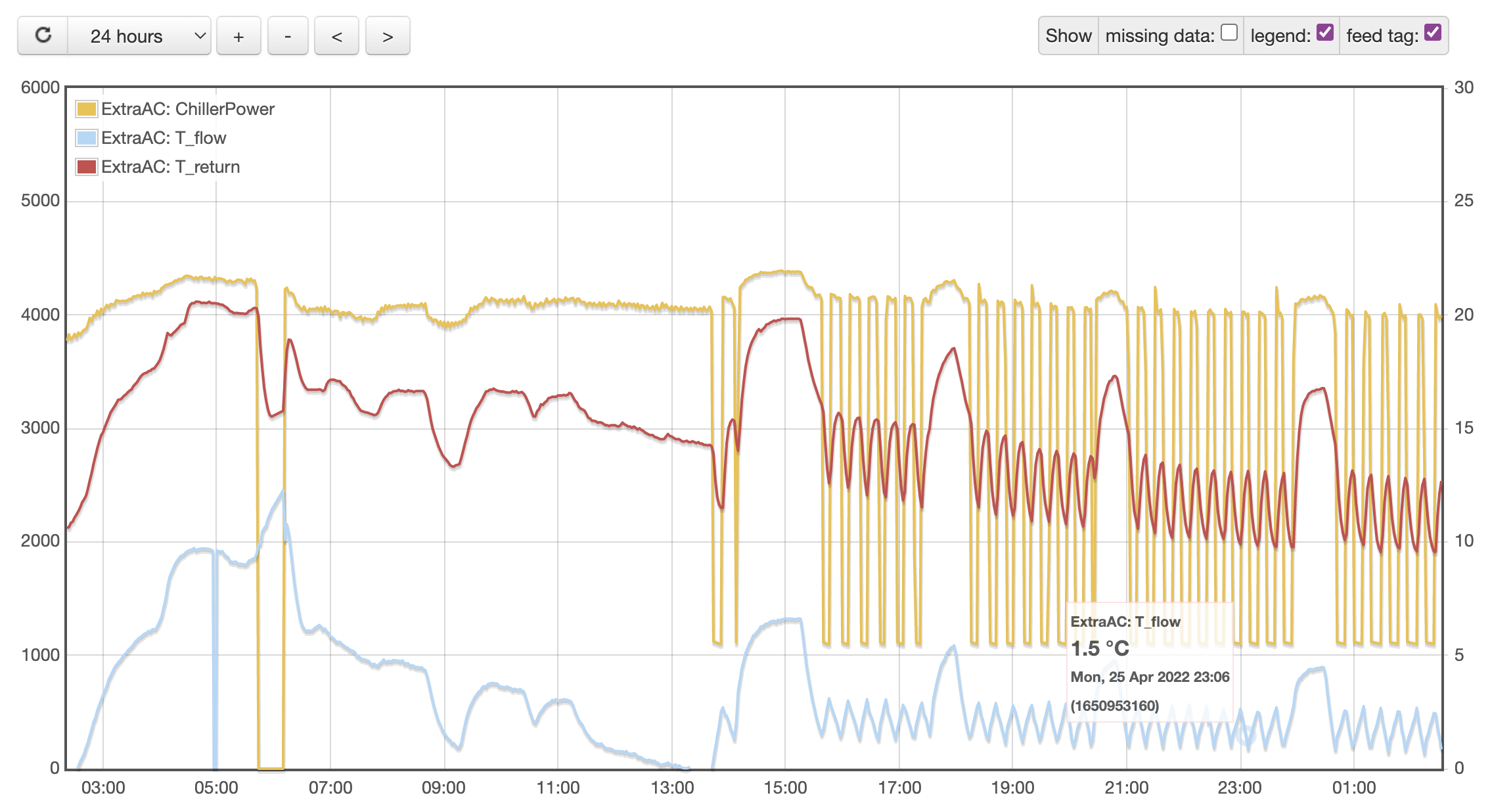

04/28/2022 at 20:05 • 0 commentsWe monitored our chiller power and temperature with the open source monitor extraAC, based on the excellent IotaWatt. We attached the monitor to our glycol chiller, a coolwine.com labeled G&D Chiller. 3 Ton / 10 kW. Data is forwarded to the open source emoncms.org for offsite viewing.

When the tank temperature needs to be lowered during cold crashing, a lot of cooling power is needed from the chiller. However when the tank temperature is stable, only a moderate amount of chilling power is needed to keep the temperature stable. For moderate cooling power, the compressor cycles on and off, and the circulating pump still runs. This wastes pumping energy, and energy keeping the glycol loop cool.

Before adding the chiller control, below we can see the tanks cooling at full chiller power as of 6:00am until 13:30, then the chiller runs on partial power, PWM-ing the compressor, for the rest of the chart. By adding an IoT switch, we can largely eliminate this second PWM part of the chart, simply by running the chiller less often by scheduling it with the IoT switch.

Energy saving for brewery glycol chillers

Thermal storage means brewery or cidery tank refrigeration systems don’t need to run all the time.

Tim Bishop

Tim Bishop