Overview

Hey, thanks for checking out my project! As I said in the description, this project aims to develop a low cost method of recycling electric scooter motors into a small scale home energy generation system. This section will provide a brief outline of where the project is at, and where it is headed. Project logs provide technical details on individual elements.

Before I get into the project details - I just want to elaborate on the thanks in the description. Thank you so much to the people that helped me get this project to where it is. Thanks to Daniel (One of the best - if not the best - lecturers) for not only giving me the push I needed to get it made, but also for talking through a lot of the technical details, especially when I was deep down the fluid dynamics rabbit hole. Thanks to my dad for being there with some really solid practical help and advice - I think that the tower would have fallen over the first time I tried a live test if it hadn't been for some of the rock solid mounting methods you came up with. Another big thanks to the engineering techs at my university, for some more solid advice.

As it stands, the project breaks down into three major elements:

- Development of blades and rotor suitable for harvesting local wind

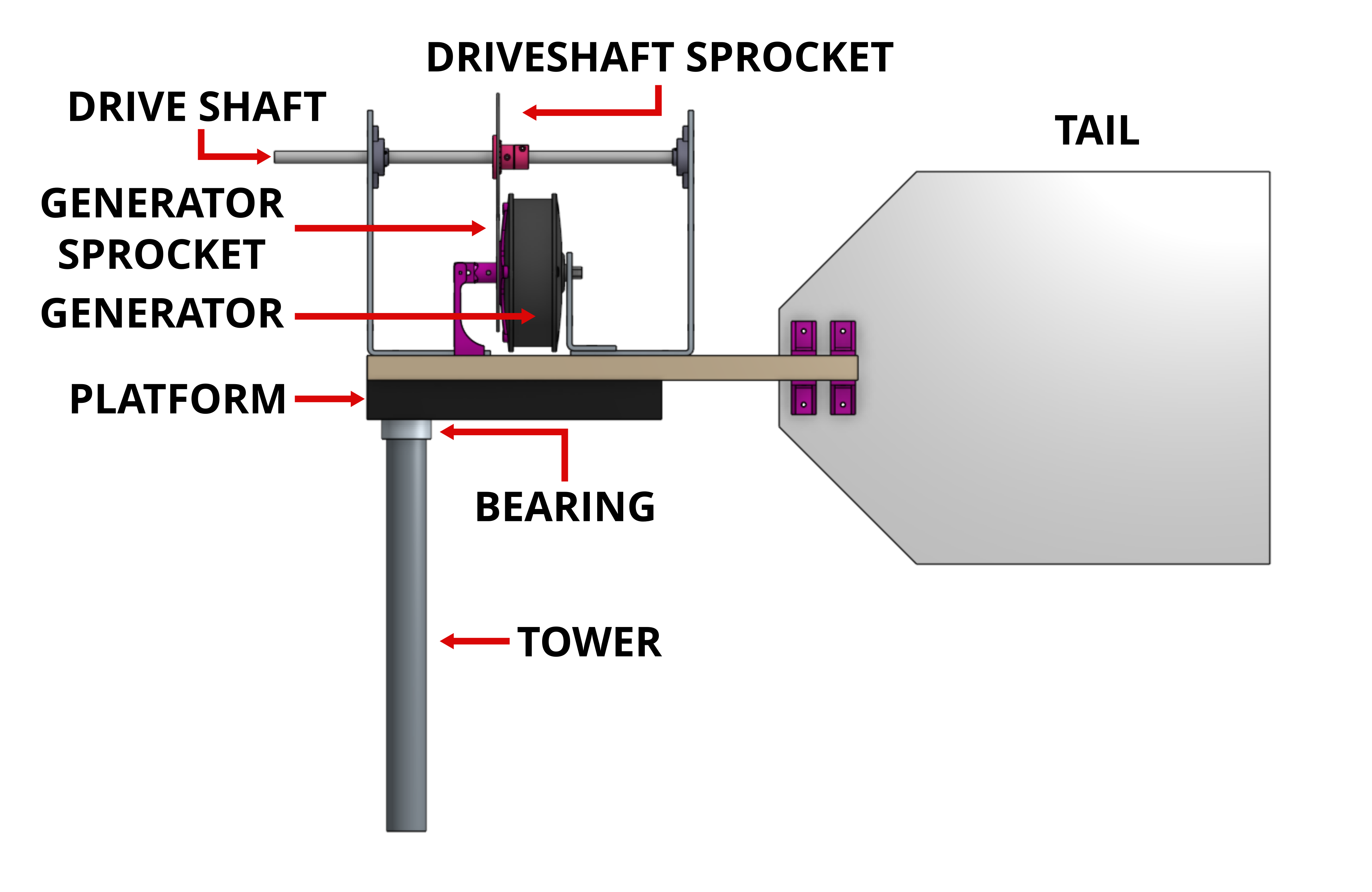

- Development of generator capable of maximising energy output for local wind conditions

- Development of an electronic control system for braking, and for handling energy output into a battery bank or local load

Currenty I have put a lot of time into the first bullet point, and developed a methodology for creating a rotor suitable for specific wind conditions. This process has also highlighted the fact that the scooter motor may not be suitable for operation by a wind generator, as in order to ensure a low cut-in speed the operational RPM of the motor must be reduced to a point where output power is minimal.

Blade Development

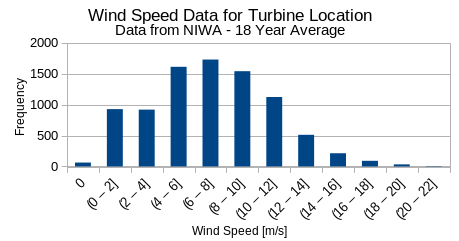

In the final trimester of my engineering degree I worked on this project as a self directed study course, giving me a lot of time and resources to develop elements of the system. During this trimester I worked on developing a methodology for analysing local wind conditions, and developing a rotor to those conditions.

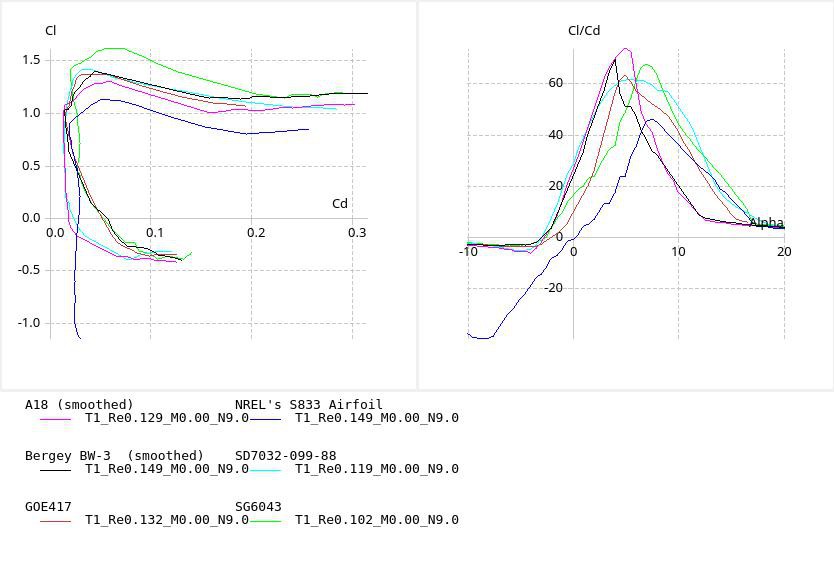

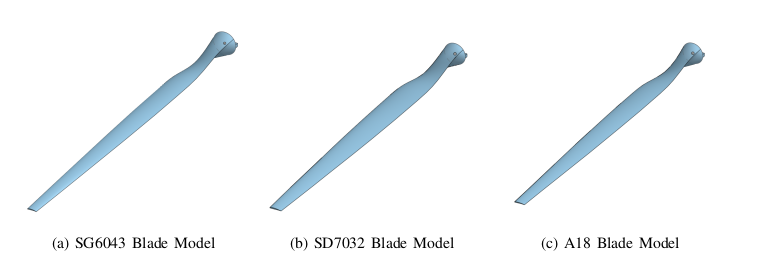

This process involved a lot of iterative design, and avoided in depth fluid dynamics (as I was studying electronic engineering, mechanical was a bit beyond the scope of my course). In order to do this, I used a software package called QBlade to handle fluid simulation. This was paired with research into airfoils developed for small wind turbine applications, and resulted in blade profiles targeting specific tip speed ratios (TSR).

Further detail is provided in my blade development project log (and in the report I wrote for this section, found here), but if you just want to see the rotor operating at maximum speed (With no generator gearing attached), check out this video:

Generator Development

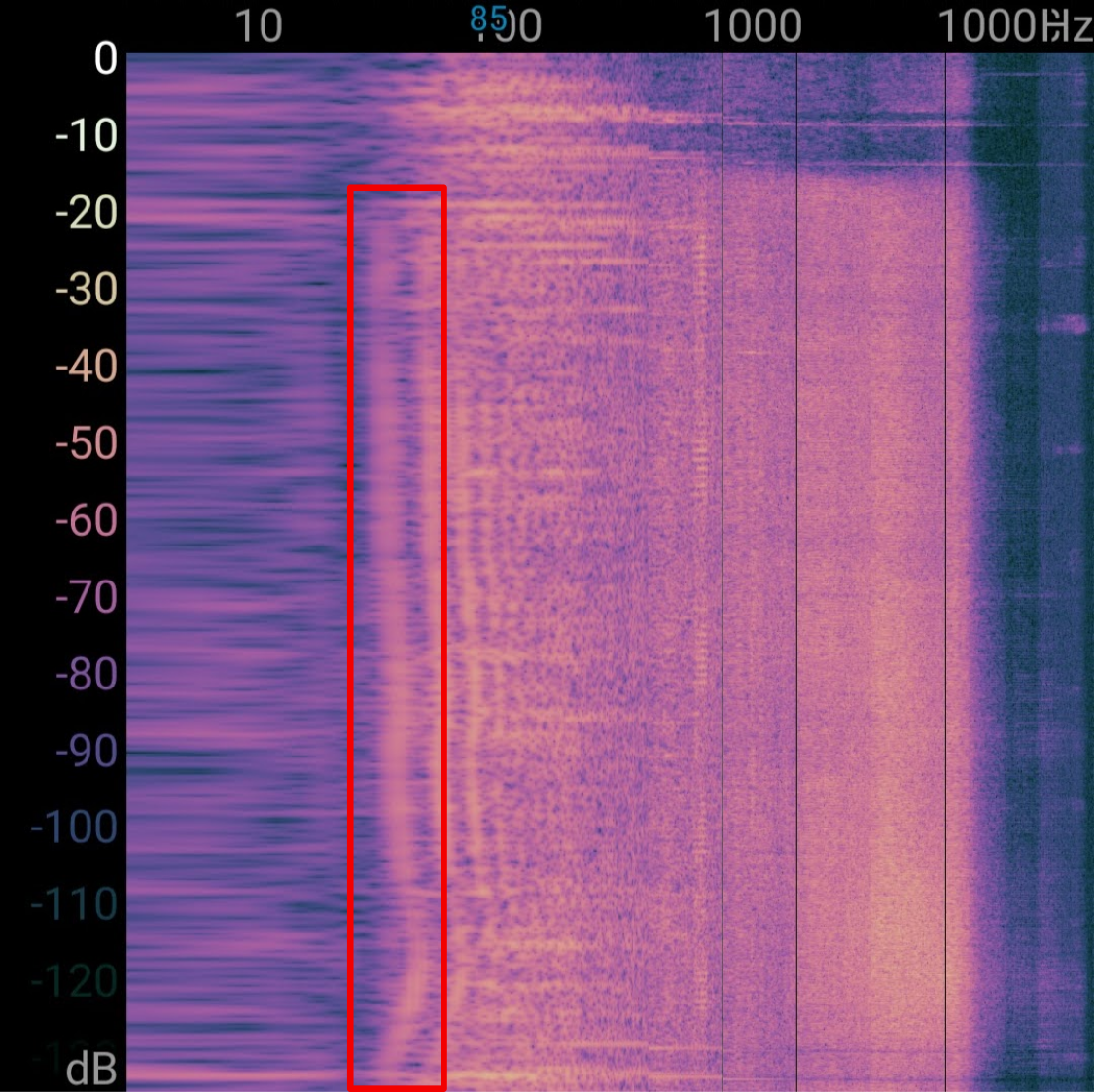

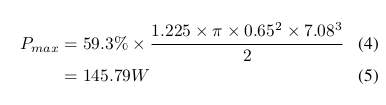

Part of the self directed study work looked into details of the scooter motor as a generator. The brief amount of research into this topic is detailed in a log, however in summary the research found that wind generators (and generators in general) tend to have what is effectively a maximum power point on their power vs RPM curve.

Additionally, it was found that the scooter motor needs to run at a reasonably high RPM to begin approaching this point. Further analysis of the motor power rpm curve could provide insights on exactly where on this curve the scooter motor should be operated for maximum efficiency.

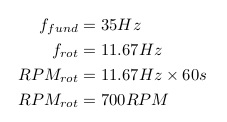

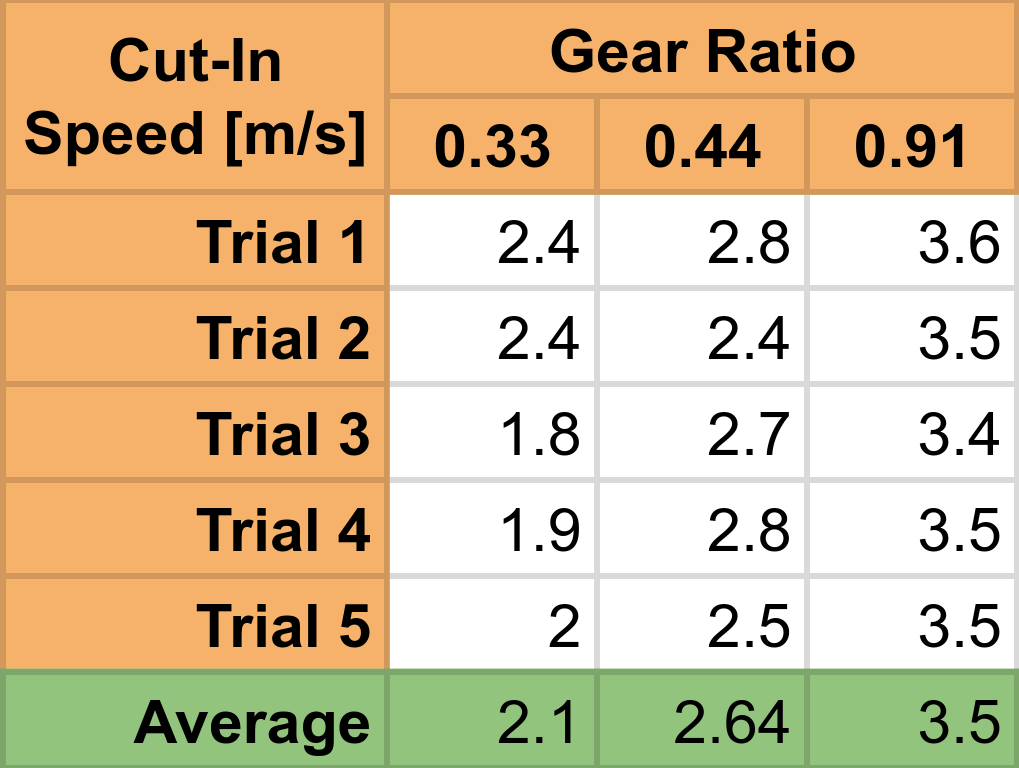

However, this produced another issue. The turbine can drive the generator at it's maximum speed, however it cannot self-start. In order for the turbine to self start, a low gear ratio needs to be introduced. This lowers the starting torque of the generator, reaching cut in speeds as low as 2.1m/s.

So a low cut in speed was achieved, but another issue reared its head. With a low gear ratio, the resulting...

Read more » Sam Griffen

Sam Griffen

Roddy "Rags" Read

Roddy "Rags" Read

Carlos Barrera

Carlos Barrera