-

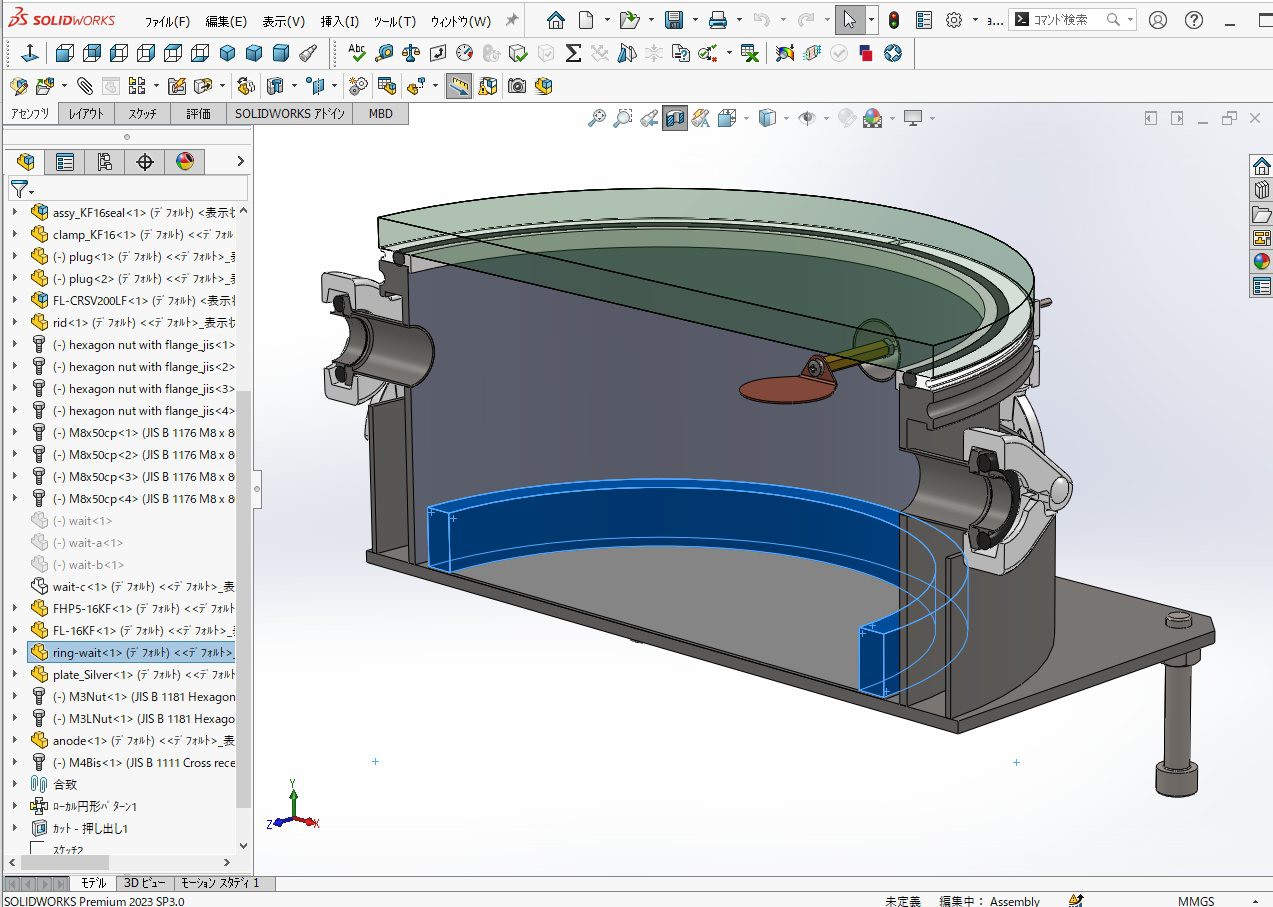

4th-gen sputtering chamber

07/07/2025 at 15:03 • 0 commentsHey folks,

Check out my 4th-gen sputtering chamber.

Back when I started doing DC magnetron sputtering @home, my first two generations of chambers were built around these cute little heat-resistant glass containers I picked up at the dollar store. The base plate was an aluminum slab with an O-ring groove machined into it.

But those setups had issues—persistent arcing and probably poor vacuum levels.

One major problem? I was relying solely on a rotary vane pump for vacuum, which led to oil mist backstreaming into the chamber.

I’m a mechanical engineer, but I jumped into the vacuum world without much background—so I didn’t initially understand some of the weird and wonderful phenomena that happen in high vacuum.

Can you believe it? Even so-called “vacuum-grade” lubricants can evaporate under vacuum, travel a whole meter backwards from the pump, and contaminate your plasma.

Once I figured that out, I finally started reading up on vacuum tech and learned that I needed a turbo molecular pump (TMP)—a beast of a pump.

Check out my third-gen chamber and the TMP startup vibes!

This thing is basically a jet engine. The turbine blades (or whatever they are) spin at near-sonic speeds. You need a backing pump just to get it started, and if you suddenly vent it to atmosphere while it’s running, the blades can explode.

As you might guess, TMPs are insanely precise machines—a new one will set you back around $5000. That’s way out of my hobby budget, so I went hunting for a used one.

And yeah, buying a second-hand jet engine? You can imagine the risks.

But hey, I got lucky on eBay—and now it’s running like a charm.

Alright, so here’s the deal: I’ve finally unleashed the ultimate creation—the 4th-gen chamber. Sourced a vacuum equipment manufacturer on Alibaba, sent over some 3D designs, and had them craft a proper, near-professional-grade vacuum chamber.

![]()

![写真の説明はありません。]()

-

New vacuum chamber progress

08/22/2022 at 10:38 • 0 commentsToday's progress.

I drilled a Φ18 hole in the SUS tray and attached an gas supply/exhaust fitting.It just like designed. ;)

-

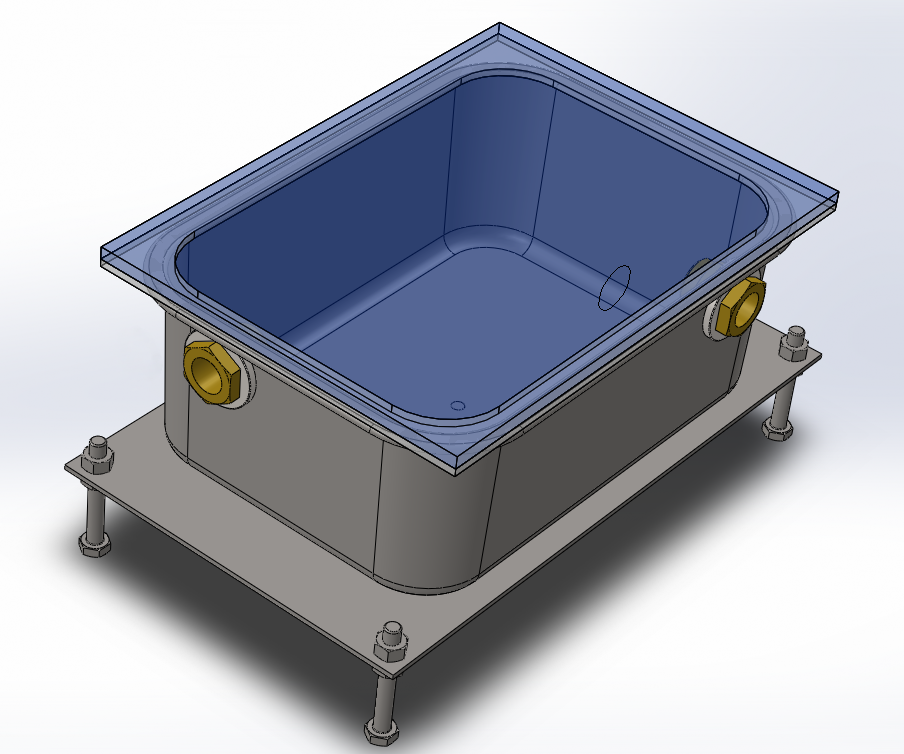

New chamber design

08/21/2022 at 12:11 • 0 commentsI've finished arranging the parts for the new chamber, and some items have arrived, so I tried to make a rough model.

The 2mm thick base plate and deep tray, the M6 legs are SUS304 (stainless steel), silicon rubber packing and 5mm heat resistant glass are on top.

Brass parts are vacuum exhaust and argon gas supply port.

The point here is the small circle visible in the center of the bottom of the tray.

Spot weld to the base plate only at this point.

The actual thickness of the tray is 0.7mm, so it is expected that the bottom will dent when vacuumed. The motive is to disperse the base plate and deformation stress with this spot welding and endure it.

The flat part of the bottom is roughly 177 x 116 mm, so I wonder if 2 mm of SUS304 will work. (You calculate the strength lol).

The concern is whether the 5mm thick heat-resistant glass will hold up. That being said, I don't want to use quartz glass. . . Please don't break it (You calculate the strength lol). -

New chamber parts

08/20/2022 at 08:12 • 0 commentsI am considering a vacuum chamber in a new configuration.

-

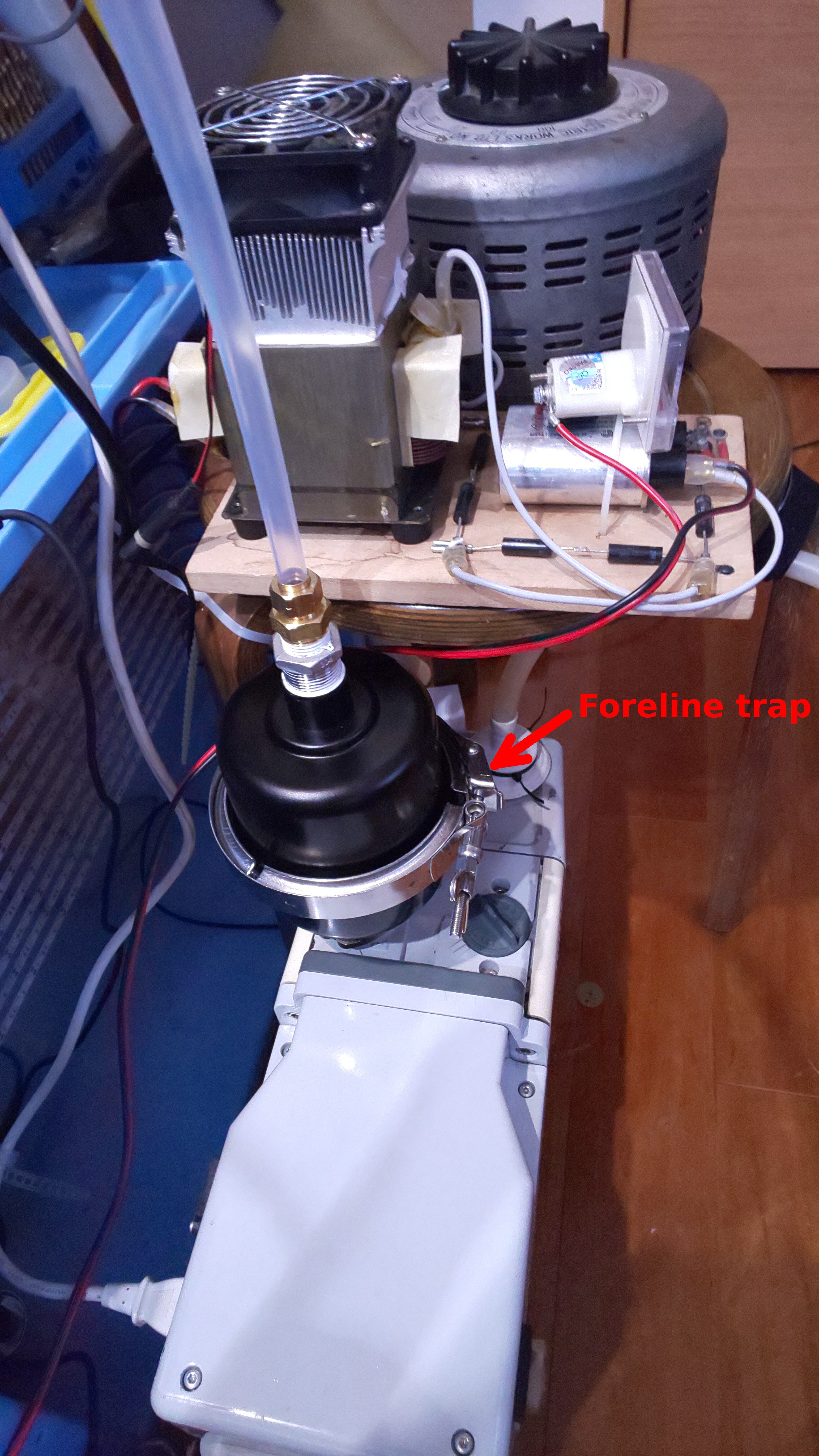

Foreline trap issue

08/17/2022 at 05:53 • 0 commentsI'm currently struggling with a foreline trap on a rotary vane pump.

Since I have not received any formal education about vacuum equipment, it did not come to my mind at first that oil mist would diffuse backwards into the vacuum chamber.

After many failures, I realized this by observing the phenomenon, and tried to make my own foreline trap using activated carbon or silica gel, but the plasma quality deteriorated due to the pressure loss.

Currently, I use a trap with a general paper filter, and although I'm getting some improvement, it's still not good enough.Professional equipment seems to use liquid nitrogen to chill the upstream of the pump to trap the mist, but it is impossible to introduce such a device at home.

This part will be an important theme in the future improvement of the device. -

Cameras I use to shoot daguerreotypes

08/16/2022 at 15:54 • 0 commentsHey, you probably don't know what kind of camera I expose a 90x120mm plate.

This is the pretty cameras that I usually use.

The first black one is a Voigtlander Bergheil from the 1920s.

The next is a pre-WW2 Japanese wooden camera.

Taking slow shots with these cameras, like 5 minute shutter speeds, feels great.![]()

![]()

-

New chambers!

08/15/2022 at 14:01 • 0 commentsA damaged chamber and two brand new chambers.

When I asked my wife, "Buy me one because it broke," an extra one grew.

I feel her love (or resignation).

Sputtering equipment for daguerreotype photography

Manufacture of photographic materials using home-made sputtering equipment.

Koji Tokura

Koji Tokura