What I want:

I'm broke and dumb, so I want an user-friendly and cheap printer that all my homies can use.

The market is full of overpriced 3D printers that are a pain in the chucks to learn and use (maybe just like conventional printers at this point, lol) with filaments that are super expensive and hard to make at home (at least for my country's currency, the dollar is 5x the value of my country's currency).

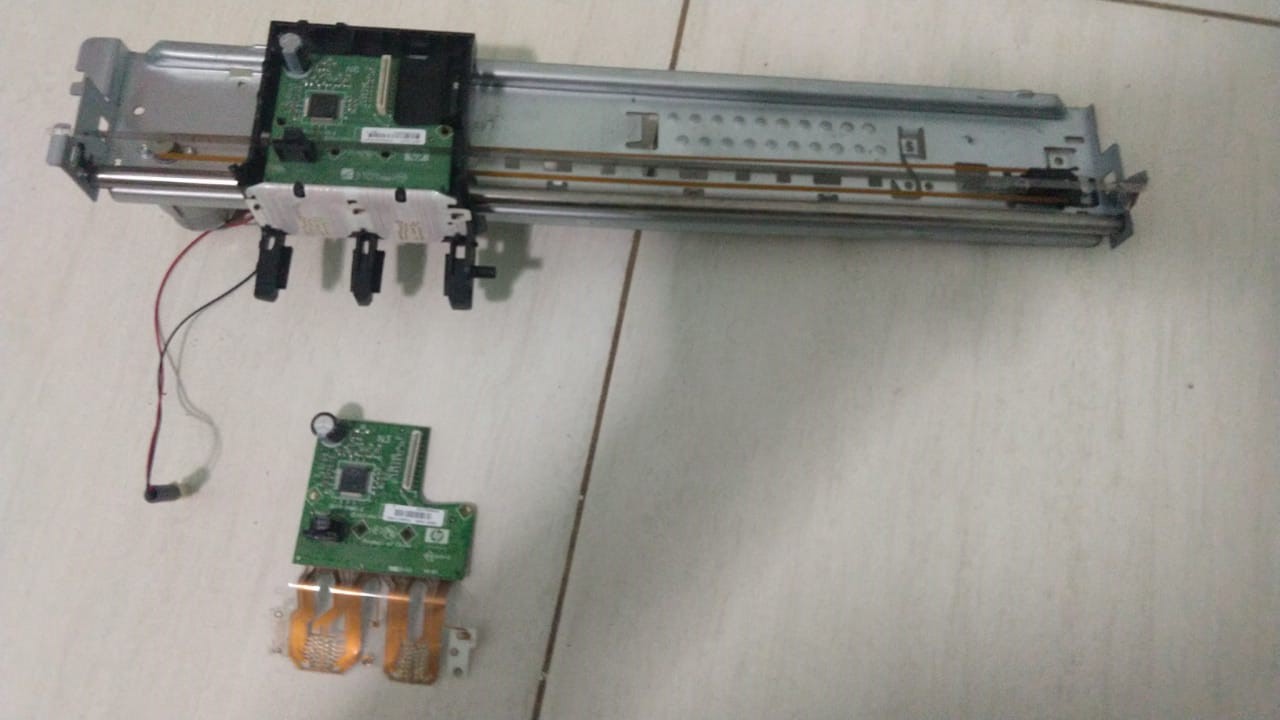

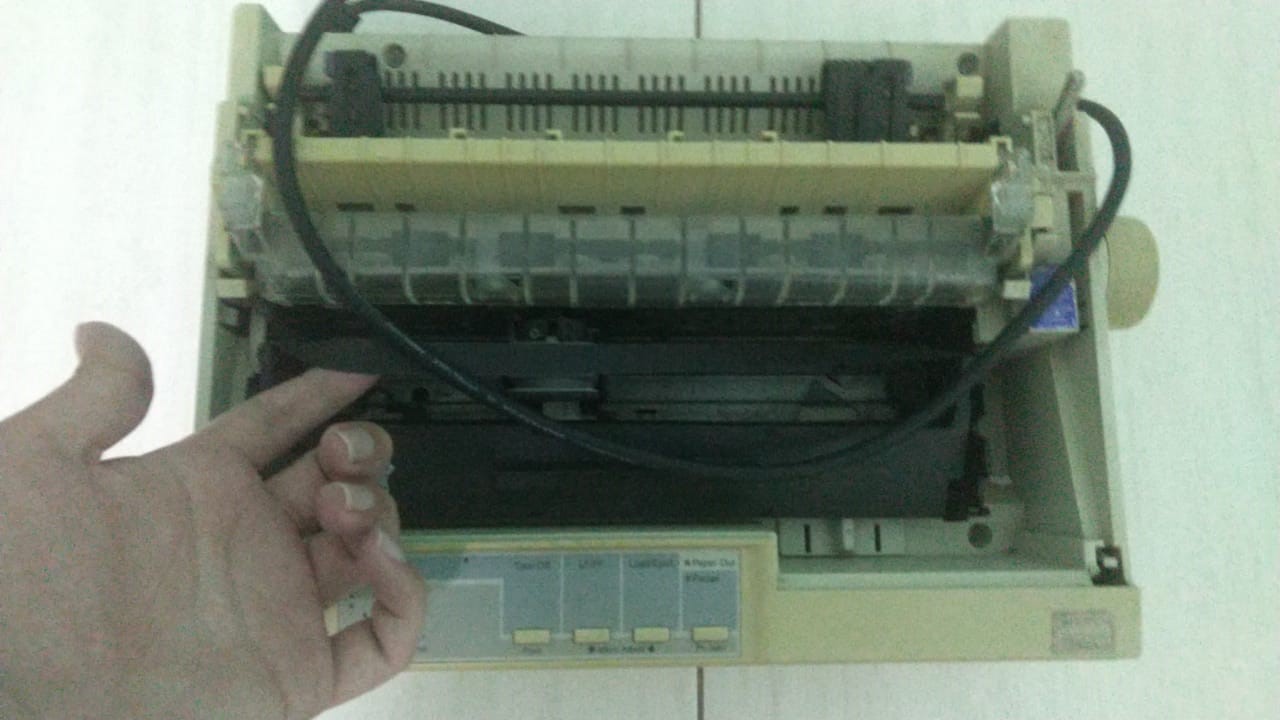

What I could find:

- There is the "Oasis 3DP", a inkjet that wets powder to print coloured 3d objects, but the objects are quite brittle and fragile (there are people that suggested to replace the powder with cement tho).

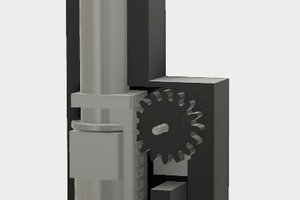

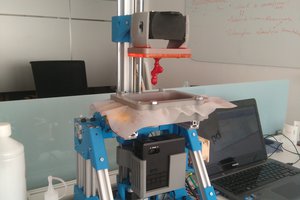

- And I found this DIY that converts a creality 3D into a conventional printer, but I don't think the results are that precise. Not to insult the creator (the project is awesome), but the actuators used are piezoelectric actuators, not inkjet nozzles.

- Some time ago I found a 3D printer company that made a method to use UV resin to print lenses, it is just a super precise inkjet printer that shines an UV light to harden the droplets.

Obviously, You can't just buy one of these, but this informational video is quite useful. - There are a ton of papers on the subject of resin printers, but I find this articlequite interesting, because it shows a method of changing the mechanical properties of the print by changing the amount of Silicon and Epoxy Resin.

- And this video about how Inkjet printers work can be insightful.

What I thought on so far:

First I thought on, just like the company, on using UV hardening resin for the printer. It simply spits the droplets and then the Printer hits it with a small UV light.

But in that case, I would need a UV activated Resin, and UV activated resins are expensive (at least on my country) and only sold to be used in laser resin 3D printers.

So the point of being cheap would be thrown out of the window.

Then I came to believe the best choice is to replace the variety of colours of a conventional Inkjet printer with resins. Like a "colour 1 - magenta" for the resin and the hardening element as a "colour 2 - cyan", so they are added simutanesly.

Of course, this allows for more options of materials and even colours to be added if you simply increase the number of printing nozzles. Materials like Epoxy, Silicon, Sodium Silicate, oil (to lubricate mechanical pieces) and even edible stuff (pasta? Chocolate?).

Eric Moyer

Eric Moyer

Josh Starnes

Josh Starnes

Giovanni Leal

Giovanni Leal

Jaime García

Jaime García

If you can, you should try to get Epson printers, rather than Canon or HP, since they use an actual piezo pump print head, as opposed to the bubble jet system of HP et al. I like your idea of printing the two parts of an epoxy with separate "colors", instead of using expensive UV resins.