You can find all the data on my github.

Pi Pico Power Meter

For my electronic developments I need more than one multimeter to get the power. Here it is!

For my electronic developments I need more than one multimeter to get the power. Here it is!

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

You can find all the data on my github.

This wilweek I found some time to improve the code base. I did general code cleanup and moved some functions to another file for better overview.

Furthermore, I implememted milivolts, miliamps and milliwatts to display if the values are below 1.

Check it out on GitHub.

While I was measuring the consumption of other projects I realised that I really need to take care of the wiring. Especially the GND connection. Eventually I destroyed one chip through misconnection.

That led me to the point that the device needs to be isolated. Only this way it is safe to use two of them to perform efficiancy measurements.

There are two ways of isolating the PPPM:

I decided to to the latter because I have no access to the USB-C connection on my PCB.

After a brief search online I found the I2C isolating chip: ISO1641B from TI. It is very easy to use and needs only two external bypass capacitors. The Clock is transmitted unidirectional and the data is bidirectional.

For the power isolation is was a bit harder to find a good space saving solution. Usually there are chips that drive a discrete transformer and on the secondary side you need a LDO to regulate the correct voltage. All that leads to a high BOM count and needed space.

But I was lucky and discovered that TI is coming up with a highly integrated, space saving and cheap chip that does all of this! It is the UCC33420.

To make space for the two additional chips I moved some components around. The shunt resistor and a couple of resistors moved to the back side of the PCB. Now they can be changed without removing the OLED. I should have done this before!

The layout is done and the PCBs are ordered! Now let's wait for it and that the transformer chip becomes public available.

Some Code adjustments made it possible to track the charging power of my old Nexus 10 tablet.

With a button push the data are logged to a csv file. Another press will stop the logging.

For a decade I was wondering why the charge performance is bad. I can see that the charging current is variing all the time up and down.

I have reworked the 3D printable housing.

Just have a look yourself:

During testing the Power Meter I discovered some minor things I wish I had done different.

First, and most important I wanted to get rid of the pin headers to solder the MCU module. This only adds costs and is unconvenient.

I also added some TVS diodes for the measurement inputs and a mouse bite divideable protoboard for the controller headers.

Before, I got a message from PCBway that they would like to sponsor the next revision of PCBs.

That's a really nice circumstance and I used the offer for new PCBs. It was the first time I ordered there.

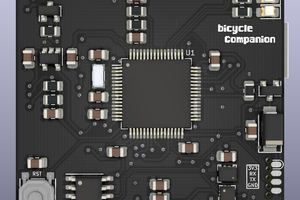

The PCBs are really nice - like I expected. The HASL finish looks very even and the silkscreen is very clear and sharp. One thing I did not expect was the outer milling of the boards. Often the outline is not that important than the dimensions on top of the FR4. But nothing caught my eye that was not finished perfectly and all the dimensions are bang on!

All in all a very good job! Thank you very much!

I finally got the printed housing from my friend.

It looks already quite good but some dimensions are not correct. I also need to think about the different height of the components: headers, button, display.

Let's see what I will think of...

After some trouble designing a 3D printable housing I have a first prototype.

I've ordered the 4 parts from a friend who has a 3D printer.

This design I need to glue. Don't know if it is the best approach. Let's see when I have the parts in my hands.

But have a view on the renderings I've got from Fusion360:

My PCB order was deliverd yesterday.

After a bit of soldering and testing - everything works!

It feels really good to have some working hardware in the hands.

With the battery and the two resistors I made a quick energy measurement of this disposable rechargeable Li-Ion battery from a vape pen.

It should contain 2.025Wh. With my measurement I calculated 1.92Wh. That is quite good!

... but actually I do!

I switched the push button mode from polling to interrupt mode.

Now it is possible to log the data as .csv file on the onboard flash. Does anybody now what happens when the file exceeds the available space?

Furthermore, I created a github repo to share my HW and SW files with you.

Additional ideas in my mind:

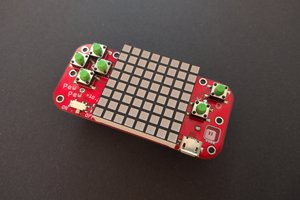

It was time for a nice GUI.

Well a really nice GUI on 2cm² is hard to realize but at least I could make everything good readable.

Due to the lack of different fonts and sizes in the default micropython library I searched for something easy to implement.

And I found it! Peter Hinch has written a really nice library in micropython hat is based on the official drivers for the frame buffer and the SSD1306 OLED display I use.

With some modifications in the code it just runs perfectly on my Pi Pico!

So, if you need a good GUI library that offers some fonts in different sizes, nice widgeds and is portable to many microcontrollers check his repo!

Now, here are some pictures of my 'pages'. With a push button it is possible to move from one 'page' to another.

Create an account to leave a comment. Already have an account? Log In.

Nice, if my project helps you with yours! Good luck and happy hacking!

I love projects like these! Can this be expanded to measure -5, 3.3, 5, 12, & 24 volts? While readings amps/power would be great, it's not completely necessary.

Thanks!

The PPPM can measure up to 26V. -5V is not possible because the INA219 chip does not support negative voltages. You can change the accuracy in the code.

With the new isolated design it is possible to measure with a different reference than the power supply.

great project, there is a lot of need for power and voltage meters at industrial sites. I work at a plant where we want to reduce energy usage. It would be great if there would be an open hardware IOT device which can measure current or voltage and sent it to the cloud Just current could be helpful as well. The idea is that you can sent people a message to turn of a device that shouldnt be on or seems to be not functioning. Imagine that current is too high for the device being off and too low for thw device being working.

Hey @Hexastorm,

thank your for your comment!

Reducing energy usage is an important thing nowadays.

I will think about an IoT PPPM. With some IOs left you could program to turn off the device also over WIFI. The device only needs to be attached to a (onboard) relay.

Hey!

Here is one that I remember:

https://hackaday.com/2022/03/28/putting-the-rp2040-on-a-stamp/

I now. There are also two more board that are smaller ;)

Become a member to follow this project and never miss any updates

Matias N.

Matias N.

Boz

Boz

deʃhipu

deʃhipu

Pep3175

Pep3175

Love this! I came here trying to solve a similar problem for myself. I want to power up to four 12V devices from a single PSU (Mean Well LRS-75-12) and log the power consumption of each of them separately. I'll be putting this in a mini server rack (10" 4U) where almost everything runs on 12V or 5V, so having separate power bricks for each of them feels like a waste.

I'm considering using a Pico W/2W so I can push the data into Home Assistant for remote monitoring, but also with a local display for a quick glance. I'm not sure if I can wire 4x ACS712 modules directly into one Pico, or if I should aggregate them via an ADS1115 first. I've also not figured out how to power the Pico itself from the 12V supply, so your prior work helps!

Additional challenge: I want to toss in a super-capacitor circuit for short term backup if there's power failure (up to 20s max for backup power to kick in). I'm planning to use a BTT UPS 12V since that's easy to source, but I'd like to monitor it as well. It provides backpower and I'm not sure what complications that adds.