I'm not sure how far I'll get before all the additional manufacturing complexity nudges me over the edge to essentially say "Well, it was a good run, but that #SlimeSaver [gd0105] isn't solving itself and still has the optimistic appeal of potential performance." but I've currently modelled a potential heatblock candidate that is about 3.3 cm3.

I'm not sure how far I'll get before all the additional manufacturing complexity nudges me over the edge to essentially say "Well, it was a good run, but that #SlimeSaver [gd0105] isn't solving itself and still has the optimistic appeal of potential performance." but I've currently modelled a potential heatblock candidate that is about 3.3 cm3.

At 7mm, the heatblock is 3.5 cm3.

Series of events

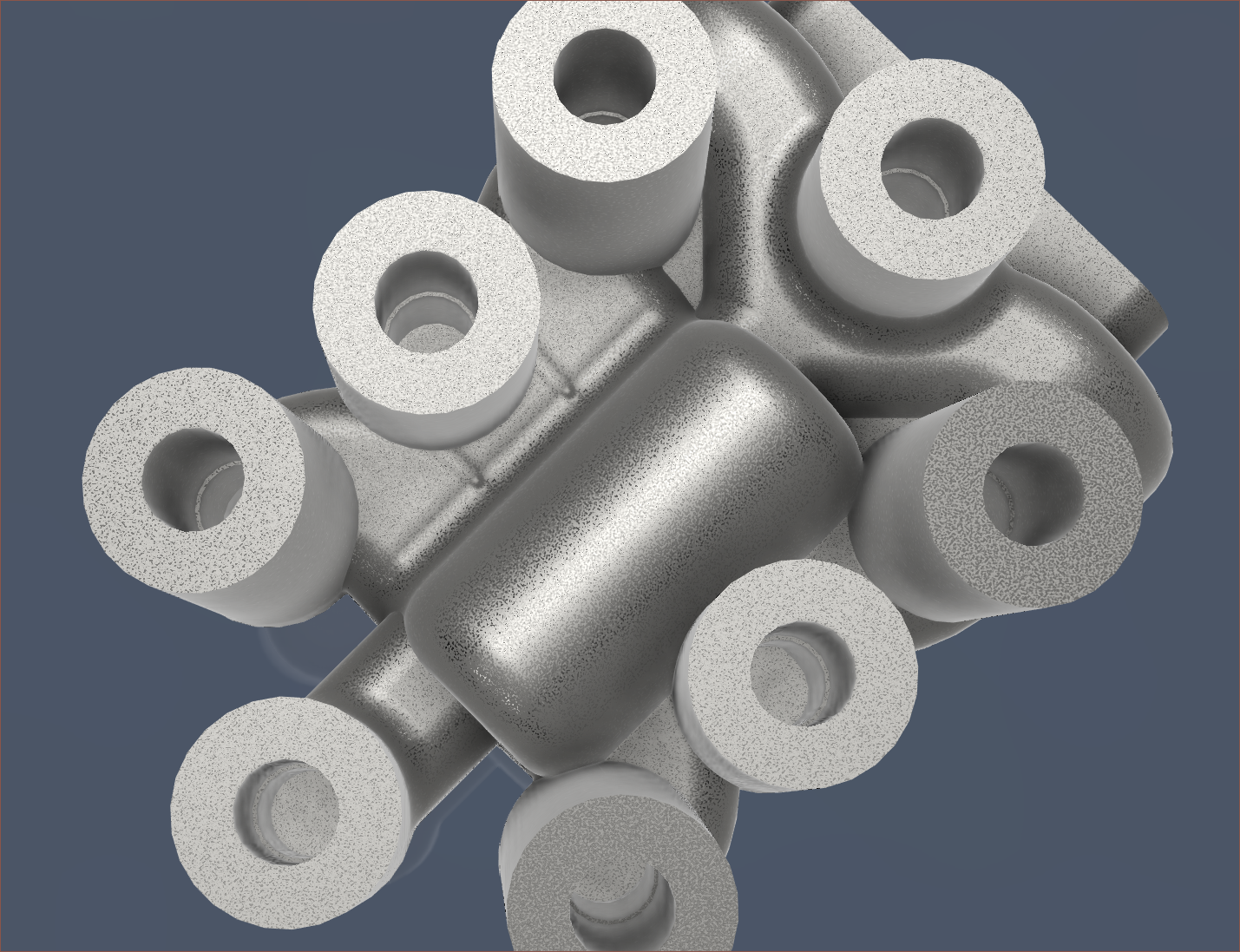

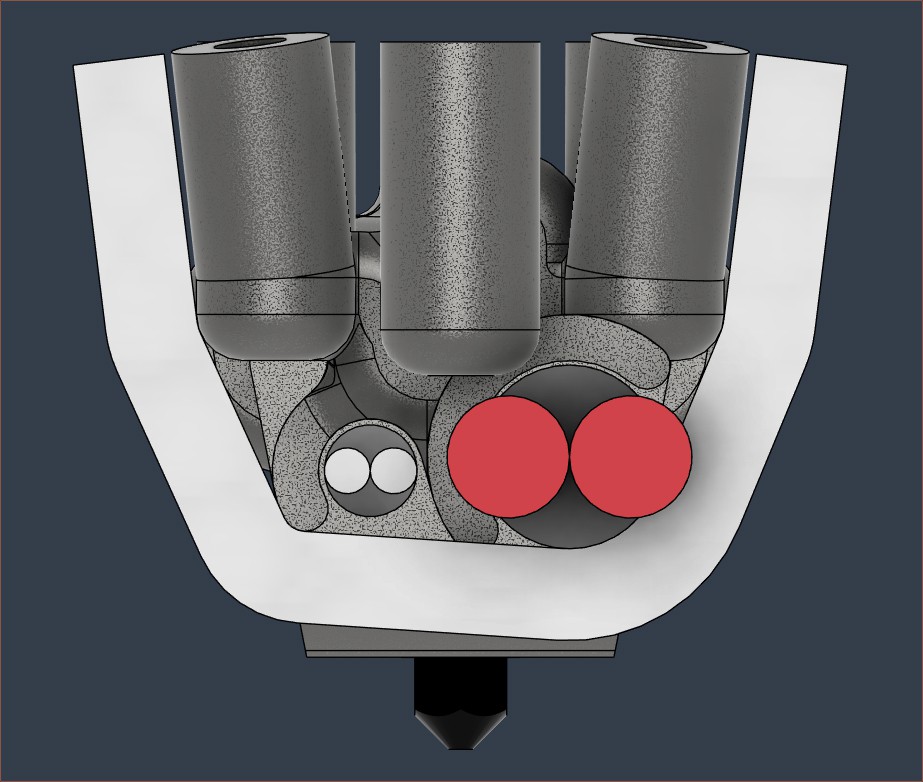

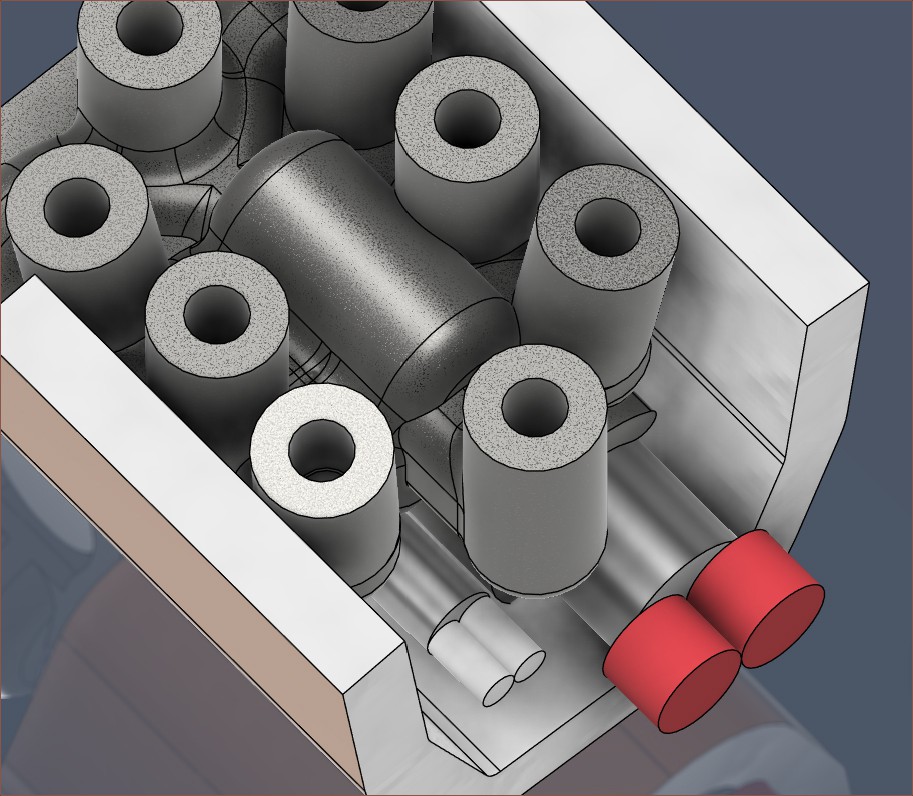

I first designed the heatblock how I've always designed ones in the past, but it seemed to use more material than I'd like:

I then had the idea to use the Shell command to create the minimum-material-needed heatblock. Only the "rounded" type works anyway. The straight-edged shell would've used more material for little benefit:

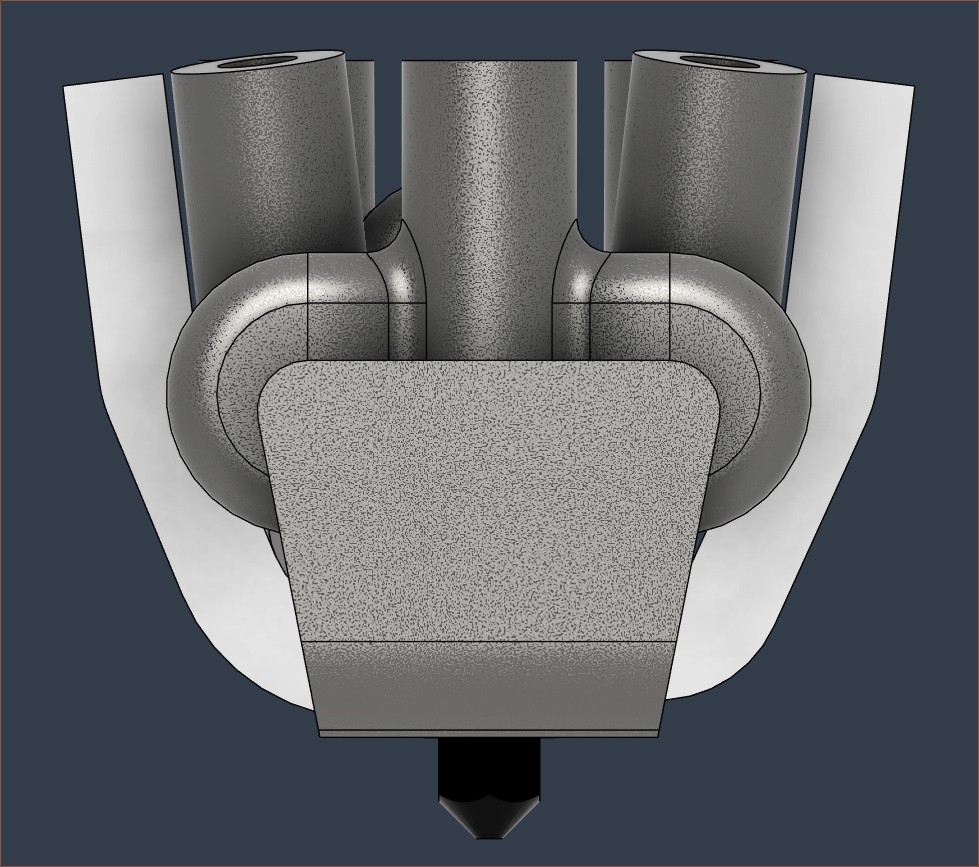

Next, I proceeded to delete a few faces, add the dowel holder, and fillet things:

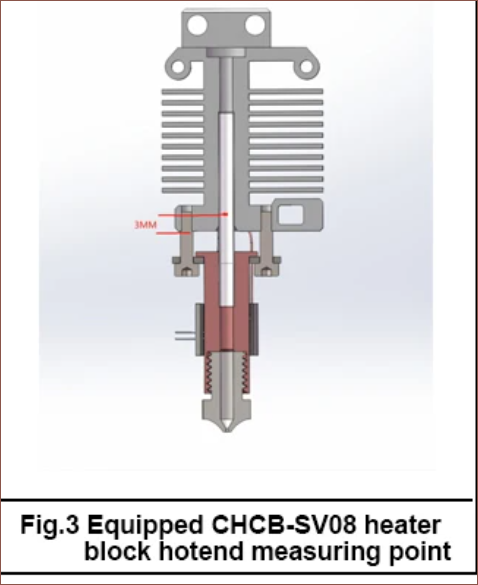

For the heater, an ideal solution might have been the clip Mellow came up with in their CHP hotend:

I don't think the clip alone is available, so I've modelled in geometry for a more traditional cartridge heater/thermistor, attached with nothing but boron nitride paste. They're not enclosed in part to save on material and to allow easy access of water to remove the cartridges if they need replacing.

Closing statements

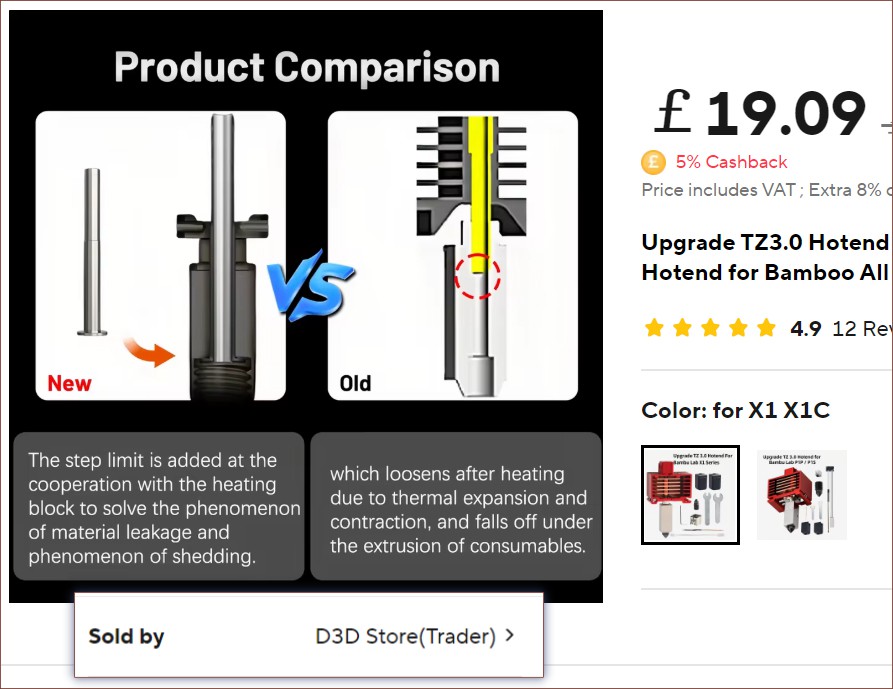

D3D, in their listing for a hotend they sell, does seem to confirm my worries about thermal expansion on this press-fit solution. I'm not sure exactly how thermally conductive this heatblock actually needs to be considering all the twists and turns inside of it, so printing in stainless-steel is still looking the most ideal.

If anything, I might just take a page out of XYZDims and see if PCBWay or JLC can print 0.5mm thin tubes which I drill on the inside. I might have to ream too, but a rougher surface finish would both help with heat transfer of the filament and would actually turn the drawback of those pre-bimetal, chinesium all-metal heartbreaks into a feature by promoting "clogging" when the input is off. It might also save money both in material savings of the printed part but in thin-wall tubing too.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.