Creating this project

I've learned something from #Coaxial Hotend [gd0144], which is that I need to get something to get somewhere. I've done a good job searching the interwebs for methods and applications of acheiving L^3 printing, but it's only when I'm doing the metephorical 'final exam' of creating an actual project -- where the pass mark is like 90+% -- that I'm going to be doing concrete things to get something that works in real life, reliably. In the situation of the hotend, having to reorder the heatblock is akin to taking the 'resit exam', which one wouldn't need to do if they passed.

Another thing I learned from that project is that refinements to the initially-created solution are largely mental-compute bottlenecked, thus #Tetent [gd0090] will not directly help speed up this part of the process. It would help speed up task management and log creation though, which do take up an unfortunate amount of my time. It actually took me 24 hours just to decide to even make yet another project, which essentially is SecSavr SuspenseSmall was supposed to be.

This project is also similar in vein to #Tetent TestCut [gd0139]. I'm likely not making it anymore, but it was still important because it really gave me some good ideas.

Requirements

Footprint

The number 1 requirement is that the main footprint (not including handle / feet) is in the aspect ratio 2:1:1 (LWH) and that the length does not exceed 60cm. The soft limit is about 50cm, but the printer would essentially fall into a different product class if it were any longer than 60cm. All the contact image sensors (aka scanner sensors) on AliExpress are essentially built for A4 paper, so it seems that the minimum boundary would be something like 50x25x25cm.

Laser

It took a while to decide on if the laser is a critical requirement or not, since it'll be mostly useless without any copper to sinter. However, airtight sealing and PCB fabrication are high priority items, and the laser in the Suspense directly (the laser itself) and indirectly (the stuff to make the laser more useful than a showpiece) increased the BOM by quite a bit.

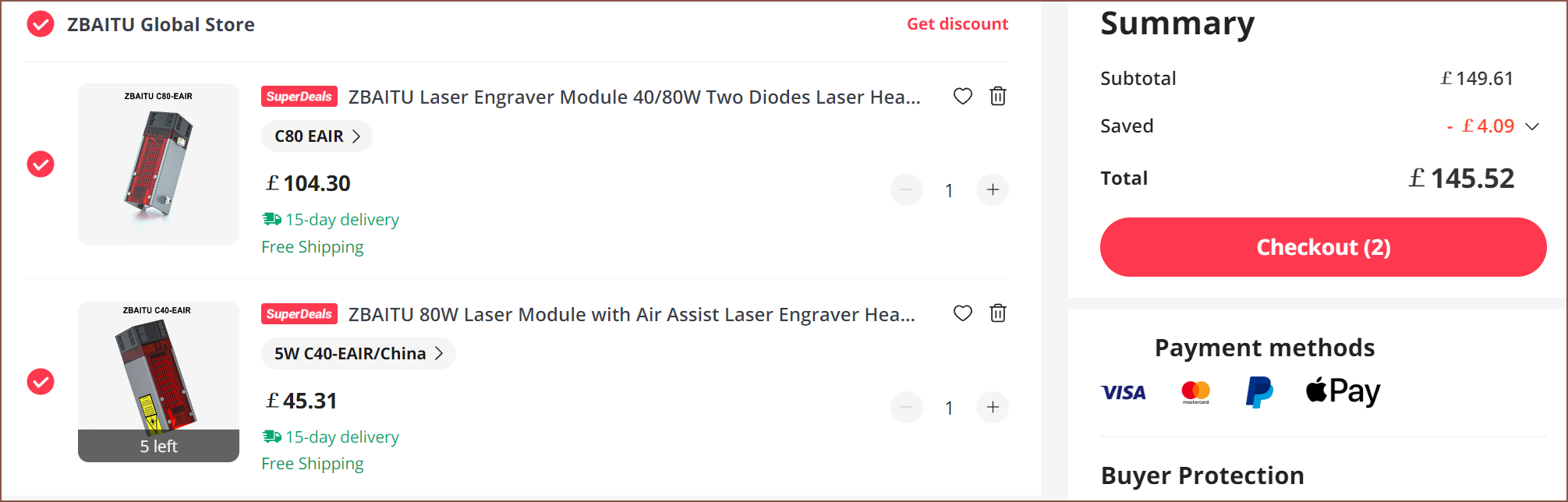

It certainly helps that the 5W laser is currently £45 and the 10W £100. Last year, the 10W was £140 alone, so it's almost like a By One Get One Free (+ £5 shipping) offer.

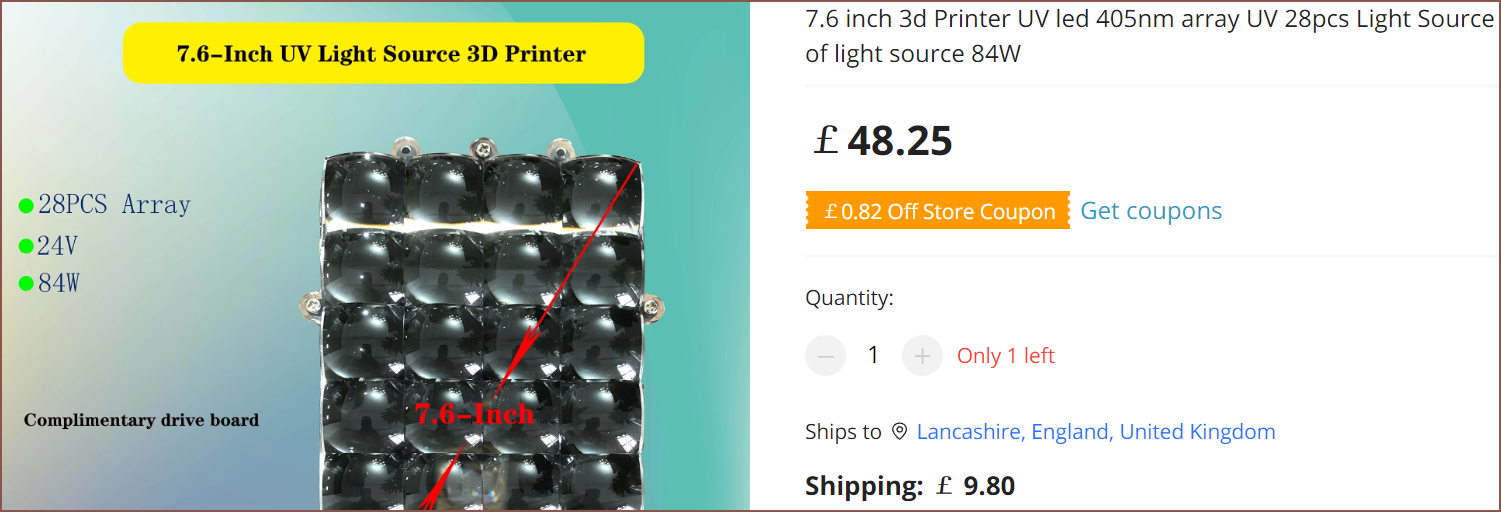

The 108W light source I had planned for the Suspense isn't going to fit. Conviniently, there's an 84W LED array now available. The light won't be as uniform, but it shouldn't matter that much since most of the MSLA printers use them.

Stand-out-from-the-crowd LED Display

Additionally, while a traditional 3d printer display is kind of useless for this kind of printer, there is something that I wanted in the very first SecSavr printer idea: a countdown LED display. It's more of a stand-out-from-the-crowd feature based on the idea of saving every second. The initial idea many years ago was a 7-segment, red LED, but now I'm looking for a white LED matrix because of the echo dot with clock:

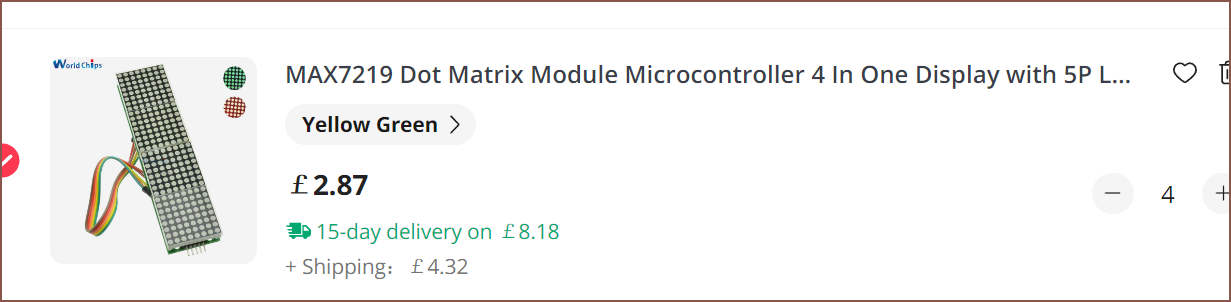

Looking online, the usual module size is 3.2cm. Thus, I may go for a 52cm long printer so that I can have an 8x128px display integrated into the printer-long carrying handle. I'll get a concept render out ASAP... if I can actually stomach the price for a proof-of-tech developer unit.

There's also no off-the-shelf white LED modules. I think yellow-green looks nice and is vaguely similar to my milky-green personal brand colour. This is a development unit, so a different display colour might make sense (like the icons for dev builds of web browsers).

It makes sense though, no? For a machine that only has a few states, the user (myself) would only care about 2 or 3 things, just like copying a file on a PC.

- Is there an issue that has stopped progress?

- When is the task going to finish?

- And, because the estimate for 2) has historically been inaccurate since the invention of the loading bar, what is the percentage of completion?

Why have a tiny screen you have to walk all the way up to to read this information, as on current 3D printers? Instead, something visible from across the room is better if you're going to bother having a display at all.

Price (and initial BOM list)

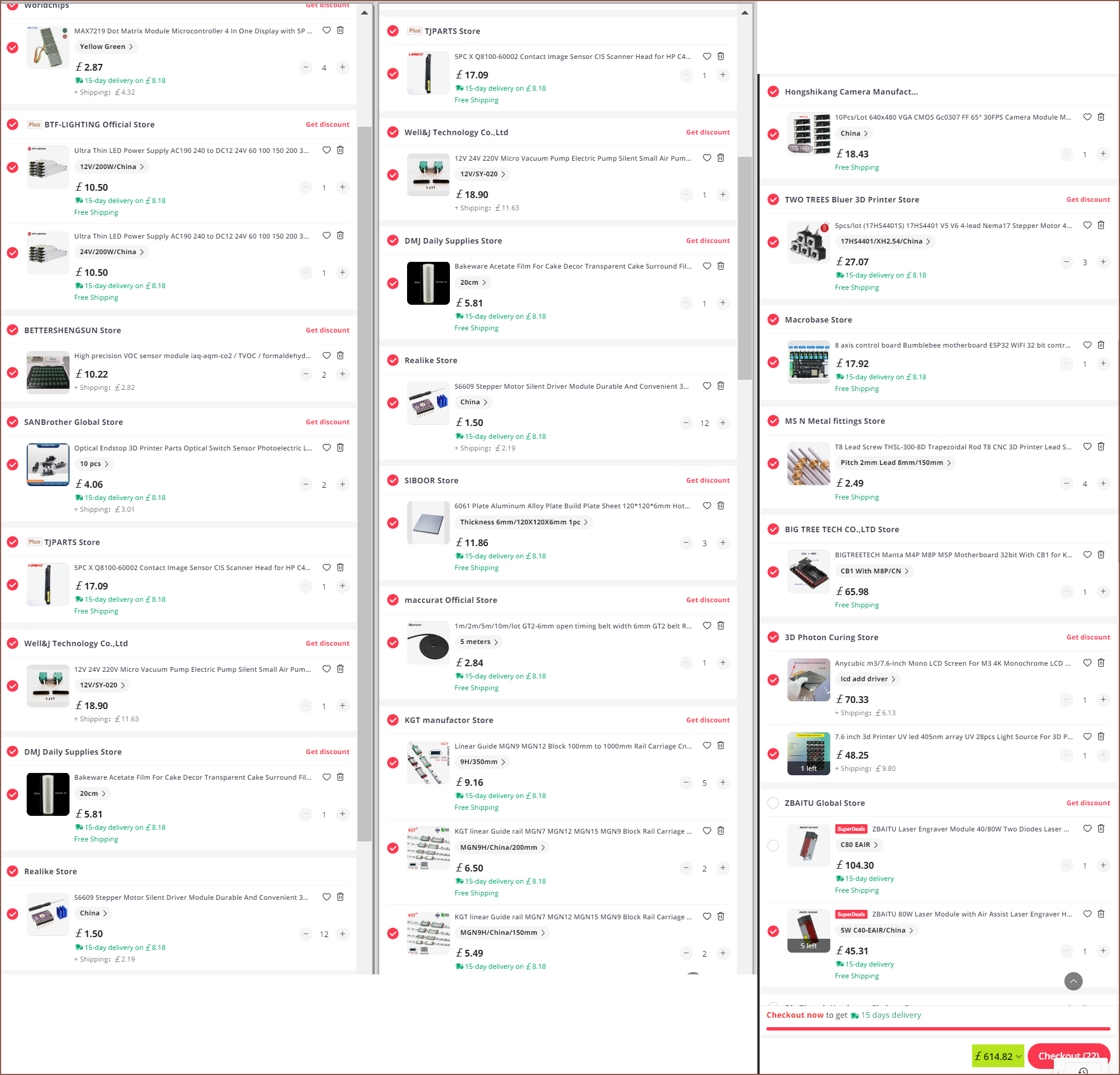

I threw some components (stepper things, cameras, linear rails...) into the basket, and it's already >£600 excl. VAT with the 5W laser, not including any frame components. As expected, the minimum viable cost is somewhat high, but the BOM only slowly increases as the print volume increases.

At this time, $1000 = £790 and I think that's what the final BOM is likely to be (excl VAT). Printers are seperated by price bracket, and hobbyists are usually only concerned with Under$200/500/1000/2000, so I guess it's still could be worth the effort instead of the sub$2000 SecSavr Suspense being the only L^3 printer.

Still, while I know I'd go over budget with the SecSavr Suspense, I find it unlikely that I'd go £800 over. The main advantage I can see is that I can try the automatic detaching idea from SLAminator on a smaller scale first. On the other hand, the Suspense answers one of the main questions on my mind: can it scale to a medium-large print volume?

Other notes

This printer is going to be a dual material one. This should allow for black and white 3d prints via dithering.

The build volume should be around 200 x 160 x 120mm. The Z needs to be at least tall enough for the laser module.

Questions I hope to answer with this project

- Can the CB1 drive the 4096x2560px screen at full resolution?

- Can the printer be made airtight?

- What should the implementation for resin lamination be?

- Will components overheat?

- Can I detach parts with a bed of nails.

- Can I clean the part using static electricity and the film?

- Can I sinter copper, ideally with a 5W laser?

- What happens in a power outage?

- Can I use the scanner sensors for auto material calibration?

- Can I use galvanised tube for the frame whilst having print dimensional accuracy?

- Can I keep the film tensioned correctly?

At the end of the day, I need to balance development time, development cost and development risk. There's good arguments for and against making a smaller printer.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The 5W laser + everything needed to actually use it is £150 (VAT incl). Considering that I just want to sinter copper and cut cardboard, I think that's a price high enough to justify trying to get the lowest wattage to work; only looking to higher wattages if it doesn't.

Are you sure? yes | no