-

Hardware Design is finished! Files available!

08/28/2023 at 12:55 • 0 commentsI'm pleased to say the hardware part is done! It's taken a fair amount of my free time, but I'm happy this part is done. It's possibly over-engineered and I'll take all criticism for that. 😅 My resin printing adventure has been somewhat costly, but I've gained valuable skills. I feel very confident that the parts I designed are adequate for the design. I've recommended some specific types of resin springing for the various parts on GitHub.

![]()

![]()

![]()

-

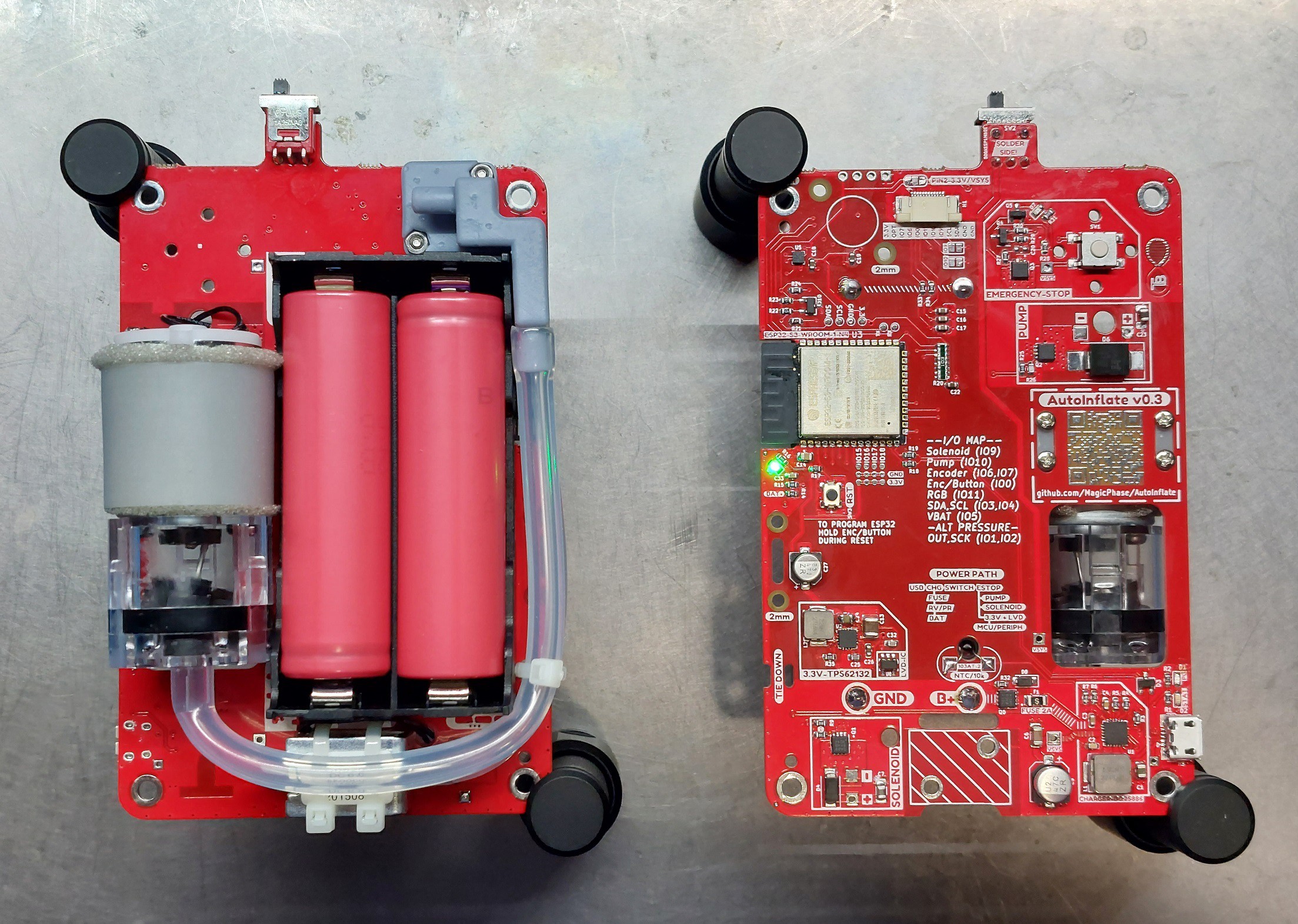

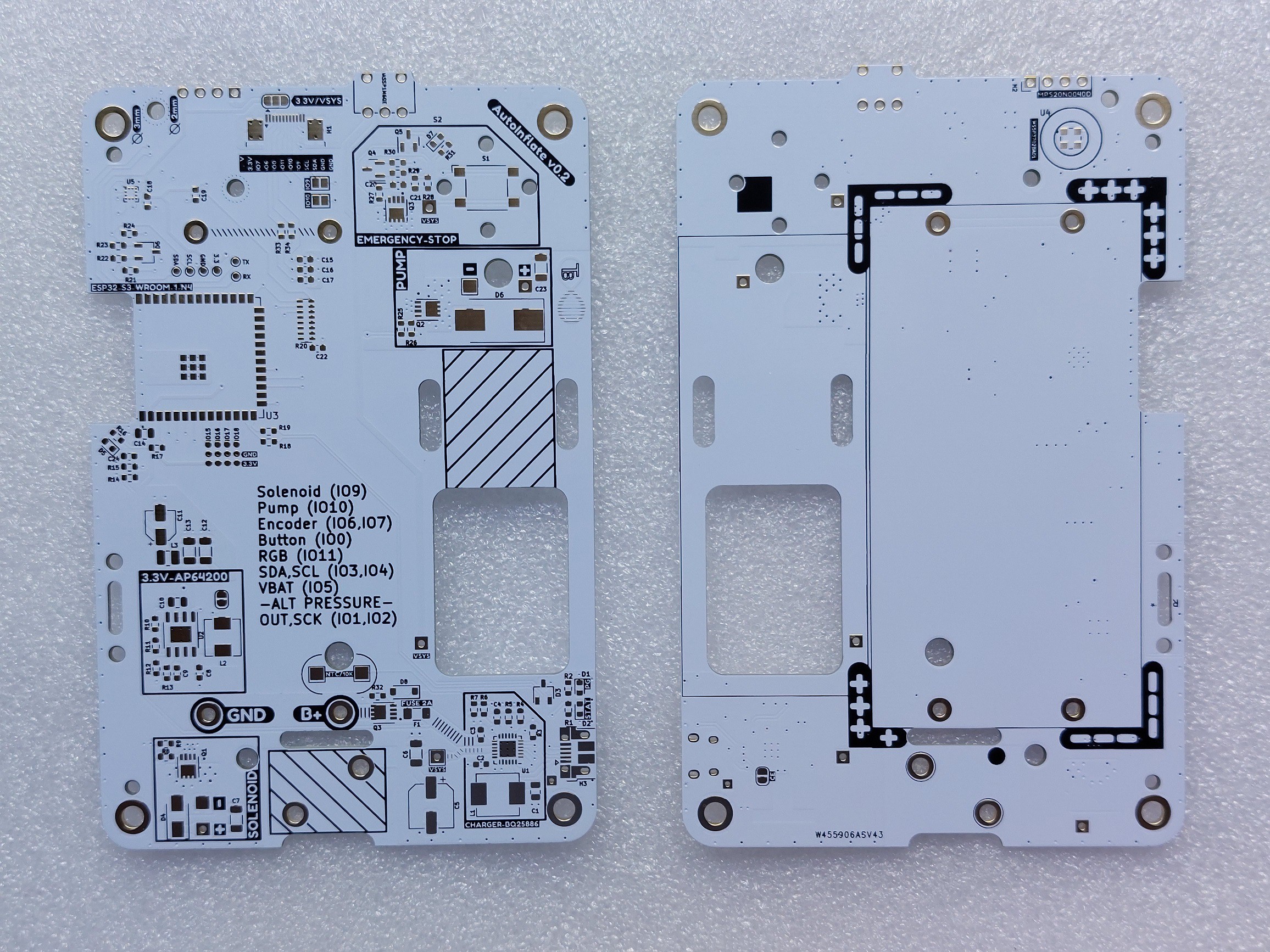

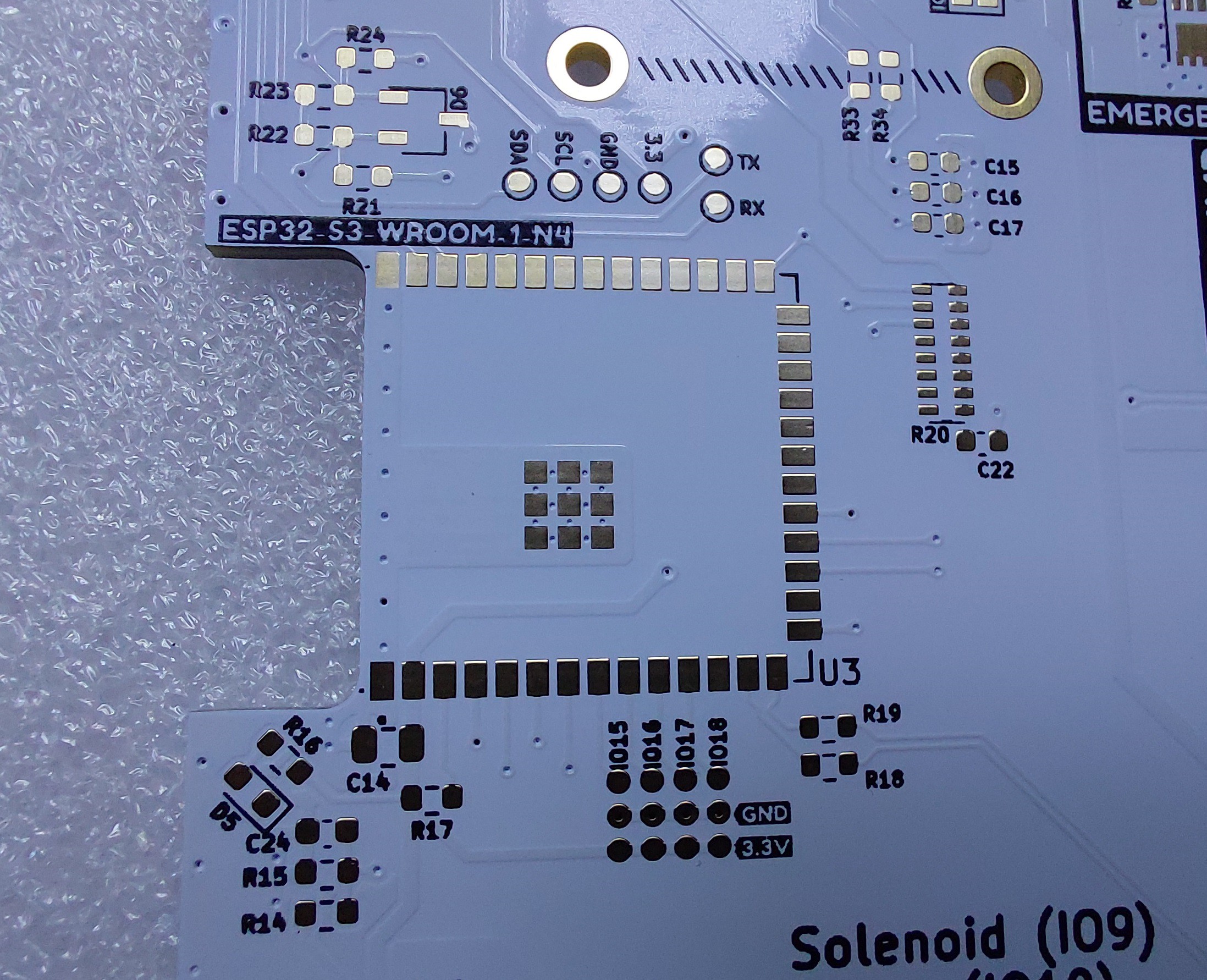

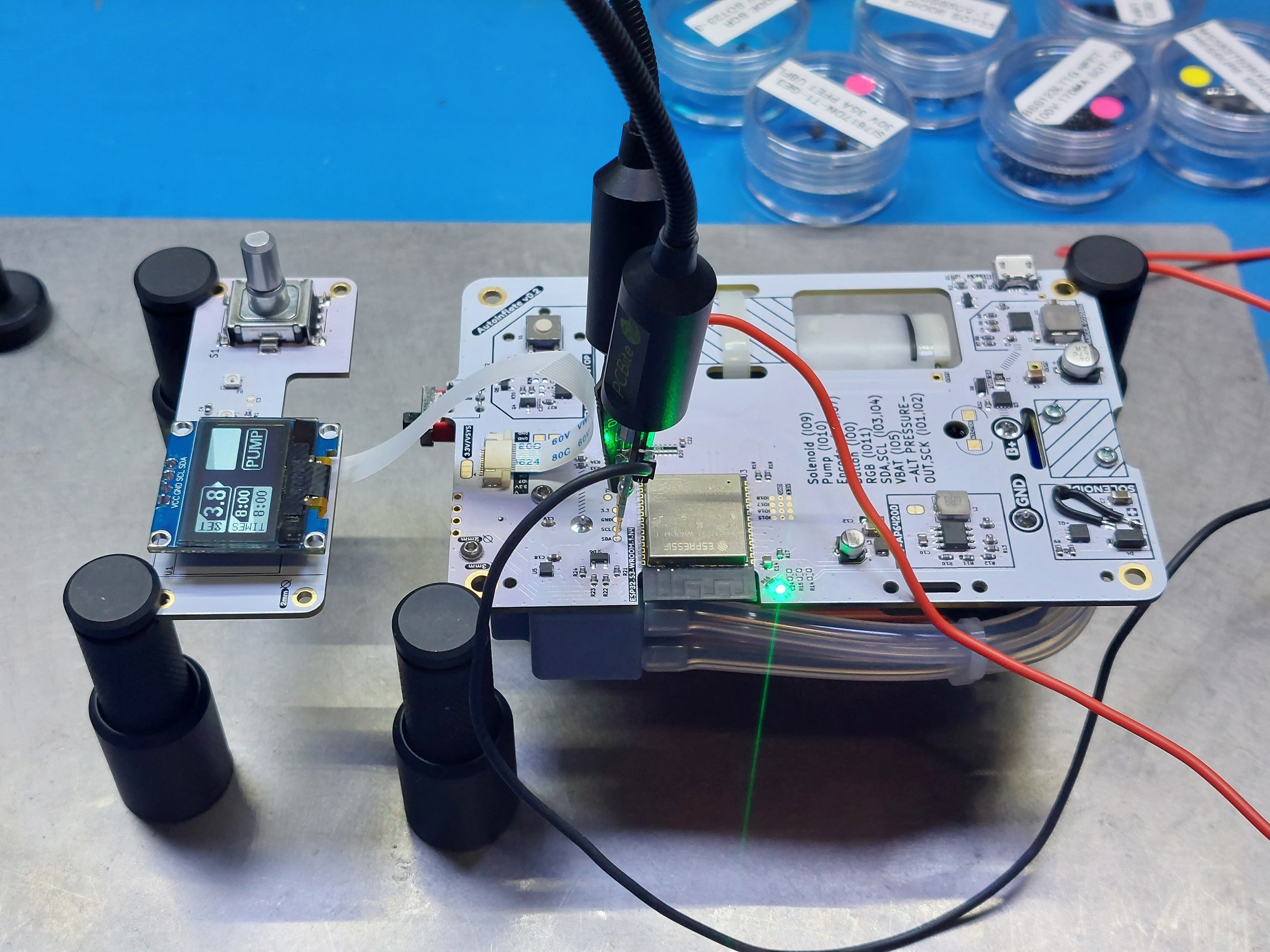

Next PCB version. (PCBWAY)

07/21/2023 at 12:25 • 0 commentsPCBWAY was gracious enough to sponsor this revision. With their support this project is one step closer to completion and I'm very pleased with the results.

A few changes from the last board to streamline things. While using dev boards can make things simpler, sometimes they can be difficult to integrate smoothly. I've decided to simply use a ESP32-S3 module directly for this project. This removes the issue of dealing with multiple USB ports and potential power supply conflicts. So we get all the power of an ESP32-S3 for a cheaper price with none of the hassle. This was an easy decision since this board requires reflow soldering. Adding the vanilla module doesn't add complexity and reduces the overall cost. The only "must have" sensor to satisfy the initial goals is a simply IMU/accelerometer which has also been added (MC3479).

Also included is a simple battery monitor line to an IO pin, reverse protection for the lithium cells, red indicator light for E-Stop function, and a change to a 12 pin flex ribbon vs the bulky standard header cable.

Thanks again to PCBWAY for these cool looking white and gold PCBs. Looking mighty fancy! ☺

![]()

![]()

![]()

![]()

-

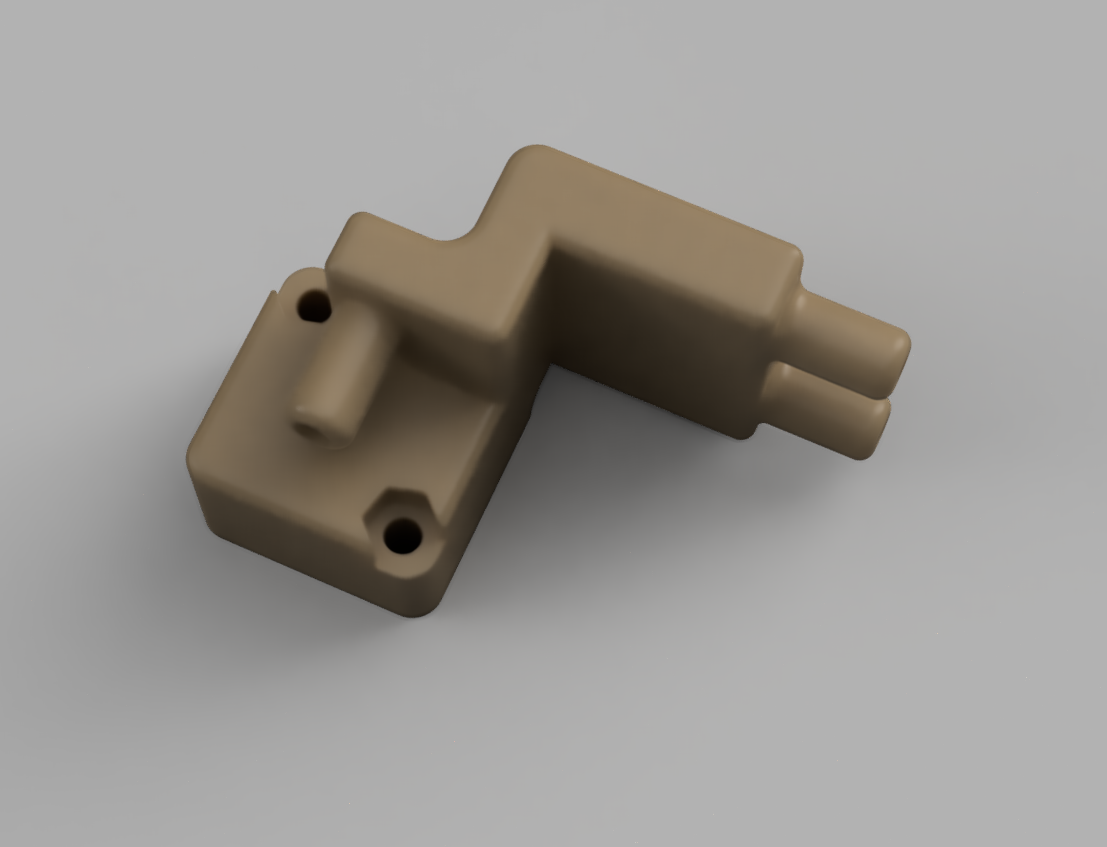

More modeling of the custom air manifold.

06/10/2023 at 14:14 • 0 commentsThe finished project will most likely include a few build options determined by part availability and cost. Specifically concerning the enclosure and a few custom plastic parts that will need to be printed.

One such part is a custom manifold that will cover the pressure sensor eliminating one air tube. I'm now getting my feet wet with resin printing and things are looking very promising. It's important that these parts are feasible to print either at home or by a 3d Printing service. I figure if I can print these at home, a service should have no problem. This part was made at home with a resin printer and Elegoo ABS-Like grey resin. This part requires high accuracy on a small scale to be air tight at low pressures. Because of this, it may require SLA printing vs Filament 3d printing.

![]()

-

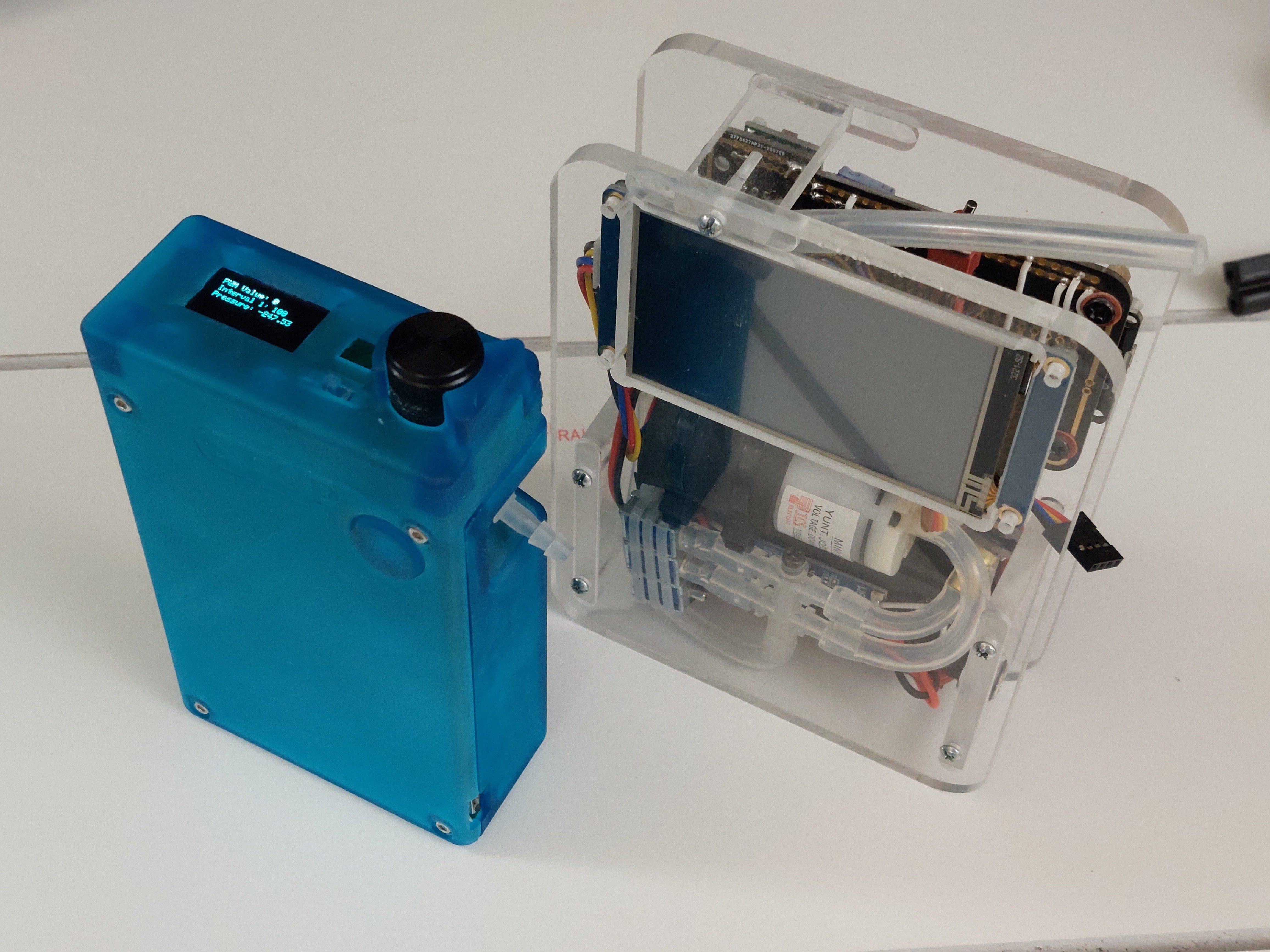

Working on the enclosure.

06/09/2023 at 11:02 • 0 commentsModeling and printing the enclosure has been a learning curve for sure! Along with the next revision of the PCB, the enclosure definitely needs some work to ensure a secure fit!

![]()

![]()

-

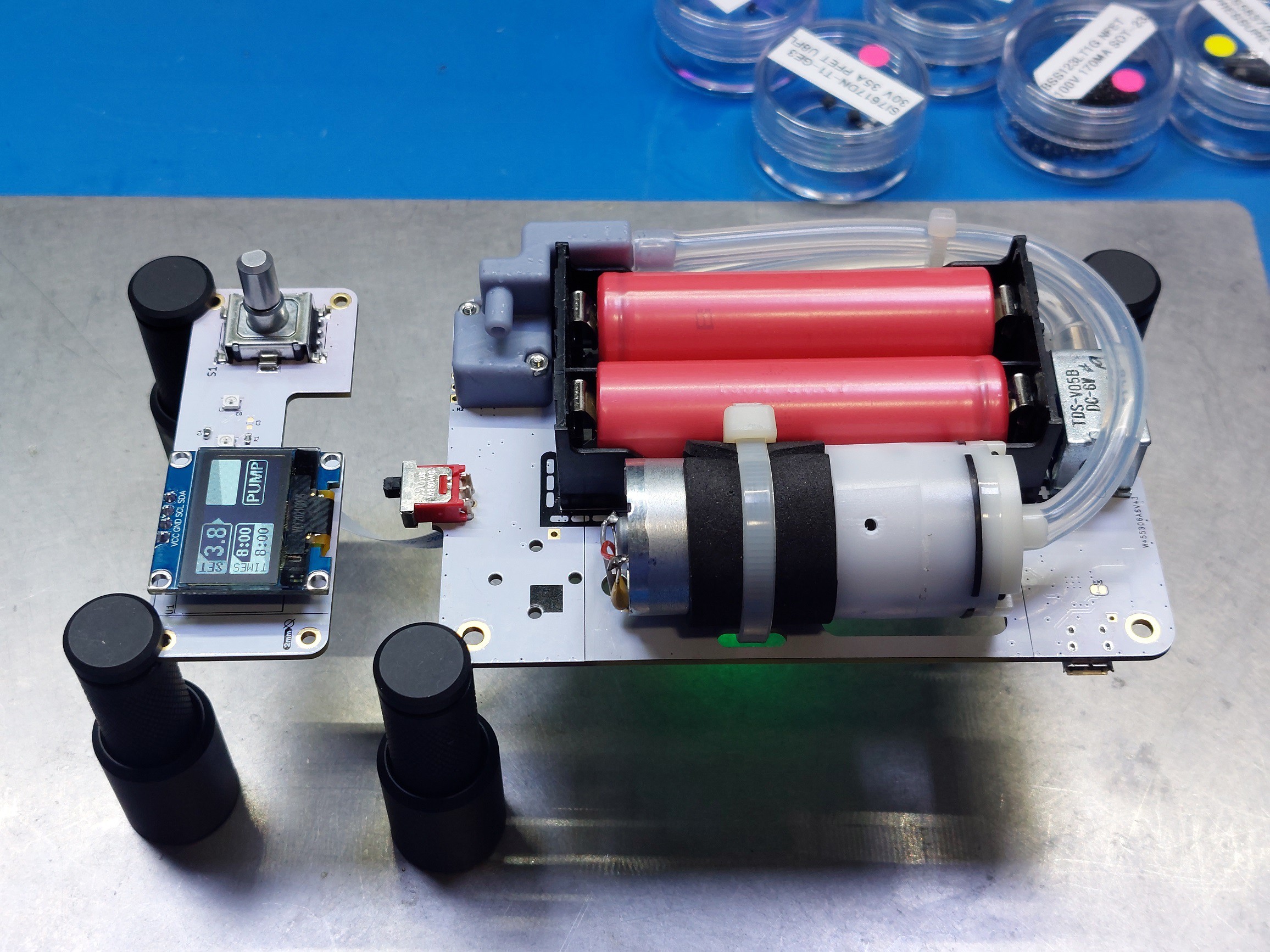

Feasibility Test Assembly

05/27/2023 at 12:07 • 0 commentsFinally received all the parts for the feasibility test and all the peripherals works as expected! YAY! There are already some minor changes I can make so that will be for the next version.

The casing needs to be finalized and printed so that the next item to tackle.

![]()

-

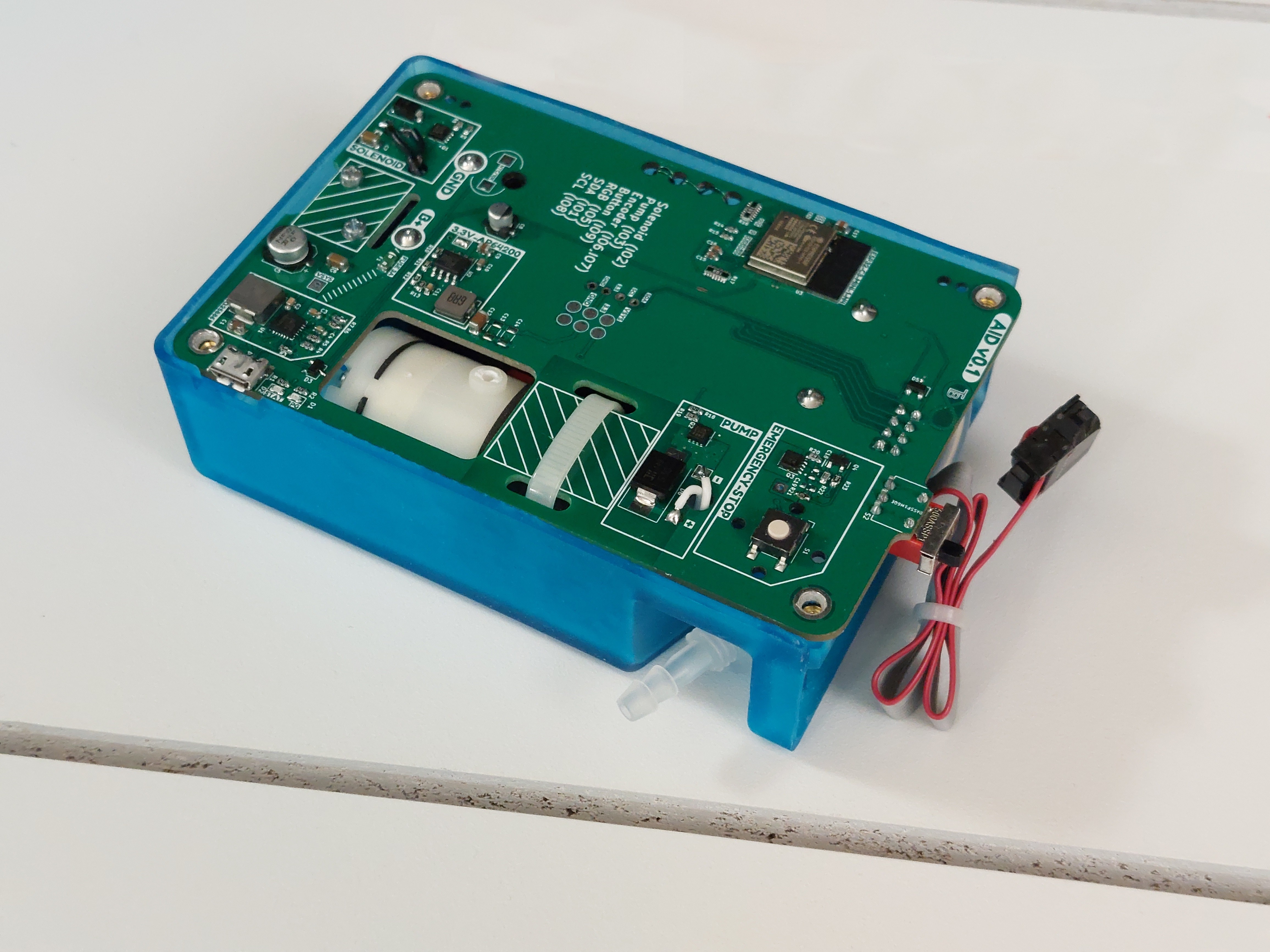

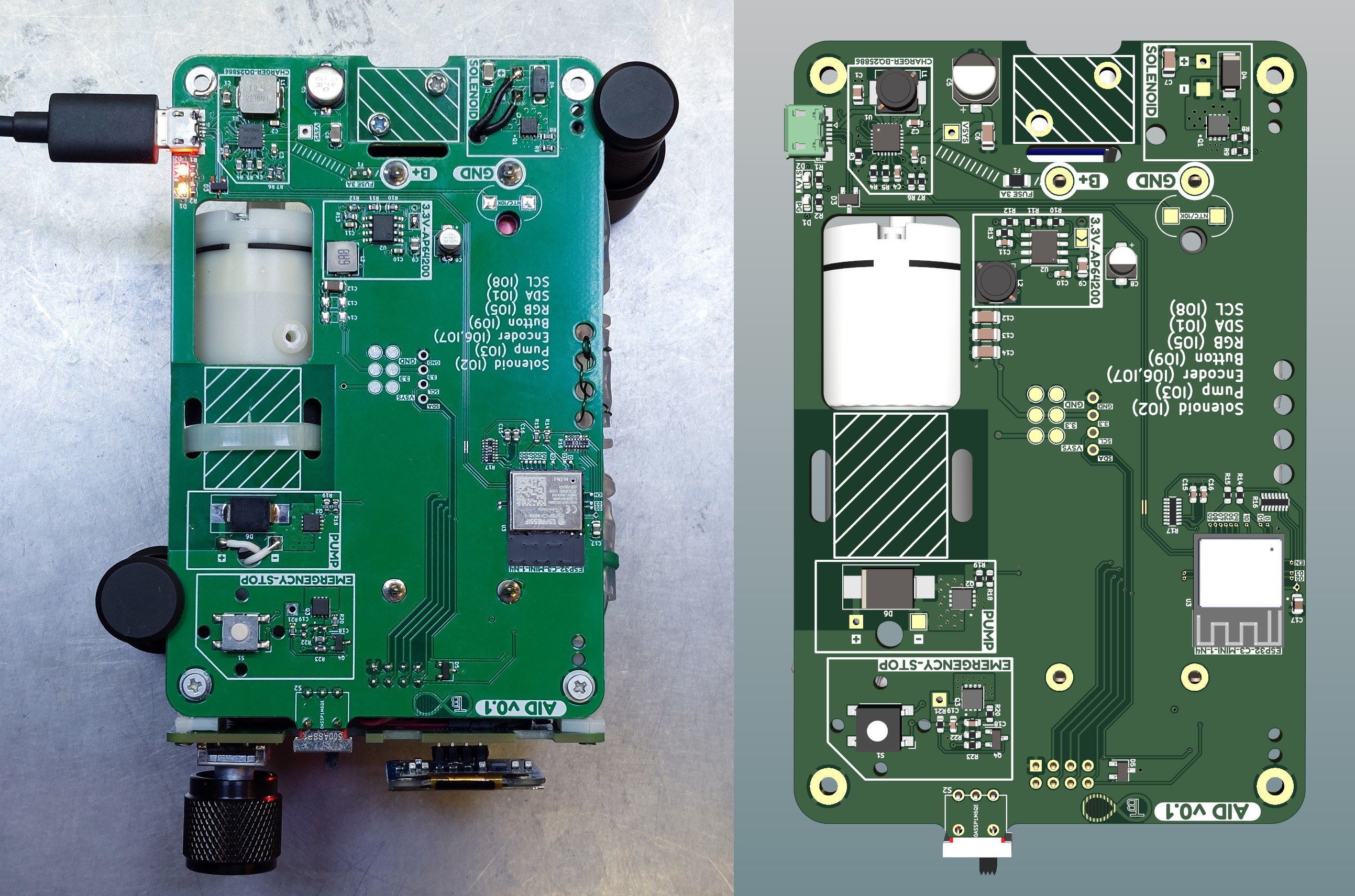

First Prototype PCB

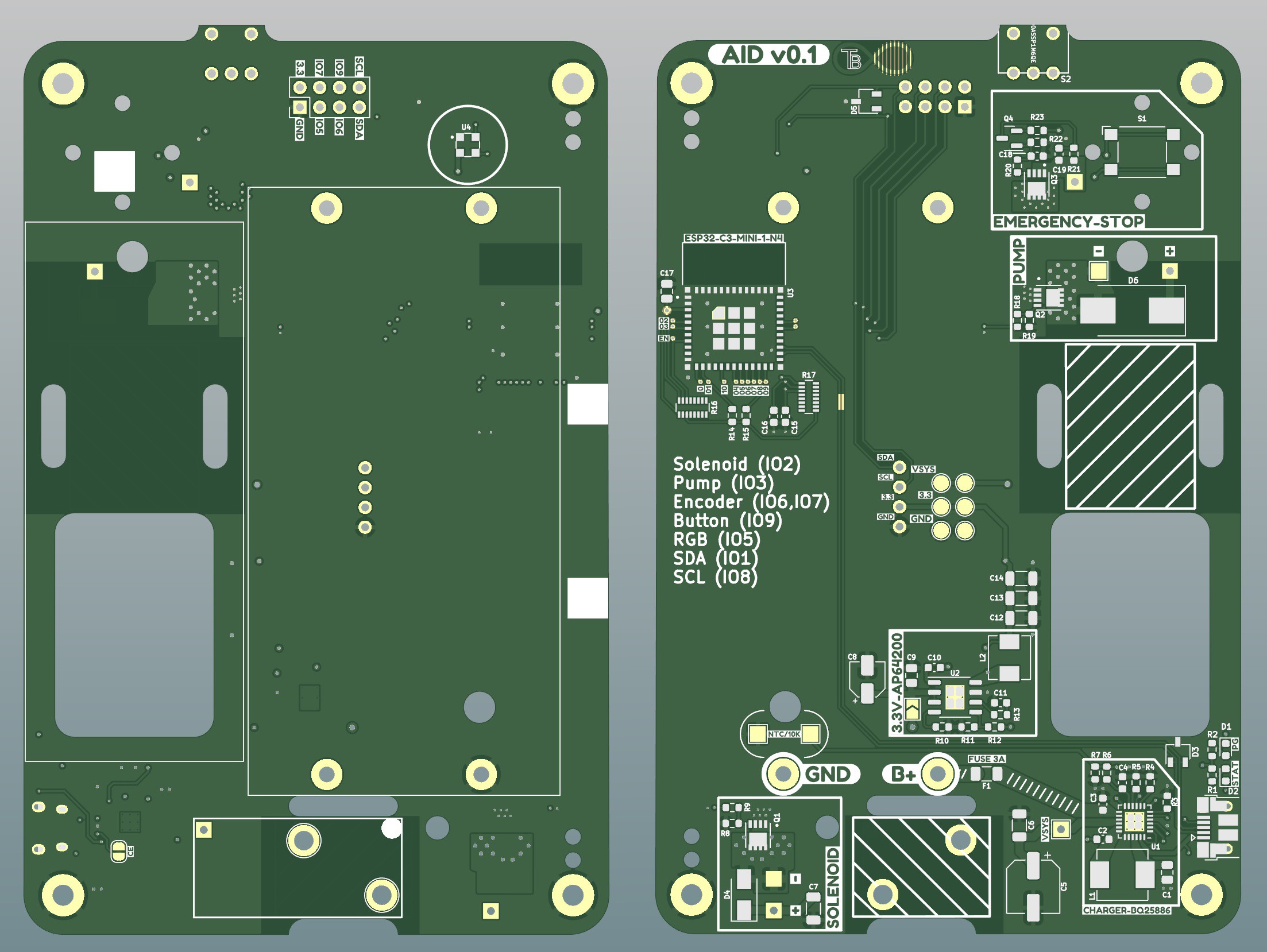

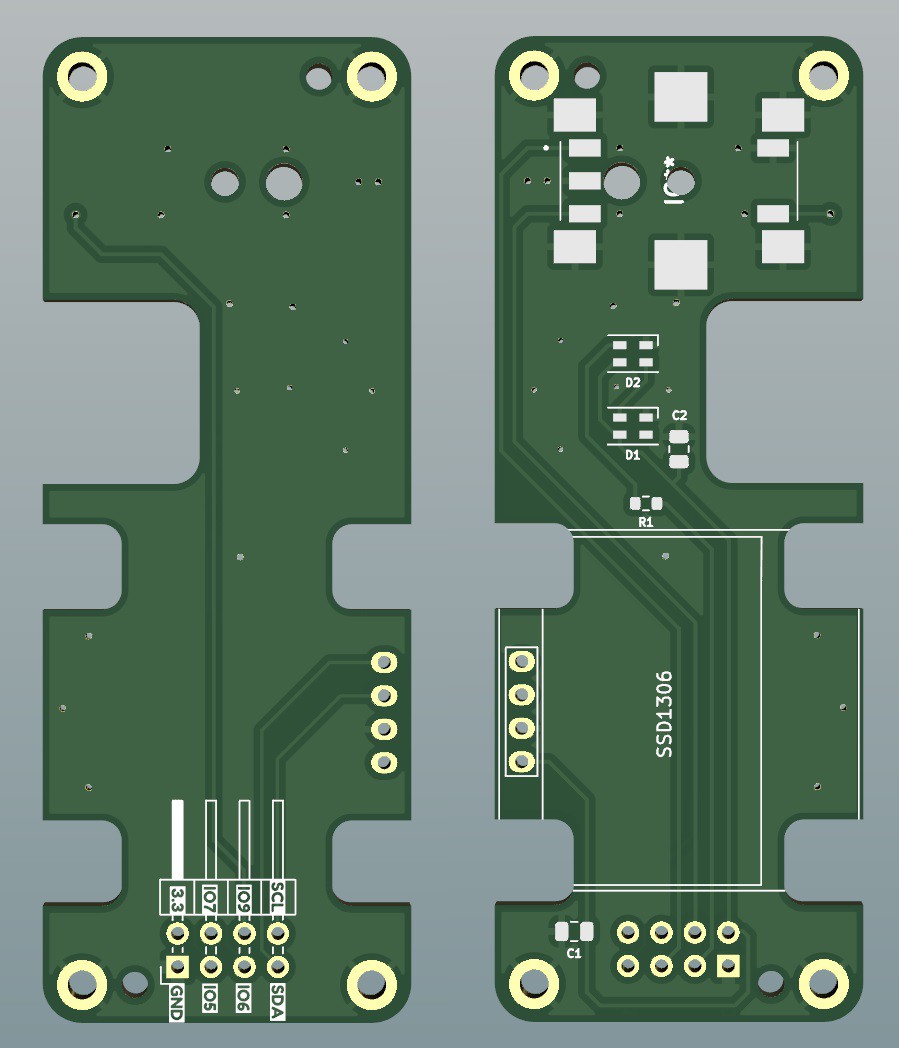

05/14/2023 at 07:16 • 0 commentsThis project is currently in the prototype stage and the first version of the PCBs has been ordered. While my first project was very much a throw-together DIY device, my goal is to create a design that can be implemented and modified for other potential use cases. This includes leaving ample space for additional MCUs and other sensors to be added in future versions for more enhanced features. This will be a feasibility test with the current component choices. This first test will give insight into potential changes and further refinements to the layout and case design.

This design uses two PCBs. The main PCB carrier board will all low-pressure pneumatics and batteries with the second PCB containing the display and encoder.

![]()

![]()

Auto-Inflate (AI)

An "auto inflation" device specifically designed for inflation style sensory/anxiety vests.