The title says it. I'm making a wood lathe primarily from garbage and dollar store items. Why? because that's what I do here. What makes it fancy? The electronics. Well, that's relative to the usual DIY lathe projects I see. There are many of them out there, and they are typically a hand drill or a motor with a switch attached to a board. Some of them look beautiful and work really well, but mine will be a tad different.

The main feature that makes this project different is that it will have closed loop speed control. With a lathe, speed control is pretty important, but I'm certainly not going to put together a complicated gear set to achieve it. I'm going to take a stab at controlling the speed electronically.

Here is a quick overview of the project. All of the details will be added in the project logs.

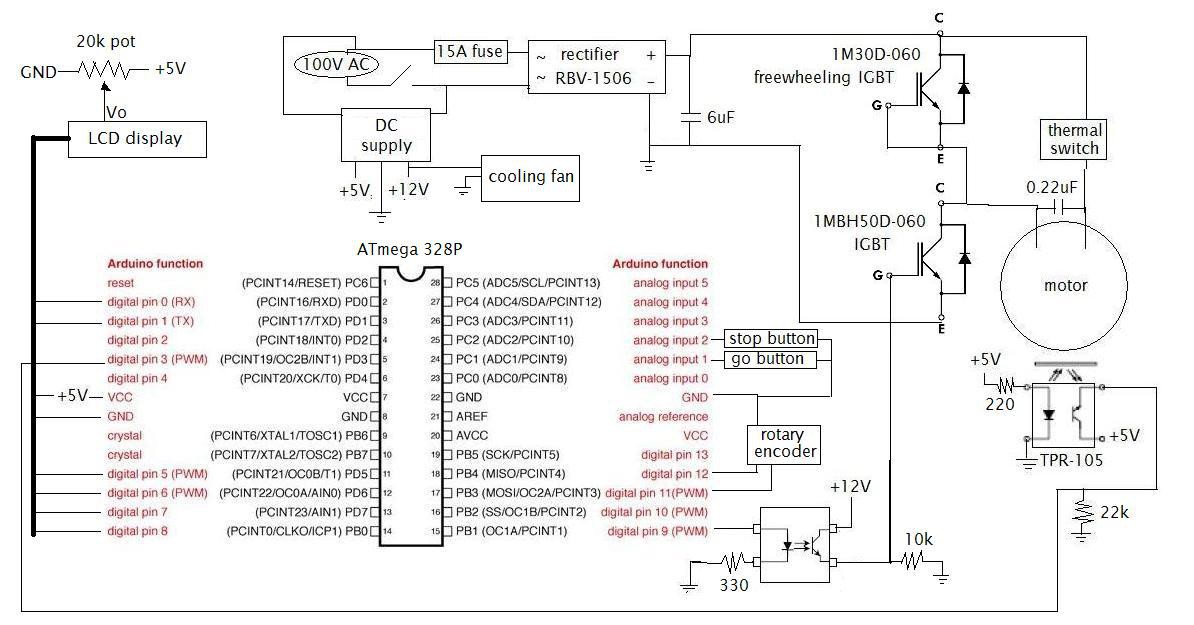

Attempt 1 of 2 (unsuccessful):

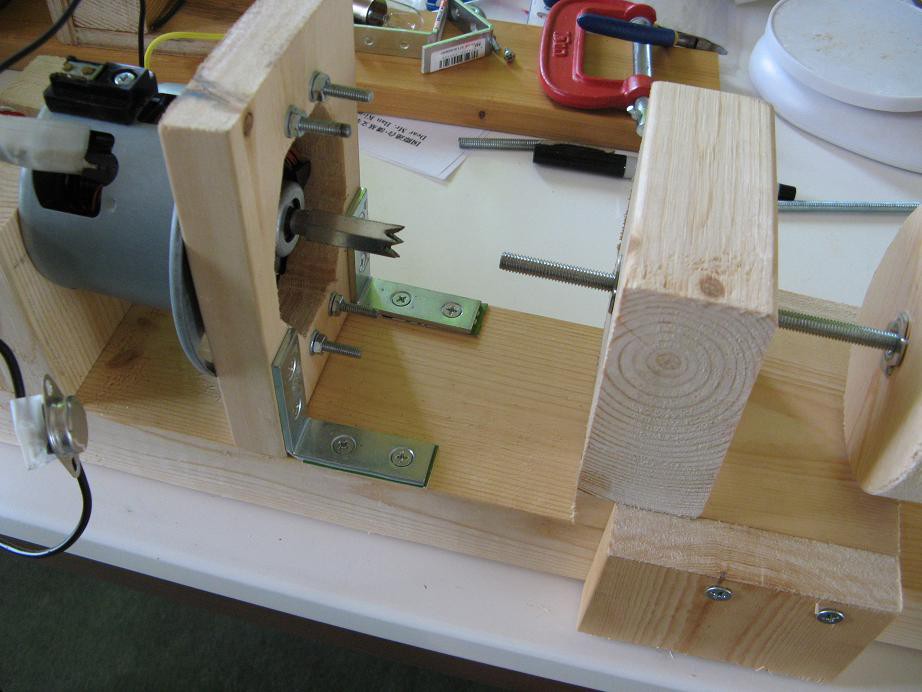

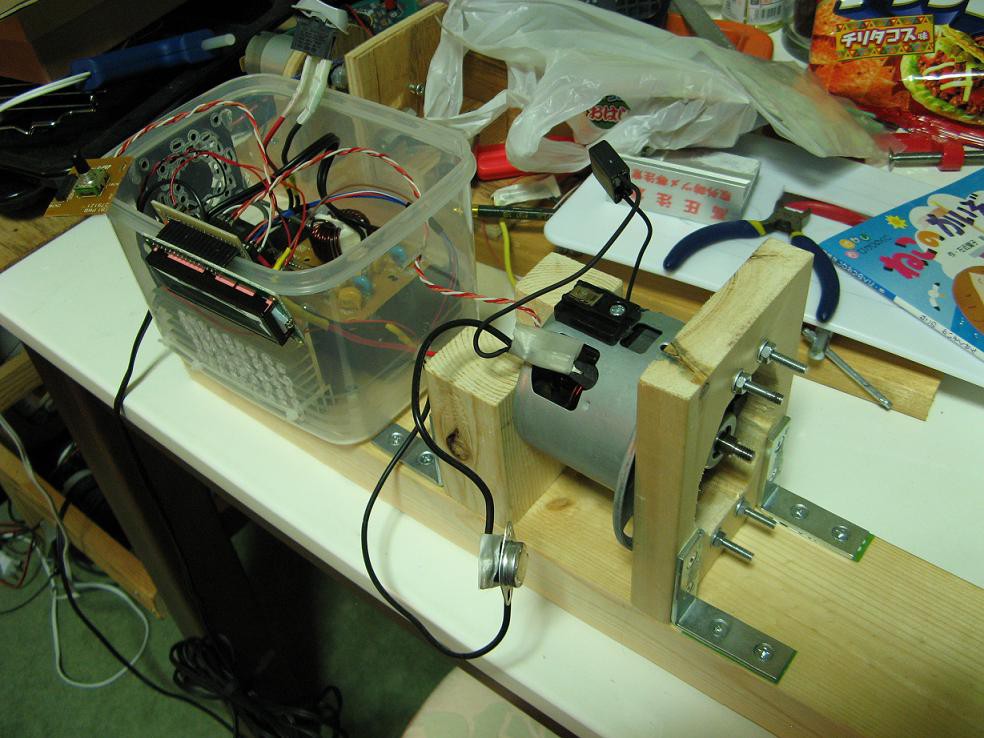

- 100V 1kW universal motor from a vacuum cleaner.

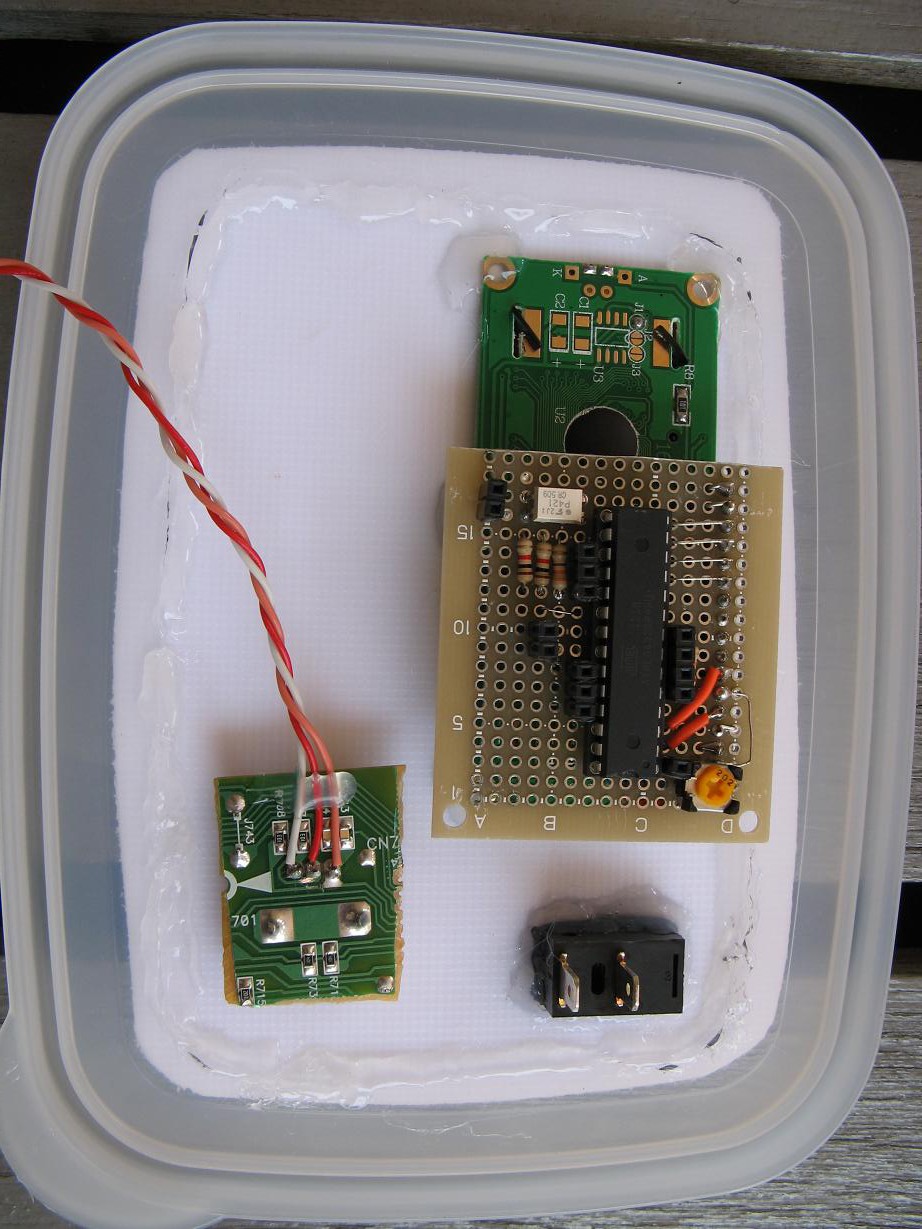

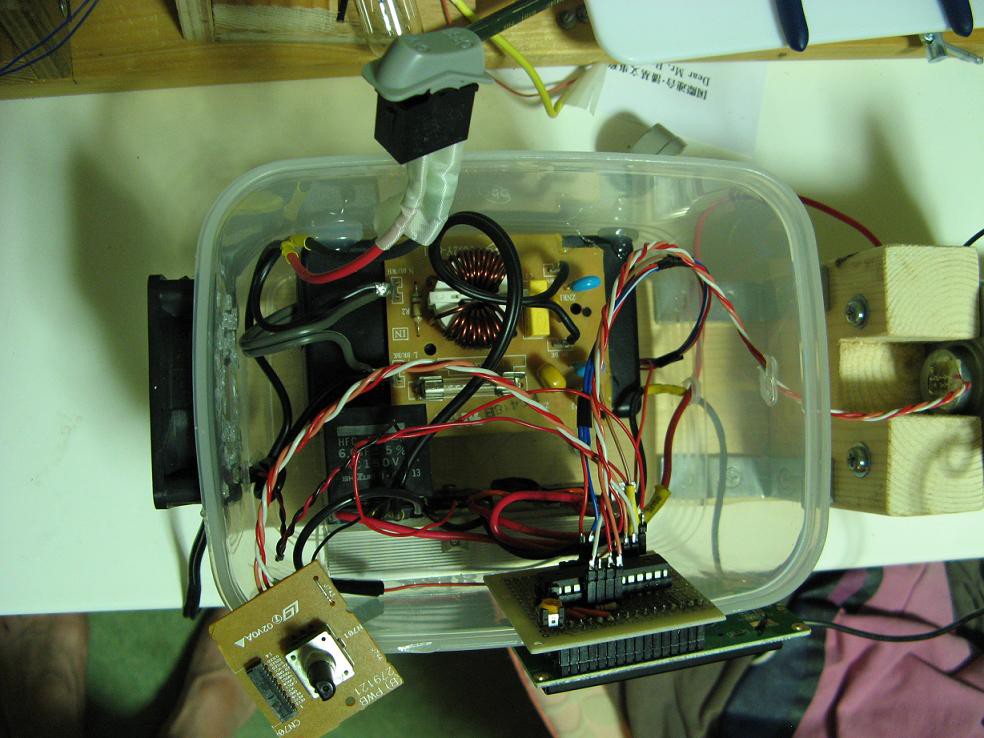

- high power rectifier and IGBT set from an inverter type microwave oven.

- ATmega 328 controller

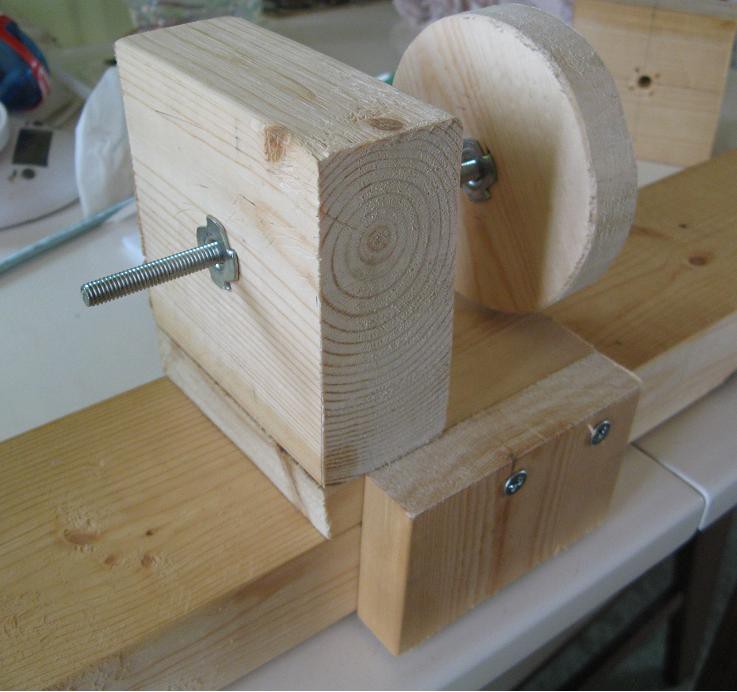

- structure made from 2x4 and other scrap lumber

- reflectance sensor attached to motor for tachometer

- LCD display on the control panel

- Here's the schematic (or click the one on the left for larger version)

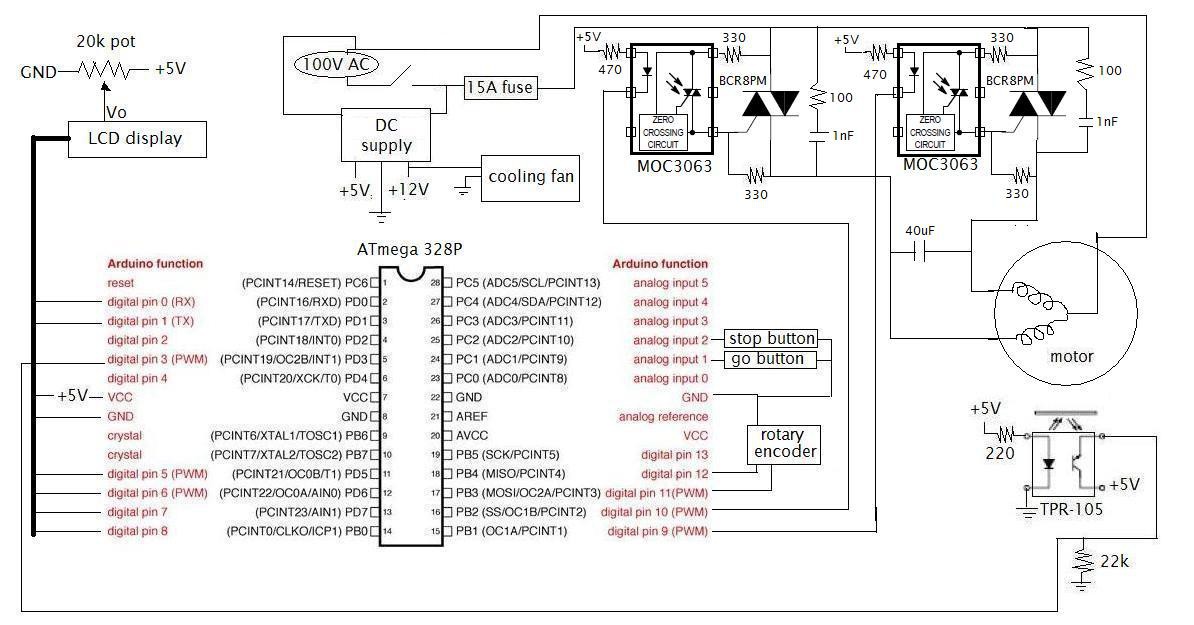

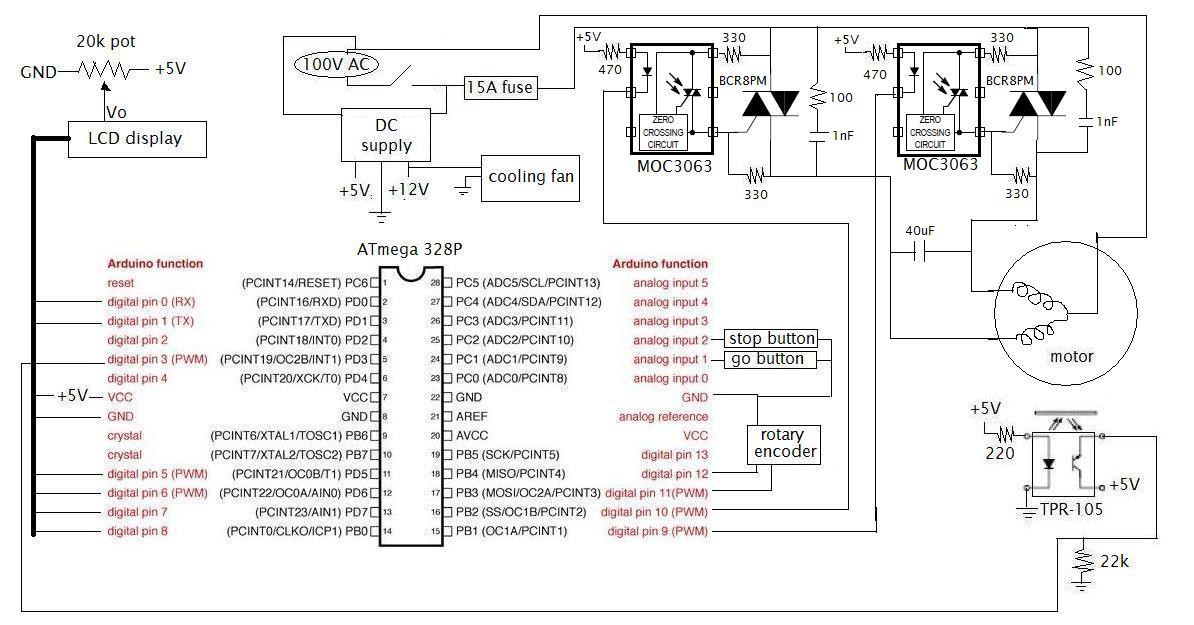

Attempt 2 of 2(also unsuccessful):

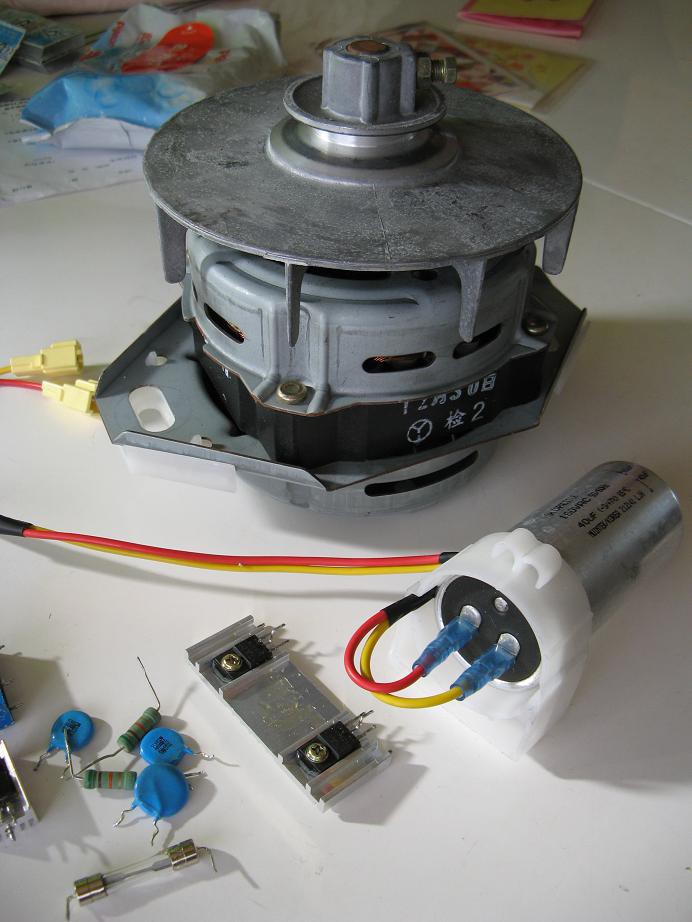

- AC motor from washing machine

- Triac pair (BCR8PM) and accompanying circuitry from washing machine

- MOC3063 triac drivers

- other parts from attempt 1

Here's the schematic:

shlonkin

shlonkin The controller doesn't use regular PWM. Rather it switches on full 60Hz cycles. Thanks to the MOC3063 drivers this switching occurs at zero crossings. For example a half power setting would switch on every other cycle.

The controller doesn't use regular PWM. Rather it switches on full 60Hz cycles. Thanks to the MOC3063 drivers this switching occurs at zero crossings. For example a half power setting would switch on every other cycle.

I'm not sure how I got here 9 years after the last update, but I am not surprised it did not work very well. You can reduce the speed by controlling the voltage, but you can not increase the torque of a motor with electronic control. The torque a motor can deliver is limited by the current though the motor. Another problem with vacuum cleaner motors is that they tend to have a quite low efficiency.

You can increase the output torque with a mechanical transmission, and that is exactly what most (older) washing machines do. They have a multi-V belt and two pulleys and a gearing ratio of about 1:20. Unfortunately such pulleys are quite big and hard to use in hobby projects, because they need some enclosure because of the pinching hazard. An alternative could be to mount them high up near the ceiling, a bit similar like the old flat belt distribution system.

A few years ago I took apart a washing machine (from a no-name brand), and to my surprise it contained a BLDC motor. The 3-fase driver on the controller PCB was burned out unfortunately. The motor itself is still waiting for some kind of application...