-

The commercial components

07/06/2023 at 14:16 • 0 commentsOk, full disclosure. I wanted to include one type of screw only, but the holes in the devboard were just a wee smaller than needed for everything to be M3. So PCB assembly screws are M2, and enclosure assembly screws are M3.

Lately at the Lab we have been exploring the use of hex nuts for fastening, instead of screw inserts. In principle it should work, but it does require a bit of adjusting and this time around time was of the essence. So, I had to go for the old, tried and expensive screw inserts. These little beauties are easily inserted into the bosses, and when fastening a screw they expand and the knurled section holds on to the plastic walls. I recommend using heat to insert them for enhanced grip. It works better than glue.

-

Protecting the LED's

07/06/2023 at 13:46 • 0 commentsThe LED's on top of the unit may look like common LED's, but they were carefully selected to provide readings through discrete near-infrared (NIR) spectroscopy. I'll let Jerry and the team explain it.

The important thing is that you want to protect those precious LED's from scratches, splatter, hits, dust, etc. So here is a sliding cover to prevent any of that.

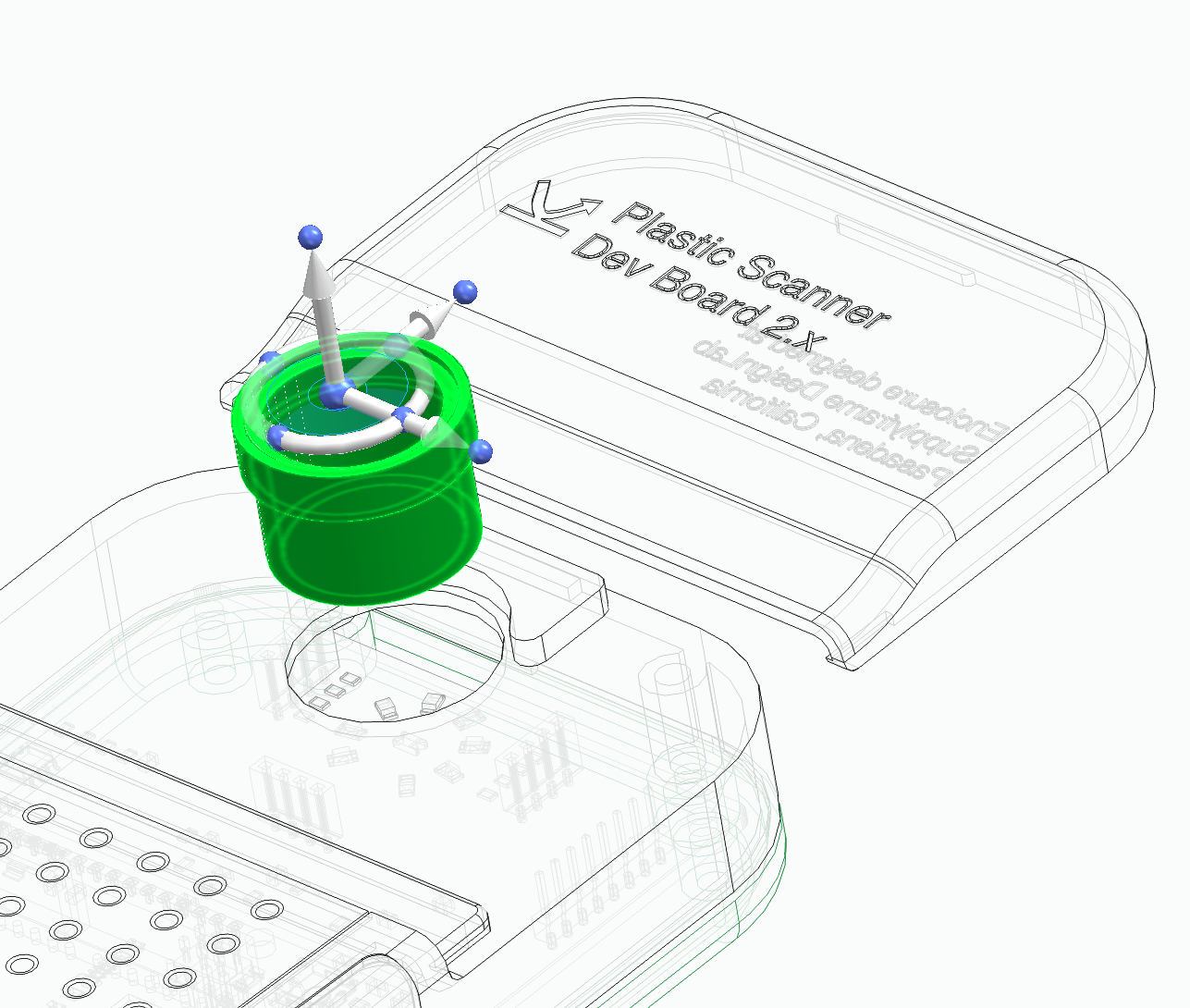

The cylinder that connects the LED array to the surface needs to be consistent in material and inner diameter. There is enough material to decrease or increase the diameter, and even the height. Once this part is fully calibrated, it can be easily glued to the top part of the enclosure

-

The concept

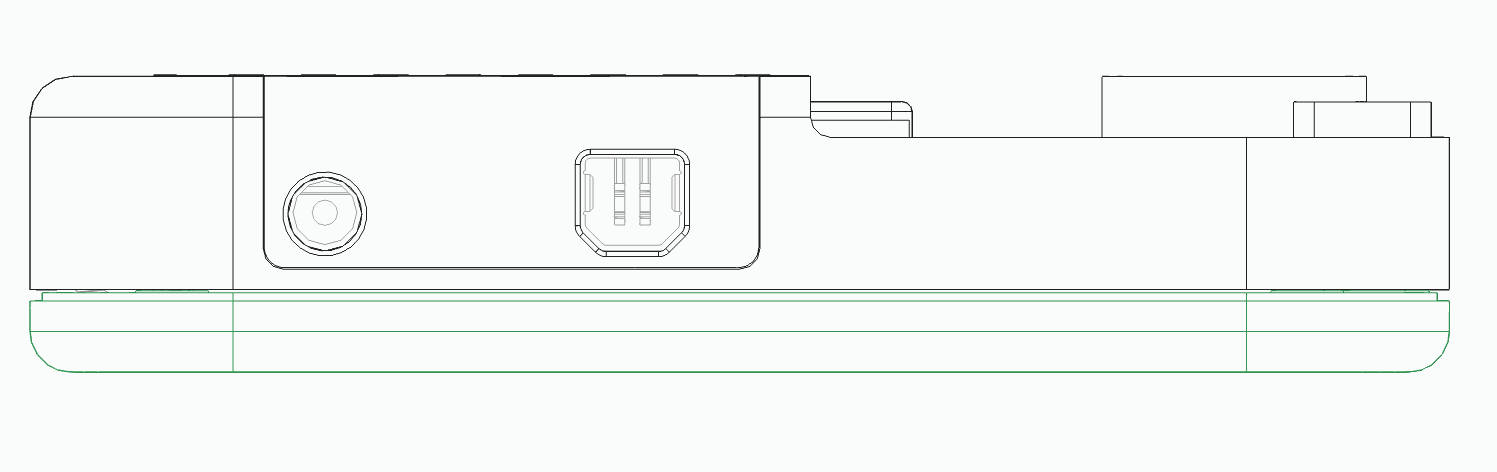

07/06/2023 at 13:26 • 0 commentsWatching Jerry's videos when comparing plastics made it clear that the unit has to be on a horizontal position for extended periods of time. Additionally, it needs to be connected to a computer at all times to send the data, and it needs an external source of power.

Therefore, it was important that the unit's front surface be at the same height as the LED's , in case they have a plastic sample that extends a little over the perimeter of the LED's cylinder. Since the unit would not work without external communication and power, the ports need to be easily reachable at all times.

-

Middle journey

07/06/2023 at 13:19 • 0 commentsI asked Midjourney to do my job and it came up with interesting proposals, but the shape factor was completely out of whack. So after these I asked it to come up with similar things, but rectangular.

![]()

I read about a very cool option in Midjourney which is the possibility of adding a sketch and asking the AI to generate something inspired (or fitting) to these parameters. So I did a few quick sketches to see where it headed to. Results were ok, not amazing. "You need to work on your prompts", I hear a crowd saying.

![]()

![]()

![]()

![]()

-

The inception

07/06/2023 at 13:06 • 0 commentsThe ultimate goal for Plastic Scanner is to become a fully portable unit. That looks increasingly doable. Before getting the production unit ready, there are a few things to smoothen out. I saw a few in their Discord server (and that sound all too familiar!):

- Testing testing testing

- "Great! this is the perfect component! What do you mean "0 in stock, Ship date estimate 2025"??"

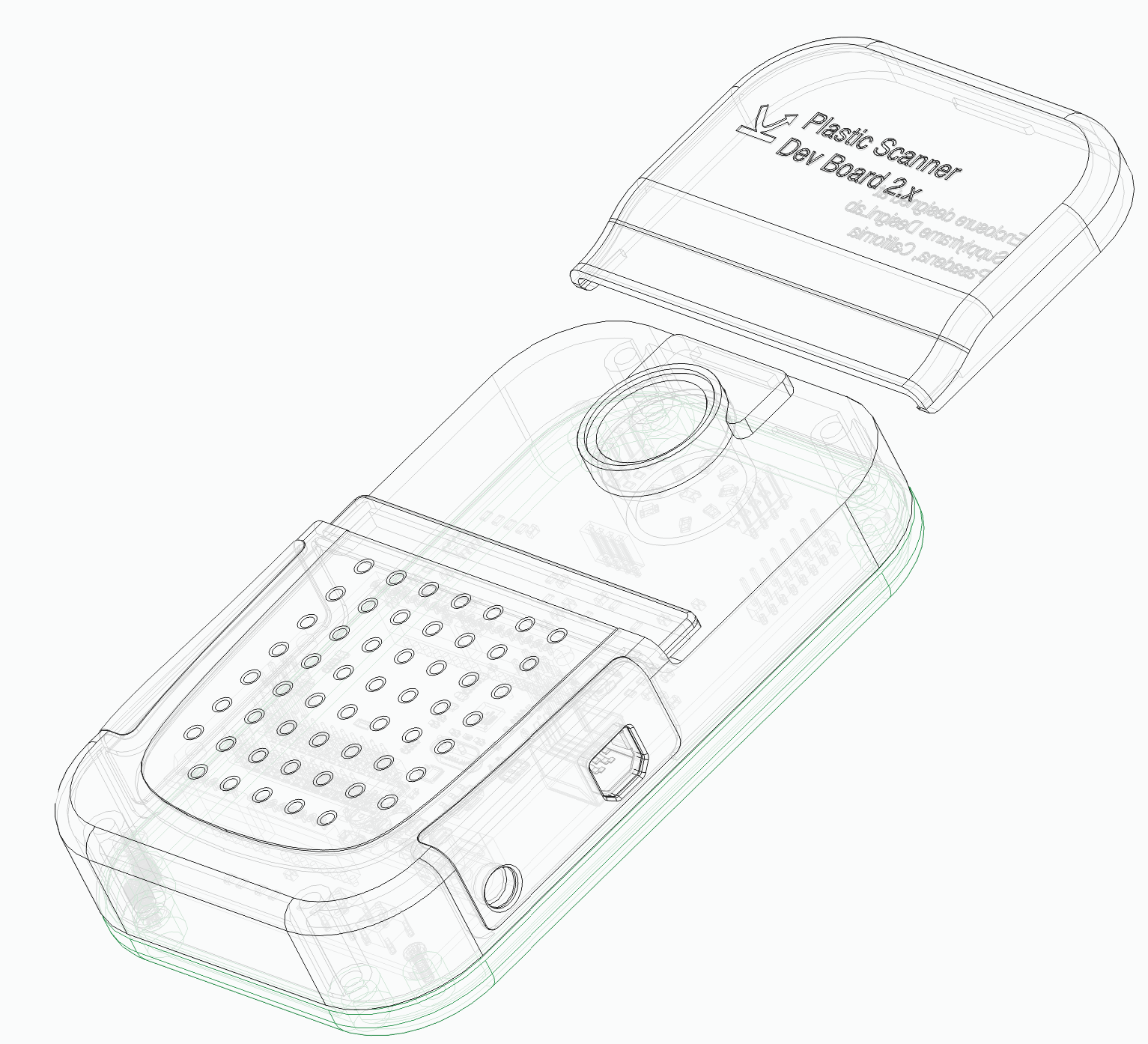

During the testing phase there will be a lot of plastic samples, and the devboards are going to be moving around a lot. PCB's are pretty sturdy, but a lot of touching cannot be good for them.

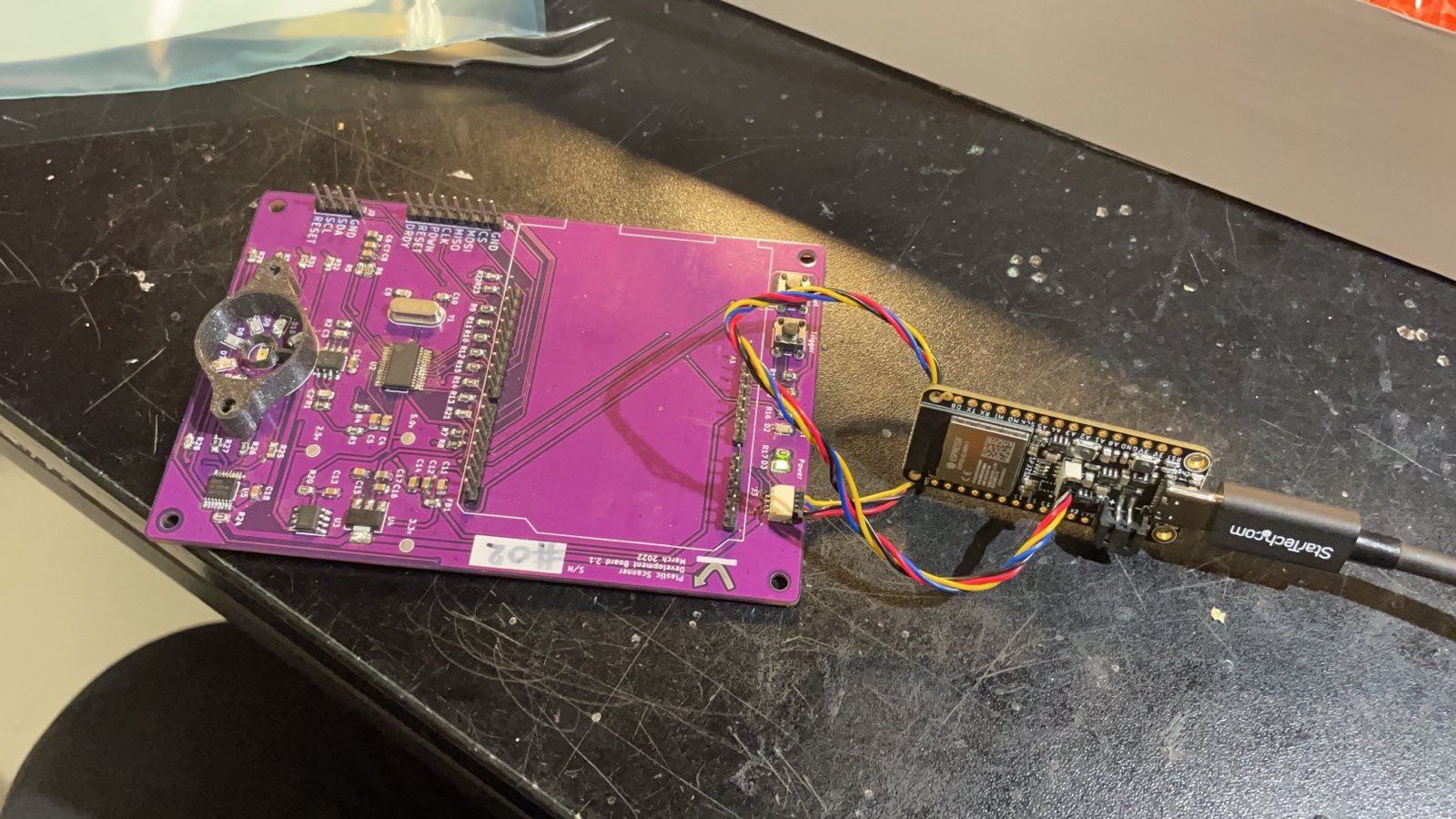

I took a long look at their devboard in order to see what I would be working with.

![]()

![]()

The first devboard was an Arduino UNO, but they are still exploring different options, one of the chief factors mentioned above is the supply chain resilience. There are a few factors that remain the same, however: LED's array on top of it, shape, assembly holes.

2023 DL Builds - Plastic Scanner Enclosure

An enclosure for PlasticScanner's prototyping unit

Supplyframe DesignLab

Supplyframe DesignLab