-

New Laserdriver is assembled

08/11/2023 at 15:50 • 1 commentWe assembled our latest version of the laser driver and it is ready for testing:

![]()

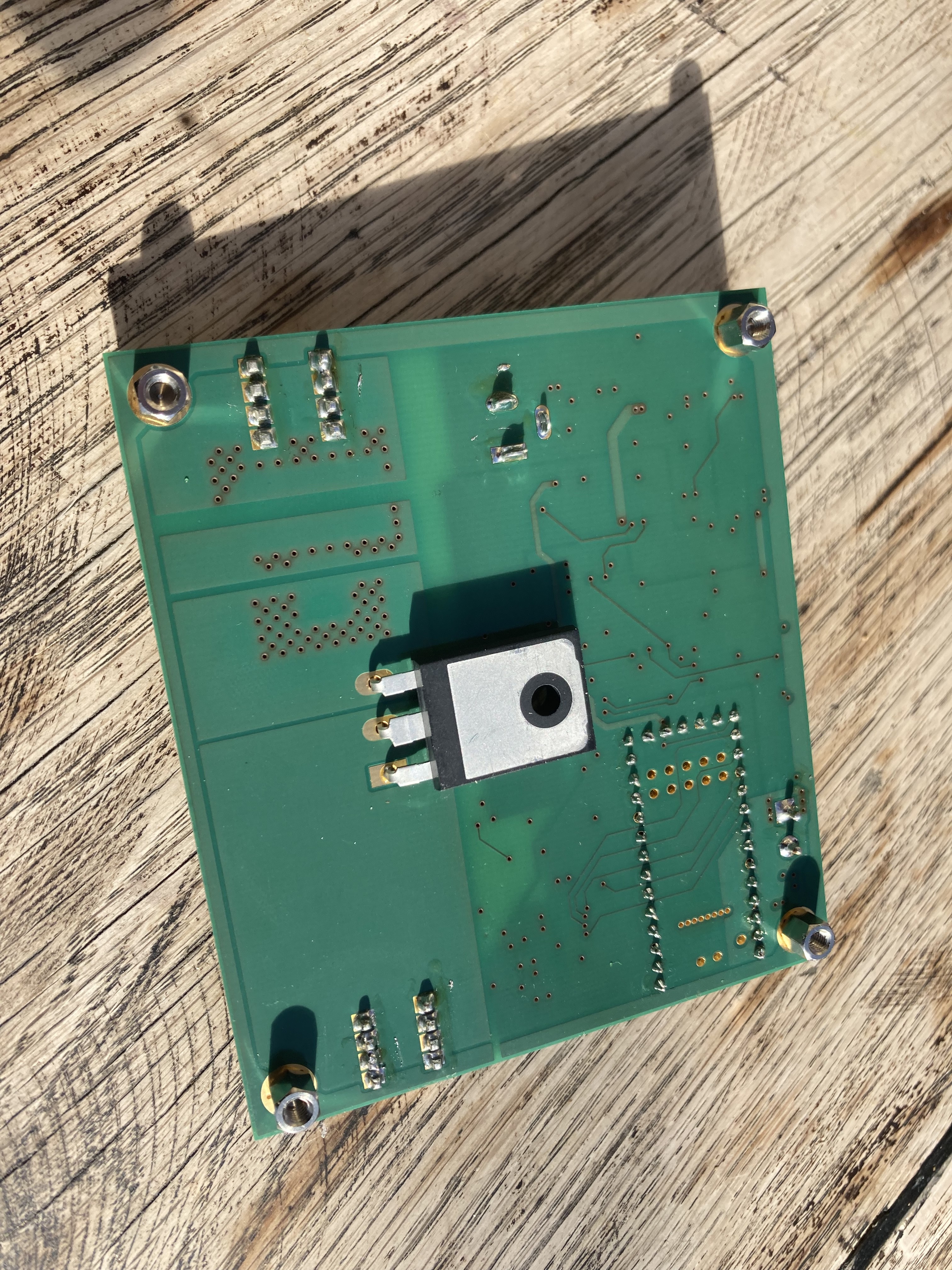

Here you can see the underside with the power dissipation transistor before final assembly:

![]()

-

Laser4DIY on the Hackaday Podcast!

08/07/2023 at 09:03 • 0 commentsIn case you missed it: On the July 21 Hackady podcast Elliot and Dan were talking about our Laser4DIY project!

Lazzzor talk starting at min 29 :-)

![]()

Small correction on what was discussed on the podcast: our pump diode driver is running in constant current mode. We do not pulse the pump diode (yet). But yes, the magic of the q switch works with a cw pump diode too, and we indeed generate pulses ~2.5ns with almost 50kW peak

-

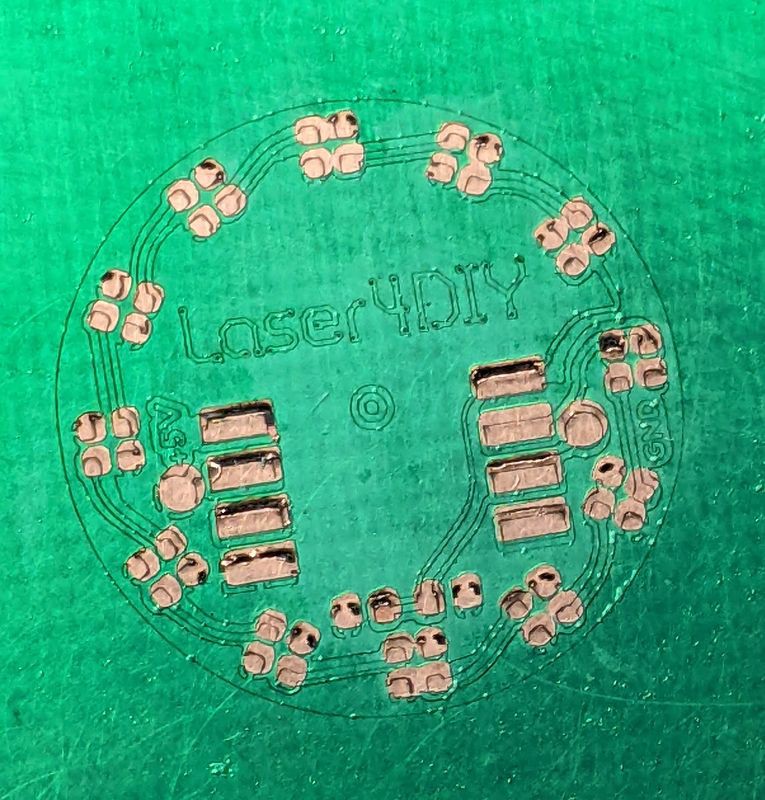

Solder mask laser etching? part 2

07/27/2023 at 12:12 • 0 commentsLast time we did a test to see if solder resist film can be laser engraved, see https://hackaday.io/project/191904-laser4diy/log/221159-solder-mask-laser-etching

That looked quite promising, so we went one step further and tried to put a solder resist mask on a PCB we created with Laser4DIY:

![]()

That worked... but not exactly great. :-(

First of all, this PCB is tiny. It's our Laser4DIY Coin made by Alex, measuring only 17mm in diameter. So the pads are tiny as well and that caused issues:

- The registration is off. We tried to do it using the red pilot laser on the CO2 laser cutter and that is not precise enough. We have to think of better ways

- The pads are too big in the solder mask. I guess this is caused by the laser spot size. The resolution of our CO2 laser (we used an Epilog Zing) should be sufficient, but simple engraving the exported solder mask pattern does not do the trick. We have to shrink the engraving pattern to compensate for this.

- And finally, we got ugly dark spots during the process. At many places where the CO2 laser was engraving on previously ablated copper, the underlying FR4 was burned and at some places even causing defects on the copper. We hope that this is a non-issue as soon as we got registration and engraving area right, because if the PCB design is correct, the solder mask should only be removed on copper areas.

Definitely need more experimentation in that area...

-

Laser4DIY on the Hackaday Blog!

07/18/2023 at 13:33 • 0 comments -

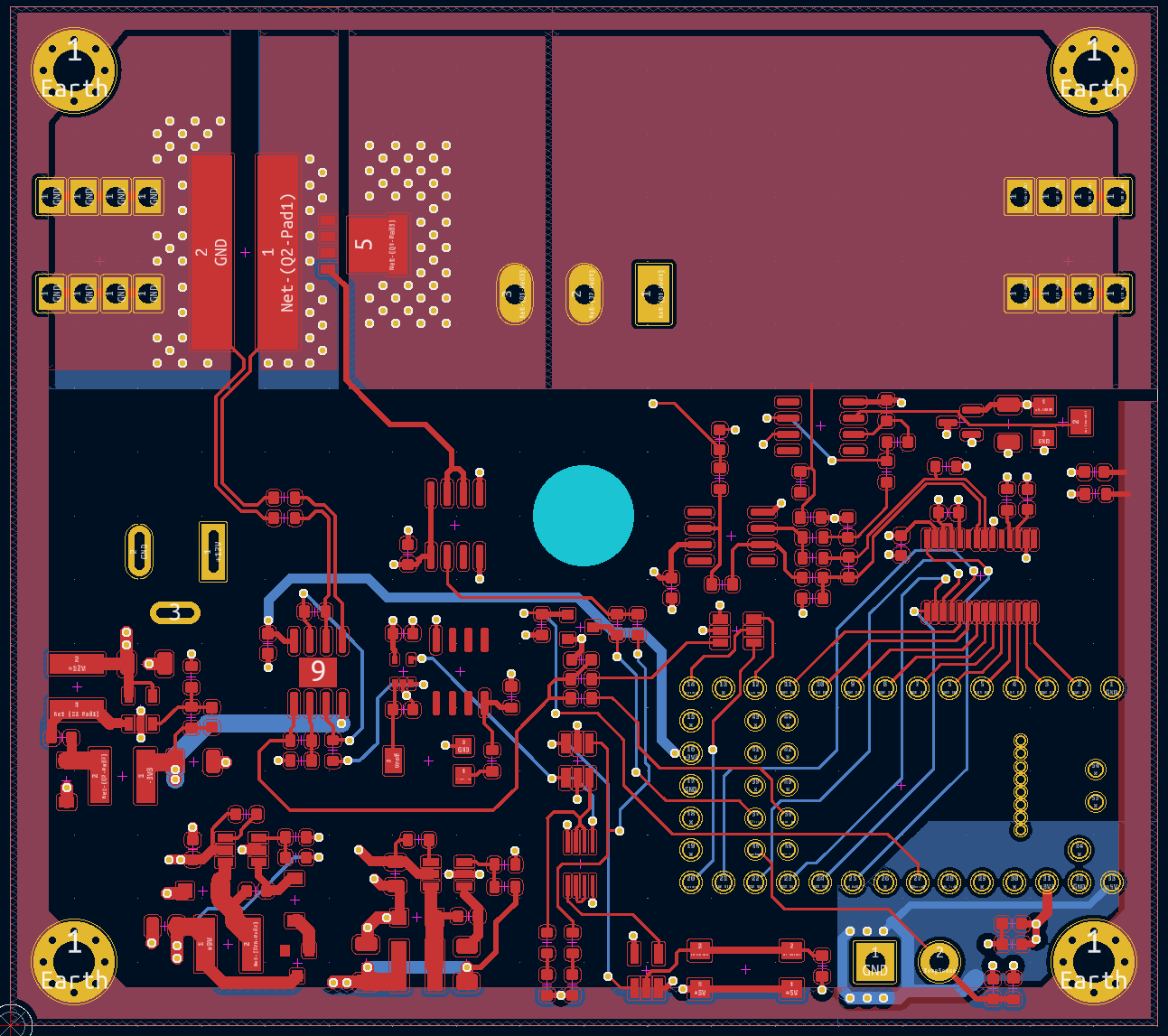

New Diode Driver Electronics Version

07/14/2023 at 07:31 • 0 commentsOur new version of the diode driver is coming along nicely! We had a version running already, but it needed a couple of fixes, so here is the new layout. It's manufactured right now, we can't wait to try it out!

Here you can read up on the new concept: https://wiki.fablab-muenchen.de/display/L4DIY/Laser4DIY+Laser+Diode+Driver

![]()

-

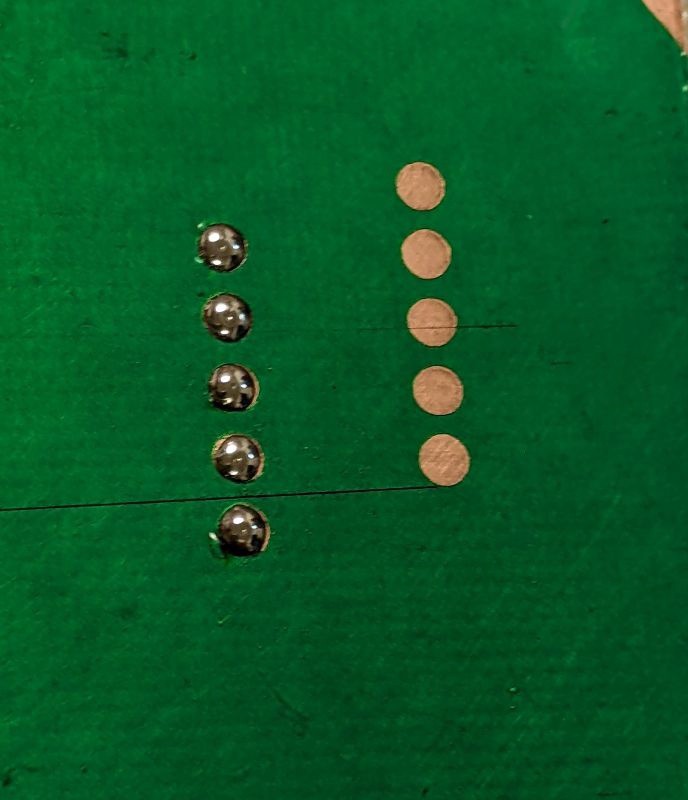

Solder mask laser etching?

07/13/2023 at 10:41 • 0 commentsWhen you are done with laser structuring the copper your PCB still is not finished. A proper solder mask is one of the thinks you'd want. Wouldn't it be nice if it could be done with a laser as well?

We did a quick test with a solder mask film (Bungard Lami). This film is meant to be used with a photo etching process, but maybe it can just be selectively removed with a laser?

We used a heat press to put the film on the PCB (usually a laminator is used), then put it under a UV lamp for a minute to cure, and threw it into a CO2 laser cutter. A couple of engraving passes at full power later revealed the bare copper. But the question is: is it complety removed so that solder sticks to it?

We wiped the board with isopropanol and hit it with a soldering iron.

![]()

That worked!

(These are solder pads with D=2mm)

Crips edges, takes solder well, very promising!

-

Beta Testing Status

07/11/2023 at 15:39 • 0 commentsThere are currently two teams trying to build a Laser4DIY device, and beta testing the machine and giving us feedback on the documentation and assembly manual. The teams are located at two hacker/makerspaces, at Das Labor in Bochum, Germany and a team locally here at the FabLab München, which is in Munich, Germany of course.

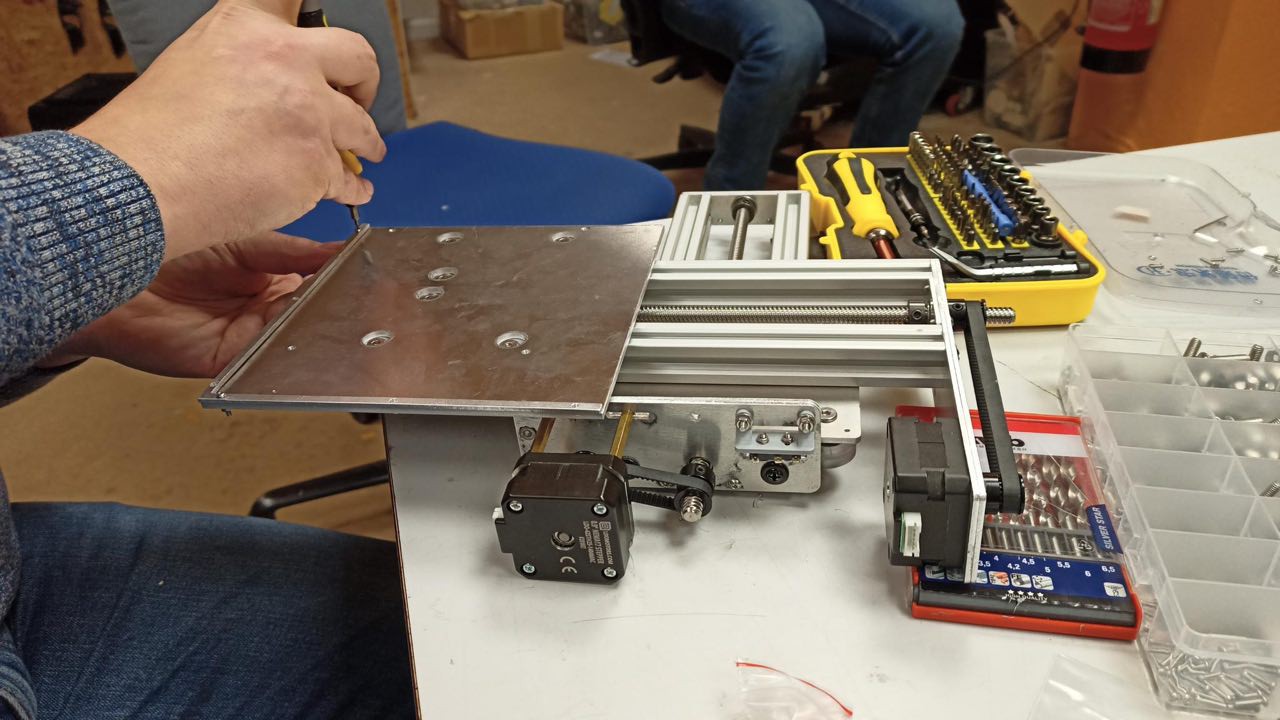

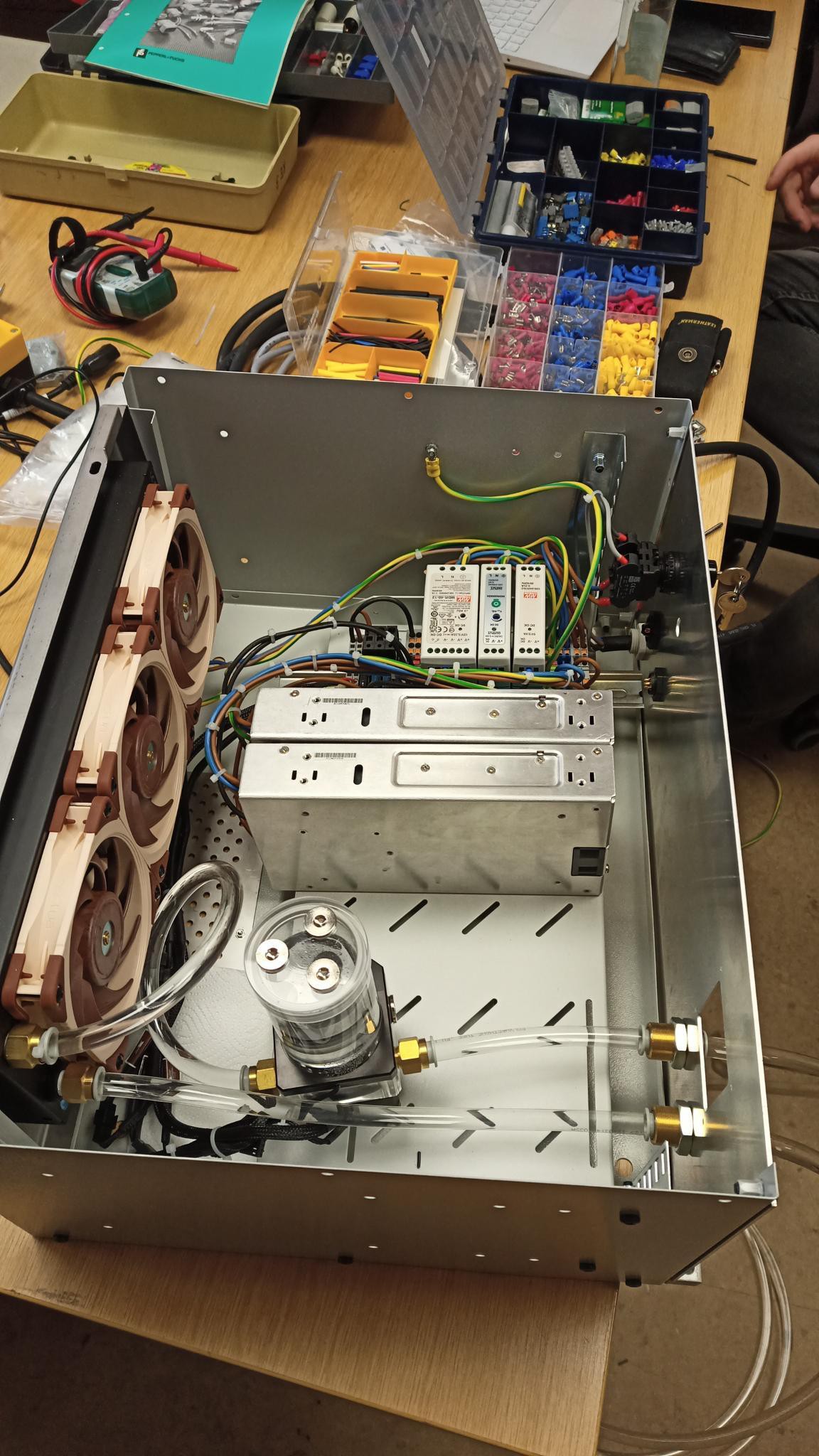

The teams started with the motorized XY table and the supply unit. Next thing will be the safety enclosure. Here are some photos of the progress so far:

![]()

![]()

![]()

![]()

Photos: Jan/Andre (Das Labor), Ralf/Felix (FabLab München)

-

Finally on hackaday.io

07/11/2023 at 15:26 • 0 commentsOK, it took a while, but finally we are on hackady.io 😁

Laser4DIY

Laser4DIY is an open-hardware machine for producing PCBs by ablating copper with a laser

FabLab München

FabLab München