In our first design, we used a CoreXY mechanism, commonly found in 3D printers due to its speed and precision. However, CoreXY relies on two belts stacked on top of each other, making it bulky and adding complexity to assembly and maintenance. To make the chessboard more compact and cost-effective, we reconsidered our design decisions.

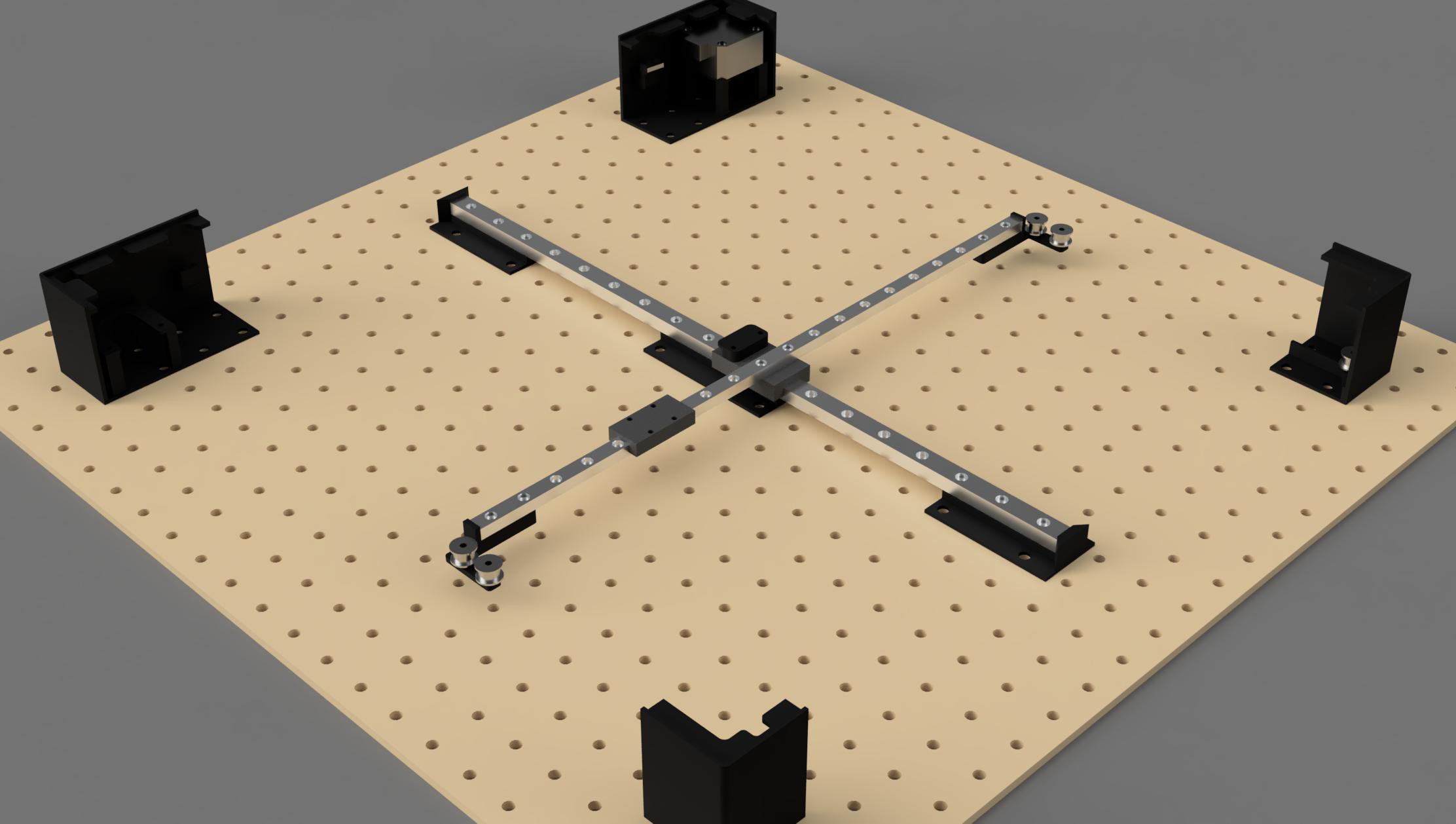

Our goal was to fix the motors in place and reduce moving components, improving reliability while simplifying the build. Cartesian mechanisms were considered but require moving a motor or a more complex belt setup, increasing system size. Instead, we switched to a T-Bot design - a reduced version of H-Bot that requires only two linear rails instead of three and a single belt. Inspired by Phantom Chess we opted for a similar choice in movement.

Why T-Bot?

- Smaller & More Cost-Effective - Using pre-assembled linear rails instead of custom V-slot assemblies reduced both cost and footprint.

- Fixed Motors - Unlike Cartesian setups, both motors remain stationary, reducing moving mass and simplifying wiring.

- Efficient Calibration - T-Bot moves diagonally, requiring more complex control logic. However, when it hits an edge, it naturally moves along it, allowing calibration with a single limit switch for fast and accurate positioning on both axis.

This switch allowed us to dramatically shrink the movement mechanism while maintaining precision. By replacing custom V-slotted rail assemblies with off-the-shelf pre-assembled linear rails (MGN Series), we reduced both size and build complexity. This not only simplified assembly but also made the design more reliable and cost-effective, resulting in a compact and efficient robotic chessboard.

Jonathan Good

Jonathan Good

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.