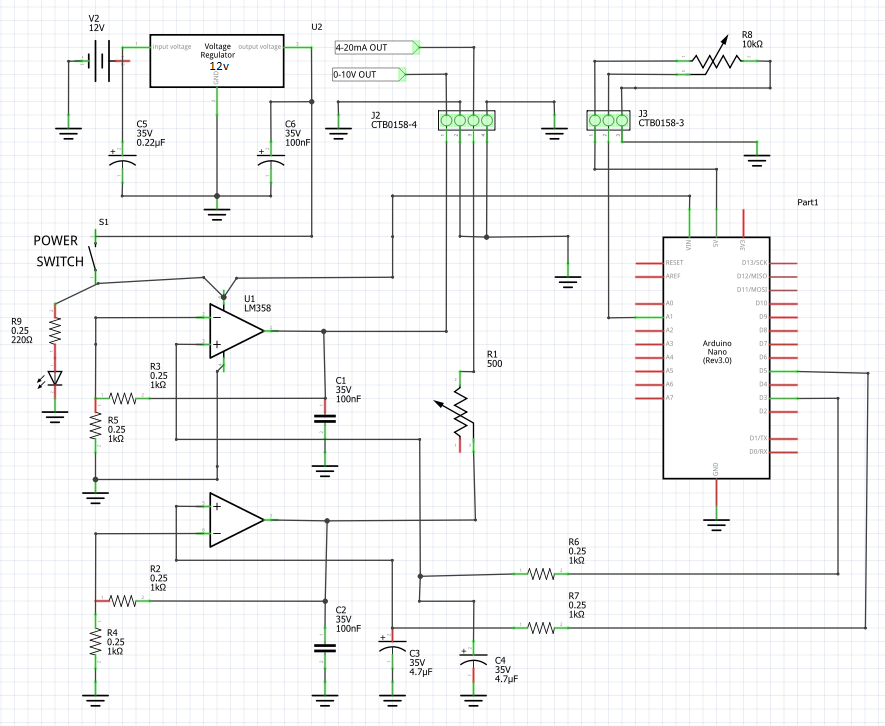

The most commonly used analog signal in Industrial Controls is the 4-20mA analog signal. This "protocol" is commonly used in industrial automation and process control systems. It represents a continuous electrical current signal where 4mA typically corresponds to the lowest possible measurement or signal value , and 20mA represents the highest value. For example 4mA might represent 0 bar pressure and 20mA would represent 16 bar.

The 4-20mA current loop is used so commonly because of the advantages it offers, such as noise immunity and long-distance transmission capabilities, making it ideal for industrial environments where electronic noise is common. Factories often have tons of inverter driven motors and fluorescent lights.

The 4-20mA signal from the sensors, instruments and transmitters is sent to receiving devices (usually hard wired) such as programmable logic controllers (PLCs) or Trip Amplifiers and the signal is used to control the Industrial Process. For example, if the pressure is below 8 bar the sensor would have a 8mA current loop. The PLC program would then turn on a pump when the pressure in below this threshold and turn the pump off again at another threshold.

A 0-10V analog signal works the same way as a 4-20mA signal and many sensors and instruments are equipped with both protocols however some instruments only have the 0-10V protocol as it is a cheaper and easier signal to generate. For this reason you really need both a 0-10V and 4-20mA generator in your tool box if you want to reverse engineer, fault find or test industrial control systems.

The 4-20mA signal is most often preferred over voltage signals in industrial applications because even in the presence of electrical noise, the receiving PLC's and SCADA system can accurately interpret the current signal's magnitude, ensuring reliable and accurate data transmission over long distances, often several thousand metres.

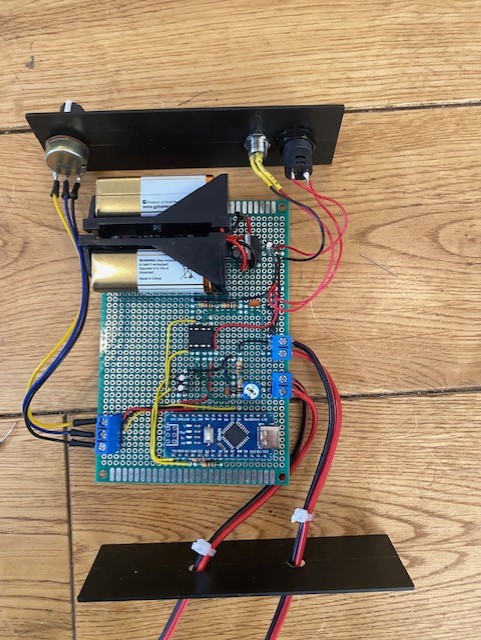

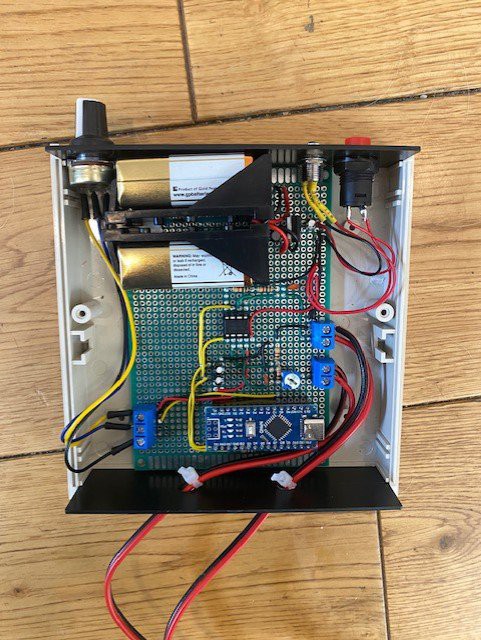

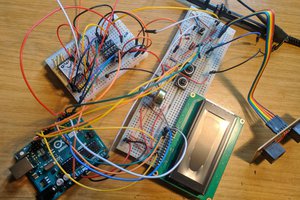

Although this device is a hand held tool the same circuit could have another use case for trialling sensors and instruments when interfacing to Industrial Control Systems. You could utilise an Arduino and the multitudes of cheap Adafruit or SparkFun sensors to try things out before committing to purchasing a $500 instrument.

The whole project probably cost about $20 to build and 3 hours for assembly so the cost very much stands up to even the cheapest loop calibrators available on eBay or Amazon.

Tom Goff

Tom Goff

James Cannan

James Cannan

ensafatef

ensafatef

Tlamangile

Tlamangile

As a final note to this project I actually found my commercial signal generator the afternoon after a built this one. It was hiding under a drum of cable that I needed to move just before I did some home decoration I promised my partner I would do....