-

Making Larger Boards

09/14/2024 at 18:59 • 0 commentsOn the way through a long, hot, summer, I decided to lay out two variants of these displays. Neither of these boards was done with a specific project in mind. Both are 4 character boards built from the same schematic but have different mechanical setups.

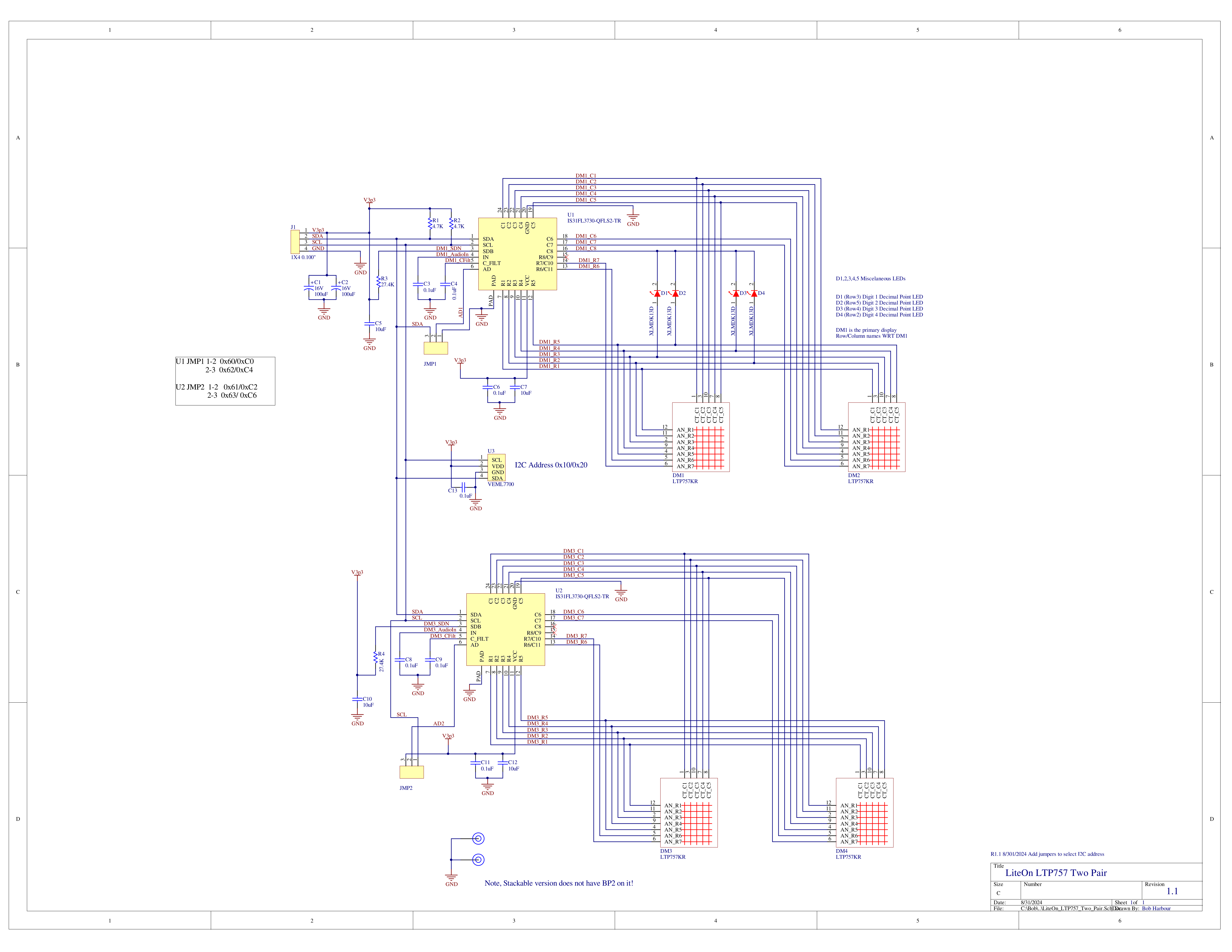

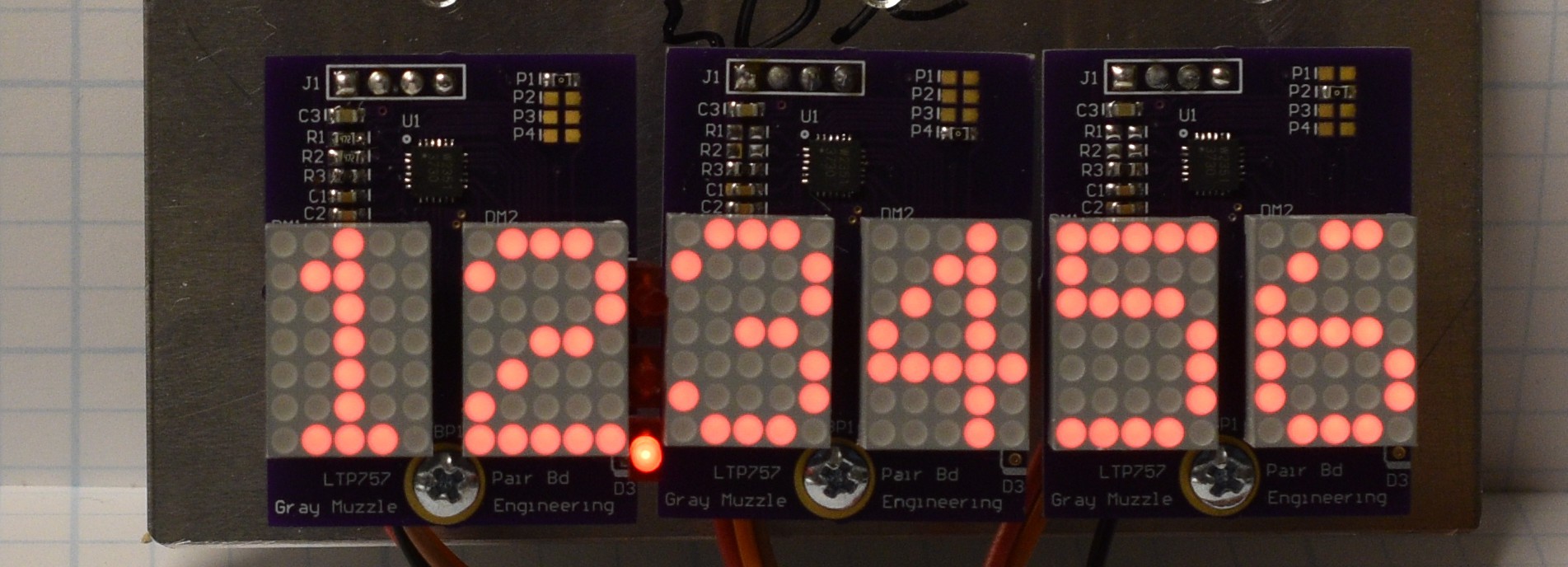

Schematic for the 4 Character Boards with Ambient Light Sensor The first board is designed to go into an application needing 4 alpha-numeric characters on a line. Maybe a meter or something similar. The second board is designed to be end to end stackable, so you can add characters in increments of 4 per board. Both boards have an ambient light sensor on them for auto-dimming the displays. Note that the auto-dimming is done in software.

There are two driver chips per board to support the 4 characters. Each chip can listen on 1 of 4 addresses, so an I2C address mux will be required in a system using more than 1 of these boards. On rev 1.0 of these boards, the addresses for both driver chips are hard wired, meaning you will need one mux channel per board. The week after I sent the boards out to OSH Park, it occurred to me that with a couple of 3 pad jumpers per board, I could get two of these boards on the same I2C bus or mux channel. That will be rev 1.1 of the boards.The schematic shown is rev 1.1 with the jumpers added.

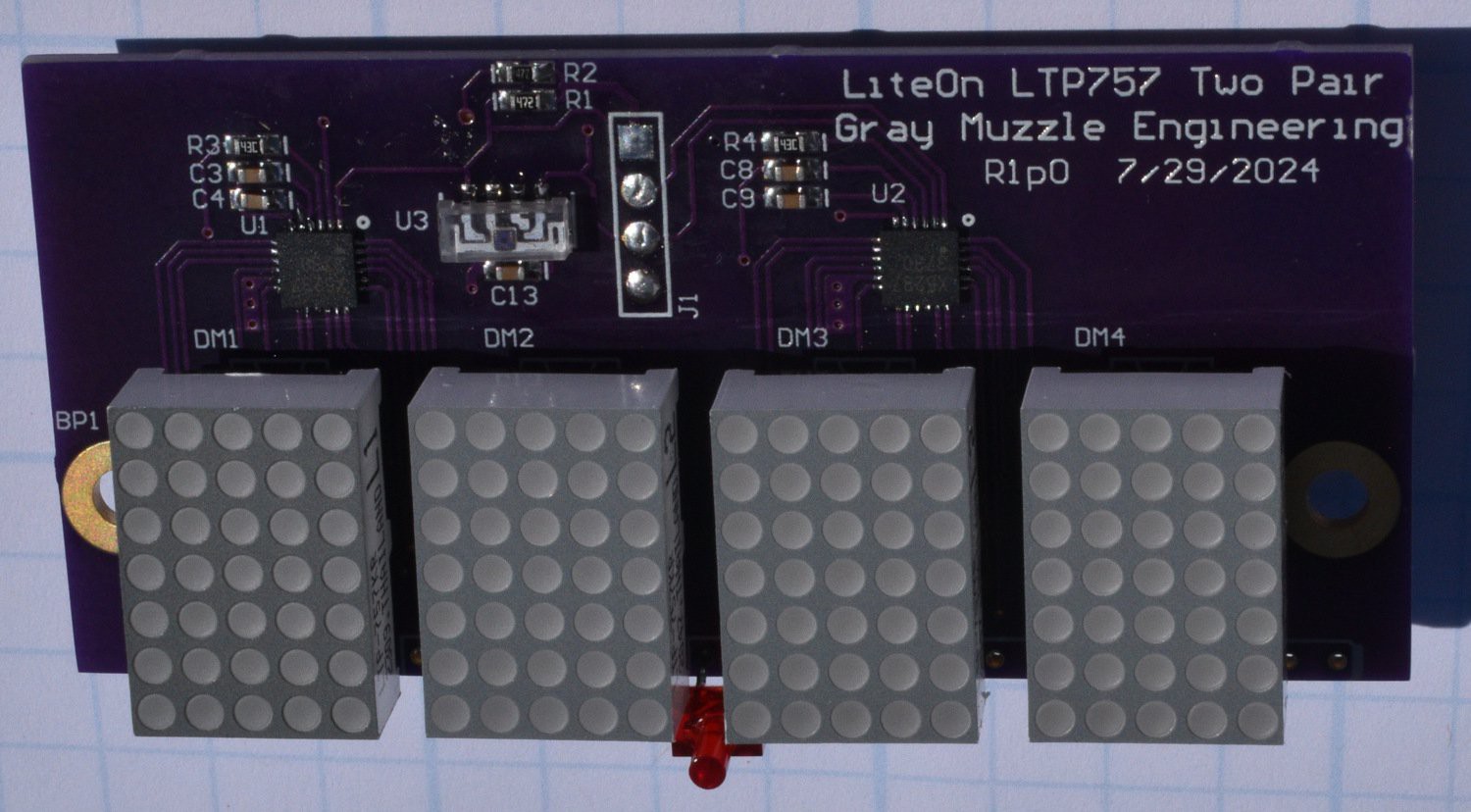

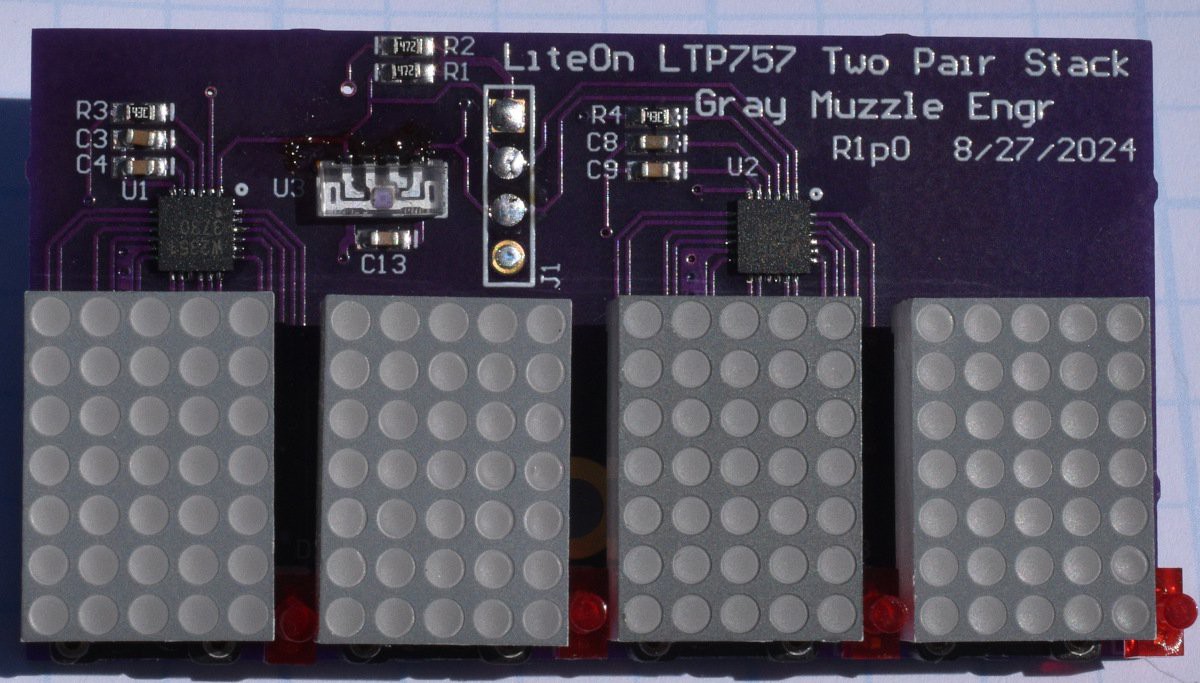

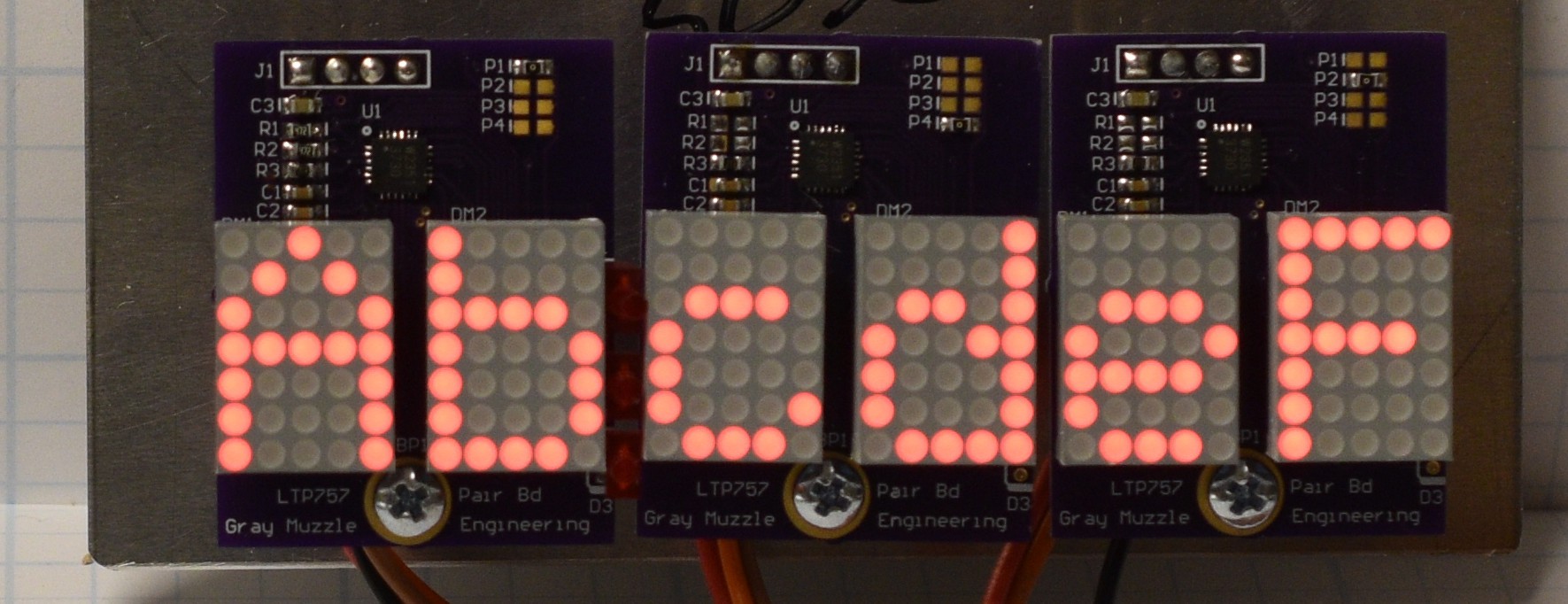

4 Character, Non-stackable Version 4 Character, Stackable Version I have added discrete LEDs between the characters to use as decimal points in numeric applications. On the stackable version of the board, the discrete LEDs are in line with the bottom row of pixels of each display. On testing this, it doesn't look good. The decimal point does not stand out from the numbers and looks more like a bug than a feature. On the non-stackable version, the discrete LEDs are below the displays and this looks much better.

Mounting for the non-stackable boards is done with a pair of machine screws that will thread into standoffs on the back side of the board. Mounting for the stackable version of the boards uses a single machine screw between the second and third character.

A right angle connector adjusted to be a little less than right angle provides the power and I2C bus connections for the boards.

-

Fixed the Extra LED Mounting in Rev 1.1 of the PCB

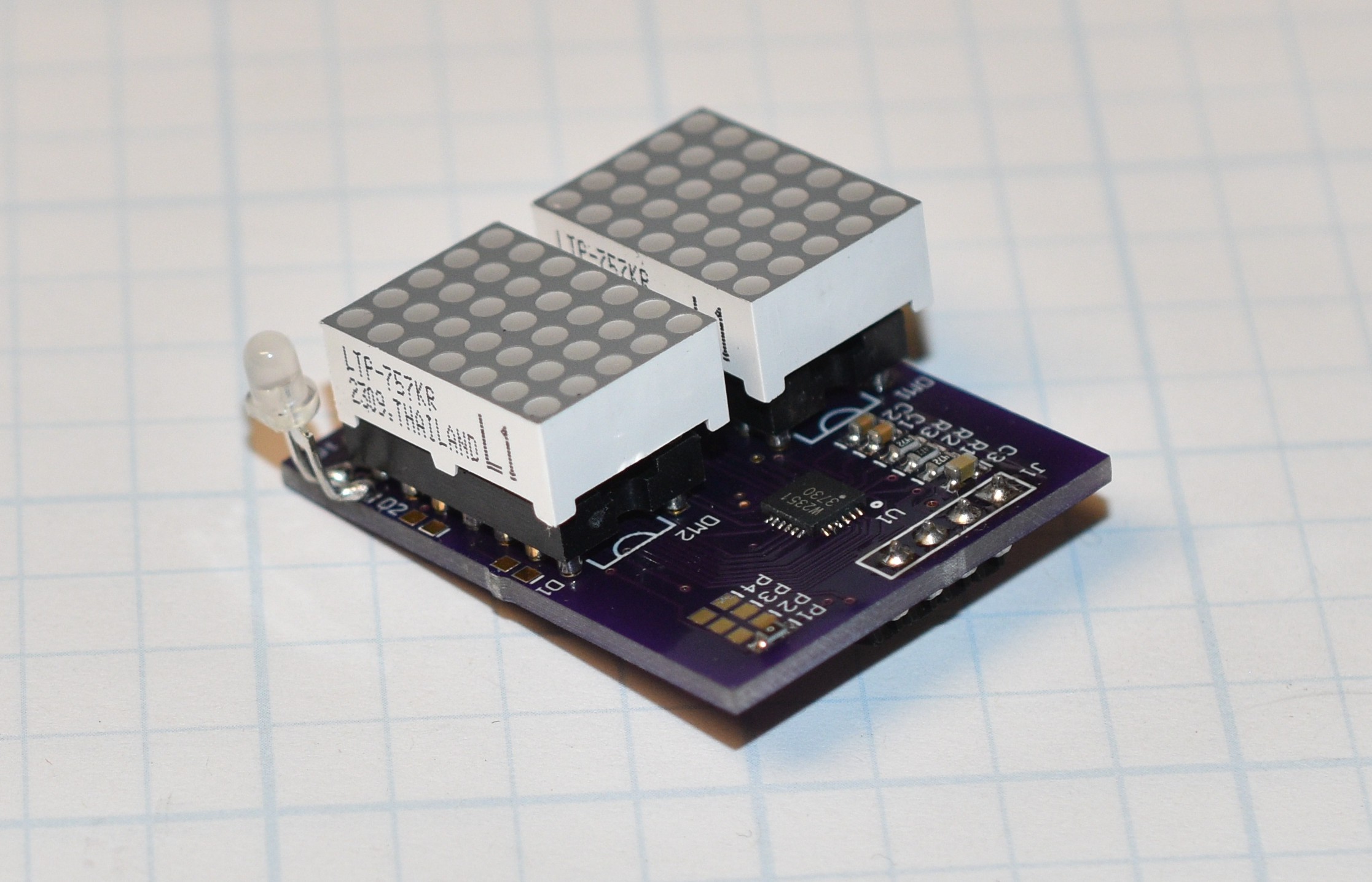

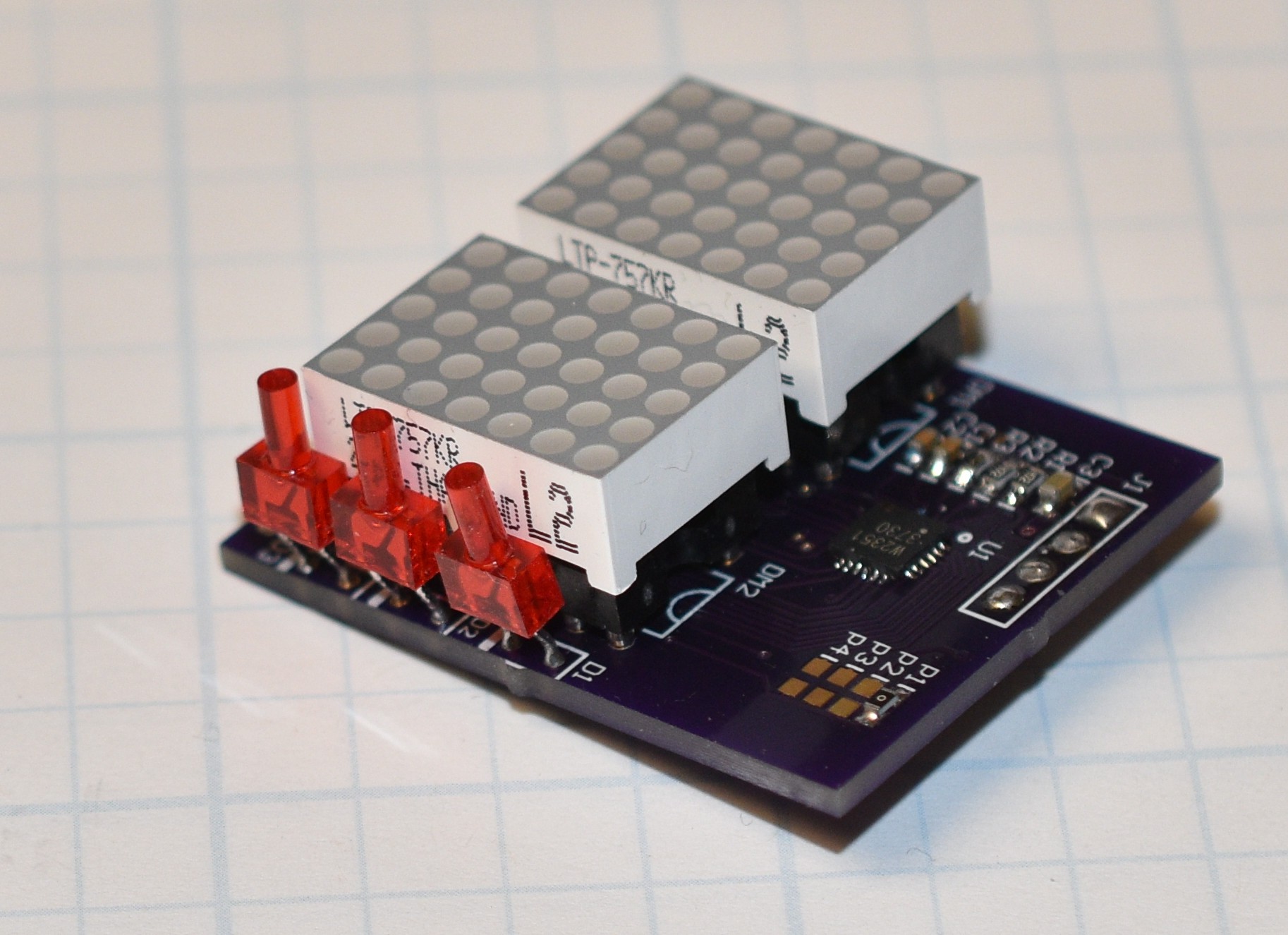

07/18/2024 at 15:24 • 0 commentsThere are pads to place 3 "extra" LEDs on the rev 1.0 boards. Those LEDs are available to add a colon for clock type displays and a decimal point for float values. They are driven from an extra column on the display driver. For rev 1.0, I just put SMT pads along the right edge of the PCB, with the intention of soldering the LEDs to the pads.

Rev 1.0 Display with SMT pads for misc LEDs. This did not work well. It was kind of an afterthought anyway. It was difficult to get the LEDs positioned with any accuracy and it was easy to pull the SMT pads off the board along with the LEDs.

The solution to most of the problems was to widen the board slightly (.050") and replace the SMT pads with through hole pads. The mounting is much more durable, the LED lead dress to get them in the right place is easier, and the vertical LED placement is pretty consistent. The rightmost LED is a little wild on the placement here, but I was experimenting with the lead dress for the colon operation and did not get the LED re-positioned well.

The new LEDs look a lot better in this use situation, as they give a well defined dot that looks more like the display pixels than the old round dome mini LEDs that I was using on the R1p0 displays.

The board to board spacing is fairly important to get things looking good. The pixel to pixel spacing on the displays is 0.100" and between the two displays on the board, the pixel spacing is 0.200" The decimal point looks OK if the board to board spacing places the adjacent display pixels are 0.200" apart.

With 0.200" spacing, the colon visually smears into the characters and looks bad. Placing the boards on either side of the colon so that there is 0.400" spacing looks much better, but makes the LED lead dress a little more difficult. The LEDs for the colon need to be spaced about 0.150 to the right of the display module and the height flush with the top of the display modules.

All told, the rev 1.1 board is an improvement and I am happy with the design now.

Bharbour

Bharbour