-

Smaller Joints

19 hours ago • 0 commentsI've been working on the smaller joints on a off for a few weeks now and I've made some progress. The Joint is completely designed and I'm onto testing. The only problem I am running into is the planetary gearbox is too stiff causing too much friction for the motor to spin. I'm working on a fix currently and hopefully it works soon. Otherwise things seem to be working well.

another consideration for later that I've been thinking about is how the magnetic output controller is going to work. There are two options. Either I use the moteus r4 software and configure it to be an output encoder. Or I code my own script that reads the output encode and drives the moteus r4. The first option would be ideal, but I have been unable to get it to work well. This aspect of the arm is vital to its accuracy so I may just end up coding my own script though ROS to ensure I have maximum accuracy.

-

New Look

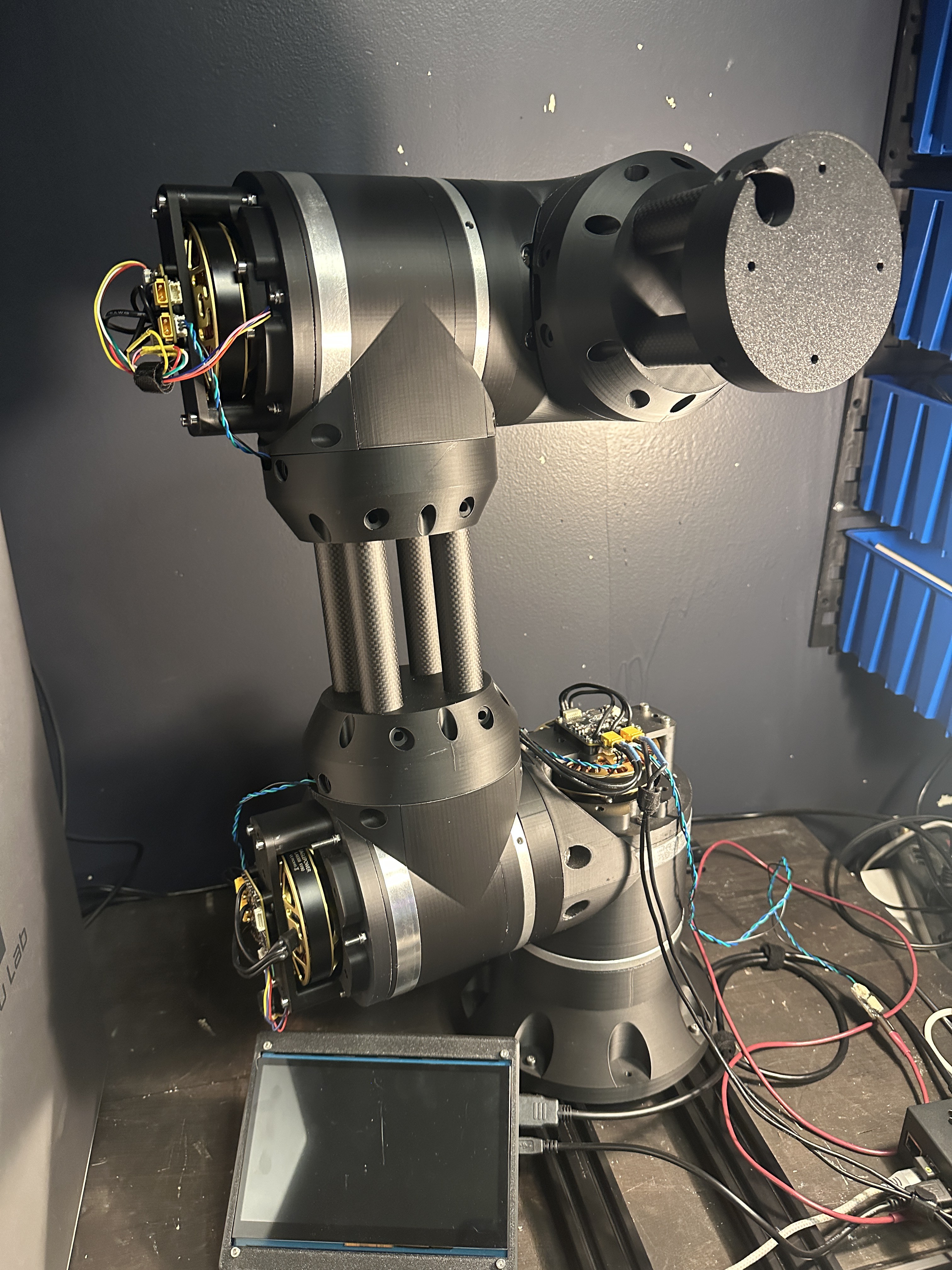

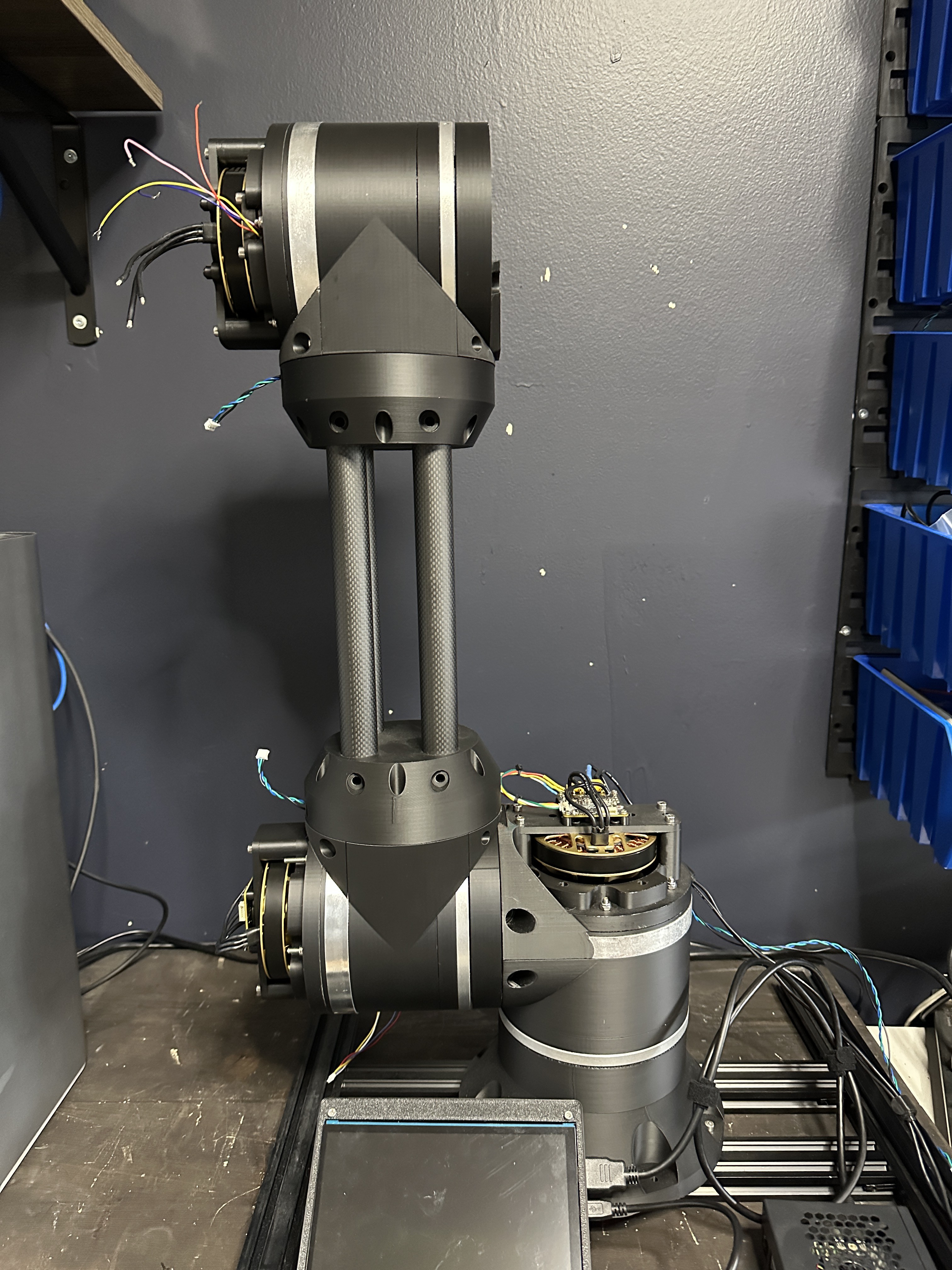

01/27/2025 at 01:34 • 0 commentsNew Arm design with smaller distance between Joints 2 and 3

-

New Silent Wave Generator Bearing with Cage

01/24/2025 at 19:58 • 0 comments -

Updates

01/24/2025 at 02:42 • 0 comments- Upgraded Wave Generator to have bearing cage.

- Added Lubricant to Wave Generator resulting in silent operation. That terrible rattling noise in the previous videos is now gone.

- Cut down Poles attaching Joint 2 - 3 as the arm was way too big.

- Build first prototype of second stage joints which are much smaller.

-

Joints 1 & 2 Test with Joint 3 installed

01/24/2025 at 02:38 • 0 comments -

Joint 3 Installed

01/22/2025 at 04:15 • 0 comments -

Progress Update

12/23/2024 at 05:34 • 0 commentsI've taken a break during school, but I'm now back at it!

For the past few months I've been slowly print and purchasing parts for the Arm. I will be assembling the 3rd joint this week, which is the last of the larger joints.

As a side note, I noticed that the Moteus R4 now has support to control an external actuator. This is amazing! With this addition, It will be really easy to add attachments to the end of the arm. This also simplifies wiring for any gripper as now I will only need to Moteus wires: Ground, Power, and CANFD.

Finally, I've been looking into using PPA-CF as an alternative to the aluminum rights surrounding the circular spline. This would be much cheaper in exchange for a minor drop is performance. I'm still debating it, the only reason I'm hesitant is because I like the look of the aluminum ring and how it matches the large lazy susan bearing.

-

Joint 2 Progress

09/09/2024 at 23:58 • 0 comments- Added Carbon Fiber Tubes which will connect Joint 2 to Joint 3.

- Used 4 tubes as it was cheaper than 1 large tube.

- Each tube is 25mm*23mm*350mm (cut down from original size)

- The 4 wires to connect the rest of the Joints will be routed through one of these tubes which has an access point next the the respective motor driver.

- To this point, there is still no problem with the backlash.

-

Joint 2 Test

09/06/2024 at 21:34 • 0 comments -

Backlash

09/02/2024 at 22:27 • 0 commentsAfter assembling the first Joint I can confirm that it has 0 backlash. Soon I will get the tools to get a real measurement of the backlash, but for now this is very impressive for a 3D printed Gearbox of this strength and accuracy.

Jared Fenster

Jared Fenster