-

Joint 2 Test

09/06/2024 at 21:34 • 0 comments -

Backlash

09/02/2024 at 22:27 • 0 commentsAfter assembling the first Joint I can confirm that it has 0 backlash. Soon I will get the tools to get a real measurement of the backlash, but for now this is very impressive for a 3D printed Gearbox of this strength and accuracy.

-

Encoders with Moteus r4.11

09/01/2024 at 04:37 • 0 commentsI connected the output Joint Encoder to the Moteus r4.11. Since I can do this on every Joint, I will not need to worry about cable management. There will only be 2 cables coming from the arm which is the CAN cable and the power cable. This will simply daisy chain through the Joints. I still need to look into improving the backlash of the output. Since the backlash is enough for the output encoder to measure it, it implies that the motor could do a better job holding the position. In other words I want the make the motor fight the backlash a soon as it is measured. This would make the arm very accurate.

Moving on, I am still working on the second stage Joints. The biggest problem is the print-in-place planetary gears. Since this Joint will be so small, The planetary gears are quite difficult to print. I am now attempting to not make them print-in-place but rather find a way to assemble them. There will be quite a few challenges like this with the second stage Joints, such as the bearing and ball bearing sizes, but I'm not too worried. I think the design could be completed by the end of next week.

-

Second Stage Joints

08/31/2024 at 05:13 • 0 commentsThe current Joints have a diameter of 140mm. My plan is to have 2 sets of Joints where the first 3 Joints are 140mm 120:1. Then I will make the last 3 Joints 110mm 75:1. This will give a balance to the look of the arm, This is also good for conserving weight. If all of the Joints were the same strength It would simply be a waste of materials as the arm is only as strong as the first Joint. This will be a very difficult design challenge as my Strain wave gear cup encoder design is not as easy to scale down as it is to scale up. Ideally the design for these Joint will only take a few weeks as I have an idea of what I'm doing already.

-

Moteus r4 with output encoders

08/29/2024 at 22:59 • 0 commentsI have just found out that the Moteus r4 has a connector for an additional encoder. If this works, I will not need to run the a cable for each encoder down the arm. This would also simplify the coding required.

I will be testing this later today once the adapter arrives.

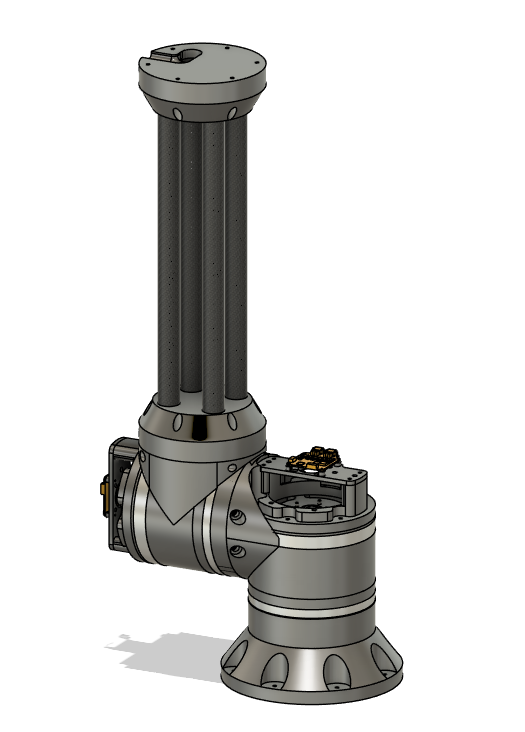

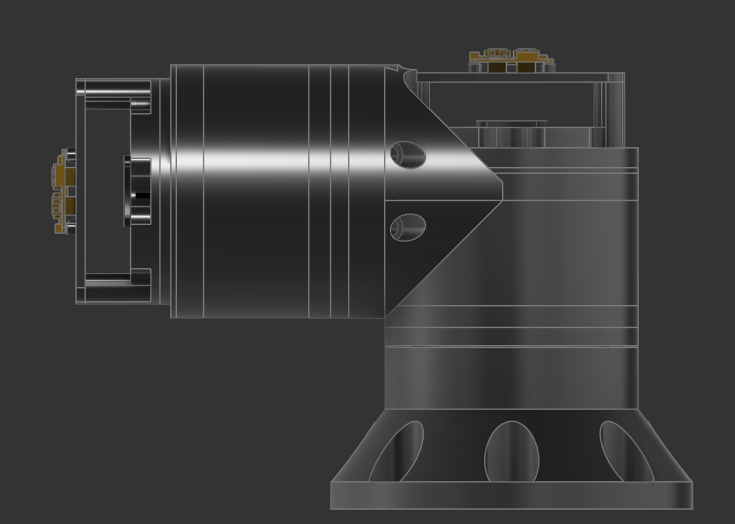

The photo below is the current design for the first two joints that I'm currently building.

![]()

-

Demo of the Base Joint with Encoder

08/28/2024 at 20:04 • 0 comments -

Arm Design Progress

08/27/2024 at 03:38 • 0 commentsI have designed the first Joint and a half of the arm. I am already in the prosses of build these Joints. I like the look so far.

![]()

-

Moteus R4 Test

08/26/2024 at 20:21 • 0 comments -

Moteus with ROS2

08/26/2024 at 01:01 • 0 comments- Setup my ROS2 package to work with the ROS2 Moteus node

This has taken some time as the design of this system is based both on my Ubuntu WSL and my Pi 5. I have another motor arriving soon and I will start building out the arm.

-

Software Update

08/19/2024 at 01:29 • 0 commentsConnected the raspberry pi 5 to my existing ROS2 package. I can now communicate over ROS2 topics between the two. In order to do this with Ubuntu-24.04 on WSL (on my separate PC) I needed to create a virtual switch on Hyper-v to get the correct IP to communicate to each other.

The plan is to have the WSL do the simulation and compute the Inverse Kinematics, then publish the Joint angles. The pi will subscribe to the joint angles, run the joints to the correct positions the finally publish the actual joint angles back to the WSL. This way I can always see where the arm needs to be and where the arm currently is. Both of these positions will be visualized with RVIZ running on the WSL

I have also ordered one more 90kv motor and 2 moteus r4 motor drivers.

Jared Fenster

Jared Fenster