Steam Controller Capacitive Bumper Mod

I find the bumpers on the Valve Steam Controller to be difficult to push, so let's replace them with touch sensors!

Whether or not you consider Valve's Steam Controller to be the most versatile gamepad available, most agree that the shoulder buttons are one of the weak points in the design. They're loud, they require a much heavier activation force than alternative controllers, and they rely on a plastic leaf spring which has been known to snap over time. Playing a bumper-mashing game like Dark Souls or Rocket League can risk breakage, and I've been adjusting my usage to relegate the bumpers to secondary, rarely-used functions.

I wanted to modify the steam controller to improve the bumpers while meeting some criteria:

- Improve bumper feel.

- Lower activation force.

- Eliminate risks of breakage.

- Mod should be fully removable.

- No dremeling the case.

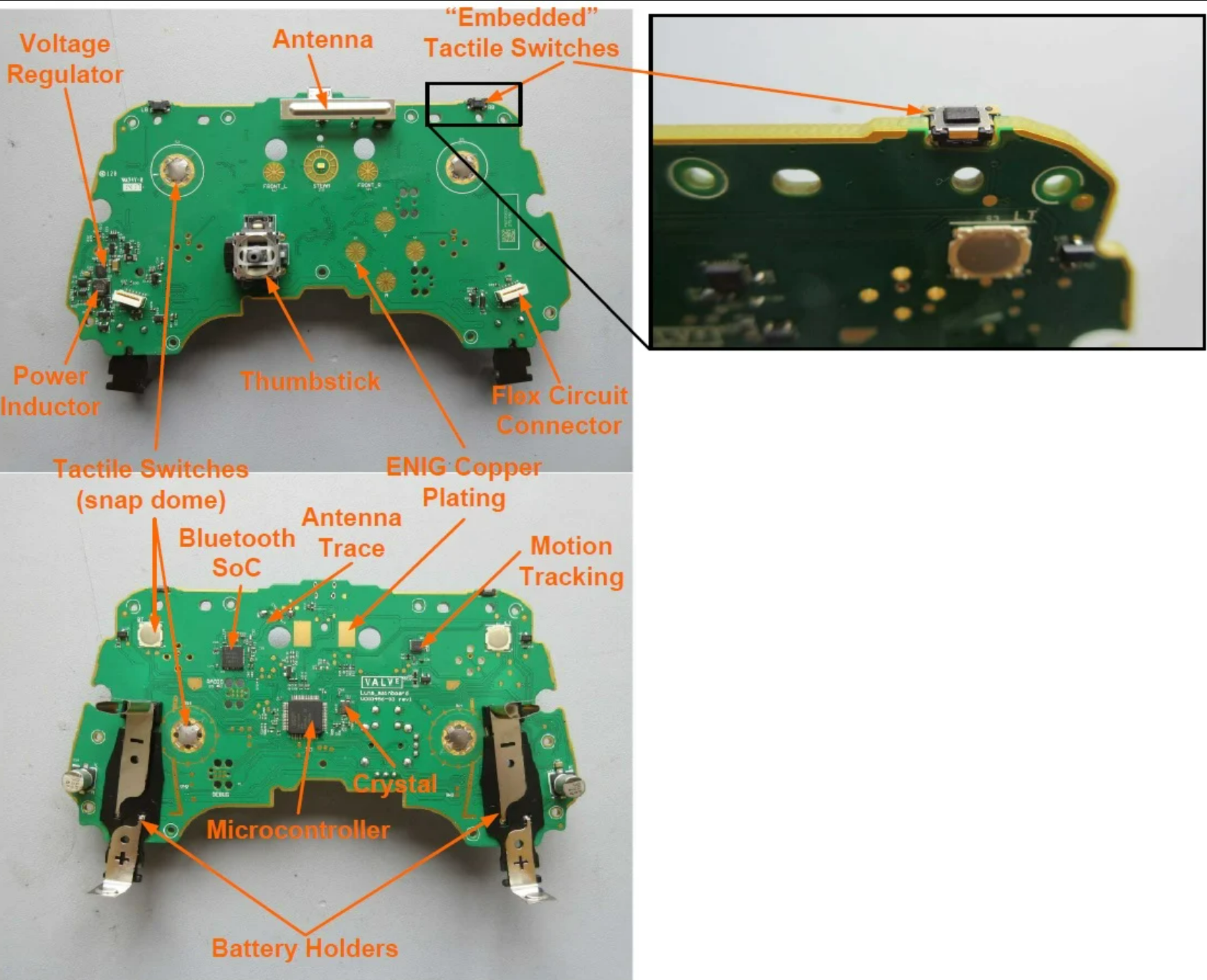

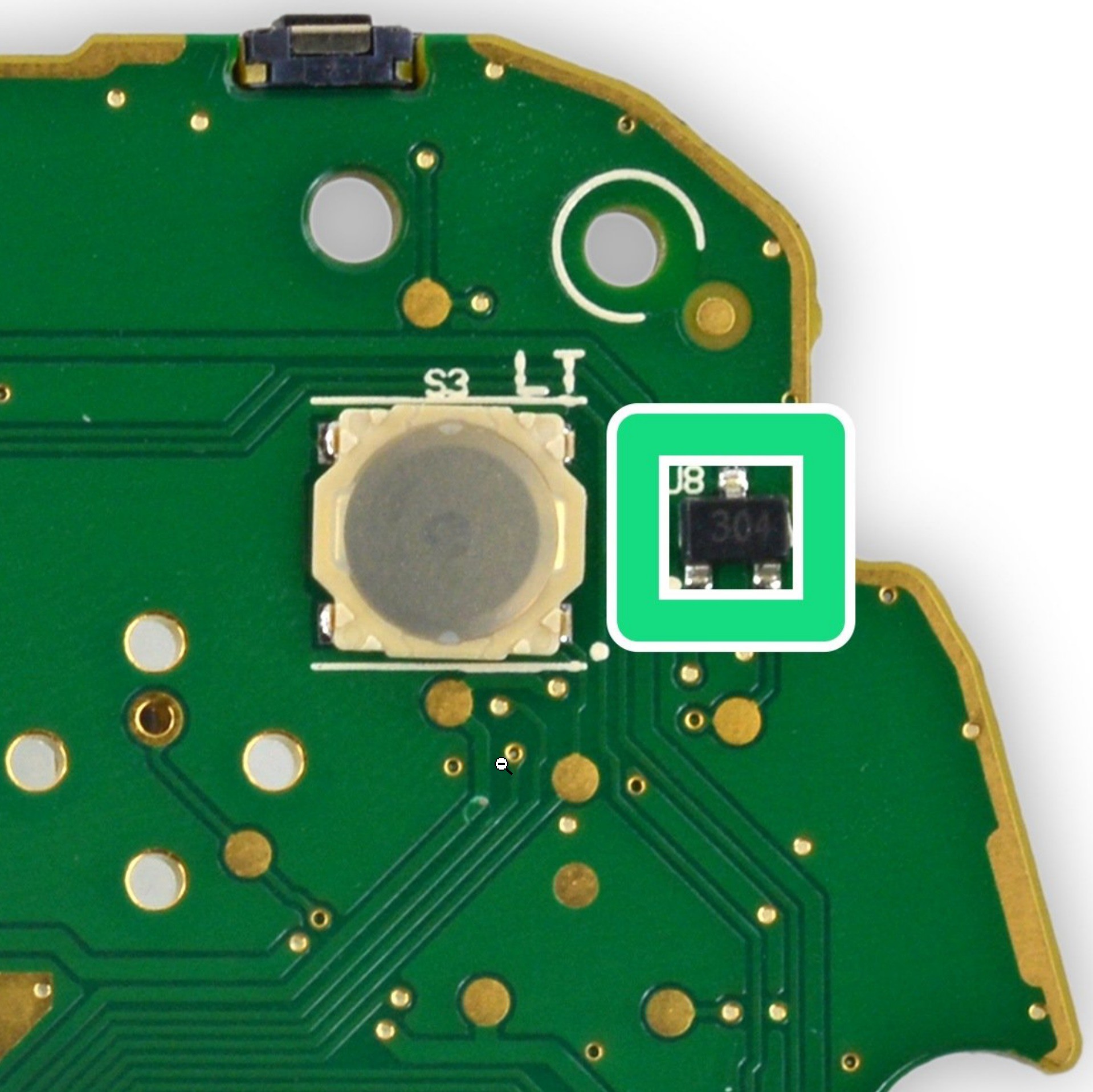

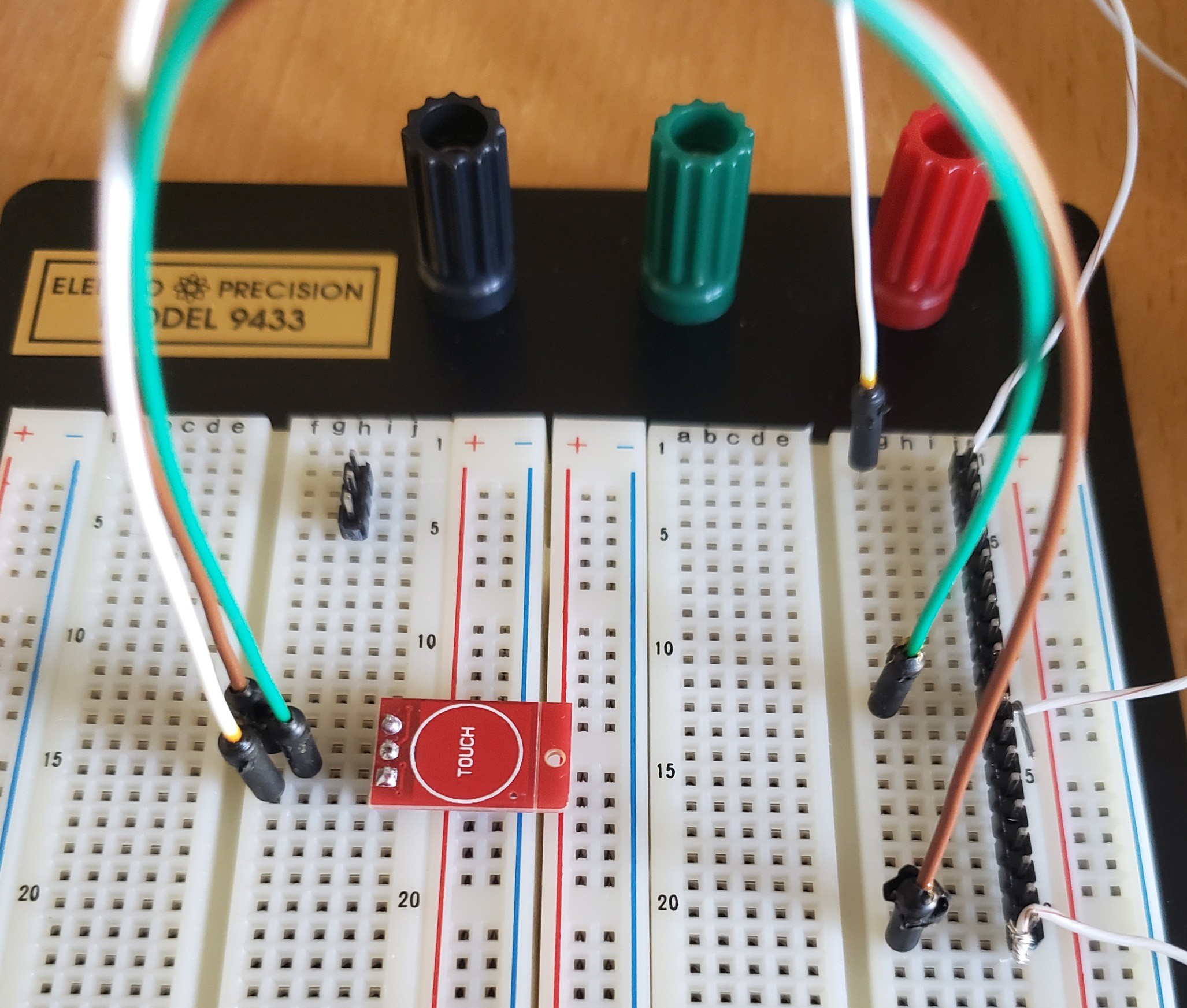

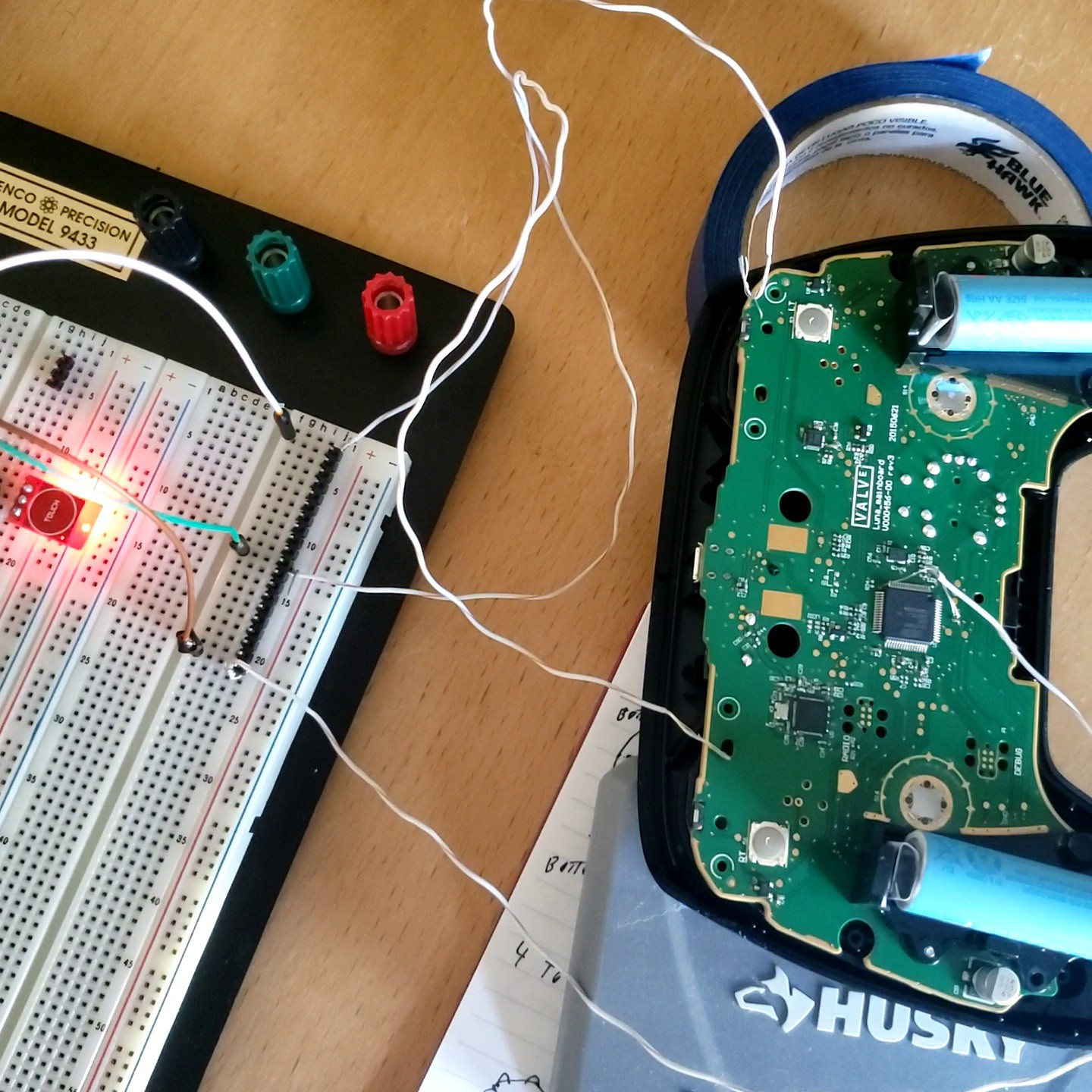

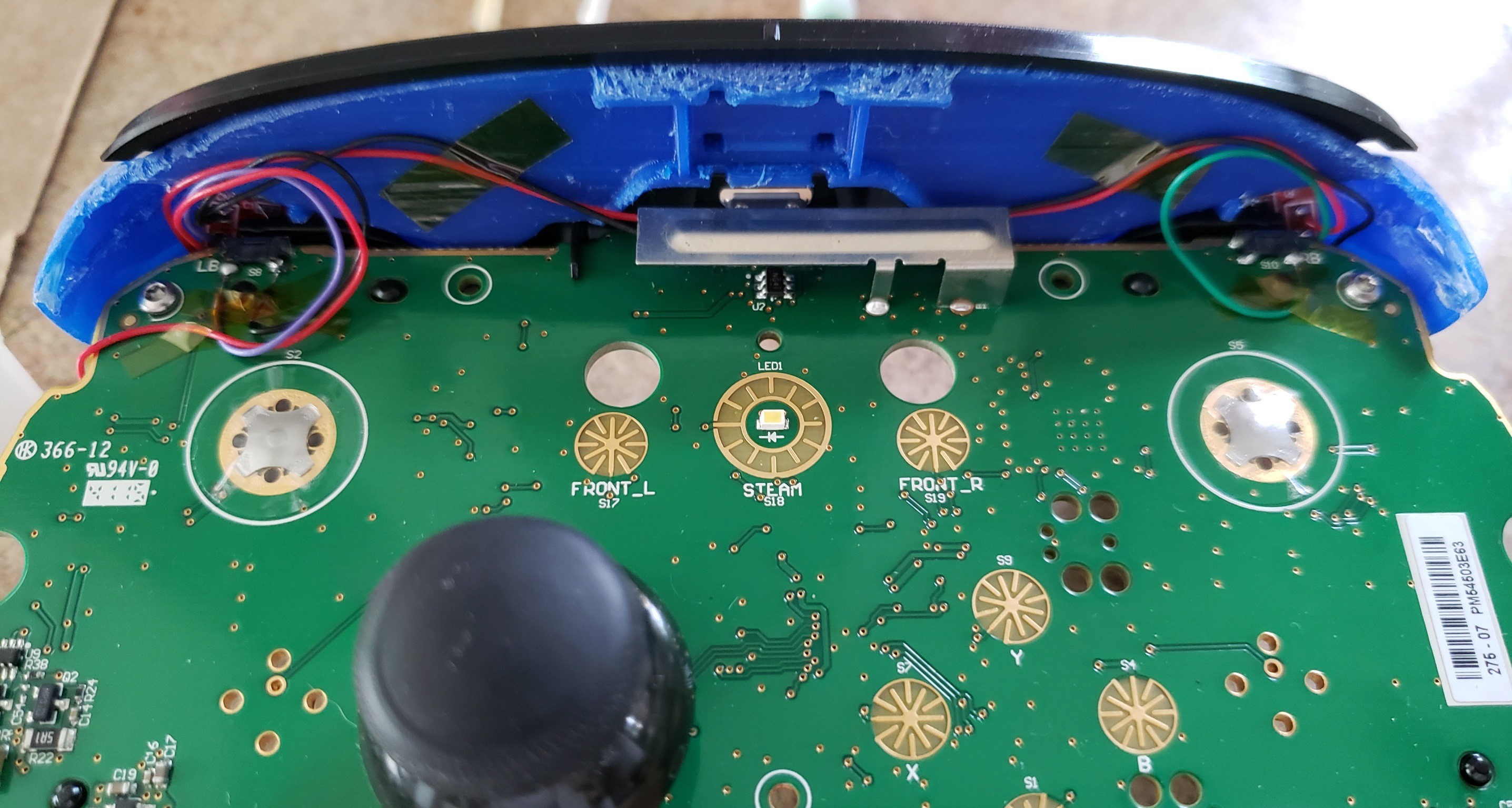

Some users have modded alternative mechanical keyswitches onto the controller itself, this redditor achieves their goals with dremel and direct wiring [MechKeyboardMod]. While I wouldn't want to make a permanent change to the case, I could instead 3d print parts of the case to allow physical modification without damaging the original parts. Valve provides CAD files for all parts on the controller [ValveCAD]. I was eventually inspired by another hackaday project [TouchButtonMouse] to use capacitive touch sensors instead of mechanical switches. Look at these tiny little `ttp223` sensor boards:

ttp223 imagery. (amazon.com)

goathens

goathens

danjovic

danjovic

Evo

Evo

victor

victor