I got all the pieces of the puzzle figured out.

Basically the decapping is done in three steps

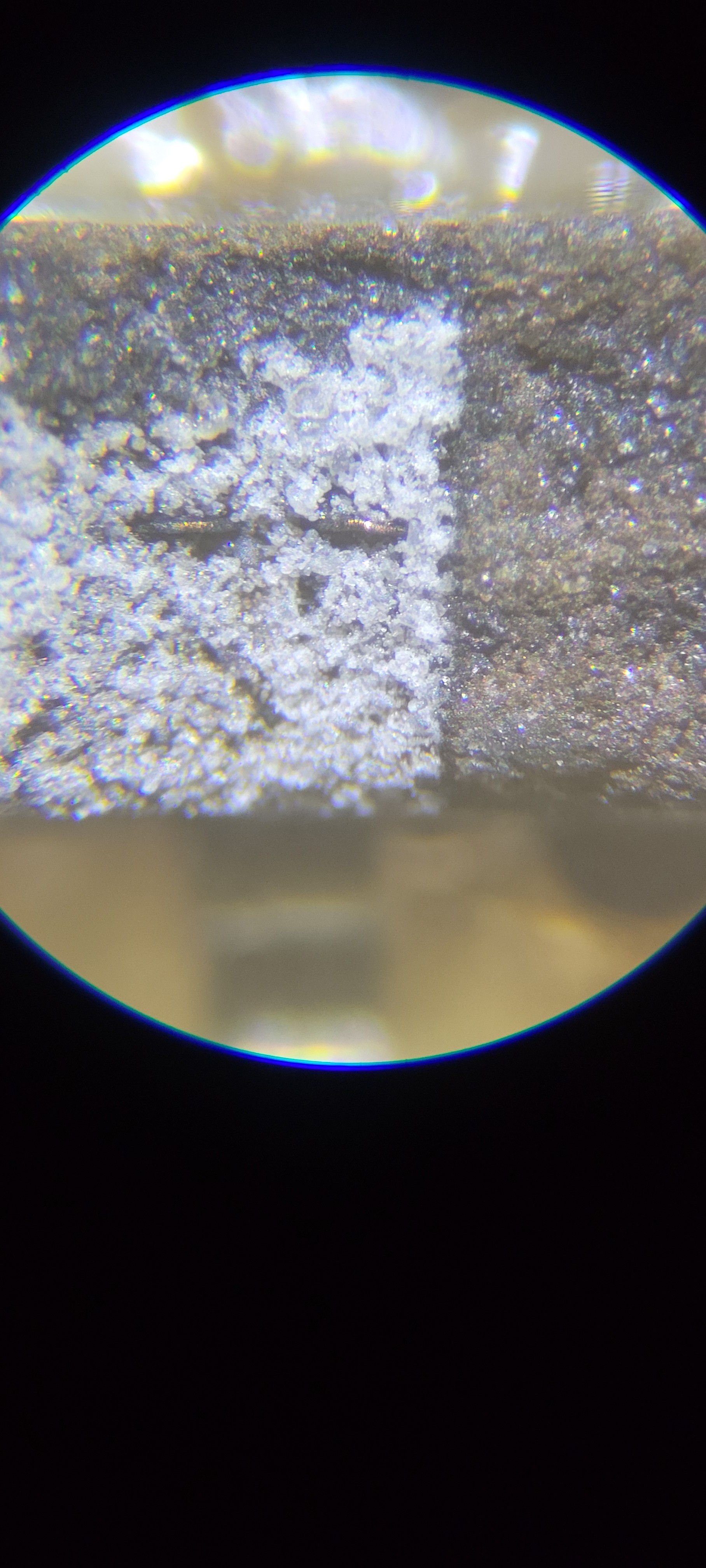

1. Get rid of package's upper level until you see the top part of bonding wires. This can be done with cheap low power laser. I have 5W optical laser for 50$. I use only about 1% of it's power.

After few iterations of scorching by laser and scrapping the glass material. You get the bonding wires.

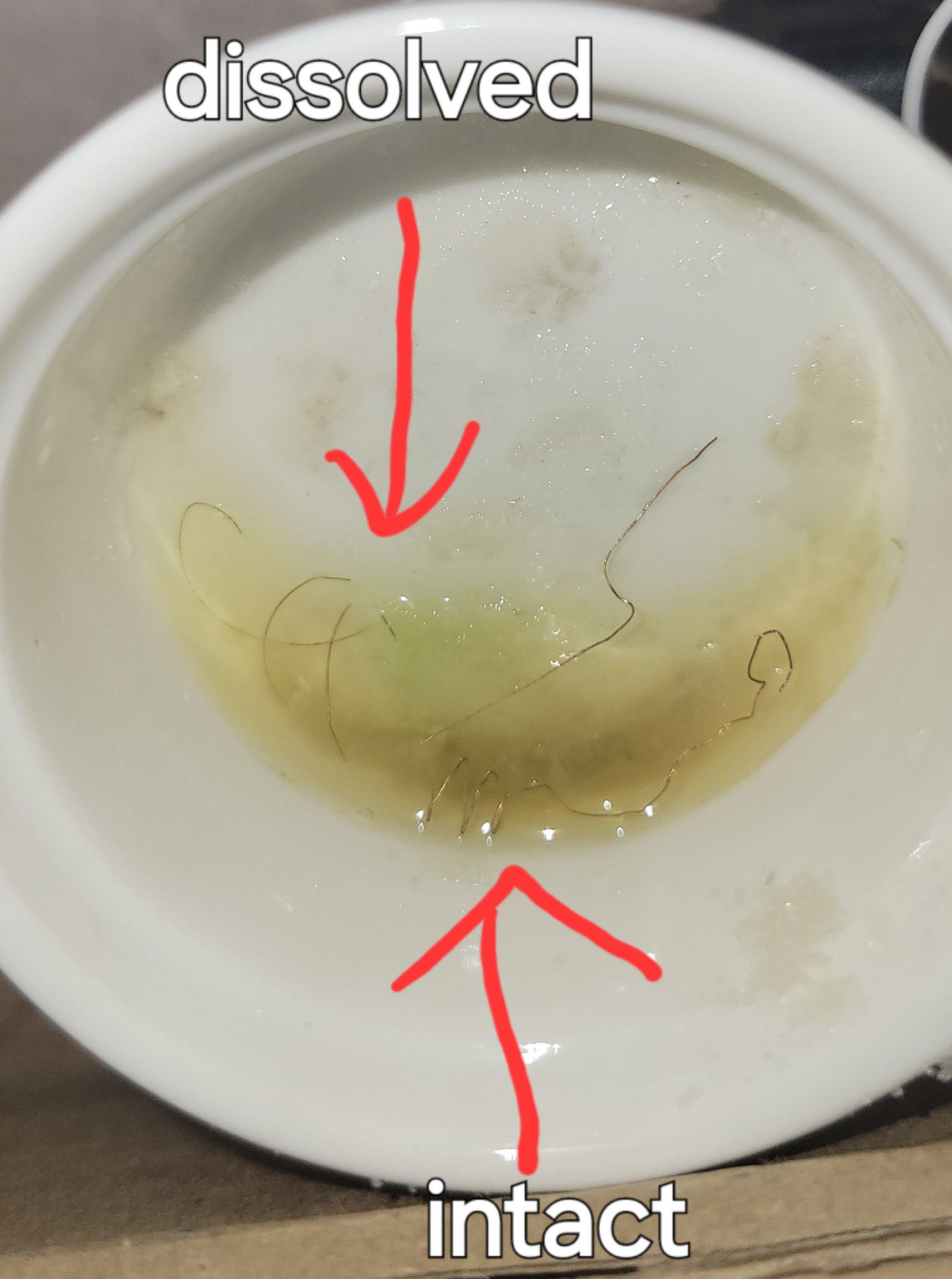

2. Coat bonding wires with some material that will oxidize copper. Thus, making protection layer against chemicals like diluted Nitric acid.

I've used NaOH (just because I am familiar with it) there are two coils one that was connected to anode other to cathode. The copper coil that was connected to anod was dissolved even without heat. The cathode's coil stayed intact.

Another test I've run was making oxidation layer using plain water.

The coil that was connected to anod (+) was coated with oxidation layer and was not destroyed by Nitric acid. The other one got rust and braked easily once I tried to remove it.

3. Use whatever nitiric acid you can get

That's what we already did in last eleven attempts.

P.S.

Although the idea of electric oxidation/coating is nice practically it's a problem to do something in such a small vicinity.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.