-

Method #8 - FAIL

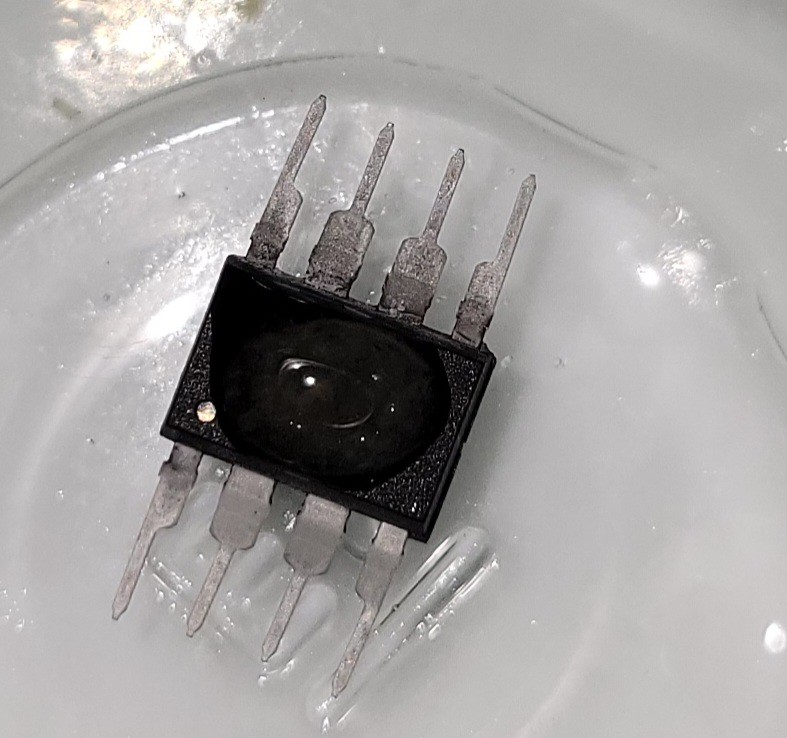

07/21/2024 at 15:34 • 0 commentsMilling a hole in IC's package and filling with Sulfuric acid or Nitric acid basically do the job. We can reveal the die while terminals still intact. This is great result but one thing is still missing the bond wires they simply gone.

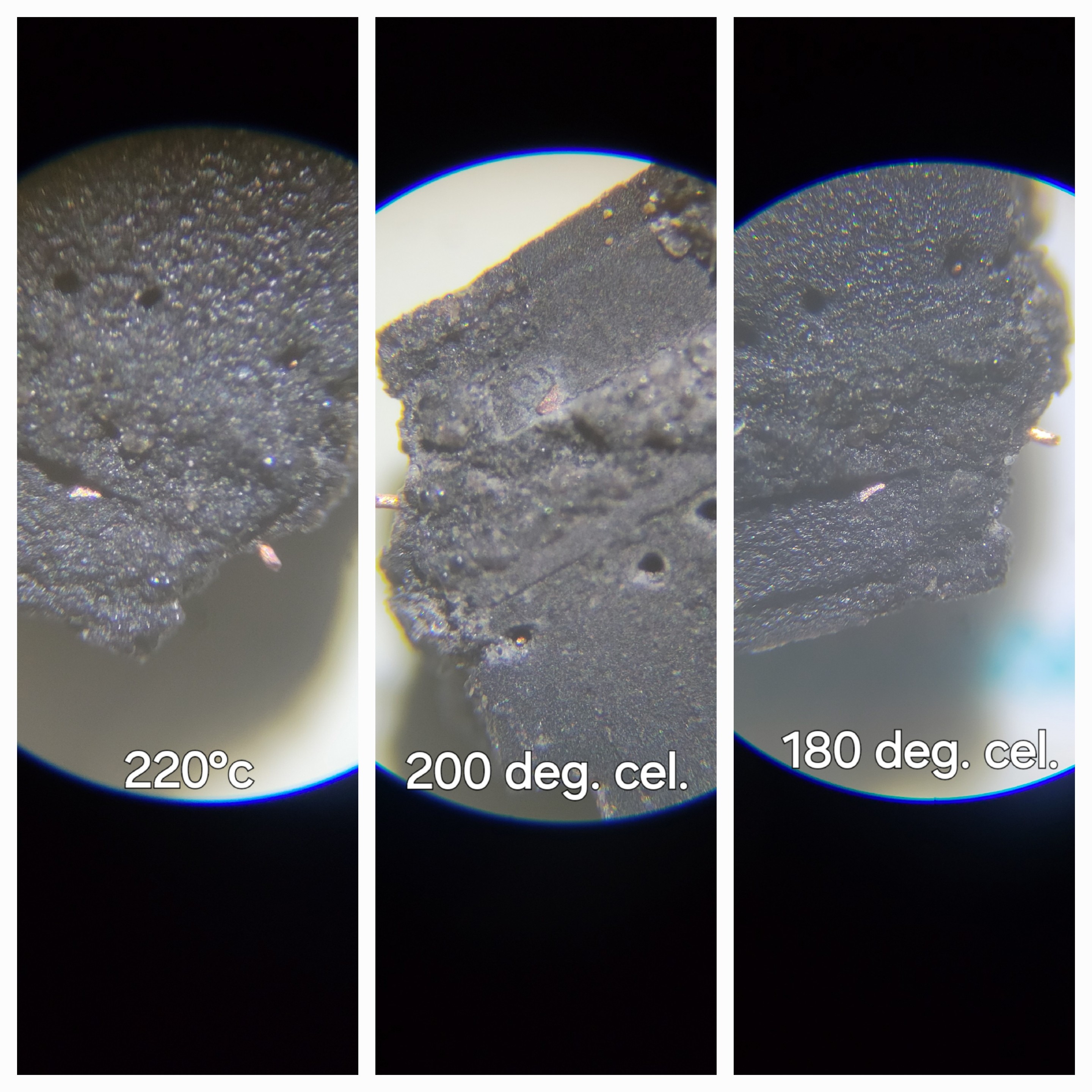

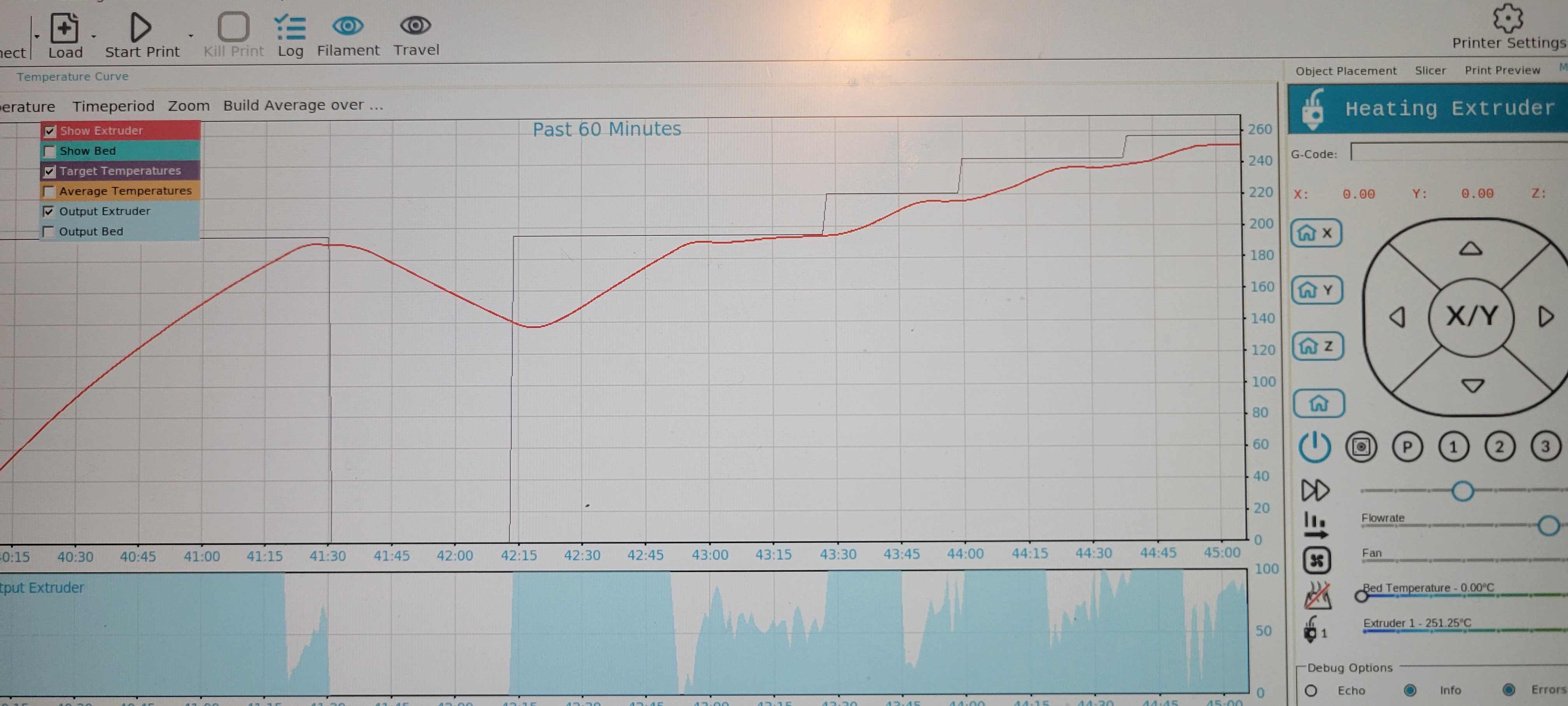

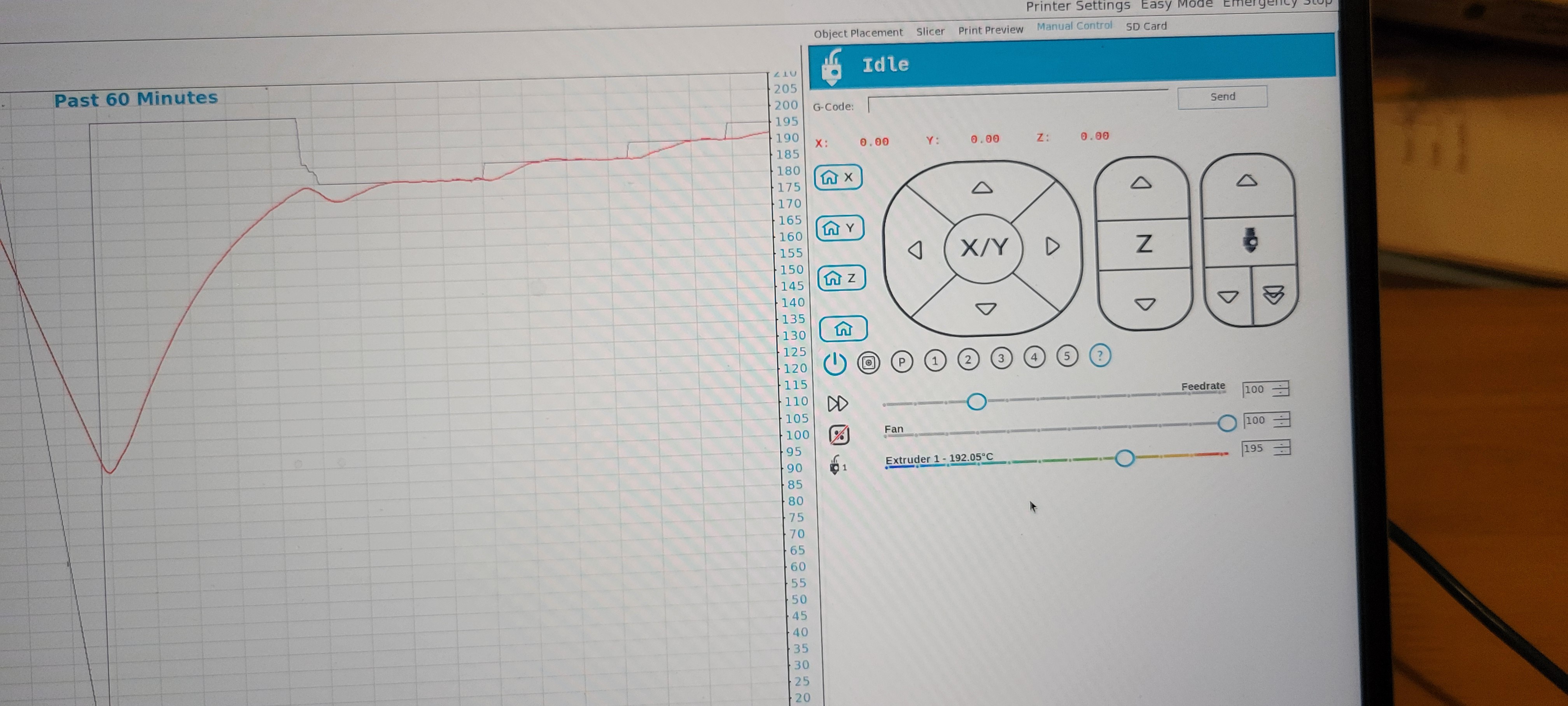

My assumption was that hot temperature has dissolved the tiny copper wires. So, I smashed some ICs and started to test at which temperature thier bond wires will be dissolved. (Same place different temperatures)

![]()

It looks like 180-220°c with Sulfuric Acid is safe for tiny wires.

So, if hot temperature doesn't destroy bond wires what does?

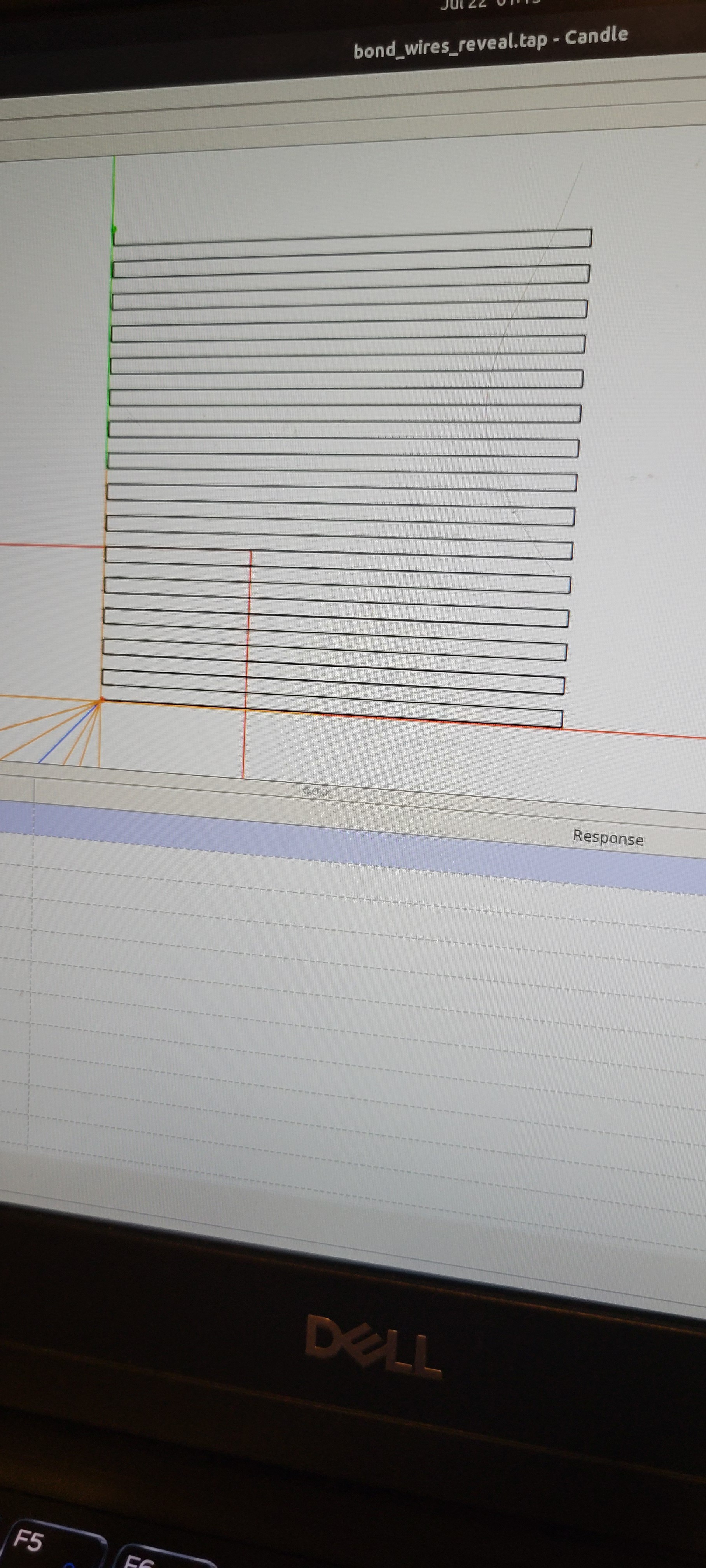

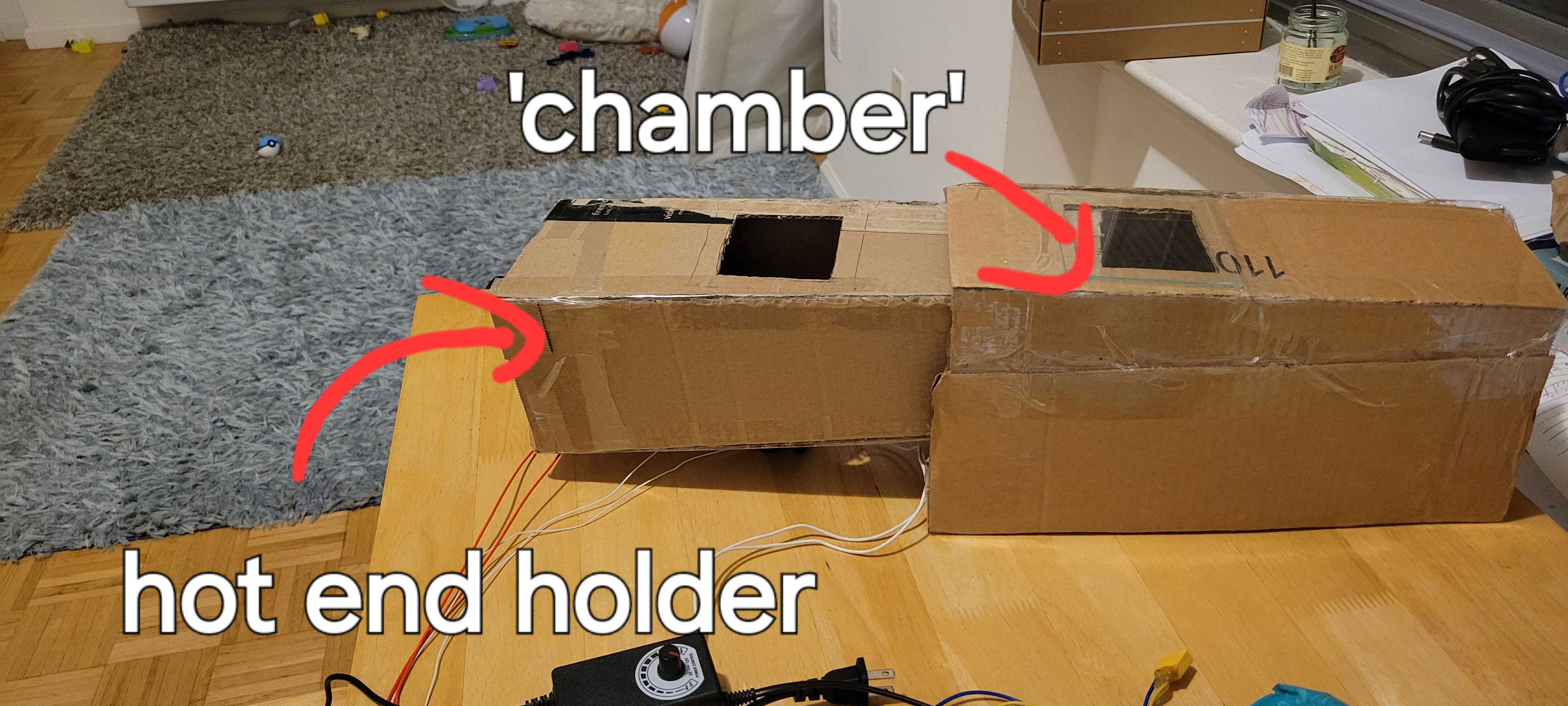

To answer this let's take another approach, instead of manually milling we will use CNC with raster scan pattern.

![]()

And milling it

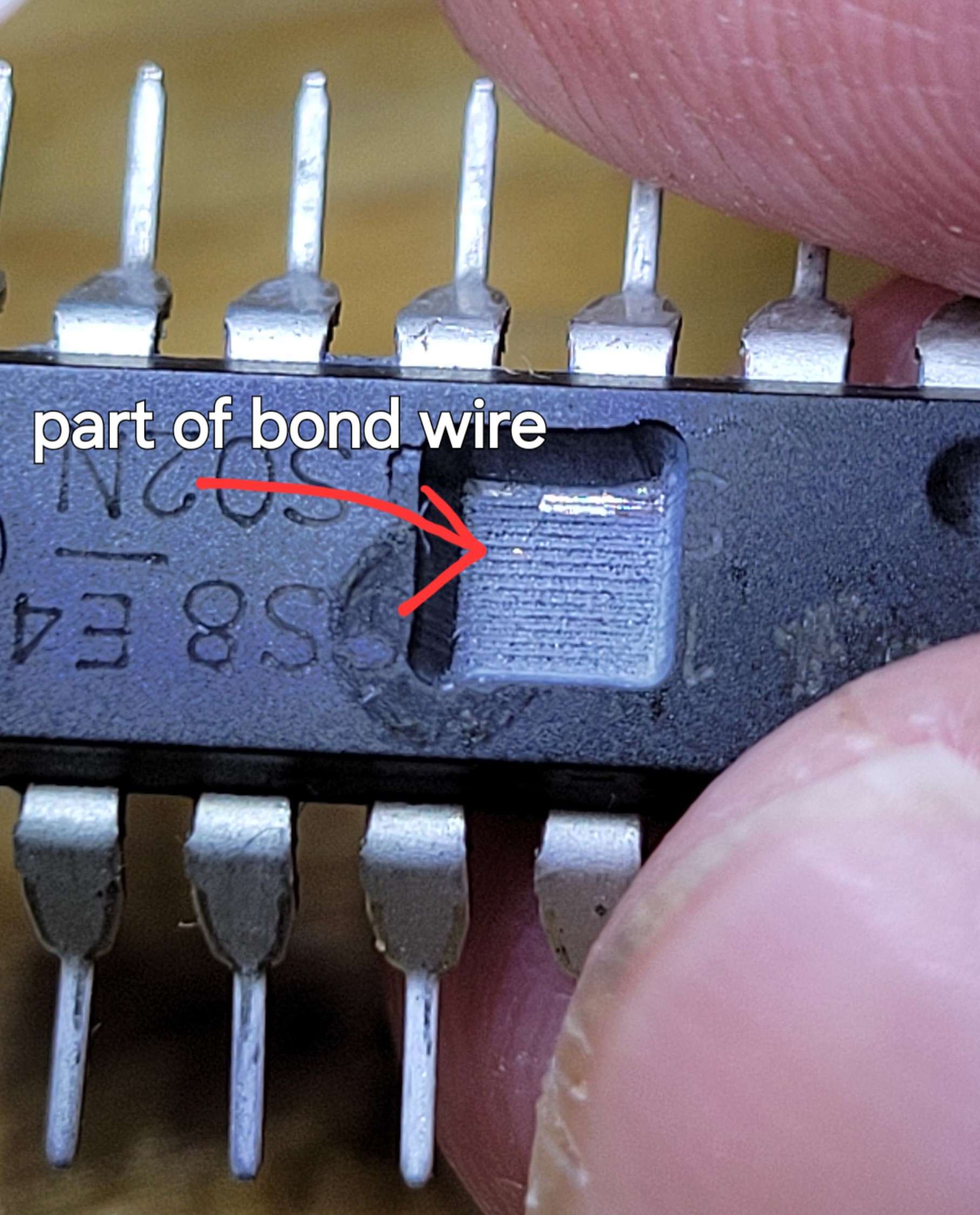

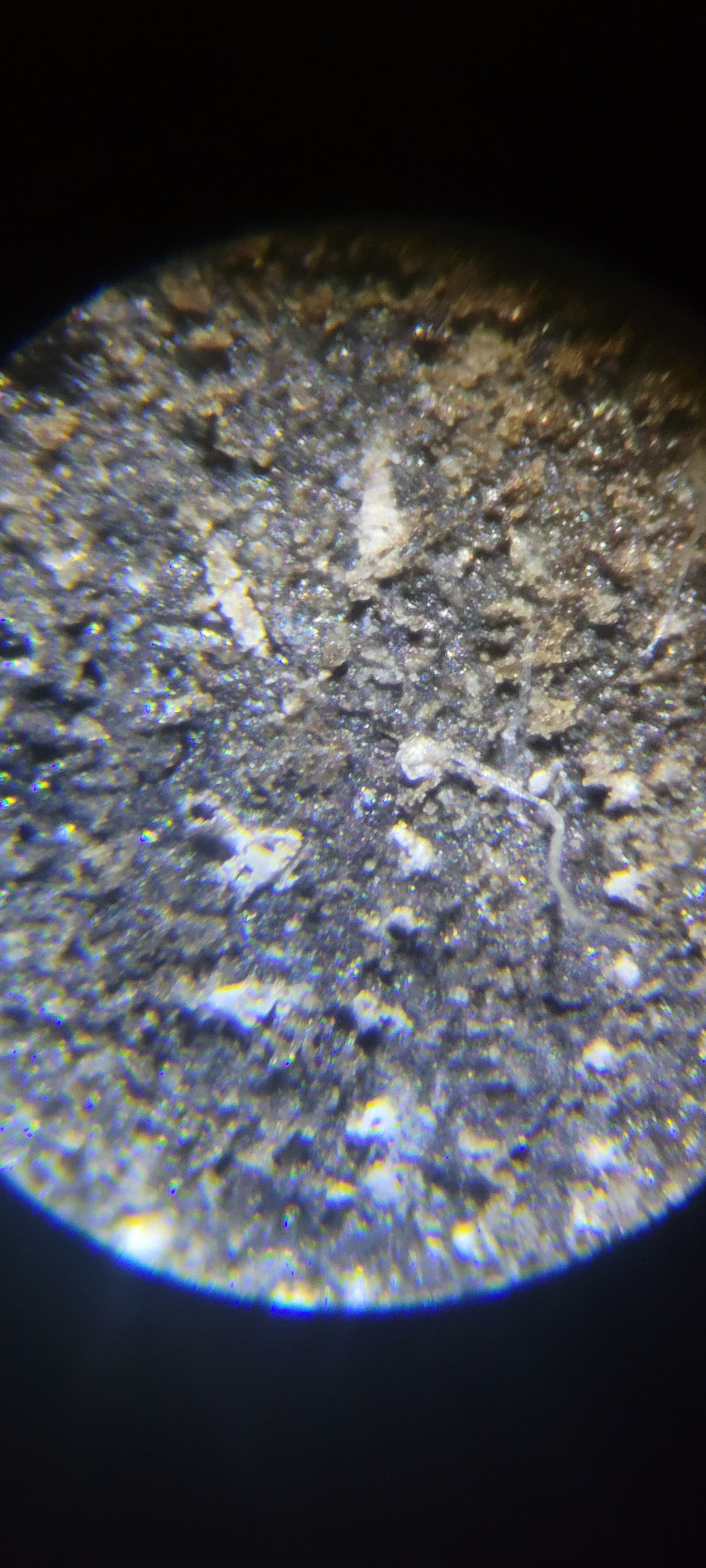

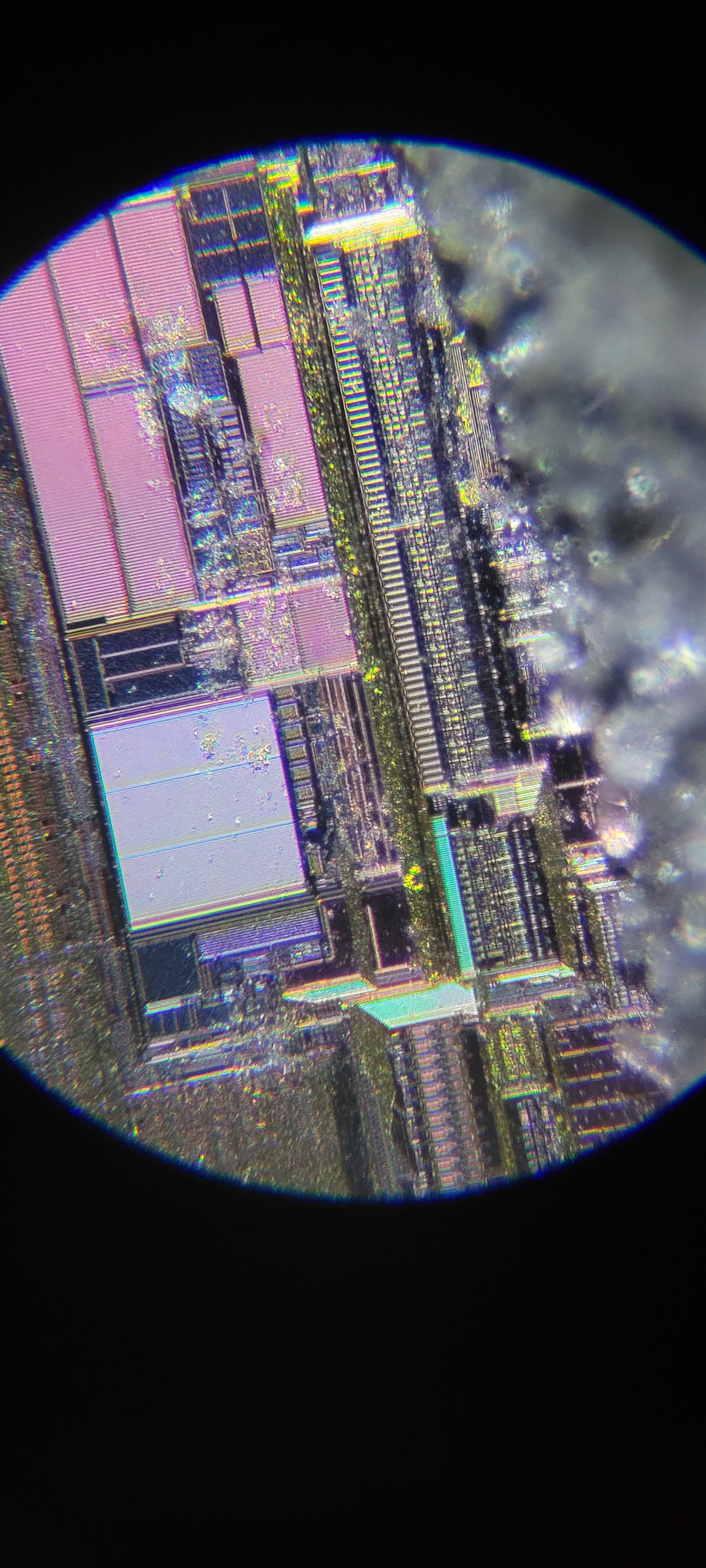

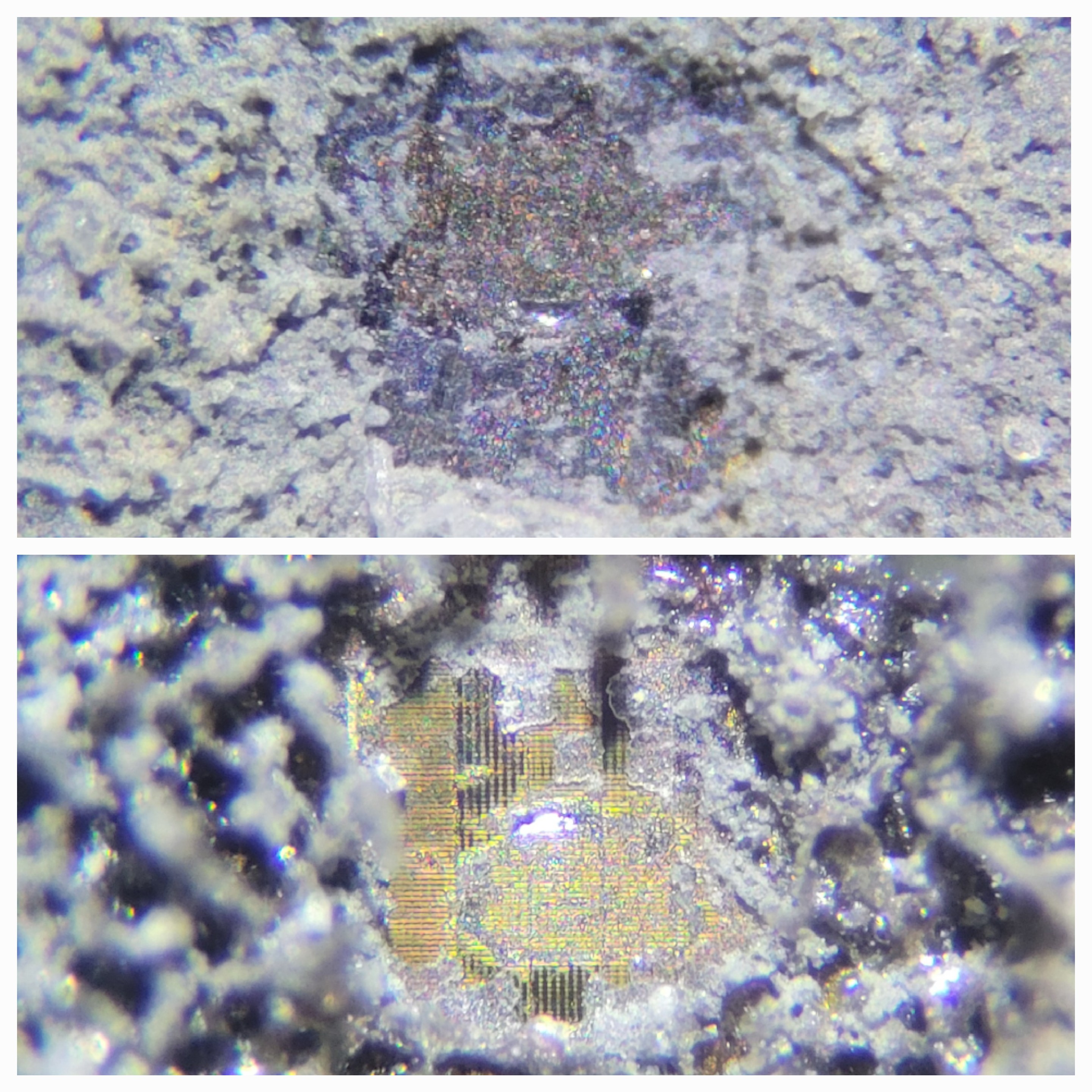

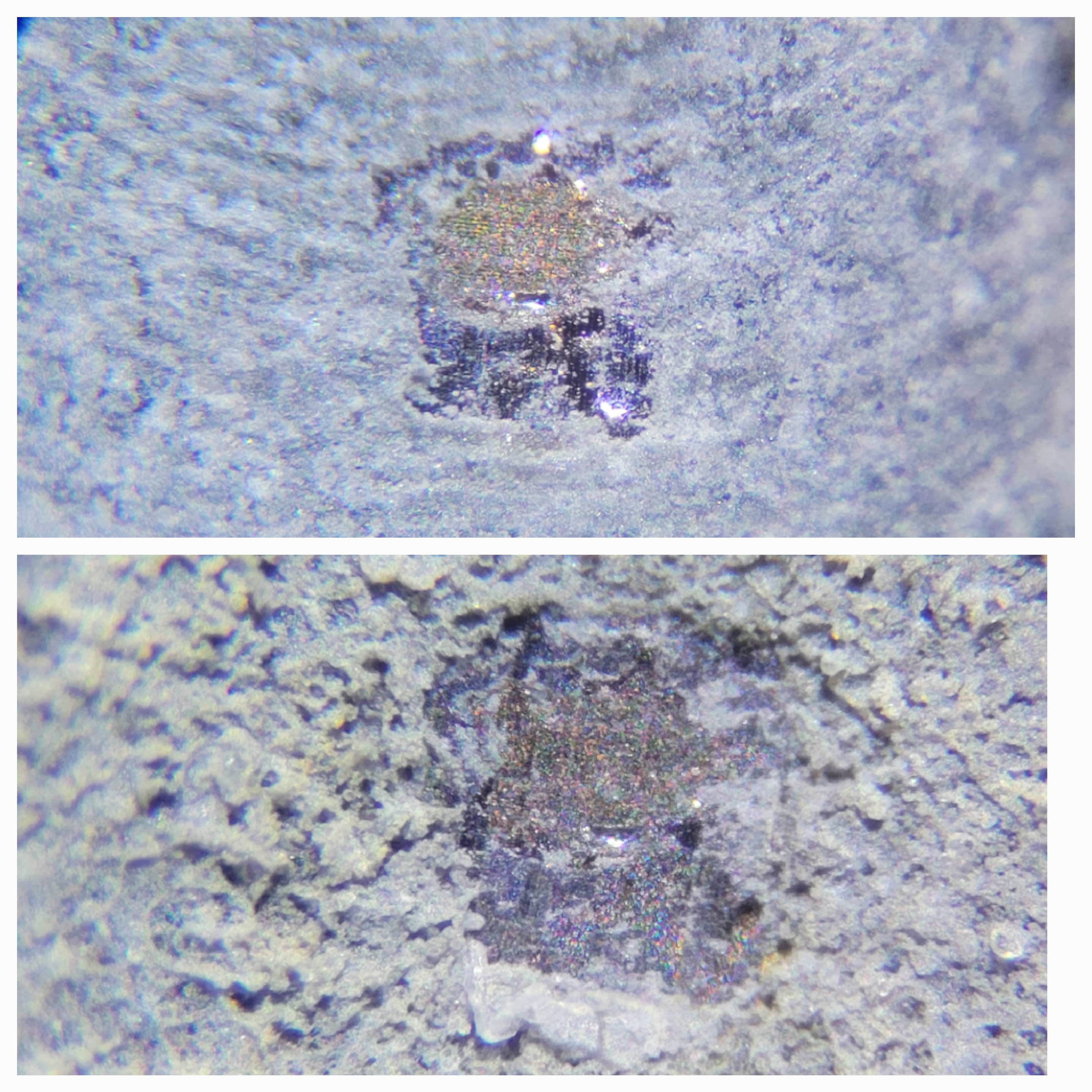

First by 0.3mm and then by 0.1mm we get this

![]()

We see the top of (one of many) bond wires.

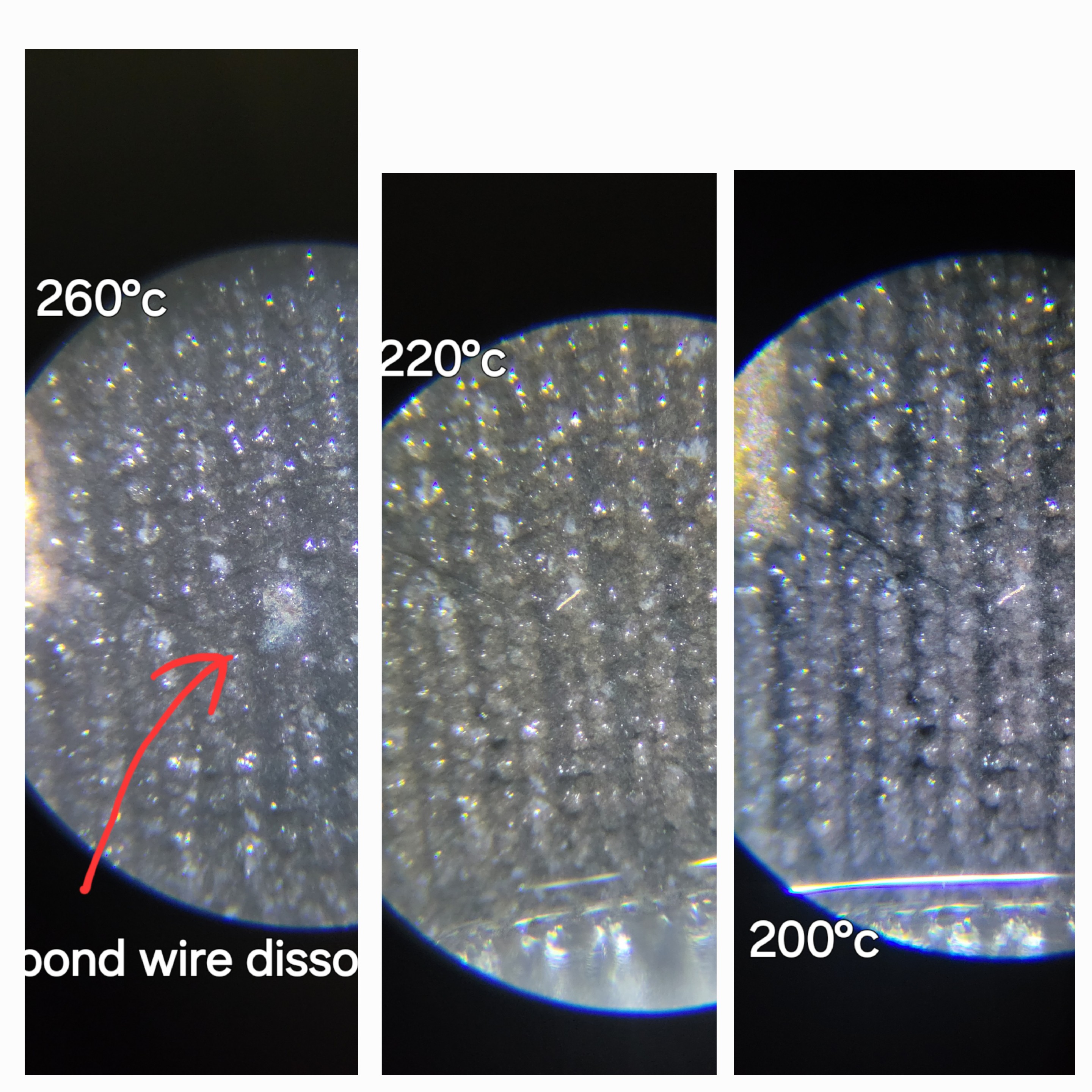

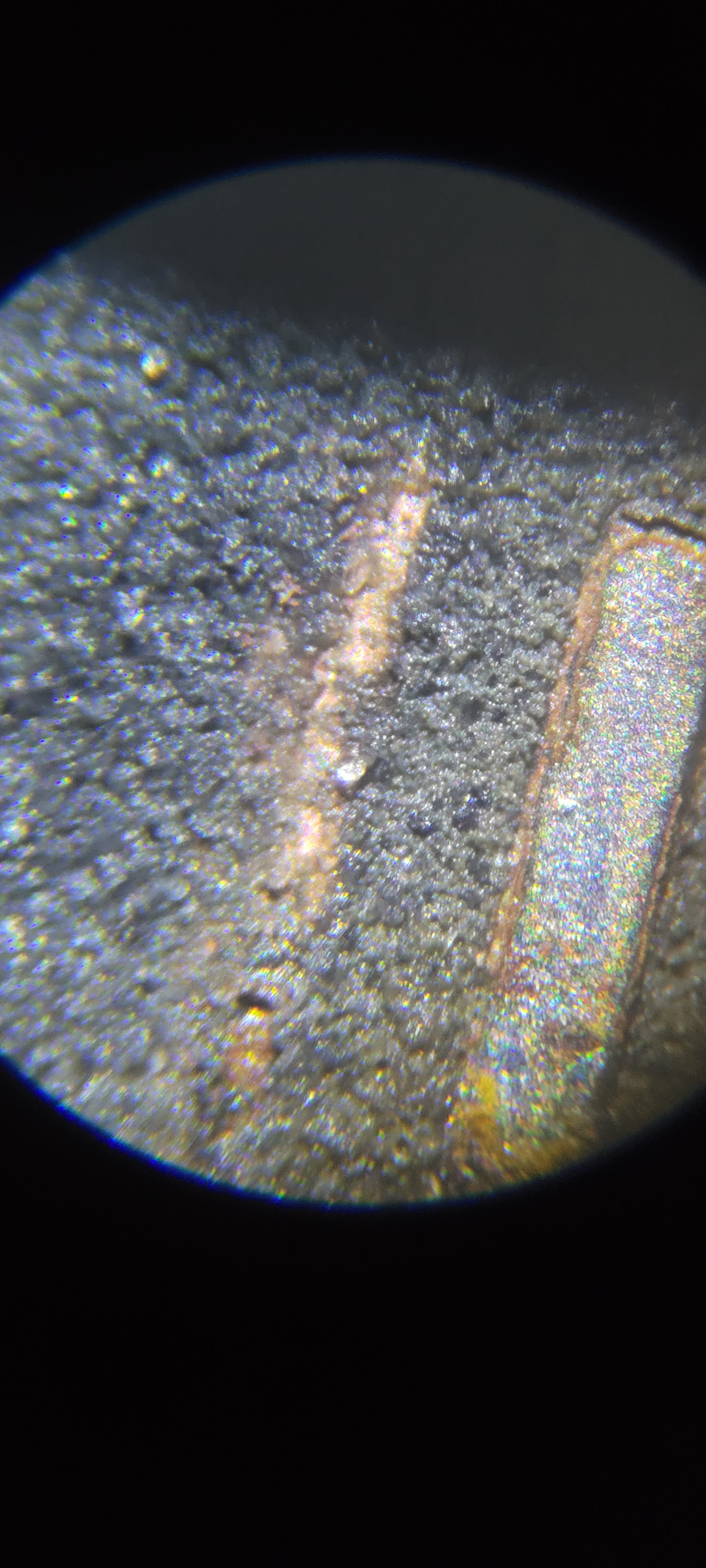

Now, if we add Sulfuric acid with temperature of 220°c nothing will happen. But if we rise to 240-260°c bond wires will be dissolved.

![]()

Same happens with Nitric acid with temperature if 200°c

![]()

The white things are the 'shell' of what used to be bond wires.

Added ceramic cup instead of thin metallic one

![]()

Now Nitric acid will not try to burn through the tray.

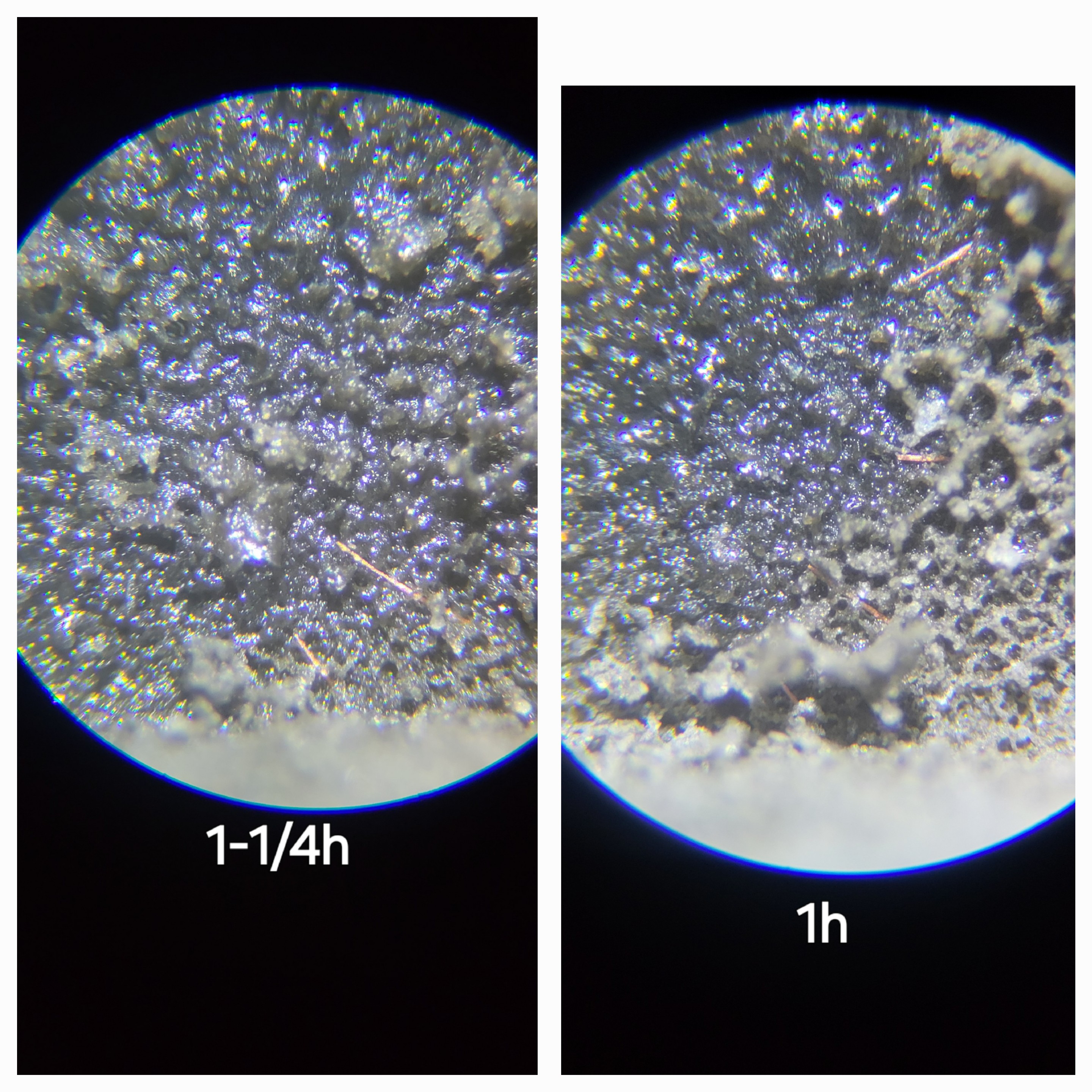

Nitric acid is amazing, only 15 minutes and some structures started to emerge.

![]()

And the bond wires? Totally intact

![]()

We can see the bond wires intact with higher temperatures. (Although at 200°c they will be totally dissolved)

It's worth trying 160&180°c but this is very good starting point.

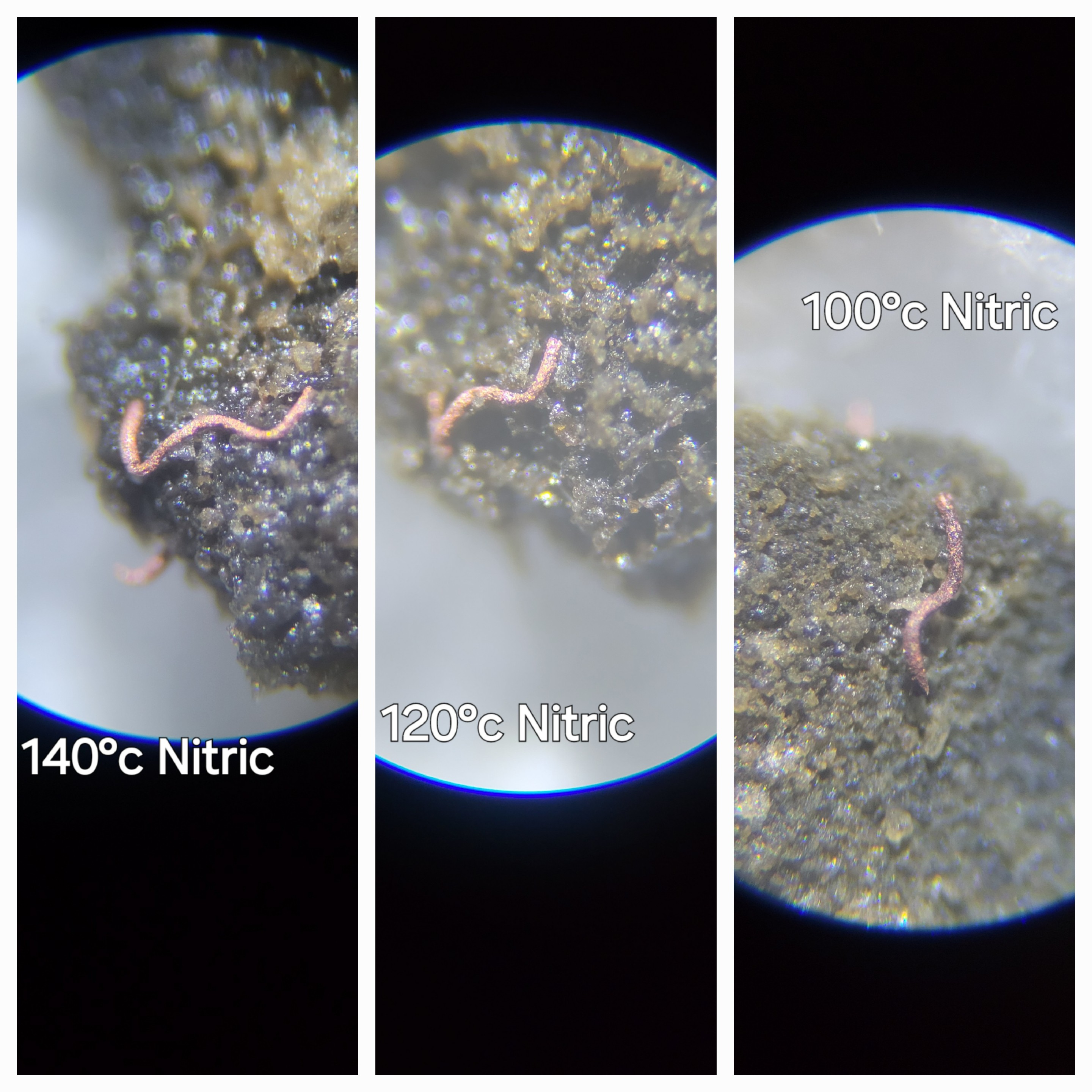

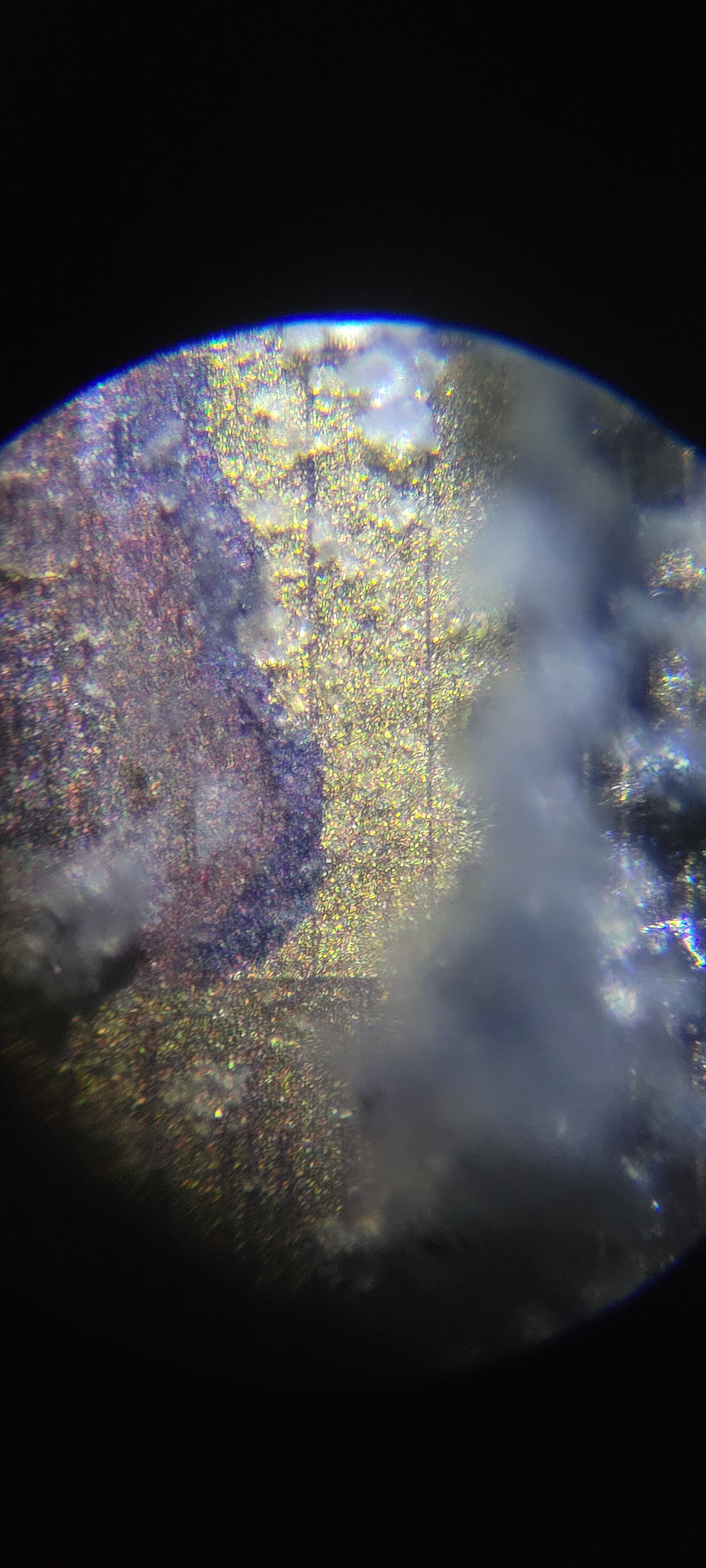

Bad news, after much testing it look like in Nitric acid, bond wires are dissolved at temperature of 120°c after about an hour.

![]()

We can see the difference as bond wires get thin and disappear eventually.

-

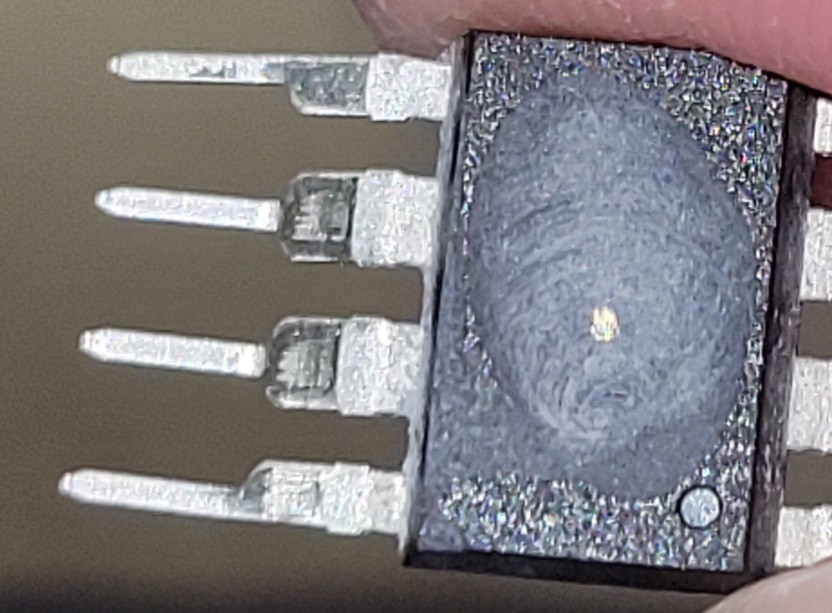

Method #7 - success without bond wires

07/18/2024 at 10:39 • 0 commentsThis method is direct continuation of previous one with some tricks.

First we use no screws between tray and heat end head. Just 'artctic silver' for better heat transfer and dots of glue to hold everything together.

![]()

Second thing is using 60 Watts hot end instead of standard 20 Watts. Unfortunately, some 3d boards, such as BTT SKR 1.4V, doesn't support such high Wattage. I've made a trick and use hot bed connection instead. (Changed pins of hotend and hotbed) (It's impossible to use hotbed connection as is since hotbed range doesn't goes beyond 100+ something.)

Now, heating to 200°c was only 90 seconds instead of 5 minutes.

And was able to reach 260°c easily.

![]()

I've run different configurations regarding Potassium nitrate vs Sulfuric acid. It loks like the more Potassium nitrate the better. The result was nice

![]()

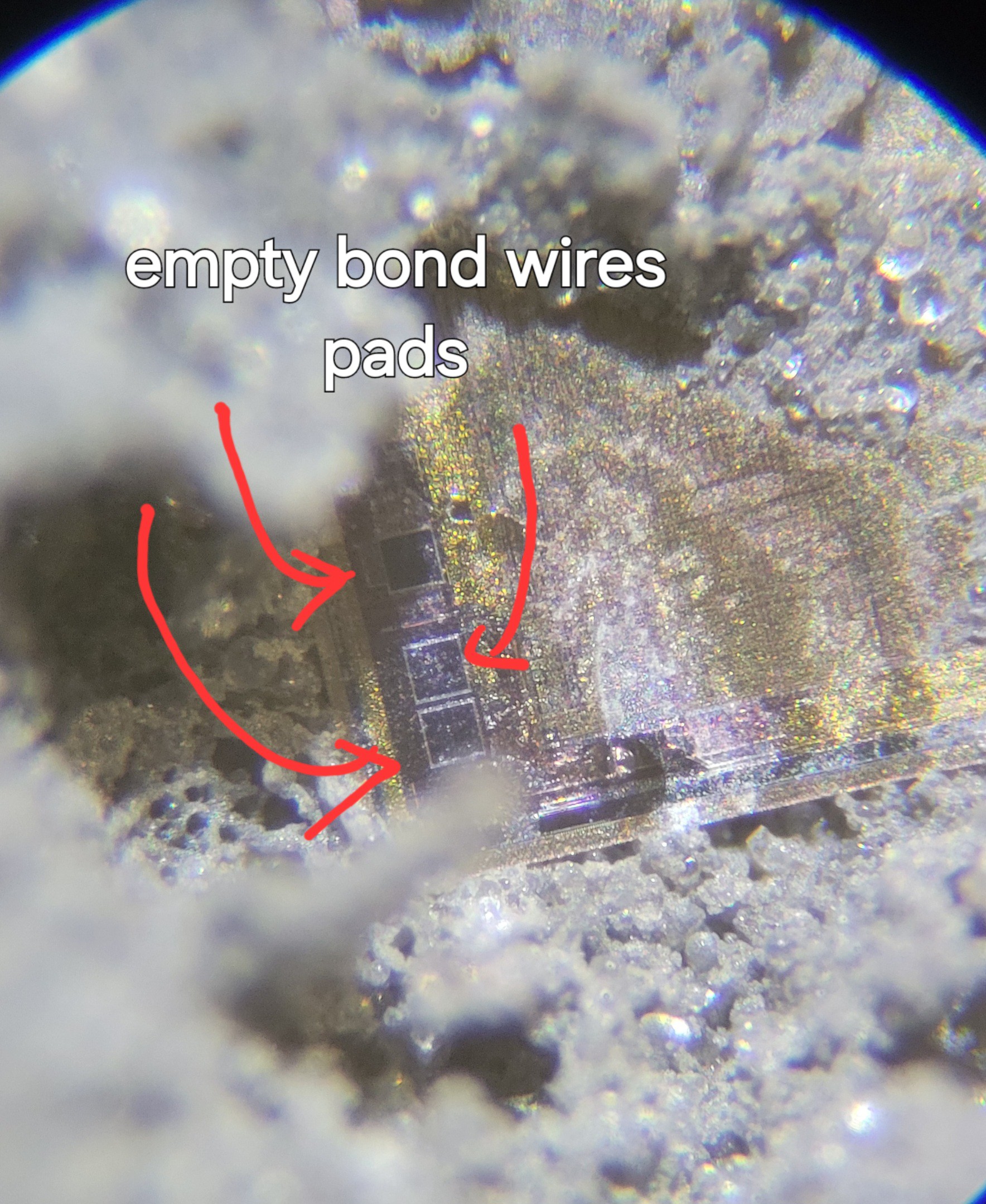

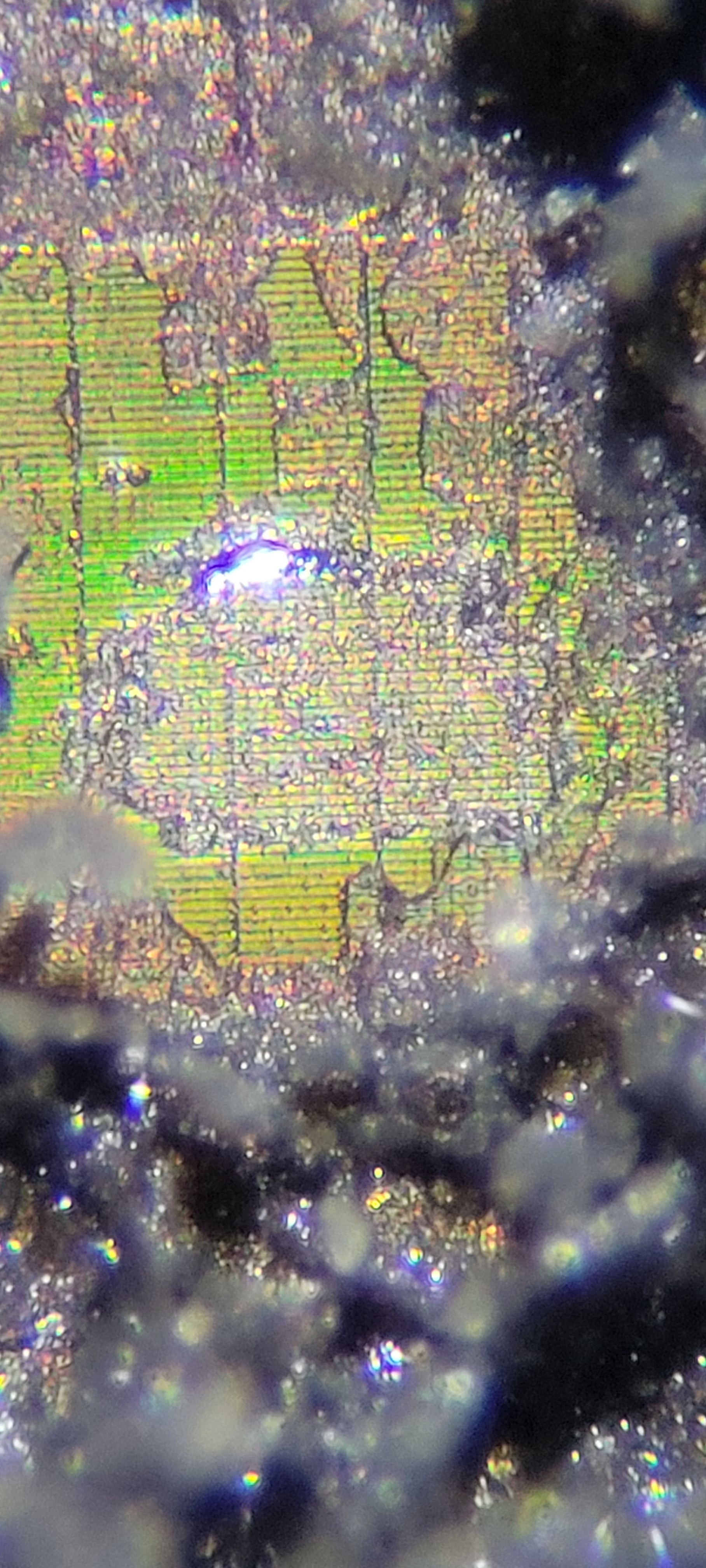

I was happy for a while but then I saw this

![]()

The bond wires are empty I have compared with some old picture where I performed decapping using plasma. The pods where there with remains of bond wires.

So, "operation was successful, the patient is dead".

We now know that with 260°c the so called 'diy home made Nitric acid' works and decapping the IC.

Now we have to find the lowest temperature where where decapping is possible without dissolving bond wires.

-

Method #6 - FAIL - too slow

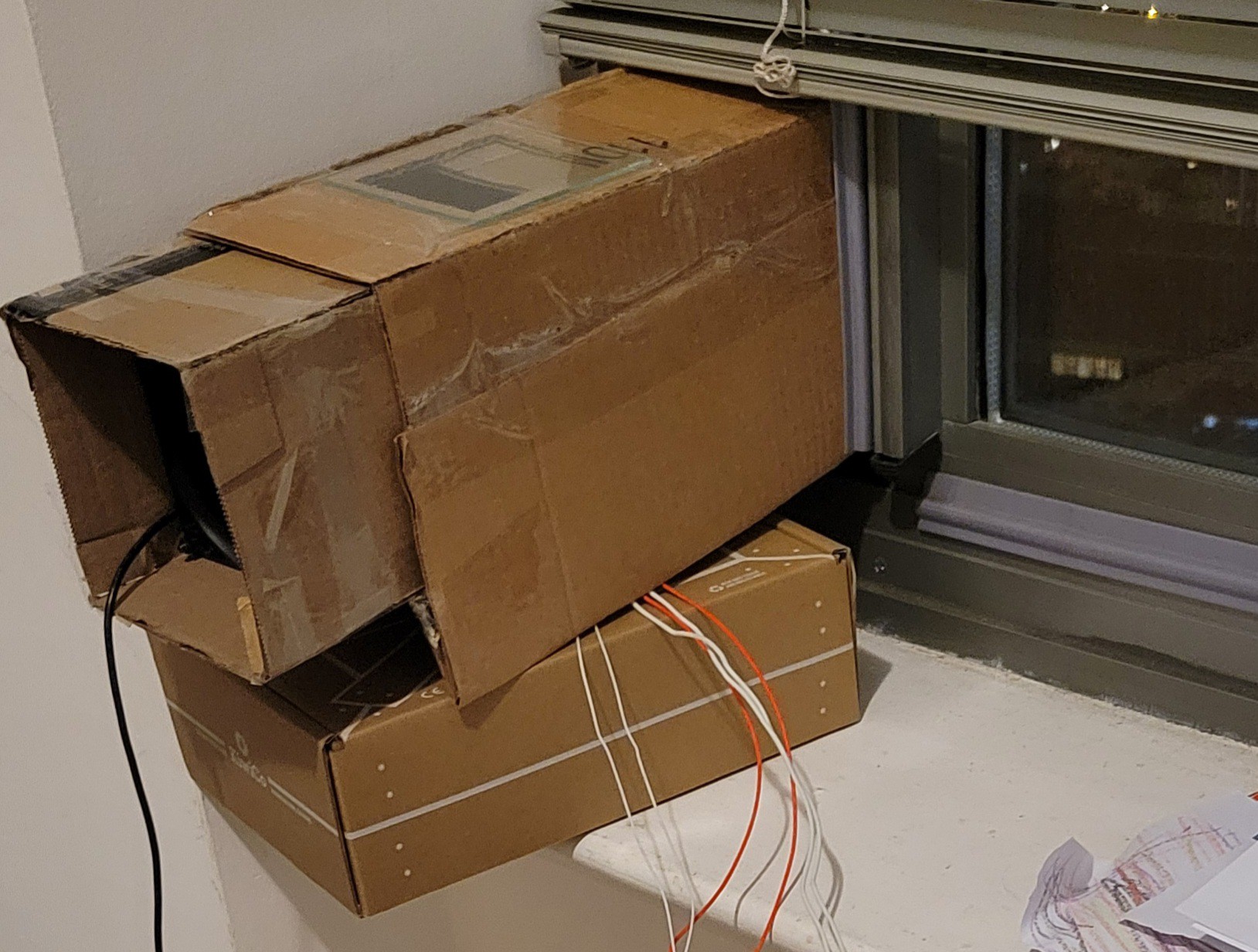

07/15/2024 at 01:57 • 0 commentsI've changed my "chamber" a bit so now main fan doesn't blow room temperature air on the IC/Tray.

Was able to bring temperature to 220°c

Now at 195°c solution started to bubble and Nitric acid (at least I think it's Nitric acid) was vaporized after 2-3 minutes. I applied another drop of Nitric acid.

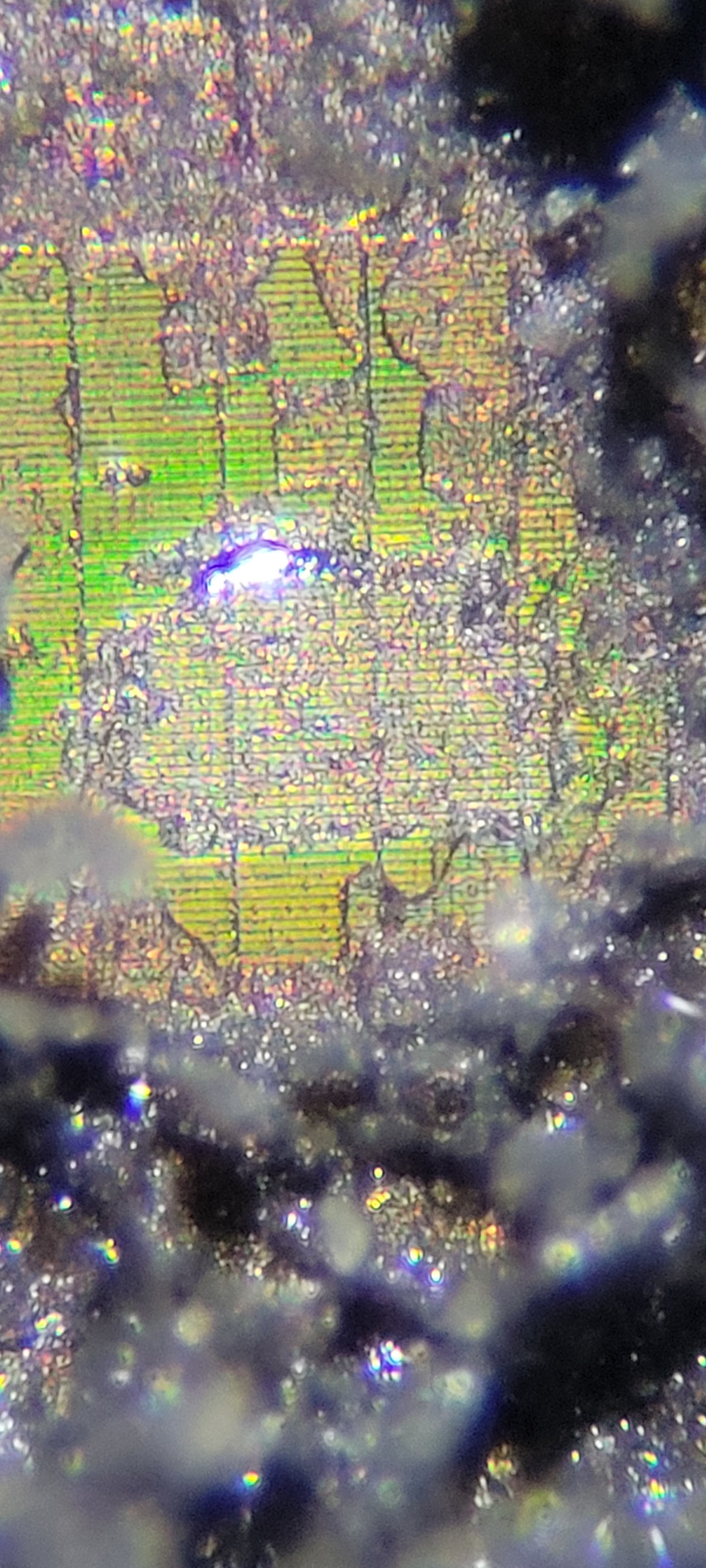

After all was done, sample was taken to be seen underneath microscope. The hole became much bigger which was a great news but something else caught my eye.

![]()

What it looks like copper being dissolved by Nitric acid. Maybe because I have accidentally broken the passivation layer.

This is another interesting point, can we remove upper copper layer just be cracking the passivation layer and applying Nitric avid?

It's very interesting question which we will deal later.

![]()

I believe the 'ice' looking sheets is the shattered passivation layer.

The gray in the middle is where drill's bit hit the silicone.

Next step will be taking new sample where passivation was not damaged.

I've tried to use new samples and I can see how epoxy being dissolved. But, it way too slow... We need more power/steam!!!

-

Method #5 - FAIL

07/15/2024 at 01:33 • 0 commentsSomeone have adviced to use Sulfuric Acid only. Tried with 195°c and nothing happened.

Note: I use drain cleaner (93%) not 98% Sulfuric acid.

Another note: I measure temperature in the hotend not in the tray where IC is placed. So maybe the temperature is lower.

-

Method #4 - partial success

07/12/2024 at 01:15 • 0 commentsThis method is a continuation from previous one. In the previous method, we tried to create Nitric acid by just adding ingredients without applying any heat. Now we adding the heat source.

Now, we making all the reaction, it's seems like a good idea to have nice fume chamber.

But do we need a full size fume chamber? Absolutely no! Since we start by adding ingredients while they cold and Nitric acid is not formed yet. Furthermore, we will wait until all Nitric acid is evaporated. So, in the beginning and in the ens we don't need fume chamber. We only need ot the middle.

Let's start from what is fume chamber? I thought it's hermetic box with gloves. It has gloves but it's not hermetic, it takes air from the room and suck it through the fume chamber and extract it using a fan/air-pump outside.

Going back to the main observation, since we don't work with dangerous materials in the end and in the beginning we don't need those fume chamber gloves.

So what left is just a pipe with a fan that can be opened when needed.

![]()

When assembled it's getting a compact form of

![]()

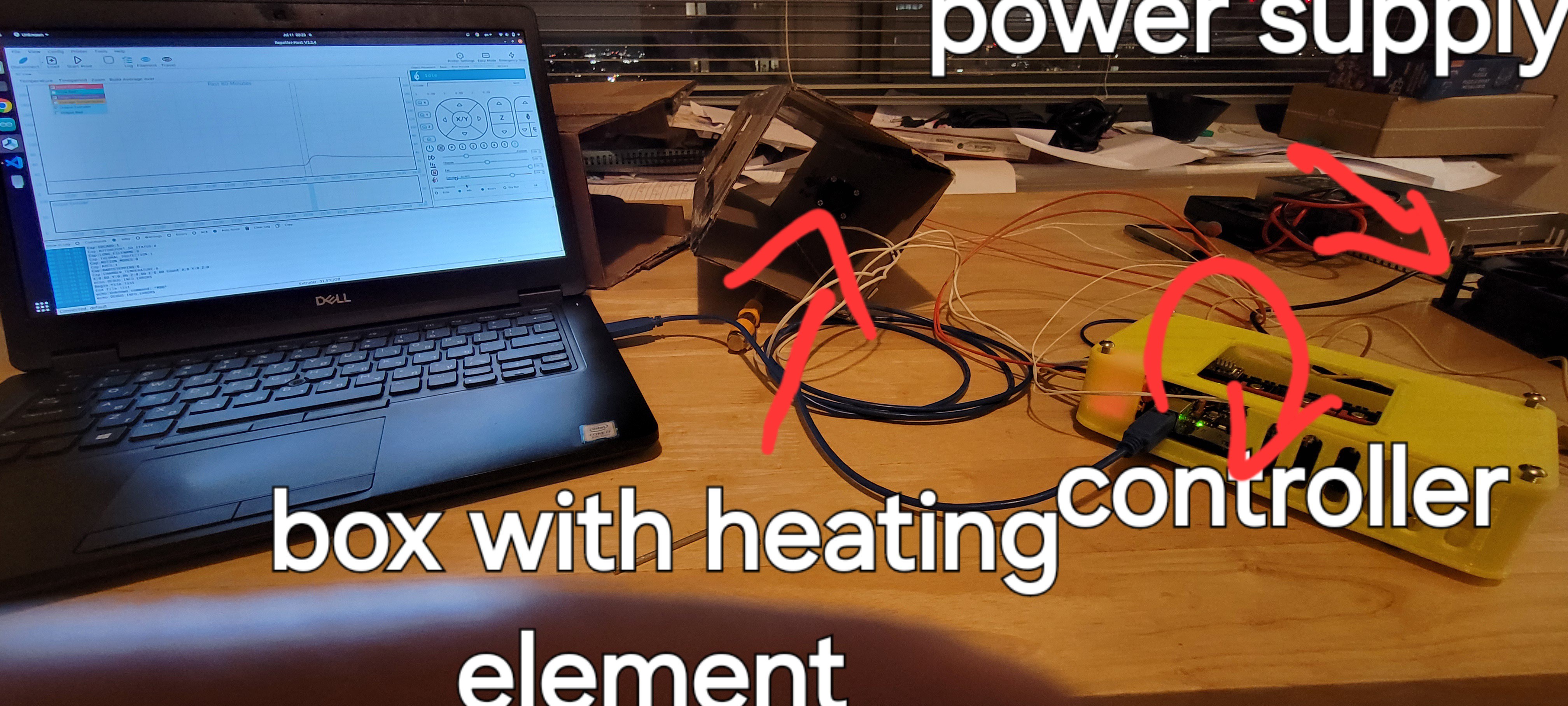

All the electric together looks like:

![]()

Run some tests, was not able to reach more than 170°c.

Connected heating element and tray in a better way, now we are able to get as high as 195°c

![]()

Simple test, I put IC with a drop of water in it. Look what happened after two minutes of heating:

Now, let's add REAL acid and see what happens. I've gradually started increasing the temperature. At about 195°c (of the hot end, I guess the tray is much cooler) there were bubbles.

This video is 10x faster than normal one. So bubbles formed but in low quantity. It felt disappointing but under microscope it looked in a totally different way

![]()

And it was only after 10 minutes. Running it for another 20 minutes gave quite the same result

![]()

The next thing will be using Sulfuric acid instead and more effective heat.

-

Method #3 - FAIL

06/30/2024 at 02:56 • 0 commentsAs the first two methods did show any significant improvement it was time for something more aggressive.

NITRIC ACID!

As I don't want to buy nor own Nitric acid. I went and bought Potassium nitrate.

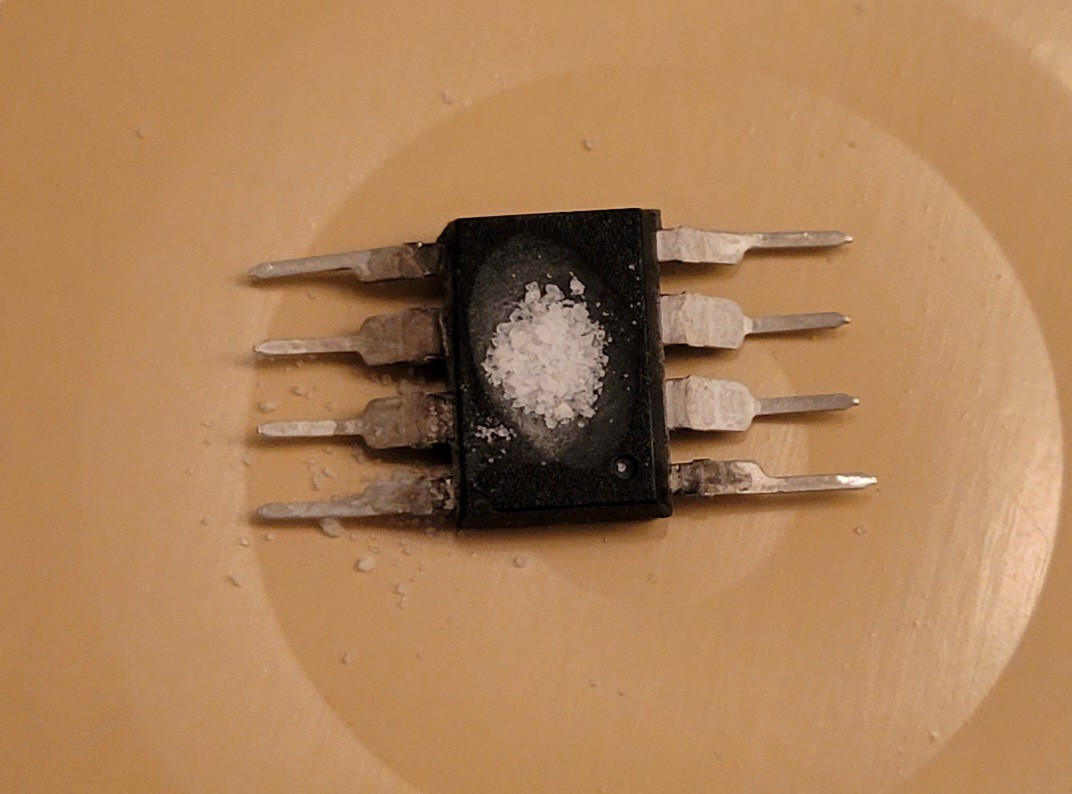

Potassium nitrate is a powder with granularity similar to sugar. I've used tiny twizers to add amount which will be 1/3 of space I have there.

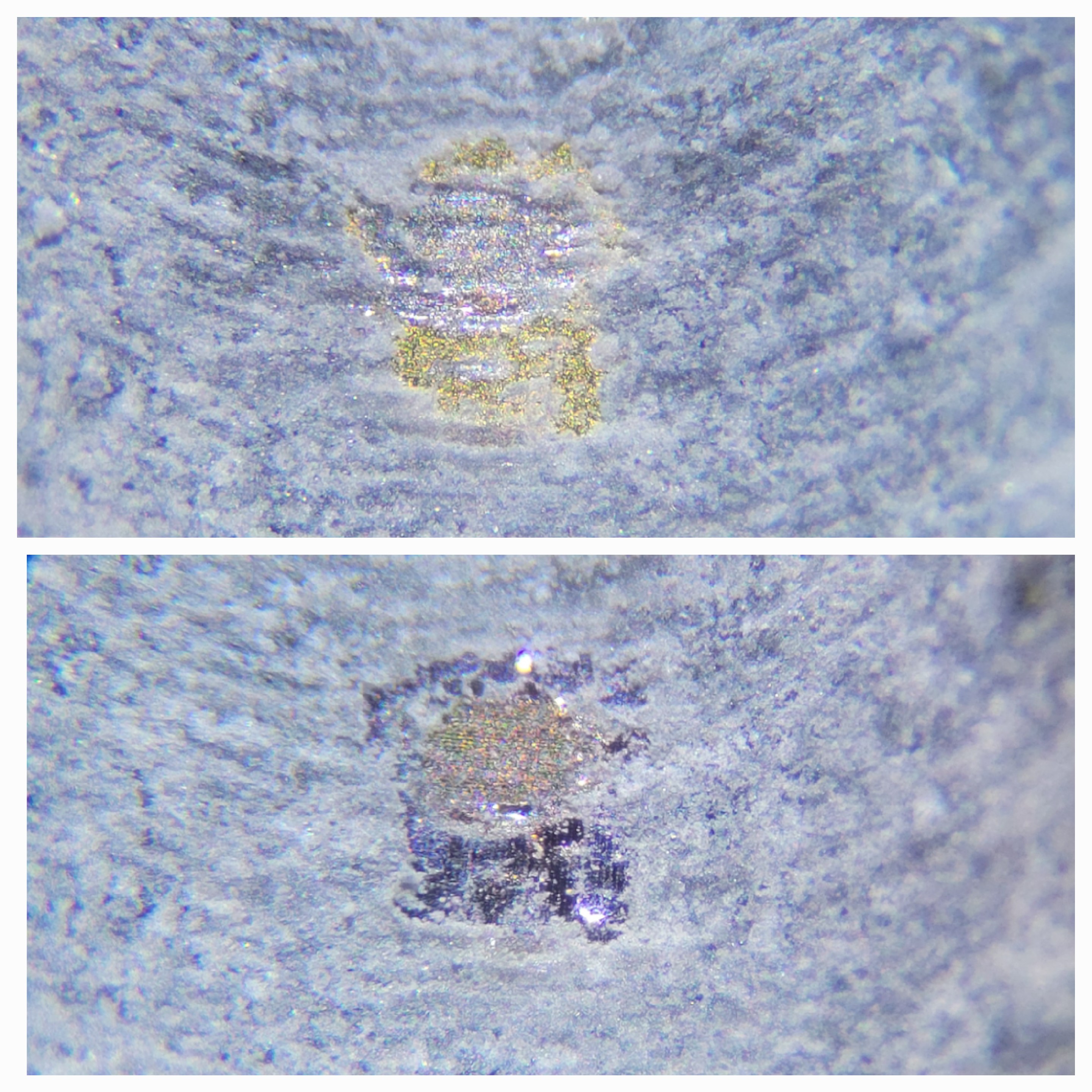

![]()

Once added one drop of sulfuric acid, potassium nitrate powder quickly dissolved and got this opaque substance.

![]()

I've placed the IC inside airtight jar and let it sit for one hour.

I've clean the drop with water (not sure if this the right thing to do, maybe I should use acetone) the first impression was that nothing really happened. On the microscopic level we got a totally different picture.

![]()

On the top picture we can see the lines/scratches of Dremel bit. On the bottom picture we can see those lines are gone and all the surface was mildly eaten by acid.

Although I didn't get all the silicone revealed it's a first step in the right direction.

Next thing would be adding heating element that could change temperature room temperature to about 220°c. Once we have this setup we can play around and see which temperature is minimal for epoxy removal.

-

Method #2 - FAIL

06/30/2024 at 02:21 • 0 commentsQuite the same as method #1 but now heat it up using 3d printer heating bed.

I was able to bring my heating bed up to 90°c.

The result: nothing at all even on microscopic level.

-

First method - FAIL

06/30/2024 at 02:16 • 0 commentsThe method is simple: drill a hole inside IC's package place a drop of sulfuric acid and leave for a night inside airtight box/jar.

![]()

The result didn't get much even looking under the microscope.

![]()

-

The idea

06/29/2024 at 21:29 • 0 commentsI always wanted to be able to decapsulate ICs. The main problem is that the most elegant way is to use powerful acids. I've already tried using plasma but it took long time and any mistake just burns everything.

I heard the lecture from HASH/RECESSIM guy who claimed not to use fumes chamber but just a went. More over he didn't buy Nitric acid (which is illegal in some countries) but created by using drain cleaner (which has 90+ percent sulfuric acid) and potassium nitrate.

There are a lot of videos that shows how to make nitric acid from sulfuric acid.

And then I got an idea 💡 what if we take tiny drop of sulfuric acid and apply directly on the IC I want to examine. The idea is that we don't need to store this powerful acid. It will created on the IC it will etch the IC and vanish.

The pros of this method:

* Easy to obtain materials

* Nothing to store

* Does need fume chamber since I work with less powerful chemicals (drain cleaner doesn't require fume chamber last time I read it's instructions)

* Quantity is really small we talking about drop size which is 1/20th of 0.25ml.

Cons:

* It will be hard to make correct concentration of Sulfuric Acid vs Nitric acid.

I recall that at the time I was banging my brains out on Tesla coil to create stable plasma. Danny (electronics guru) asked 'why don't you just ask for 100ml of Nitric acid put in a box for a week. After a week it will become jelly wash it away and you done'.

In that time I didn't know where to get Nitric acid or how to work with it. Now I feel it's time to check what Danny meant. After all I trust Danny the guy knows electronics and everything related to it.

So let's give it a try...

But first safety! Although the quantity is small it still acid and power one.

I started from watching YouTube videos on how to create those acids and most important is that those acids are extremely corrosive but not toxic. It means that if you spill this acid on you (skin) you have twenty seconds or so to wash it with water and you are fine. It's very important to know because what I thought about it is like in fight club scene.

Anyway goggles and gloves is must :) you don't want fight club scene to happen

Safe IC decapping while preserving bond wires

Decapping using hardware store available materials and relatively safe procedure