Need Statement | Project Background | Significance

The need statement for our project is a way for Matt’s UROV to obtain a variety of sediment samples with different textures/properties without multiple dives.

Studying sediment samples from below sea ice will allow scientists to better understand the natural phenomena in the area. Sediment samples can also provide valuable information on the history of an area. Our project will conserve time by using a single dive to collect multiple samples/sample types.

Critical Requirements and Specifications

Requirements

- Attachment is modular

- Arm does not exceed the size of entrance hole

- Collected samples from different areas must be stored separate from each other

- Collect multiple samples (>1)

Specifications

- Fit through a 400 mm entrance hole

- Ensure collection device is positioned such that it is in the camera’s frame

- Collect sediment while UROV is at least 400 mm above seabed during sample collection

- Collect and transport multiple sediment samples per dive

- Use at most 4 control signals

- Maintain slight positive buoyancy of UROV

- Attach or detach within 30 minutes

- Each sample size is >=250 cc

Design Description

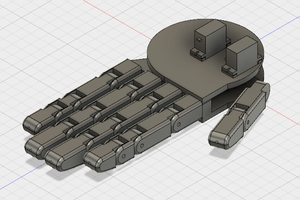

Double-Sided Scooper

- The double-sided scooper utilizes two scoops attached to the existing grips to clamp onto a middle divider, allowing the arm to grab two samples. The two scoopers will move independently of each other and be attached to the existing BlueRobotics arm for easy disassembling/reattachment. A rubber gasket may be required on the edges of the center divider plate to secure sediment inside when the scooper closes. Out of all the designs we had brainstormed in our first sprint, this design showed to be the most promising.

Features

Pros

- Simple design that will collect multiple samples.

- Grabs more than one sample

- Straightforward range of motion

- Does not require advanced mechanic application to existing solution

- Is able to grab within 5 cm from the top layer

Cons

- Only grabs two samples per dive

Scoop and Center Divider Plate Testing

With just the double sided scoop and divider plate, we simulated the water and sediment environment in a tub. The objective was to see the efficiency of the printed parts in retaining sediment with simulated motions.

Testing Takeaways

- Scoop part fits into divider part easily when lined up as the UROV would

- Sediment was secure when scooped into the center divider plate (no suction mechanism needed!)

Implementation

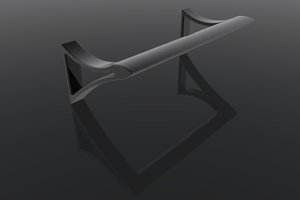

The BlueRobotics arm uses a linear actuation mechanism for the existing gripper, which causes each side of the grippers to move simultaneously rather than independently. To resolve this issue, we designed a few mechanisms to decouple the linear actuation mechanism. We designed mechanisms involving hinges/magnets, a pin and slot, which mimics the current gripper design on the arm, as well as a rack and pinion mechanism. These mechanisms would allow for the linear actuator to move the arms independently.

(Existing arm and gripper mechanism)

Hinge/Magnet

The hinge and magnet mechanism would fit on top of the linear actuation stroke rod, but unfortunately the rod is only 22mm when fully extended, as well as being small in diameter. After prototyping the design, we discovered that the PLA we had used for prototyping proved to be too weak due to the accuracy needed in printing to make small enough hinges for rotation. Additionally, using magnets and springs in freezing water conditions creates a wide room for error due to stresses placed on these small components.

Hinge/Magnet Prototyping

After 3D-printing the hinge/magnet design to be complementary to the provided BlueRobotics arm design, we were able to compare how many features were feasible with our given resources.

Prototyping Takeaways

- Retraction mechanism piece was too small for 3D printer

- Redesign with thicker walls and larger holes for pins

- Supports on printer cause error (excess material) in walls on one side of...

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Supercell

Supercell

Aadit Chaudhary

Aadit Chaudhary