Introduction

In electronics design, the enclosure plays a crucial role in protecting and providing functionality to internal components, directly influencing the usability, aesthetics and durability of the final product. However, many designers face significant challenges when creating professional electronic enclosures, especially when relying on traditional manufacturing methods.

Design complexity, limited materials and constraints imposed by conventional production processes can result in enclosures that do not fully meet the design needs, compromising both the physical integrity and operational efficiency of electronic devices.

Lack of access to advanced manufacturing technologies, such as industrial 3D printing, can lead to design flaws, development delays and high production costs. Designers who underestimate the importance of a well-designed enclosure risk launching less competitive products on the market, negatively impacting the user experience and device longevity.

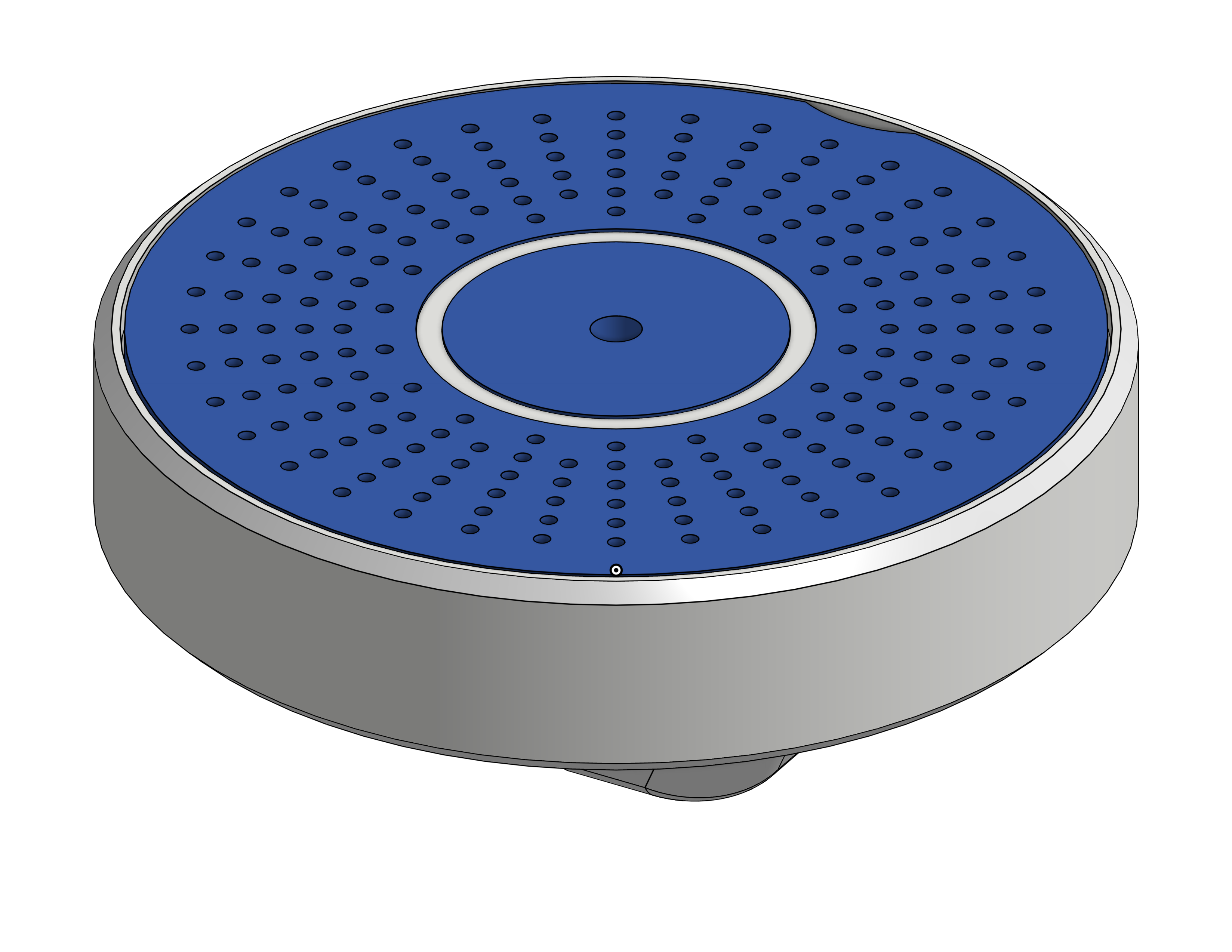

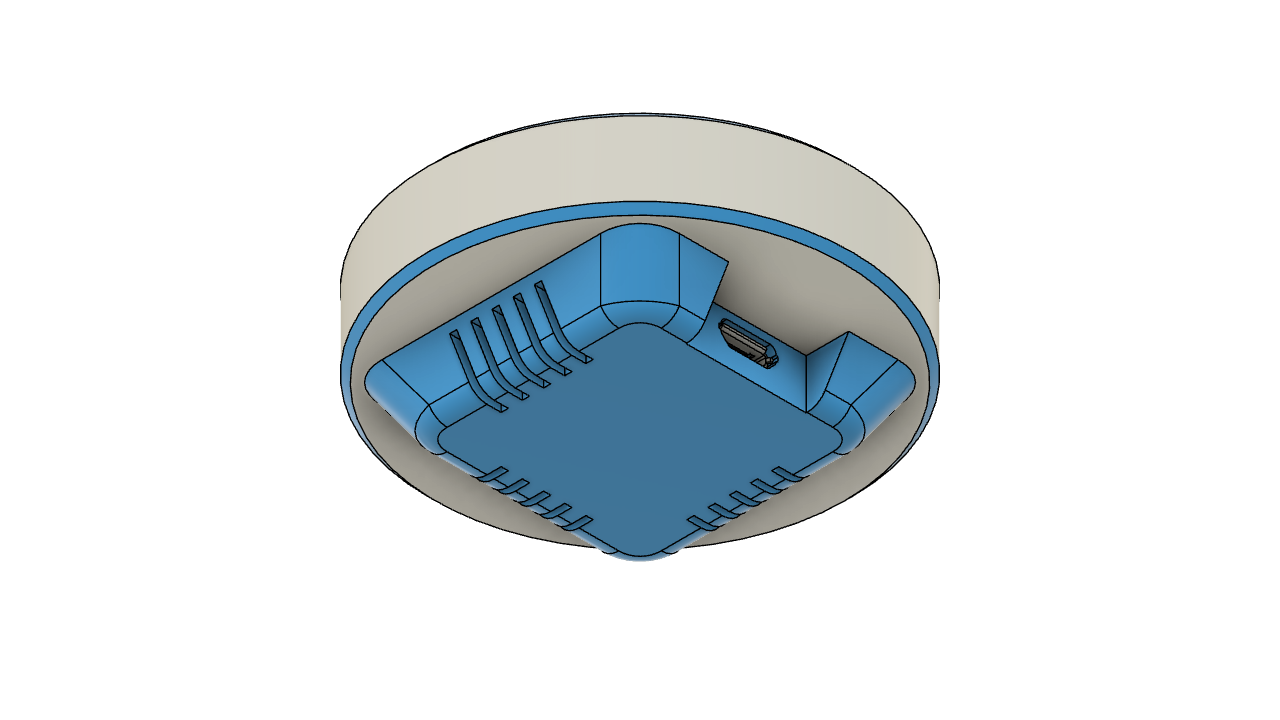

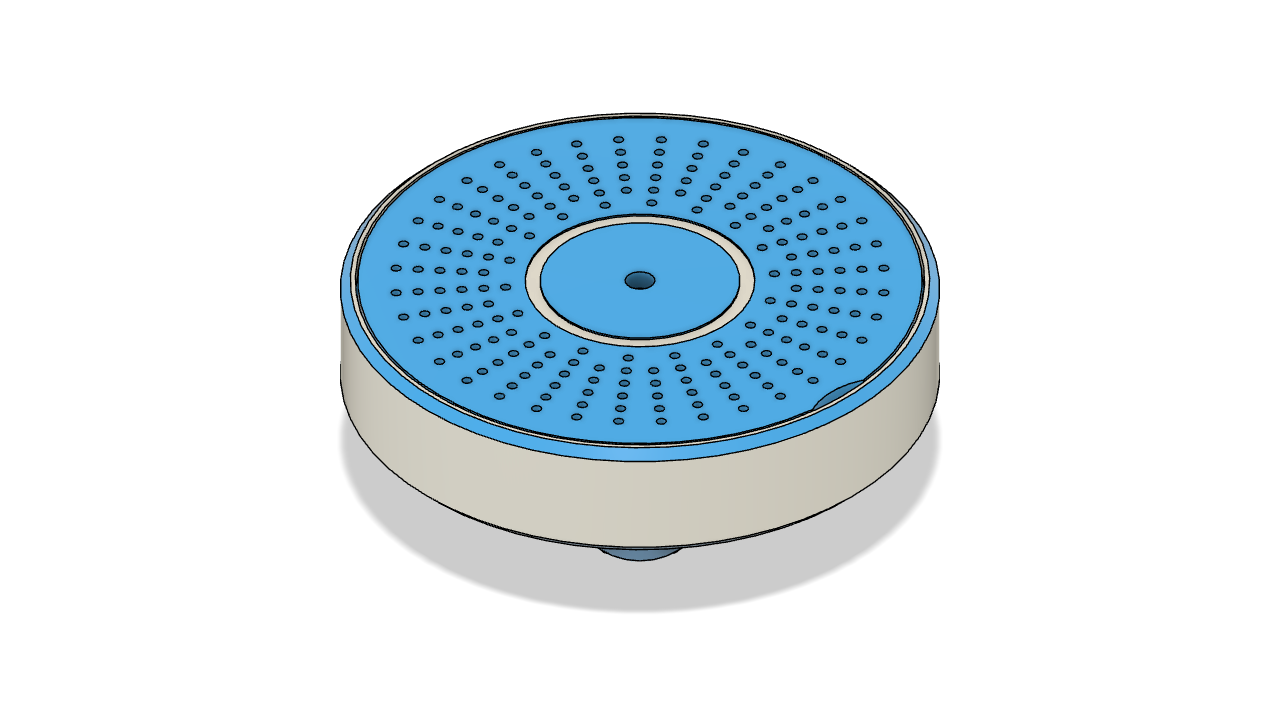

In this article we will address the development of an electronic project for an IoT sensor for monitoring temperature and humidity, as shown in the figure below. From this monitoring, the data will be sent to a web platform.

In this way, it is possible monitor various parameters, store this data, perform statistical analyses and carry out scientific studies to monitor various environments.

If you want to manufacture this project, click here.

Equipment like this can now be developed at a very affordable price.

Our main approach is to present the great impacts that printing can bring to the development process of electronic electronic, allowing the creation of innovative and personalized designs that meet the specificities of each project.

Development of electronic enclosures for electronic projects

Every day, countless electronic projects are developed and several electronic boards are created. What do these electronic boards that appear on the market have in common? Do you know?

They require storage mechanisms, that is, every electronic project requires an enclosure to install the printed circuit board.

Take, for example, this printed circuit board that is designed to monitor the temperature, humidity and pressure of a location.

Reflect on the following points below.

- Do you know why it is important to develop an electronic enclosure?

- How do electronic enclosure affect the usability and perception of product quality?

- Do you know how we can develop any electronic enclosure at low cost from 1 unit, spending little and using industrial quality manufacturing technology?

The development of electronic enclosure is of fundamental importance to ensure, firstly, the protection of the electronic circuit, usability and increased perception of quality of an electronic product.

In the past, developing electronic housings for equipment was a very expensive process and required specialized labor, since all projects were developed using thermoplastic injection molding technology. This prevented many designers from testing a product and launching it on the market, since the process was expensive and required the production of high-quality samples.

With the advancement of 3D printing technology, there has been a huge leap forward in the construction of prototypes.

Industrial 3D printing is a major advancement in manufacturing technology and has positively impacted project manufacturing due to its surface finish and final similarity to mold-injected parts.

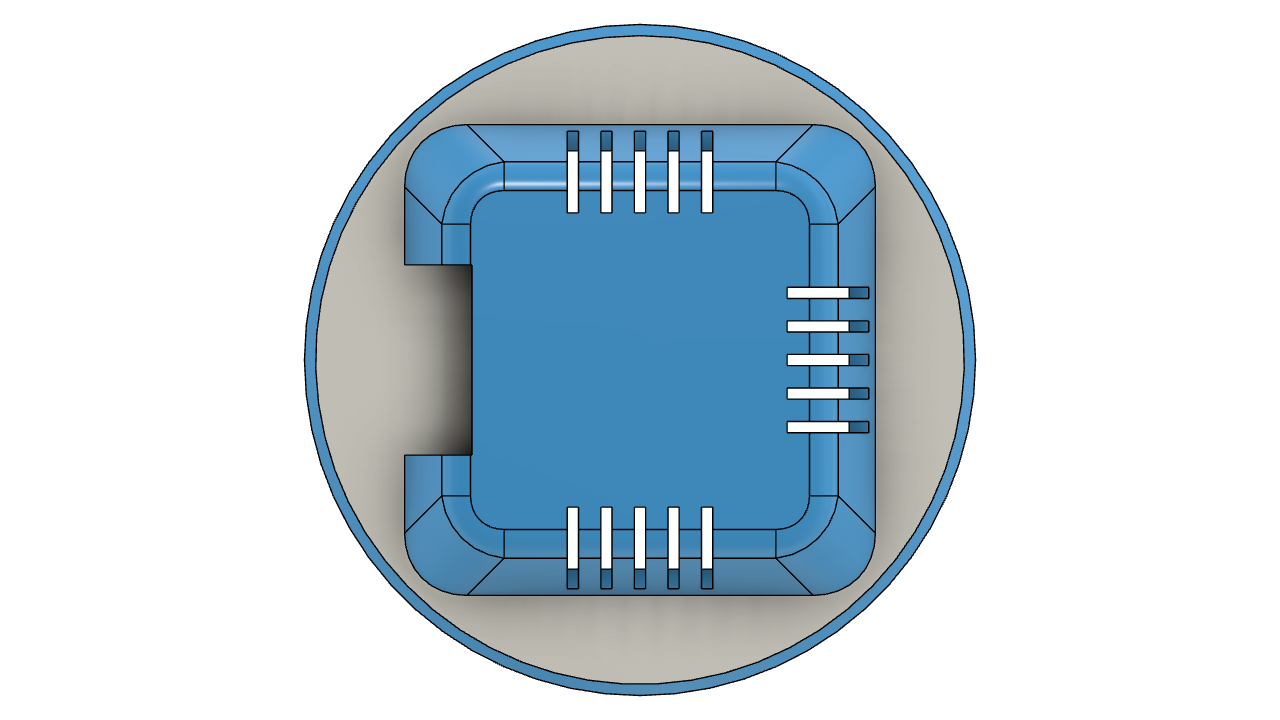

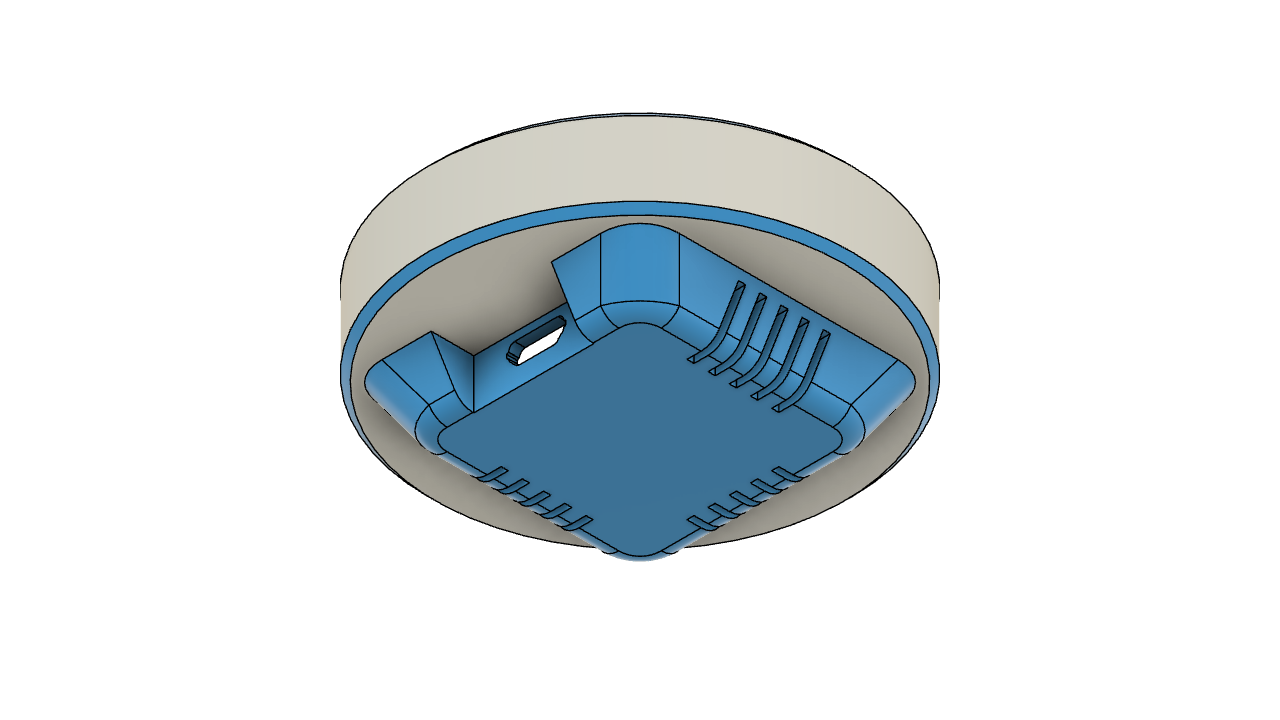

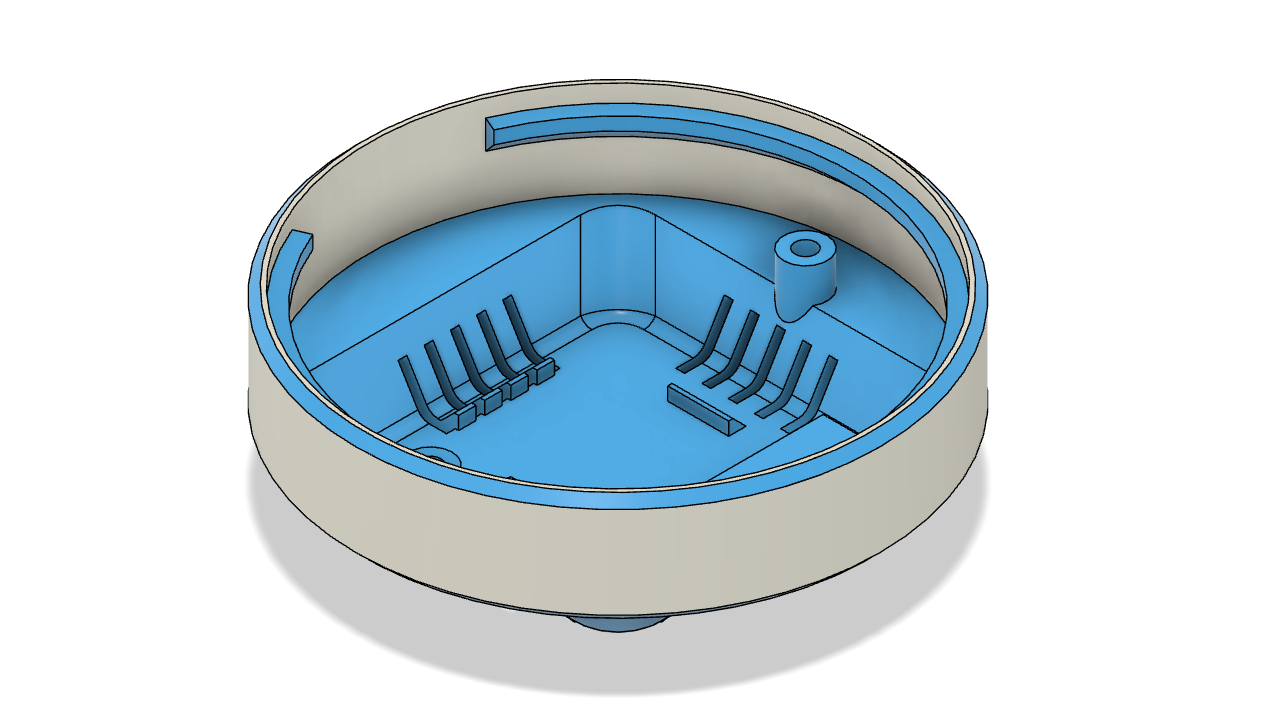

What are the requirements needed to develop an electronic enclosure for a product? Next, we will discuss the complete structure of the design requirements and construction process of the electronic prototype enclosure.

Requirements of the development process of an electronic enclosure for IoT Sensor

All of this is thanks to advances in technological development that have allowed lower costs in electronics and additive manufacturing technology with...

Read more »