-

Completed!

05/17/2017 at 12:08 • 0 commentsWell I've finished it so can finally close this project right after I've updated the details on this page.

-

Construction Finished

05/04/2017 at 07:57 • 0 commentsI've finished the construction. I'll put up some pictures soon and some test data. I was unsuccessful in getting the pictures off my old phone hence why there's been a lull.

Also I'e decided not to implement the charge indicator in this build as I can't decided on a suitable place to put it and I don't want to drill more holes in the box.

Stay Tuned

-

When a window opens...

04/16/2017 at 23:06 • 0 comments...A door closes!

Well after a productive morning on Friday, my phone finally decided to pop its clogs and refuse point blank to charge, thus I was unable to upload any pictures.

However I have managed to complete the build on this project and it functions very well; I have managed to measure the waveform off my alternator on my landrover and the tachometer output of the alternator too.

I have parts on order to fix the other phone and hopefully it will accept charge and I can pull the remaining photos off it and show the build details and testing.

Cheerio

-

More parts

04/06/2017 at 20:37 • 0 commentsSo I got round to ordering a DCDC boost converter and a battery level indicator. Unfortunately i ordered the wrong battery level indicator, I order one for a 5S pack not a 1S, so I have 2 options: 1. order a new one (more expense and another month on a slow boat from china) 2. modify the one I have.

I briefly looked at the board and it appears to be based on the LM339 comparator, so am expecting just a few resistor values need changing and they are 0603 size, so not completely impossible to rework.

-

More Ideas

02/13/2017 at 13:40 • 0 commentsGiven it'd be nice to know what the remaining charge of my battery pack is, I found these:

![]()

They would fit nicely down the side of the batter compartment and if I removed the button and used a separate panel mount one, it would be nice and flush against the side allowing the LED's to poke cleanly through some well positioned holes.

They're cheap enough, so hardly going to break the bank when I finally tote up the final bill.

-

Test Charge of Battery Pack

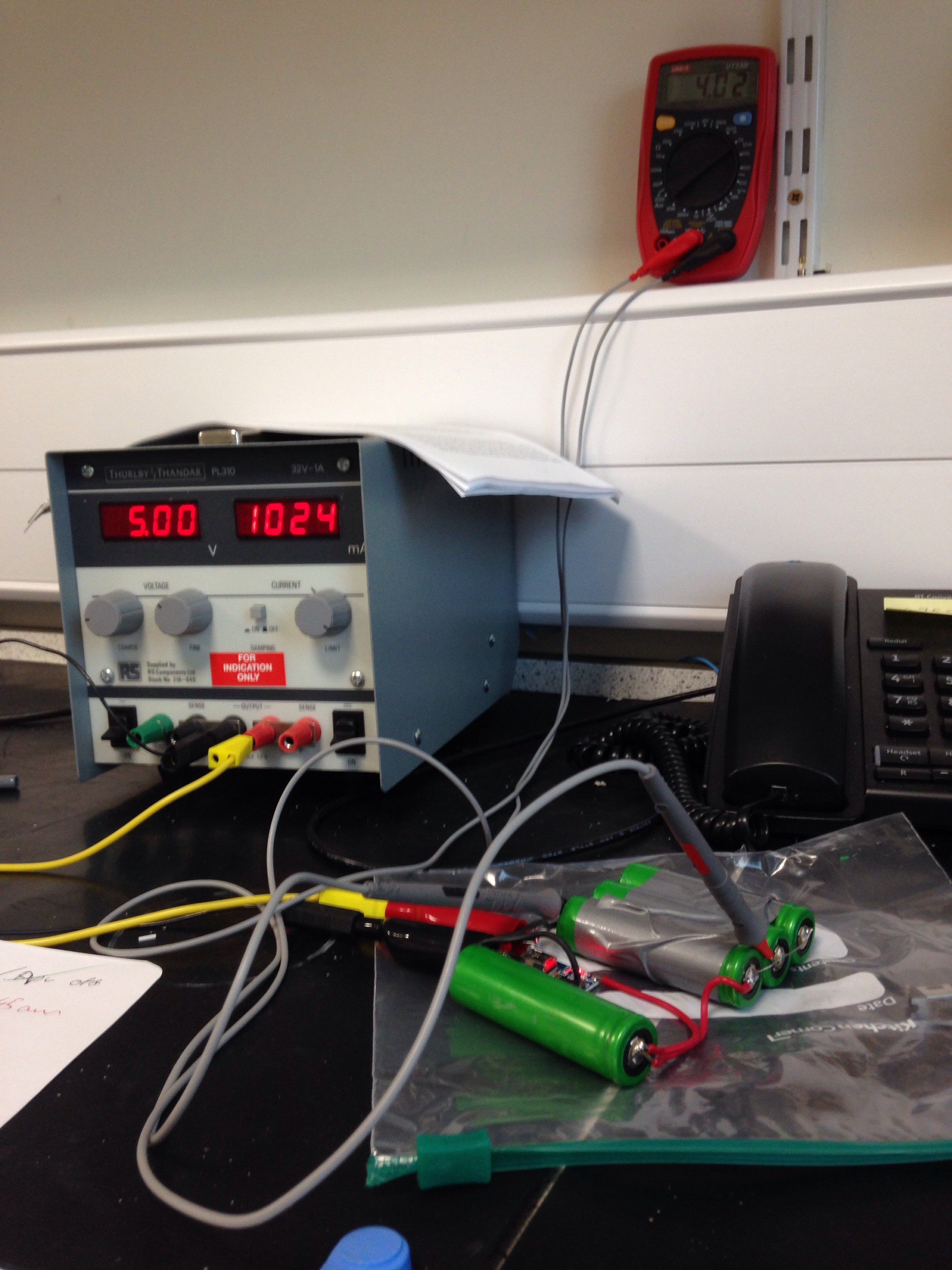

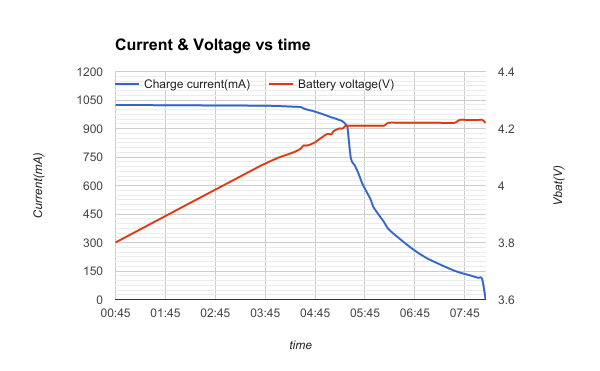

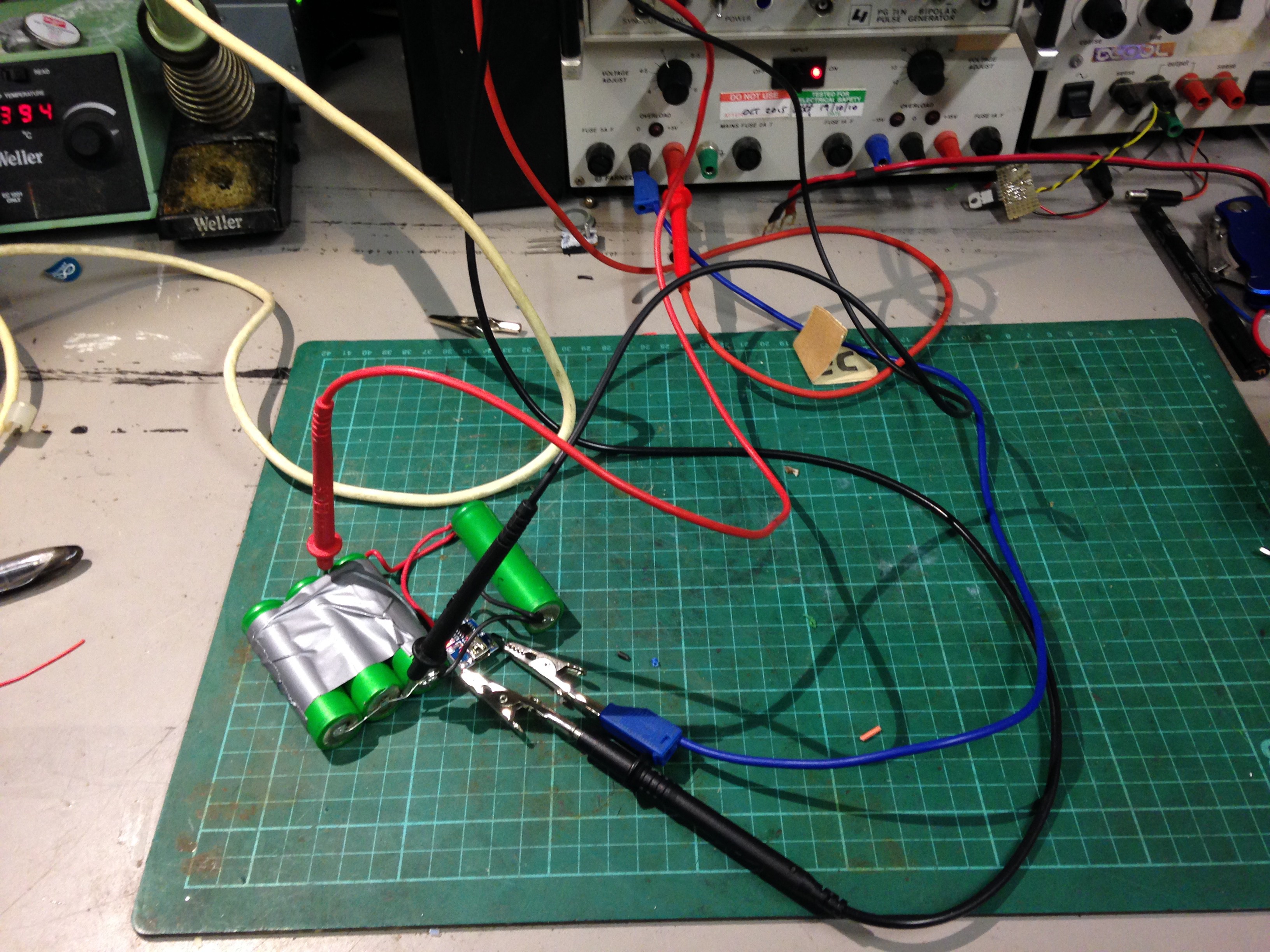

02/10/2017 at 14:02 • 0 commentsSo this is the setup I used to charge my batteries whilst monitoring their progress. The aim is to verify that the batteries can reach a charge round about the 8800mAh. I am assuming that some residual charge would be left in from the previous nights test and from its previous life in a laptop.

So anything between 4000-7000mAh is acceptable. I know that's a wide range but I'm taking into account of worst case (1000mAh per cell) and best realistic case given the cells age plus residual charge left over (7000mAh).

So I began charging at 8:45am at work using a linear bench supply and a DMM and basically took values at random points in the day. The setup was next to my Laptop, so some values are quite frequent whilst I've been looking for parts or reading data and quickly glanced over and entered them in the spread sheet, and others are less frequent as I've had be called away.

![]()

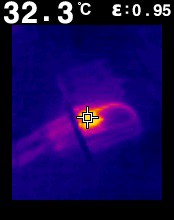

During a break I used work's FLIR handheld thermal camera to find out how hot the little charge board was getting. Not too hot. I also used the finger test and it seemed to be hotter than the FLIR was indicating. It was just bearable to touch, meaning it was just shy of 60 degrees Celsius. This is not a worry either, if it was any hotter I'd be considering a different type of charger (hobby charger maybe).

![]()

So After nearly 7 hours, I managed to obtain the above graph. As it can be seen, the battery voltage slowly rises to about 4.1V whilst the current remains constant at 1A-ish. It then slow reduces the current over the next 3 hours or so till it reduced to about 2mA, whilst the battery voltage didn't get above 4.3V. This proves the Charge board is working correctly to charge Li-Ion batteries - not that I ever doubted, but its a good idea to check to make sure you've not got a fake!

So to determine the rough capacity of the battery, I used the data from my spread sheet and did some rough integration using the Riemann Approximation with the current values and out popped a number: 5565mAh

This is bang where I expected it to be. So taking into account of some residual charge, a little charge from the previous test and the roughness of my calculations, I guesstimate the capacity to be in the ball park of 6000mAh. I will confirm this with a load test maybe, but to be honest that's plenty capacity for this application!

-

Battery Pack Construction

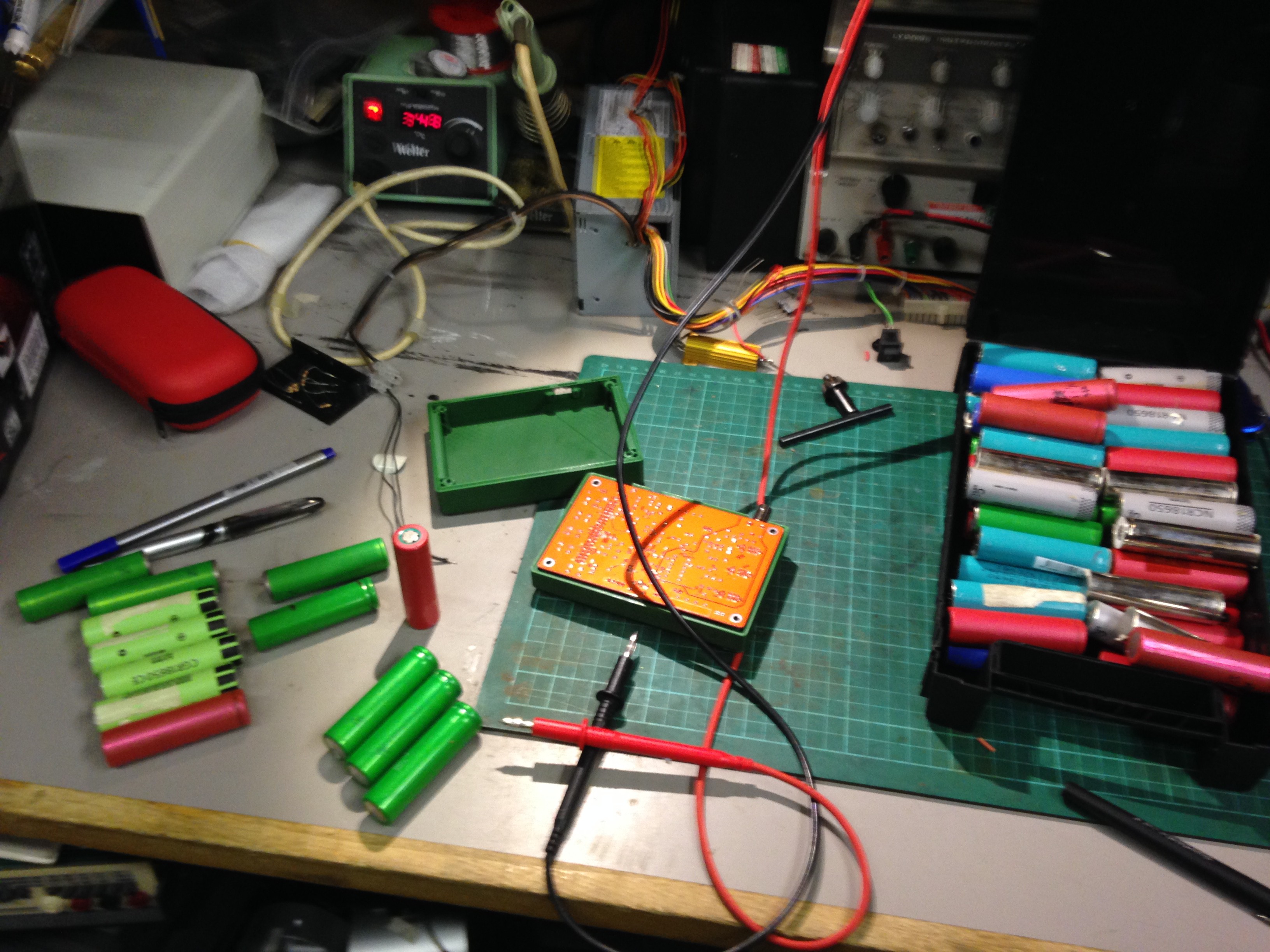

02/09/2017 at 09:12 • 0 commentsMade a start on constructing the battery pack. Since I panned to use 2x 18650's in parallell I needed 2 of them that had voltages very close it each other, which meant going through my 18650 hoard:

Managed to find 3 cells close, 2 of which were bang on 3.79V, which was also ideal as usually anything lower than 3.7V and the cell is usually deemed unusable, but I have seen people still use them anyway.

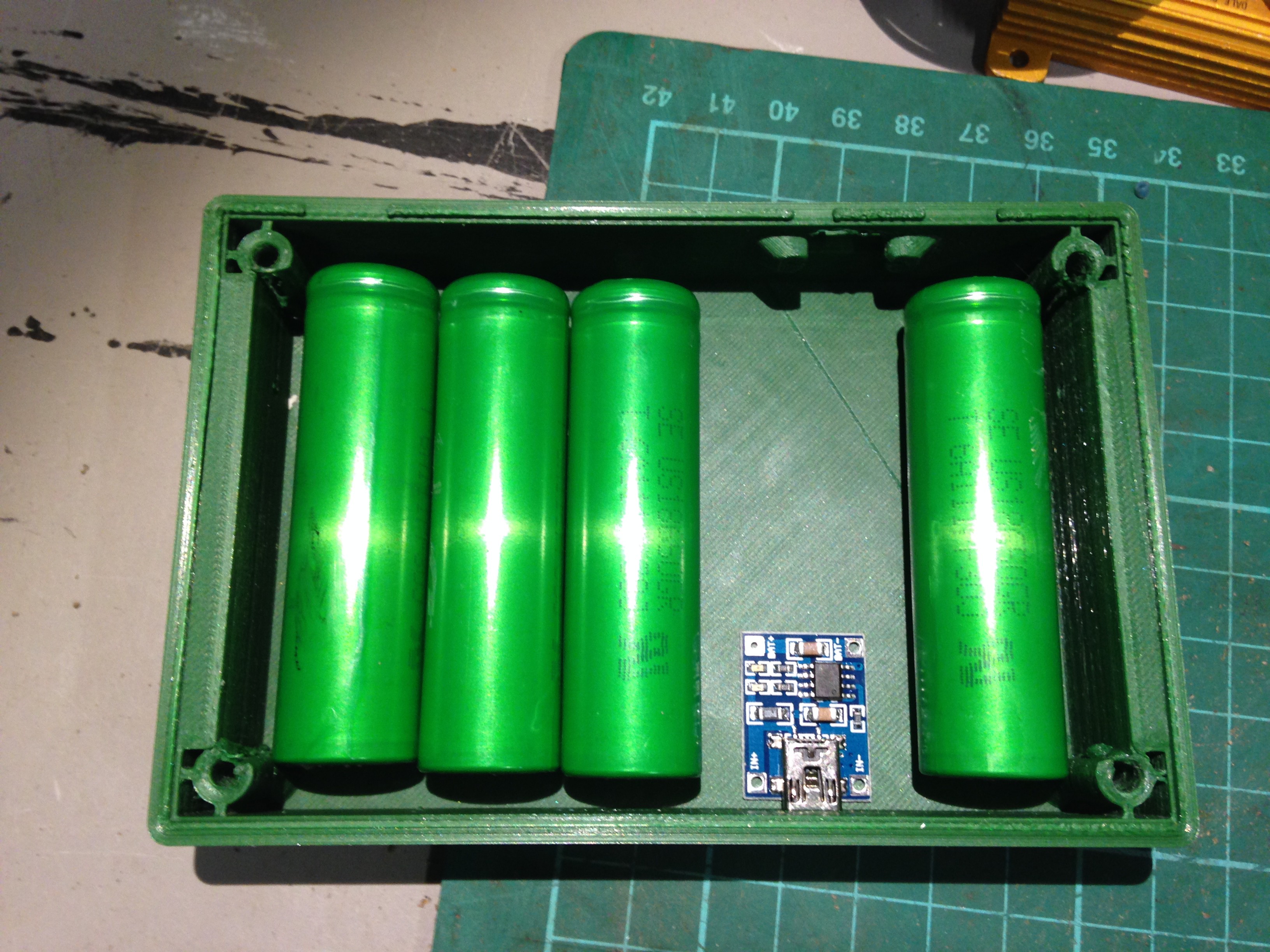

Then I checked they could fit into the enclosure and found I could squeeze 4 of them in there! The charge board could also fit in too.

The reason for this layout was having all 4 in a row fouled the area where the on switch would go.

At this point I was curious as to what capacity these cells were. So checked part number on internet:

So according to a Flashlight forum post No. 21 I could identify the capacity of this battery as out of a sony laptop battery pack and had a capacity of 2200mAh! But is also 10 years old so don't know how much of that capacity is left! Anyway here's a table on how to identify similar cells:

First line Manufacturers data US18650GR - which means its an 18650 cell and googling this also shows its made by Sony Second line - first 2 digits after letter Capacity ident G4 = 1950mAh

G5 = 2150mAh

G6, 6A, 6B = 2200mAh

G7 = 2400mAh

8A = 2600mAhSecond line - first of last 5 digits Year of Manufacture P=2007, Q=2008, R=2009, etc Second line - second of last 5 digits Month of Manufacture A=Jan, B=Feb, C=Mar, etc Second line - third + fourth of last 5 digits Day of Manufacture So I'm assuming that 2+6 = 26th day for example Second line - final digit Electrode History Some internal reference - unknown So deciphering the code:

- 6A - 2200mAh

- P - 2007

- F - June

- 3 + 0 = 30th?

So each cell is 2200mAh and they are nearly 10 years old! I expect that they will have lost some capacity over the years. But if not then best case scenario is I have a possible 8800mAh battery. Yeh that should do, but I'm not getting my hopes up. Will have to test to verify this.

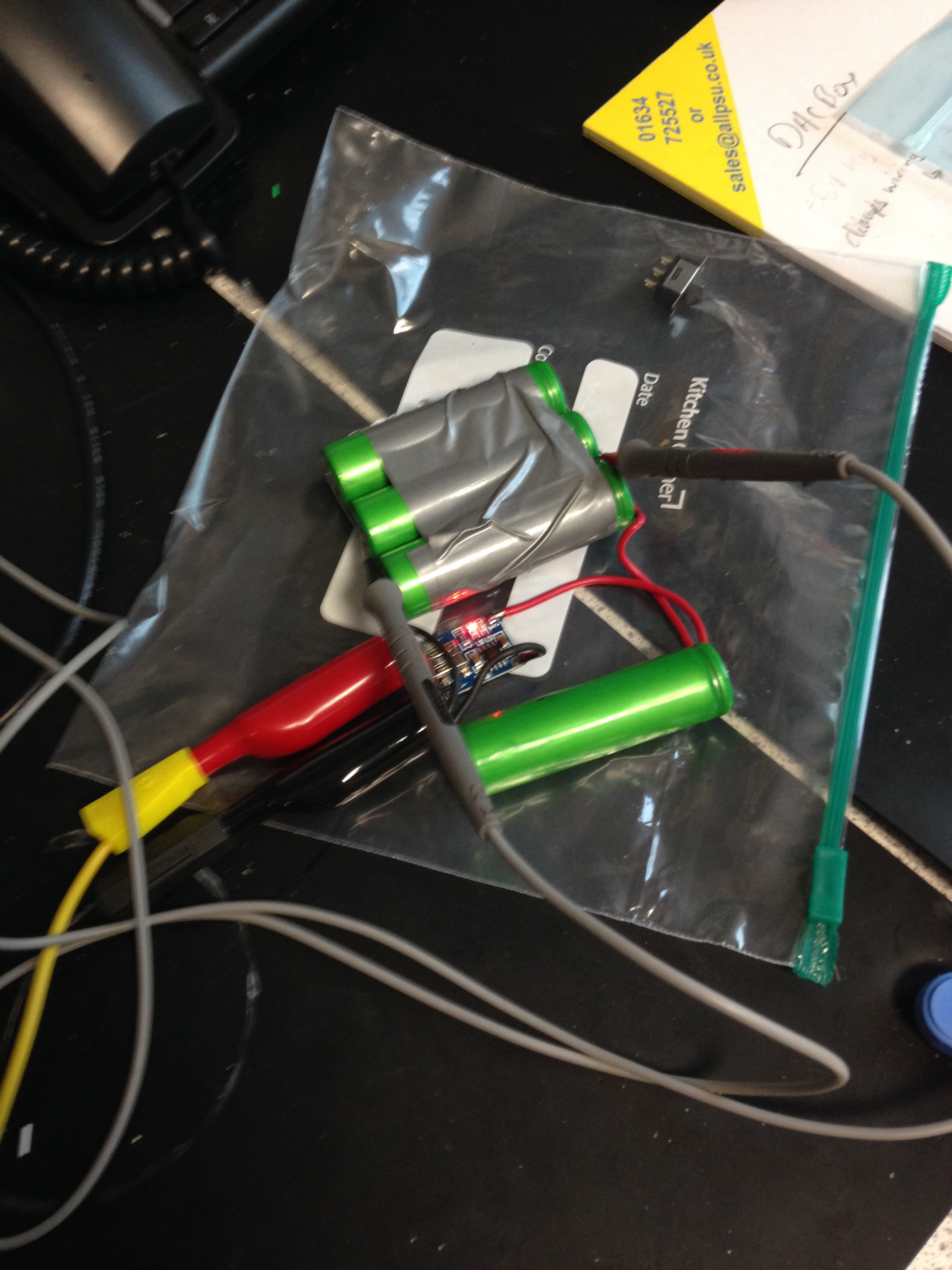

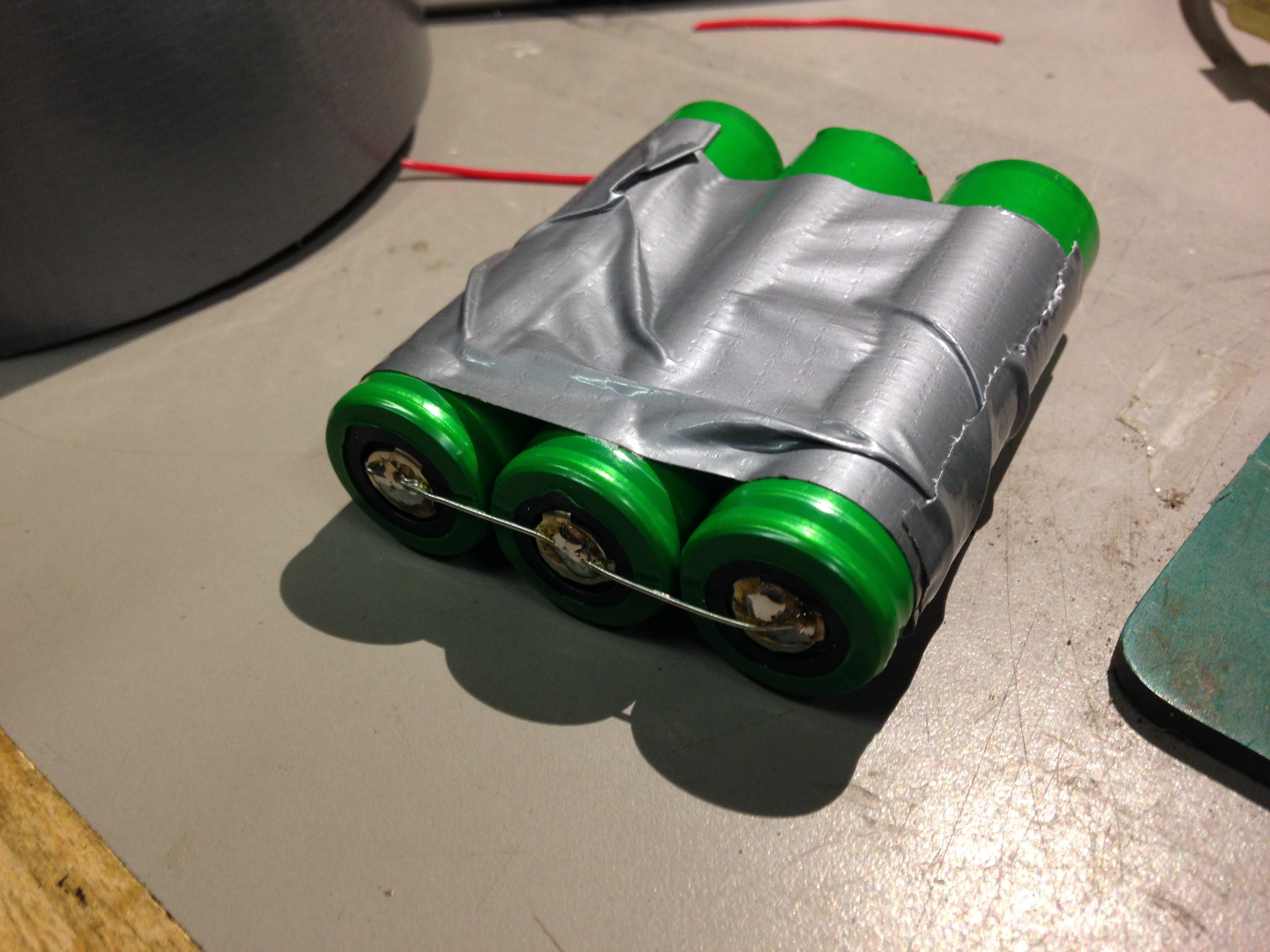

I then proceeded to carefully solder wire to the batteries in 4P configuration:

Quickly measured the starting cell voltage on the DMM:

So the cells appear to have balanced themselves out to 3.78V, without any drama. I then proceeded to solder the charger board to my batteries:

And finally gave it a quick test on bench to ensure it was charging:

Top meter is measure the current into the charger and I monitored the voltage with the lower meter. The lower meter appears to be 0.17V out when compared to the upper meter - the upper meter is more accurate. So the reading is actually 3.77V. I watched this climb to an indicated 3.97 V with a steady 1A current and then turned it off. I plan to continue charging over a working day and monitor its performance. But from this quick test it appears to work as it should!

-

Upgraded Hardware

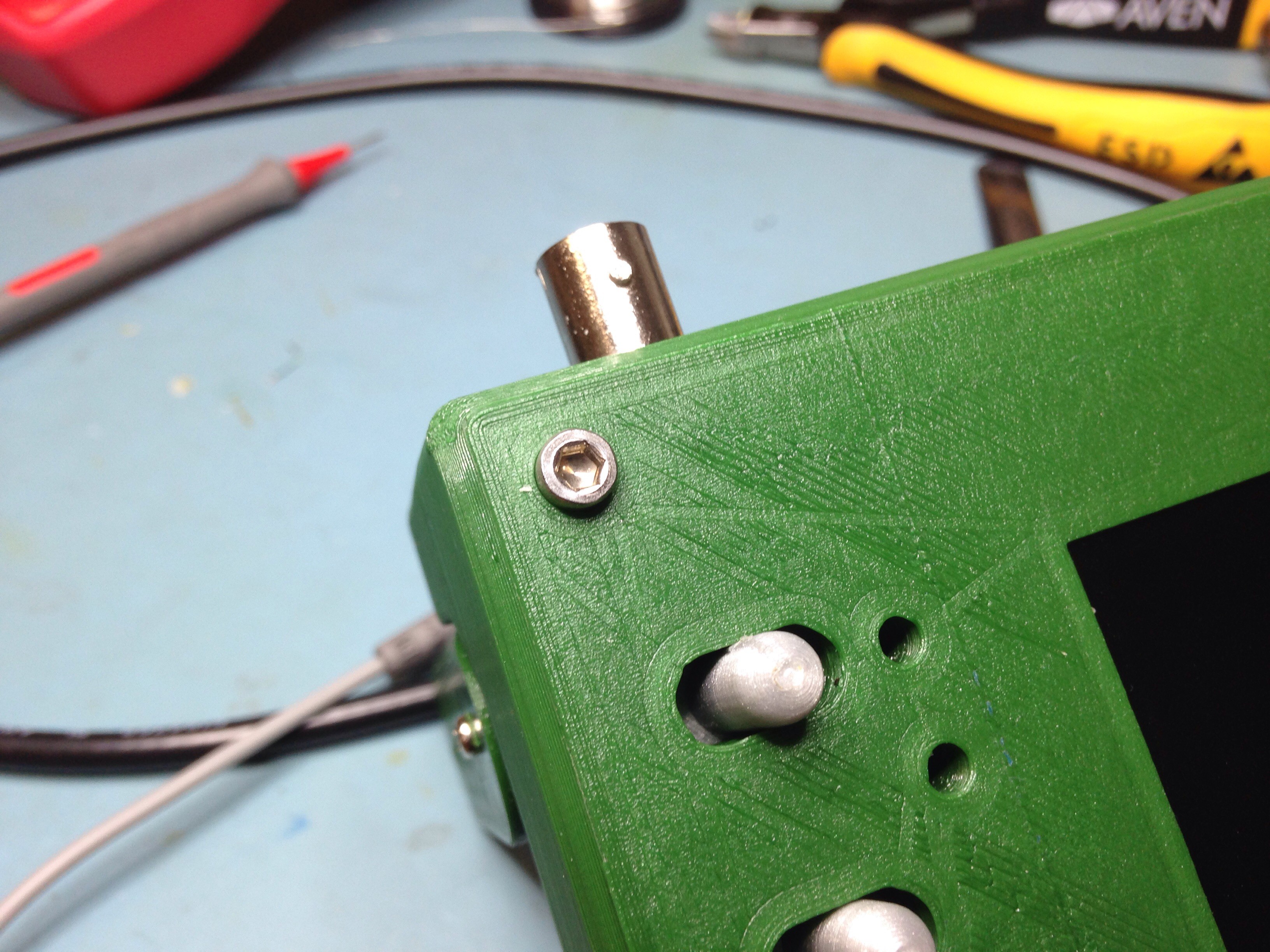

02/08/2017 at 13:32 • 0 commentsgot some Hex socket cap head M3 screws. They fit well an sit nicely into the bore of the hole. There is still a bit of material to clear out of the bore, which causes the head of the screw to sit proud but it like it lie that.

-

Hardware fitment

02/07/2017 at 22:10 • 0 commentsI managed to find some nuts and bolts that would fit but not without a bit of fettling.

The holes formed by the 3D printer are too small for M3 yet the hexagonal holes for captivating the nuts fit M3 perfectly. Confused but undeterred, I drilled out the bolt holes to 3.5mm for good clearance and managed to source some bolts that were just a bit too long.

However drilling out the holes broke through the side walls of the bolt guides a little, but not so much that structure was compromised nor the bolt became misguided.

I'm going to see if i can find some that are just long enough from the local hardware supplier, as i don't fancy shortening the bolts with a hacksaw and buggering the thread. M3 bolts are cheap enough and I know my local supplier stocks them...but in the length i need? Will have to find out.

-

Case Constructed

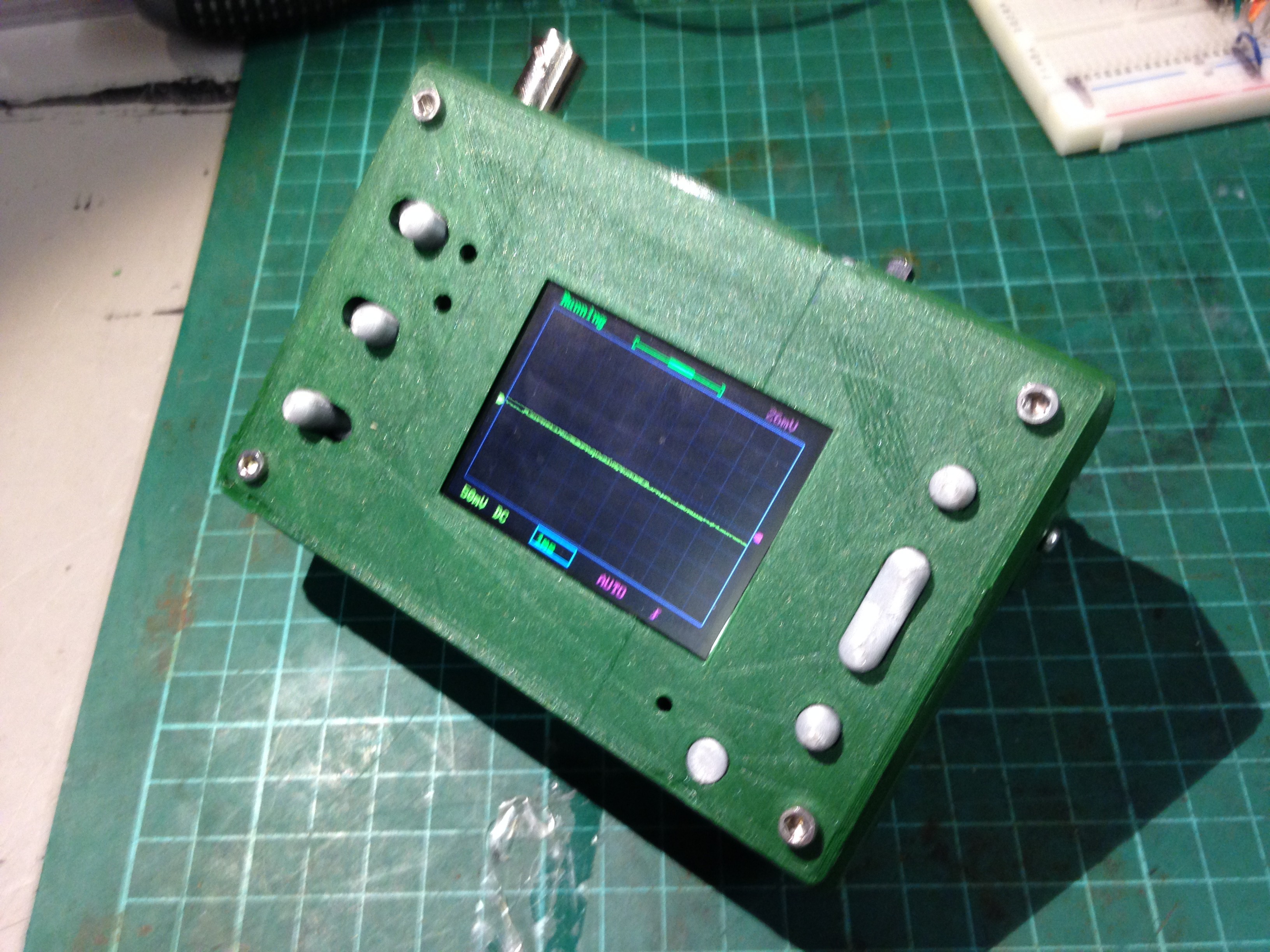

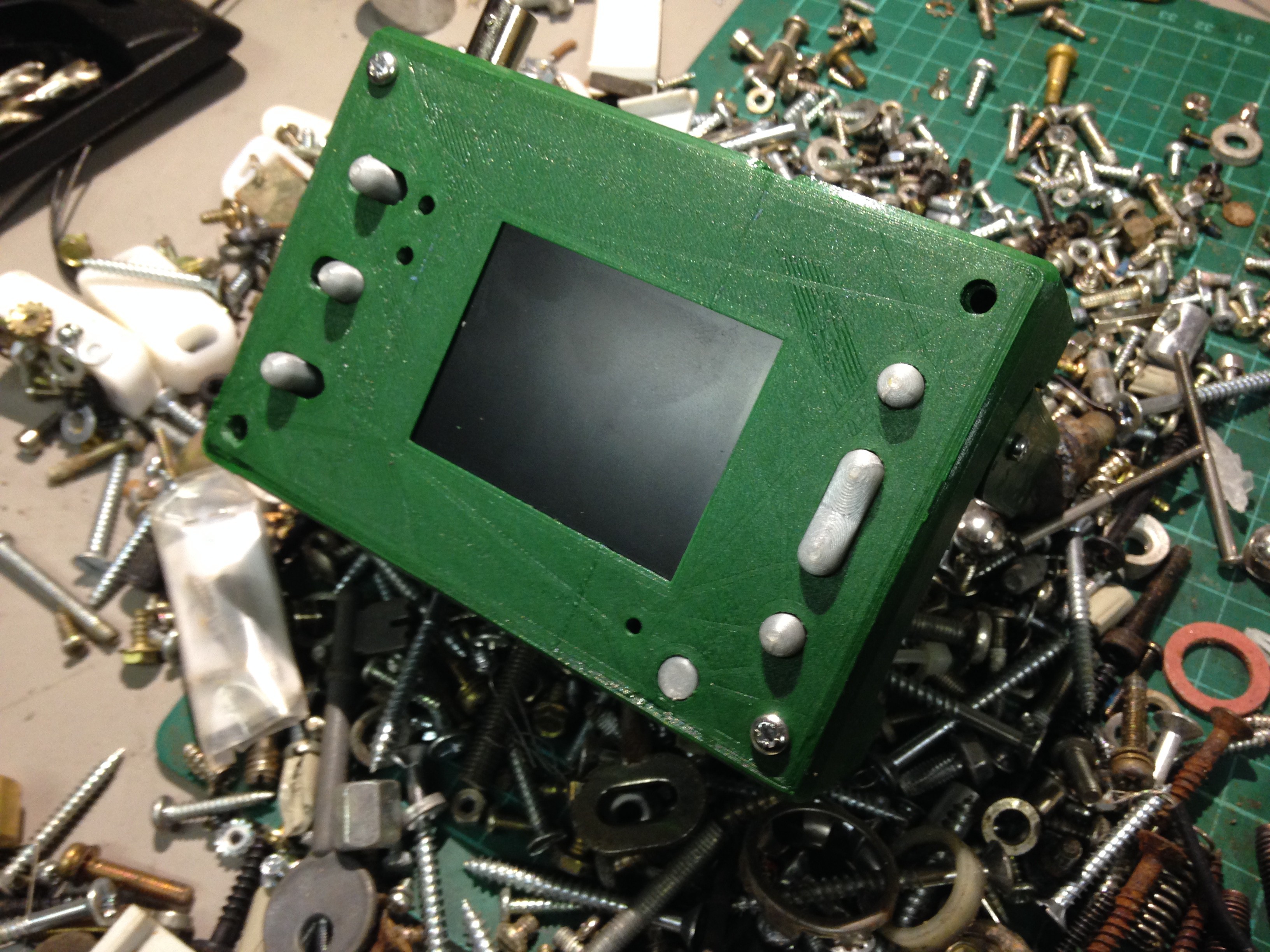

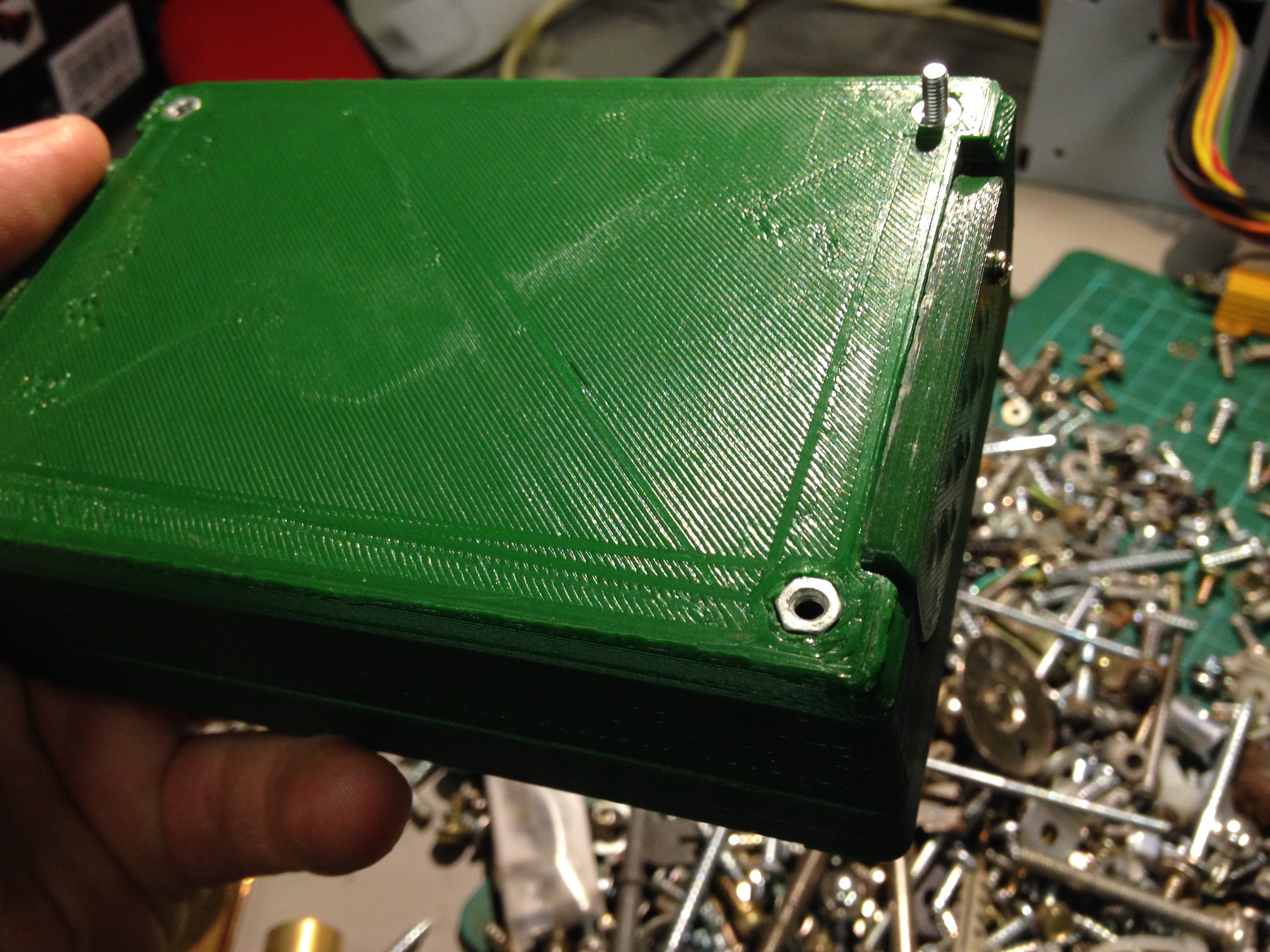

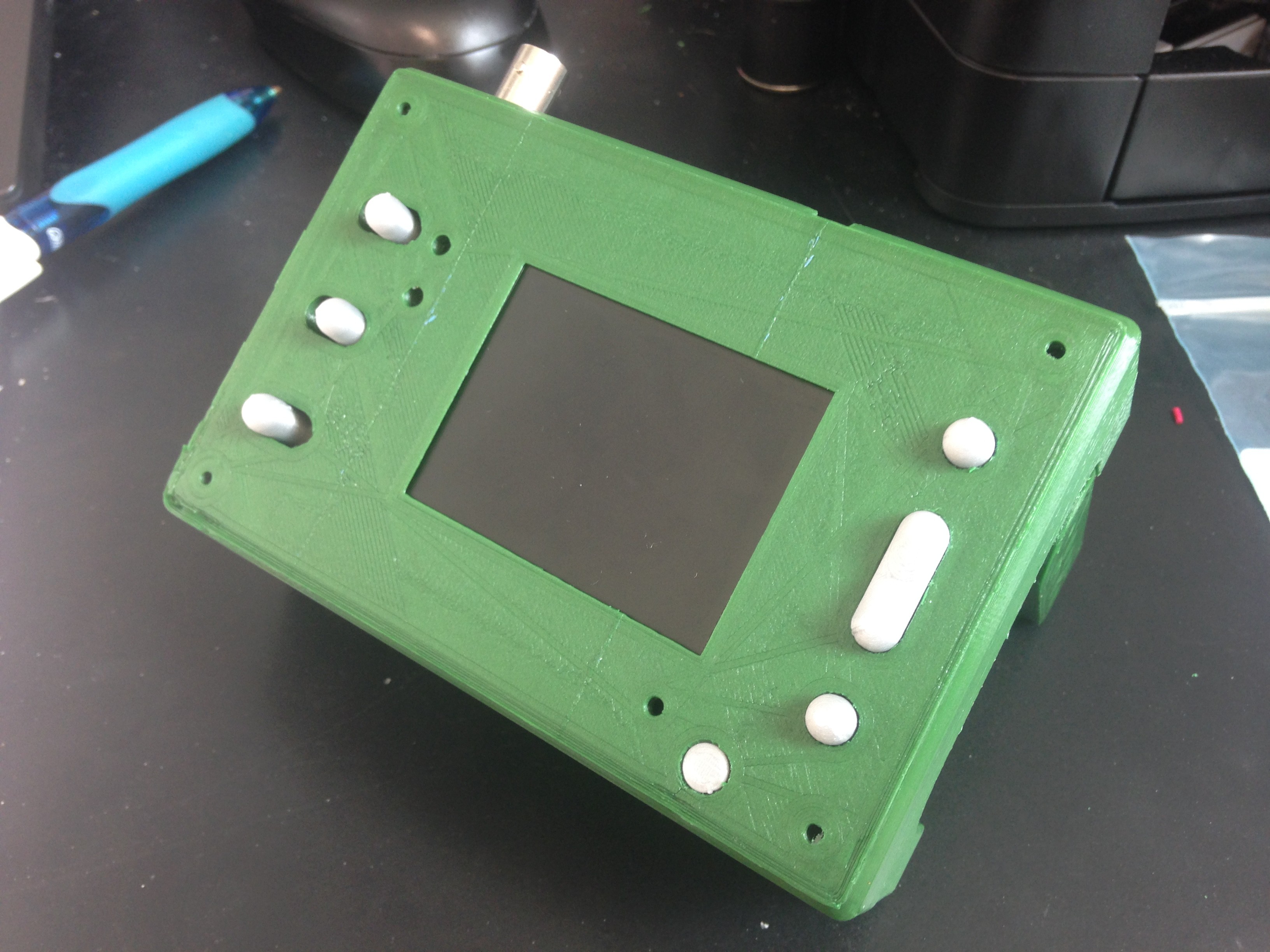

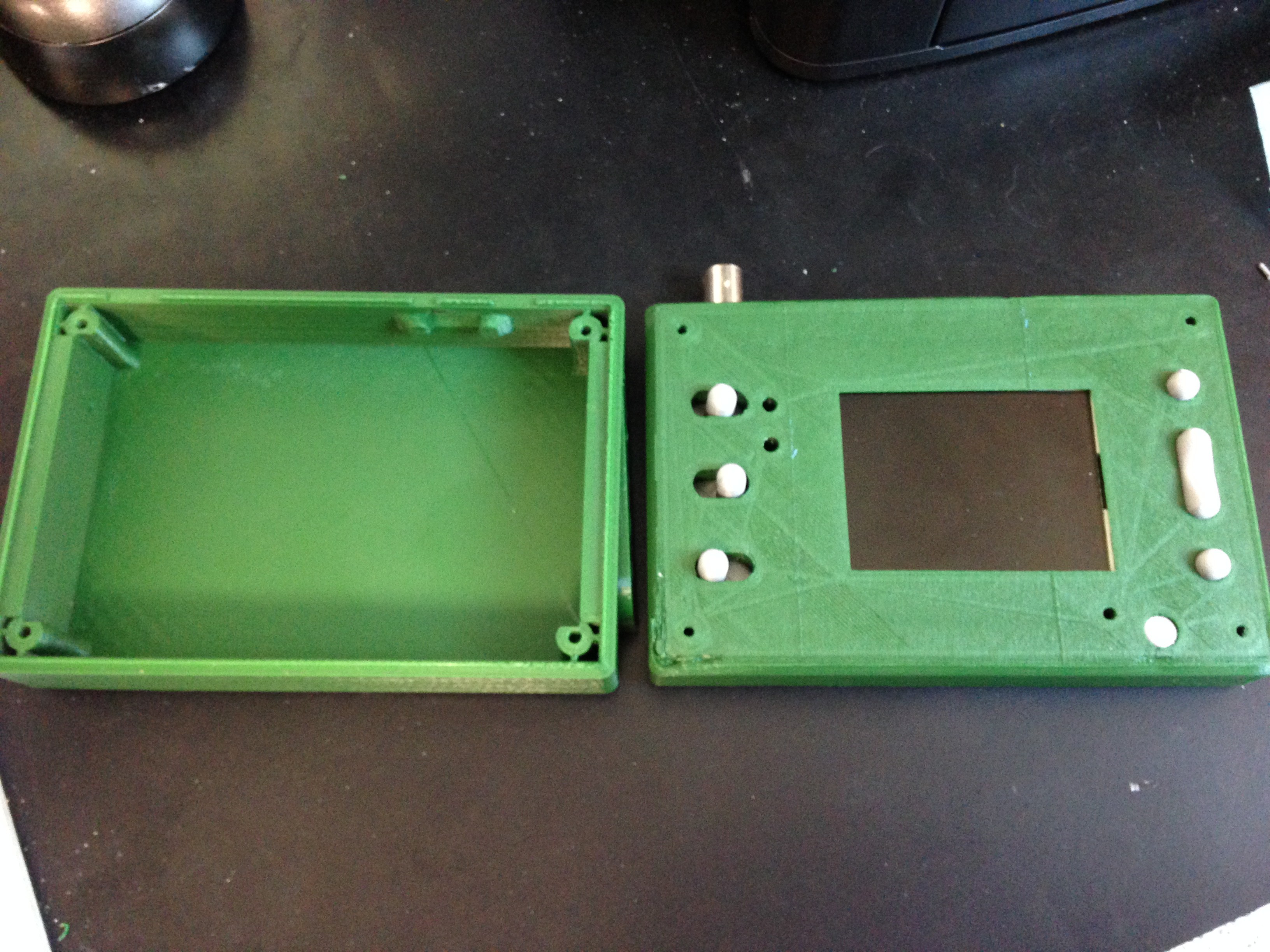

02/07/2017 at 15:42 • 0 commentsSo using a Ultimaker 2+ Extended 3D printer, I managed to print a box found on thingieverse: http://www.thingiverse.com/thing:1708650

I went with Bronze green cos its a common colour for classic Landrovers (which I am a fan) and Silver buttons which seem to complement....

...nah! I'm joking, it's all I could get and just so happened they suited!

I need to locate some hardware to screw it all together, I' going to have a rummage in my nut & bolt jar to find something close in M2 or M2.5. I am please with the fit and the overall quality.

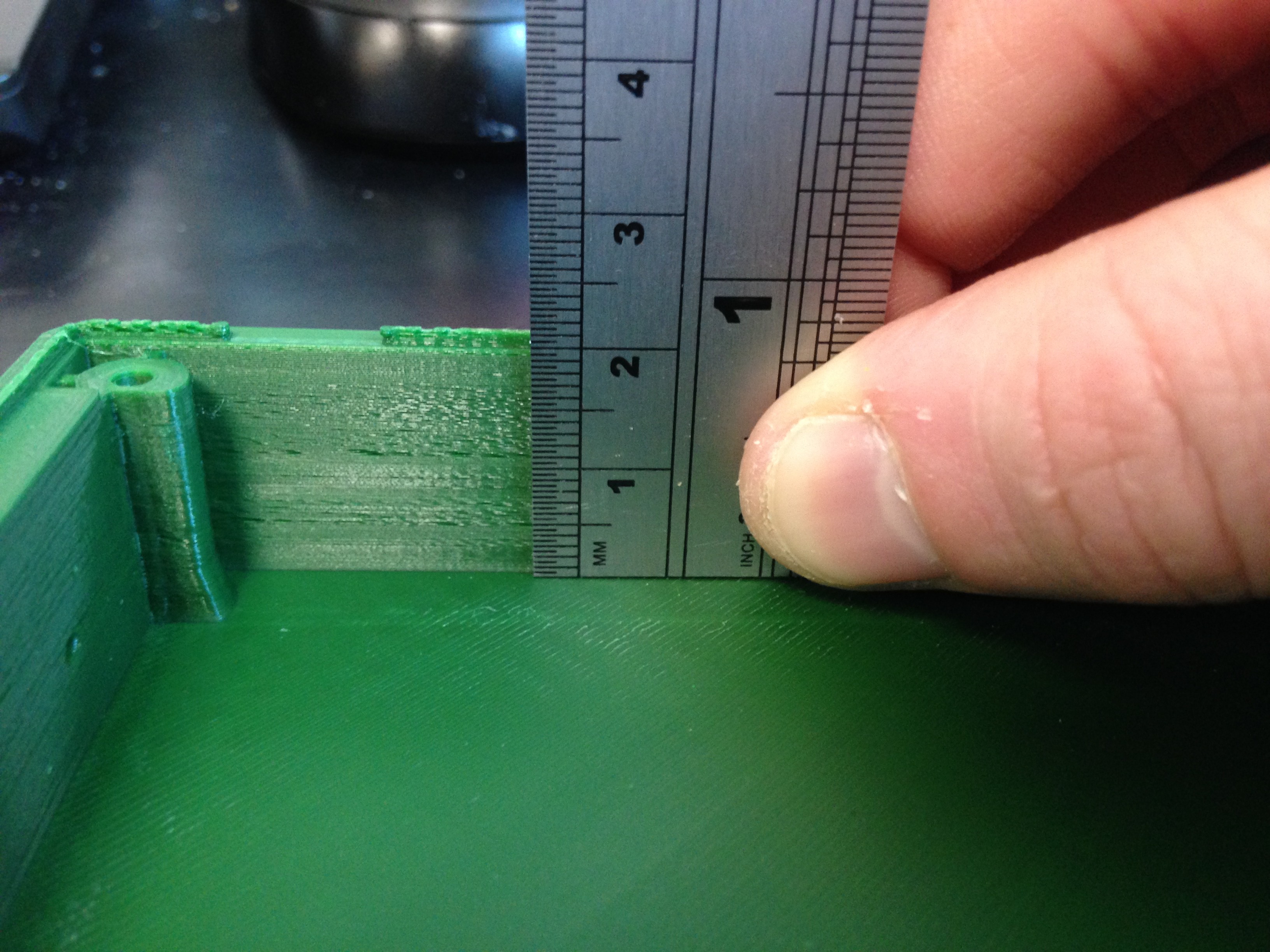

Here is the battery compartment

As you can see: I have a little over 19mm to play with. so I am going to place a piece of insulation between the battery compartment, just to ensure that the batteries don't short on the underside of the DSO PCB.

Battery Supply for DSO138 portable Scope

Turning a cheap DSO kit into a cheap automotive scope

Tron9000

Tron9000