Design idea

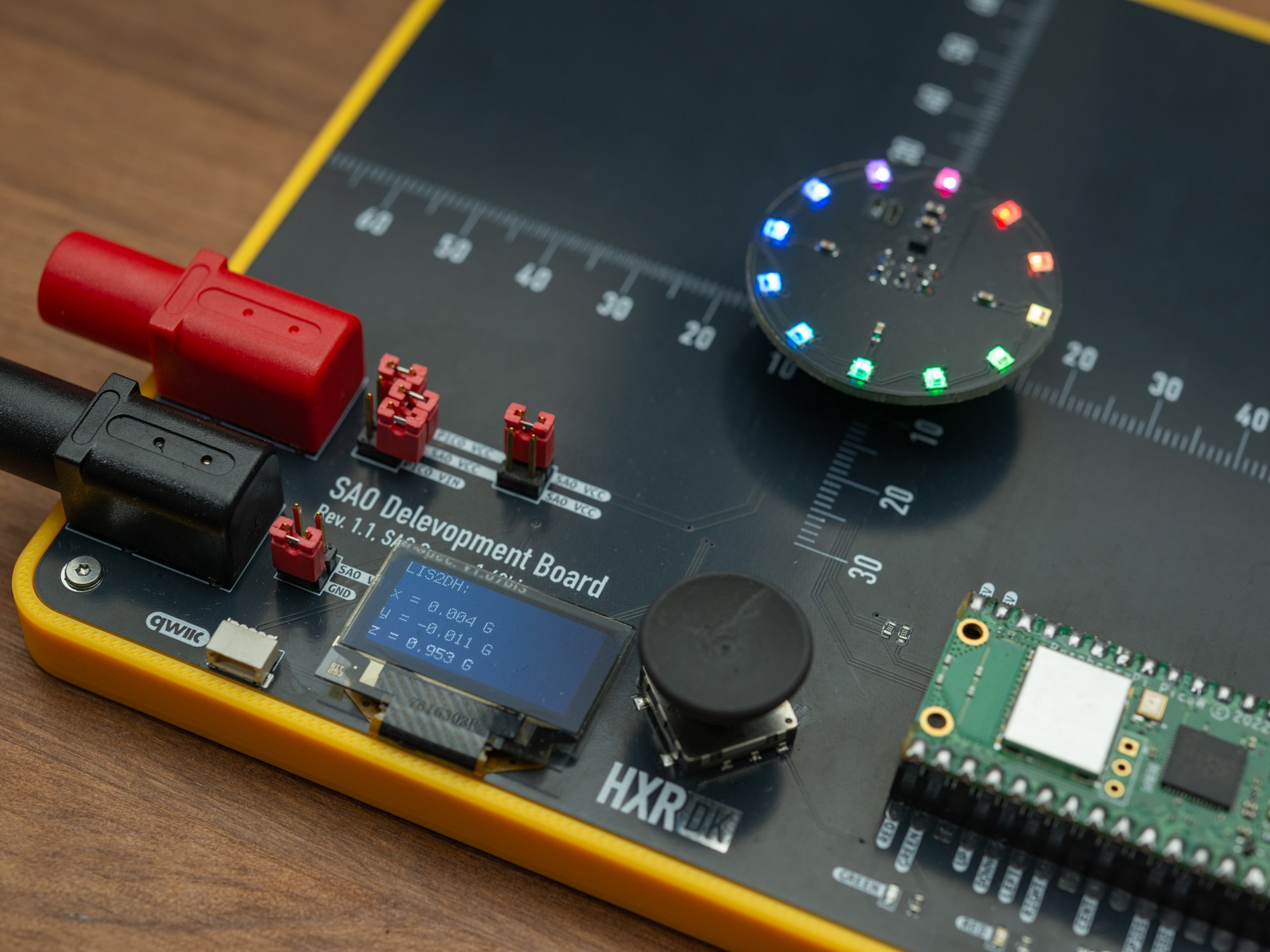

The idea was to design an add-on, that did not care about how it was mounted with a way to correct for different mounting scenarios.

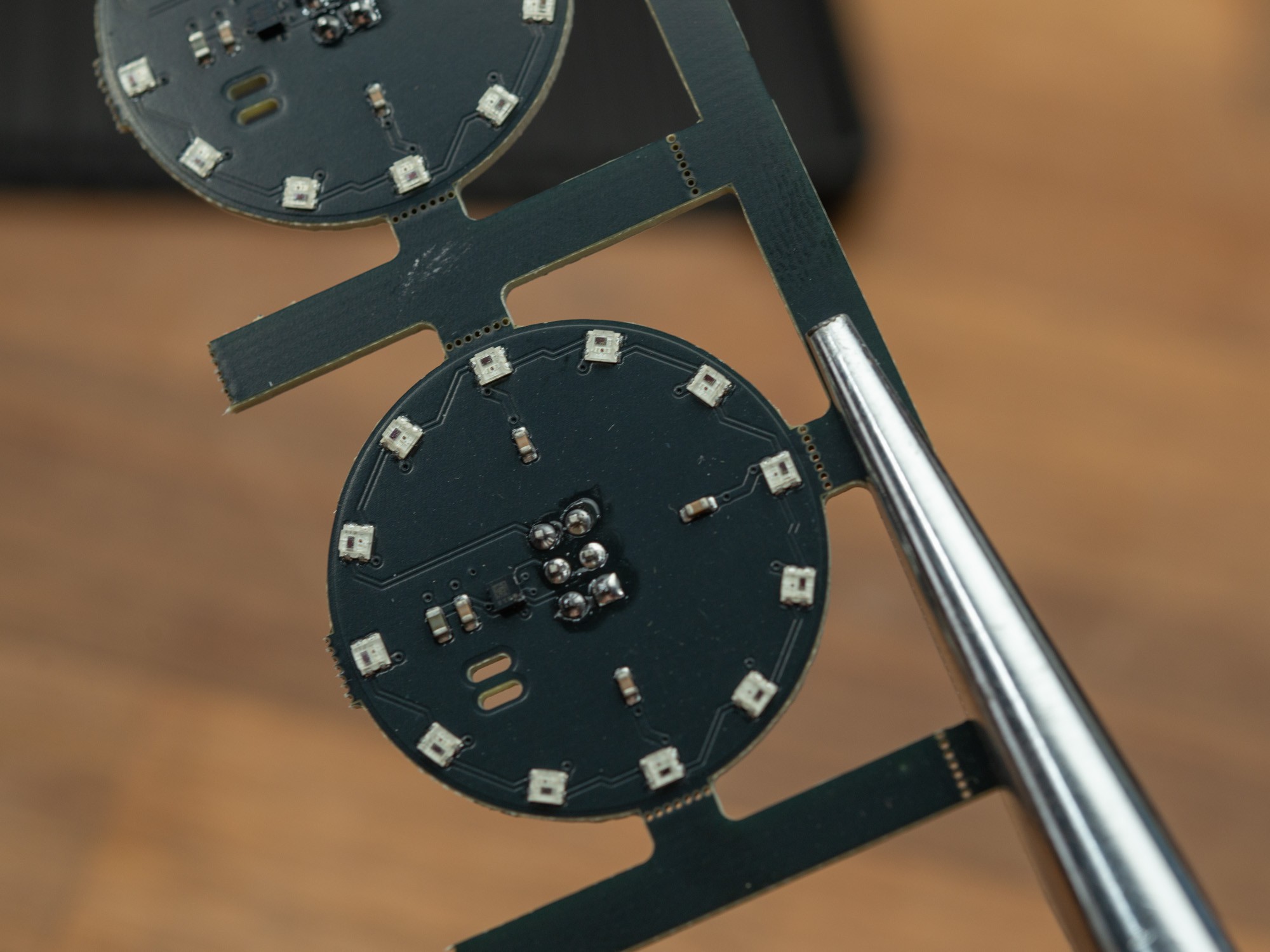

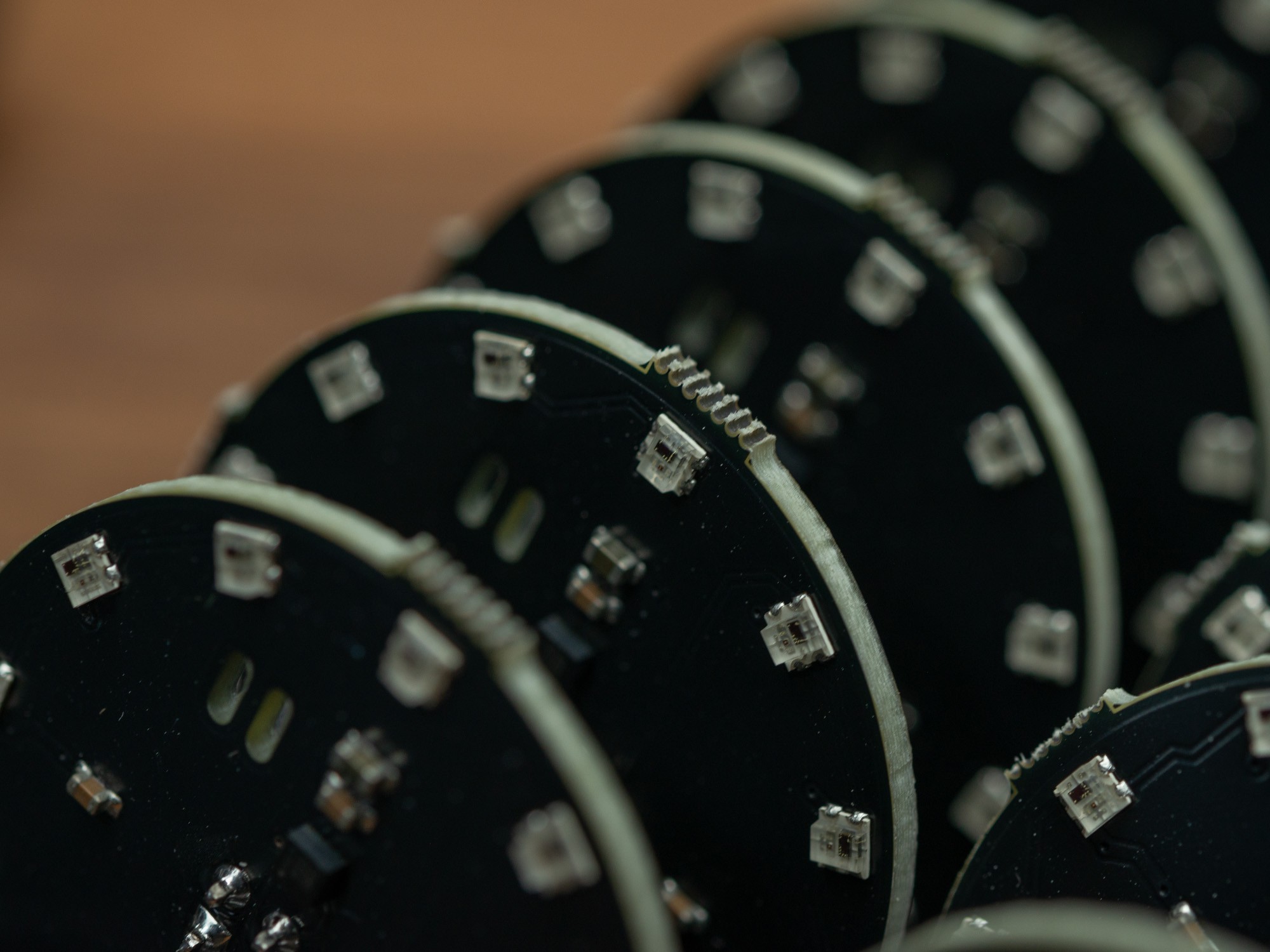

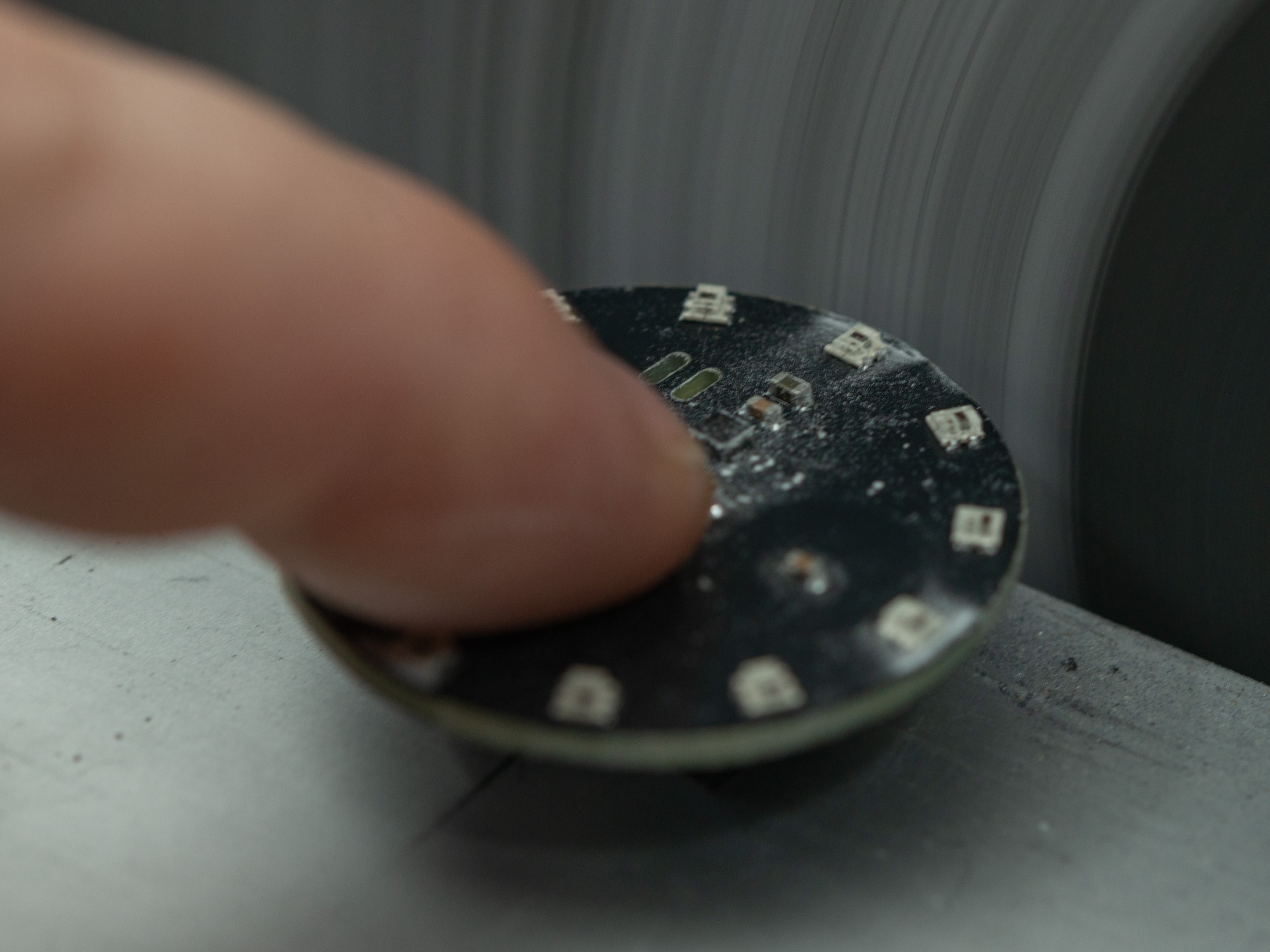

The relatively small, circular shape with the connector in the middle, makes it fit nicely in most cases and the accelerometer can help show animations up-right, when needed.

Motivate hacking

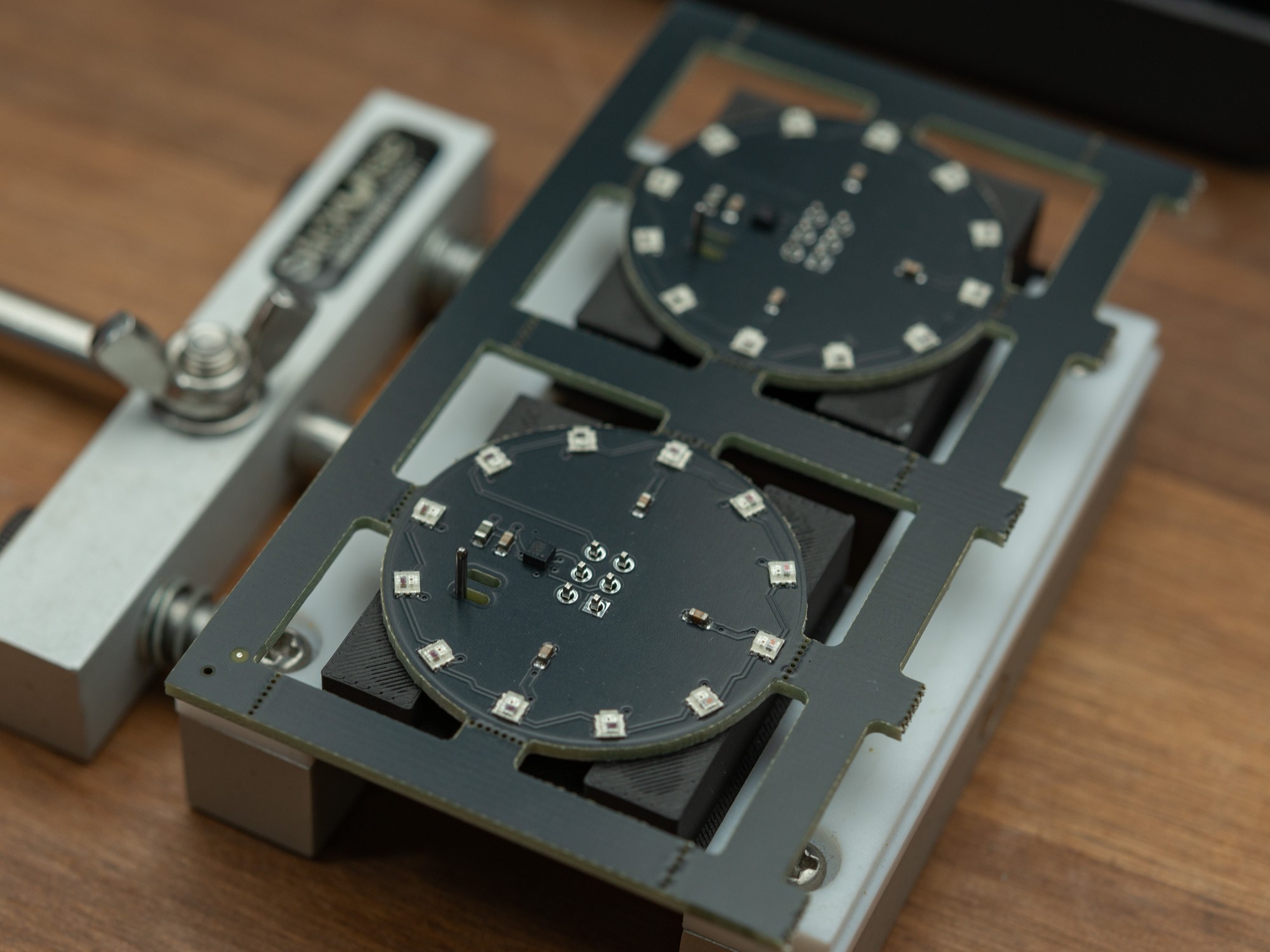

As there are no microcontroller on this SAO, it is vital for operation, that there is host support with some code running to at least control the LEDs. The string of 12 addressable LEDs (NeoPixels) are connected to GPIO1 of the SAO connector.

The accelerometer is connected via I2C and have it's interrupt 1 connected on GPIO2, which could be used for motion detection or free-fall detection.

There is also a temperature sensor in the accelerometer.

I2C Communication

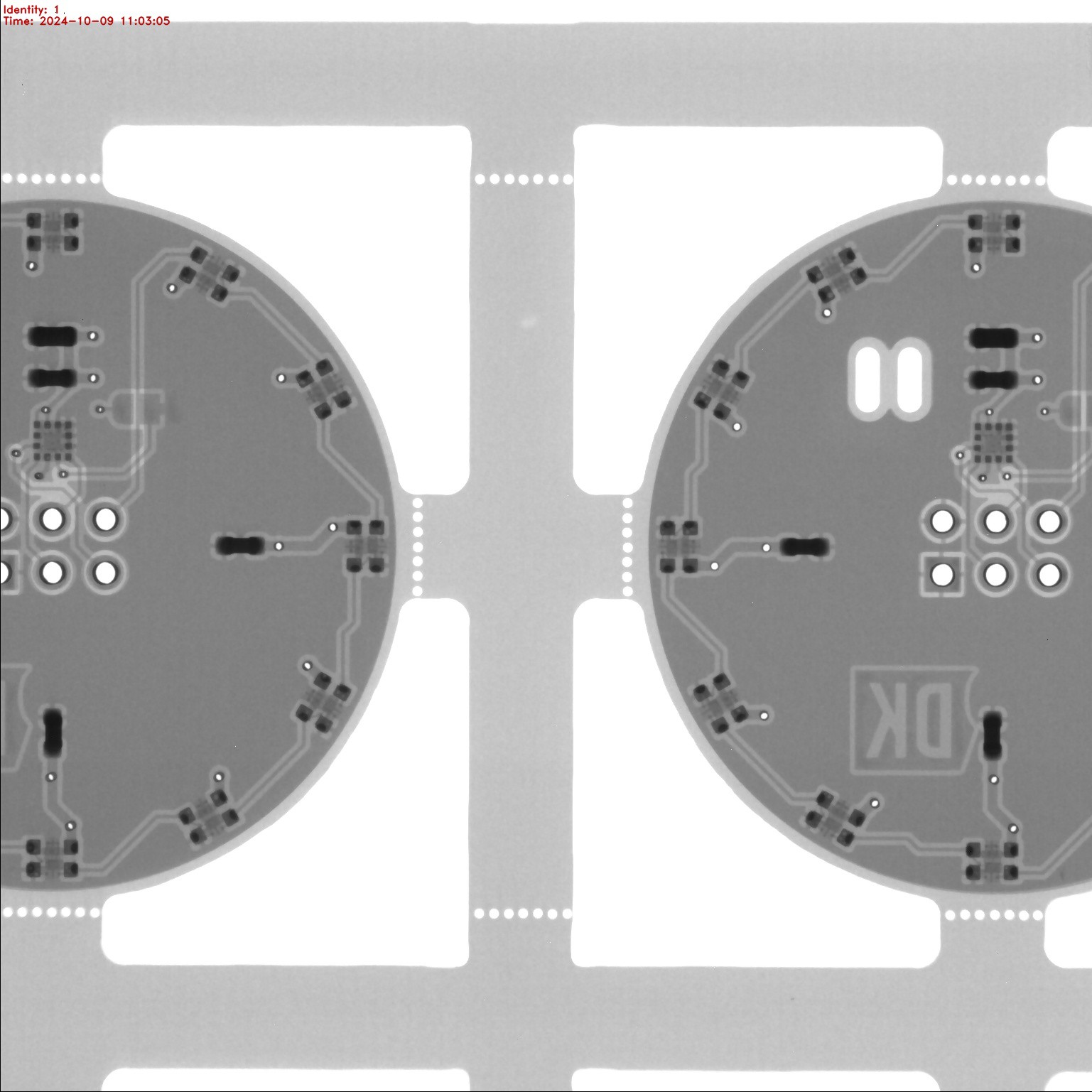

The LIS2DH address is 0x19 by default, but by cutting a trace and bridging a small solder jumper, it can be changed to 0x18, to prevent address conflicts on the I2C bus.

Thomas Flummer

Thomas Flummer

Albert Gonzalez

Albert Gonzalez

kmatch98

kmatch98

Arduino Enigma

Arduino Enigma

doctek

doctek

Thanks for this SAO, I was able to use it in my project:

- https://marc.merlins.org/perso/electronics/post_2024-11-01_Pasadena-Hackaday-Supercon-2024-SAO-Badge.html

Great to have met in Pasadena, this was fun:

- https://marc.merlins.org/perso/electronics/post_2024-11-01_Pasadena-Hackaday-Supercon-2024.html