-

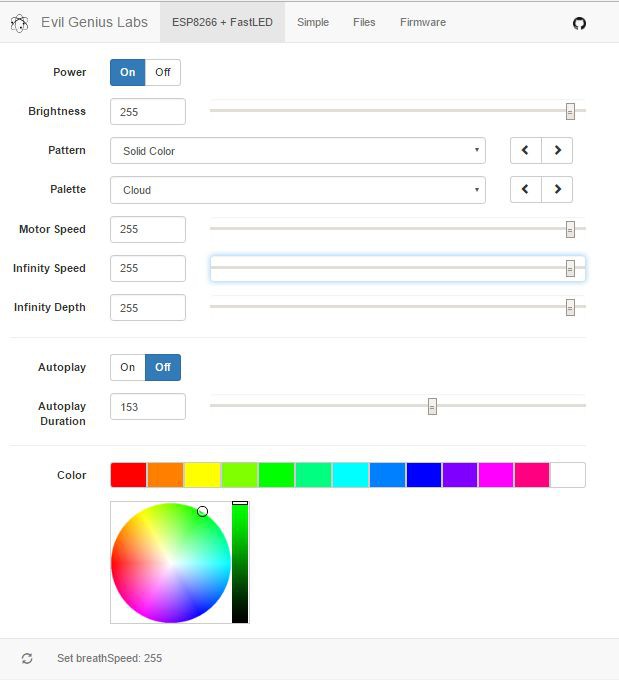

Web App Running

03/07/2017 at 12:04 • 0 comments![]()

The app works great, I just need to figure out how to make the slider values go from 0-1023 instead of 0-255.

-

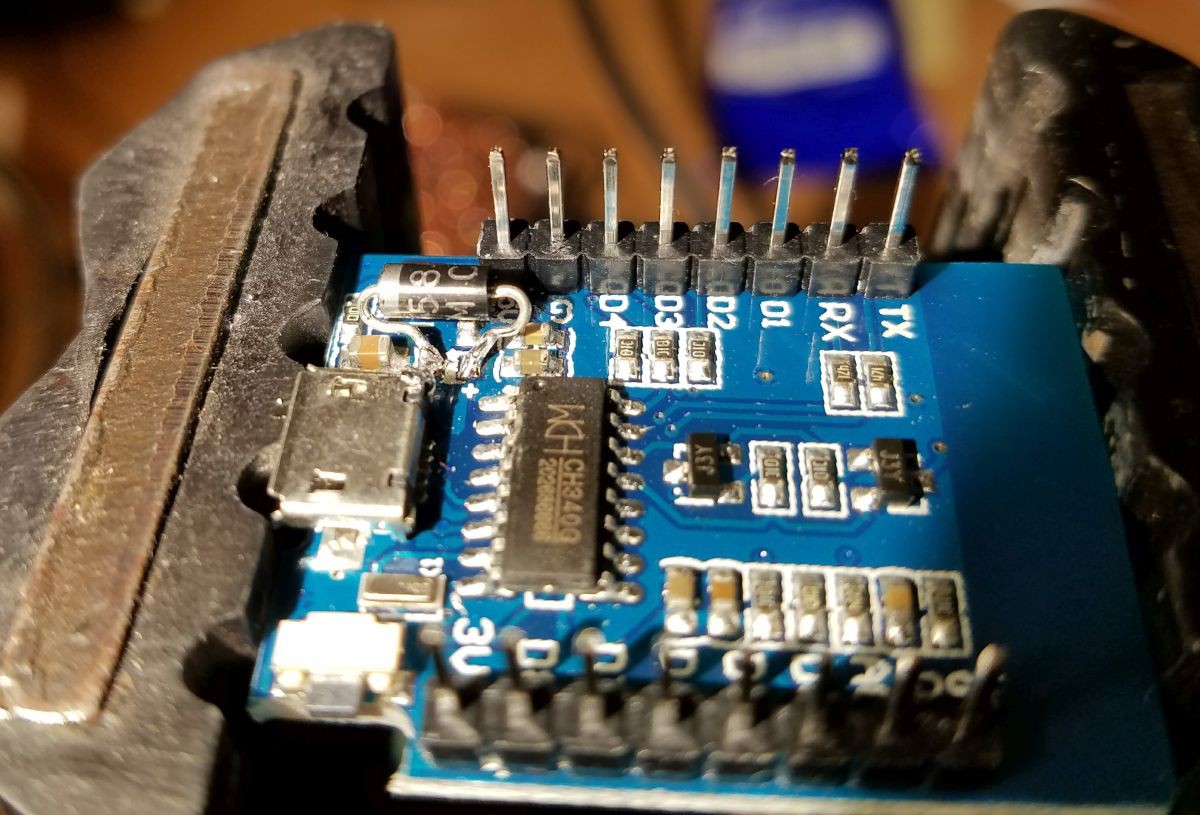

ESP8266 repair

03/07/2017 at 12:03 • 1 comment![]()

I must have pushed the Shottky diode of my clone Wemos D1 Mini too hard, it failed last night, so I found a diode in a larger package and soldered it on. It's running the ESP chip, but now I'm having trouble getting it to communicate via USB.

-

ESP8266-FastLED-Webserver app

03/02/2017 at 20:46 • 0 commentsLast night I was able to try out some code on the Vulcan Salute that seems to work. The LEDs, motor, and infinity lights were responding to commands from Jason Coon's Webserver app. I discovered that some of my LEDs are happy with a 3.3V data signal, and some LEDs are not. I got lucky, 2 out of 3 of my strands do not appear to need level conversion, but one does. It appears that the 12V boost converter requires a 5V signal. With a 3.3V signal, I could hear the inductor whining at the right frequency but it was not turning the LEDs off. The H-Bridge Motor controller also needs level conversion from 3.3V to 5V. Tonight I will try a cheap version of one of those level conversion boards based on the BSS138.

-

Finding an alternative to Blynk

02/28/2017 at 19:05 • 0 commentsThe contest deadline is only a few days away, so I'm really hoping I can write some software that operates my Vulcan Salute. The ESP8266 will use the FastLED library to drive 26 LEDs, send analogWrite() commands to the motor control board, and on another pin analogWrite() to a 12V boost converter with an enable input. I would like the user to be able to select the pattern and change the PWM going to the motor and the boost converter that controls the strip infinity LEDs.

At first, I tried using Blynk because it has a nice interface on the phone. My program works with FastLED and with the sliders in the phone app, but when I use the Menu widget to select patterns, it always crashes, with no reset cause listed on the serial monitor. So I looked at +Jason Coon's webserver code that uses JQuery and Bootstrap. Those tools are way over my head, but Jason's is one slick looking app, so I posted a question to the FasteLED users group. Jason responded very quickly with some words of encouragement, so I will try using his webserver code, adding some sliders for more control. I also prepared a bill of materials with purchasing links and added it to the project description. -

Testing LEDs

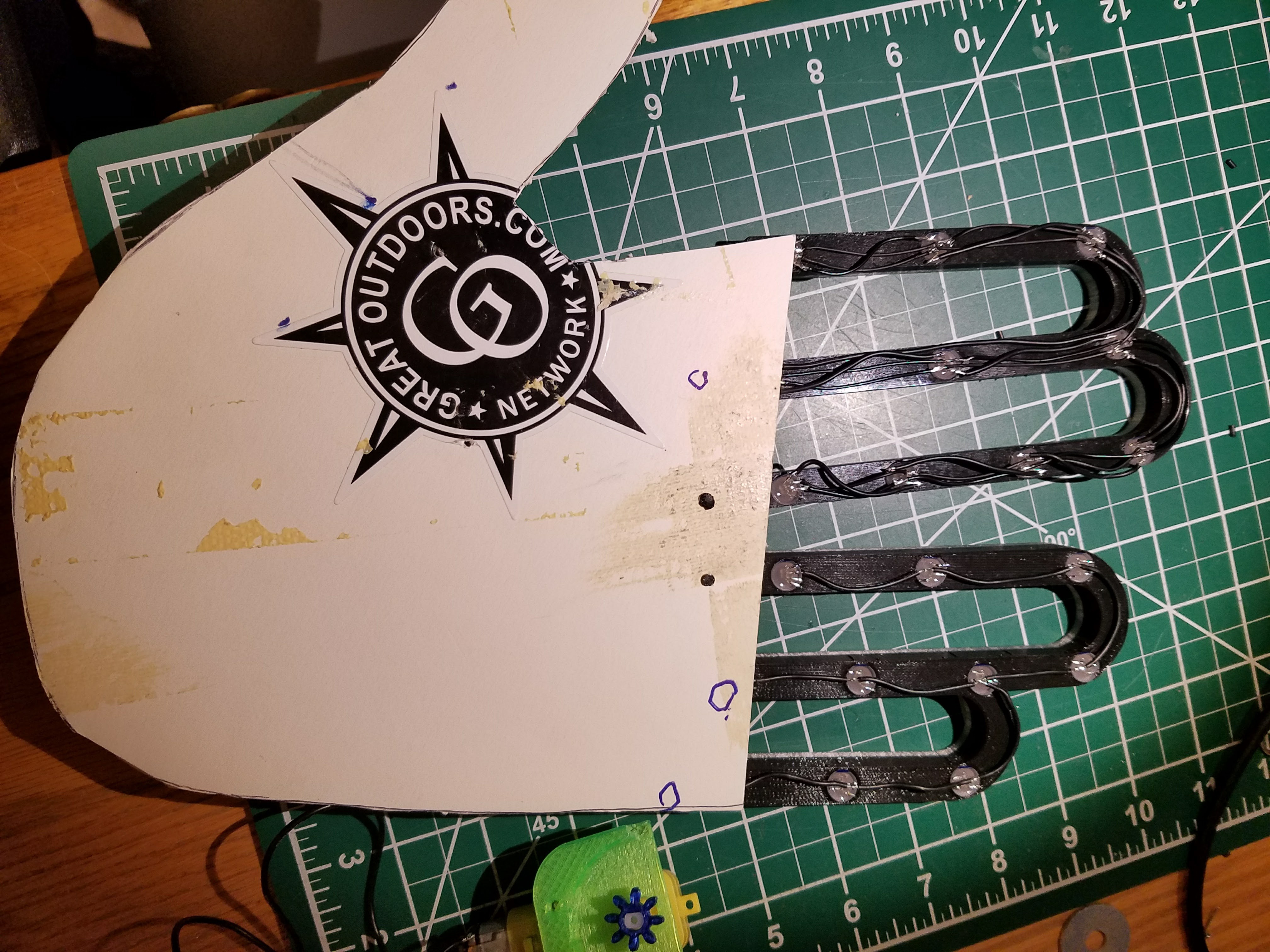

02/20/2017 at 13:16 • 0 commentsThis weekend I found the perfect plastic material for the perimeter of the hand - a piece of diffuser sheet from an old CRT projection TV. I measured the height of the motor while it was on the motor mount (the tallest item to go in the center of the hand) and I cut a slice of diffuser material 32mm in height. I then proceed to glue it to the acrylic base of the hand and made a notch for the motor wires to exit. Then it was time to put two strips of blue LEDs on the inside of the hand. The blue LEDs are on a strip with a 150 ohm resistor for each group of 3 in series. I tested the brightness on my bench power supply and found that I would like to supply at least 11 volts. I've chosen to use a boost converter to boost 5V to 12V. The converter I have on hand happens to have a chip enable pin available, so I can easily program a PWM breathing effect by using any of the GPIO pins on the ESP8266 and analogWrite commands. I was also able to test the 20 LEDs in the fingers. I have each of the 2 pairs of fingers using the same data wire, so the LED patterns will be mirrored.

-

New Bull Gear, Pinion Gear and Gearbox Holder

02/15/2017 at 13:57 • 0 comments![]()

I printed a new bull gear and a new pinion gear to get a better reduction in speed. I took the opportunity to add some flair by putting three little Vulcan Salute cut-outs in the gear. Since the 8-tooth pinion gear was so small, I decided to print it in PETG which is quite a bit stronger than PLA when printed at the correct temperature. I also had to design a smaller gearbox holder so the larger bull gear would fit.

![]()

Wiring the 20 PL9823 LEDs is a time consuming task. If I make a second Vulcan Salute, I am considering doing a design that uses strips of WS2812s. The wires coming out of the four LEDs closest to the palm of the hand are making contact with the foamboard, so I either need to cut away those sections of the board or add some spacers under the finger gears to make clearance for the LEDs.

-

First test of hand mechanics

02/13/2017 at 22:41 • 0 commentsAfter the parts were finished printing, I cut a hand outline out of foam board and used plastic rivets to hold the three gears on. I used hot glue to hold the motor mount to the foam board. The motor starts to stall at voltages below 2V, and that is about the speed that I want the Vulcan Salute to run at, so now I am designing a smaller pinion gear and a larger bull gear.

-

TinkerCad models sliced and now printing!

02/13/2017 at 18:40 • 0 commentsI'm printing some guts for the Vulcan Salute. This batch is the motor holder, the connecting rod, and the large gear. I never attempted to print the first version of the design that uses a linear bearing and the rack gear (screenshot pictured in the gallery).

Vulcan Salute

With this bit of animated art on your wall, it would be illogical if you did not receive extra long life and prosperity.

terrag

terrag