-

Enclosure design

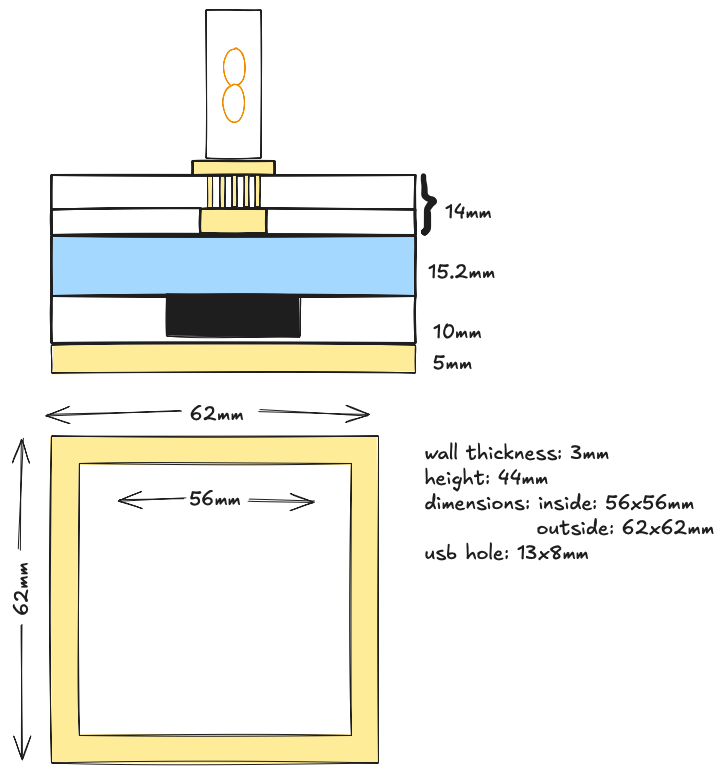

02/20/2025 at 16:15 • 0 commentsA product without an enclosure is not a complete product. While I enjoy looking at PCBs with all the components of the nixie clock, for others it might be just a dust magnet. The last puzzle piece to complete this project is moving the electronics into a box.

First step is measuring, then getting a rough idea about case dimensions and thickness:

![]()

Second step is CAD, making a design. I opted for a simple box shaped design with holes for the nixie tube and USB connector.

![]()

3D printed prototype:

![]()

![]()

Next step is to think about what material to use and how to make the case more interesting...

-

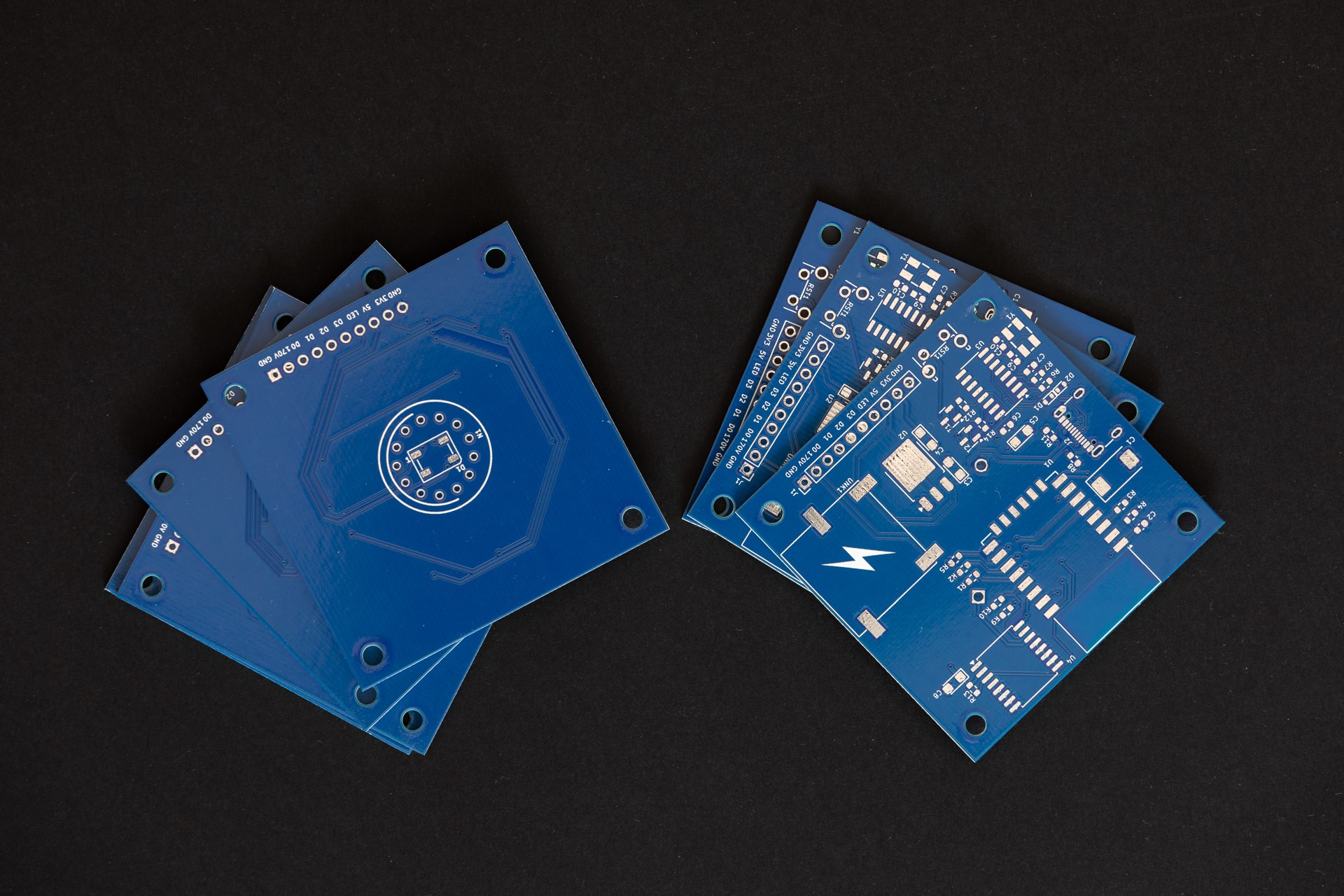

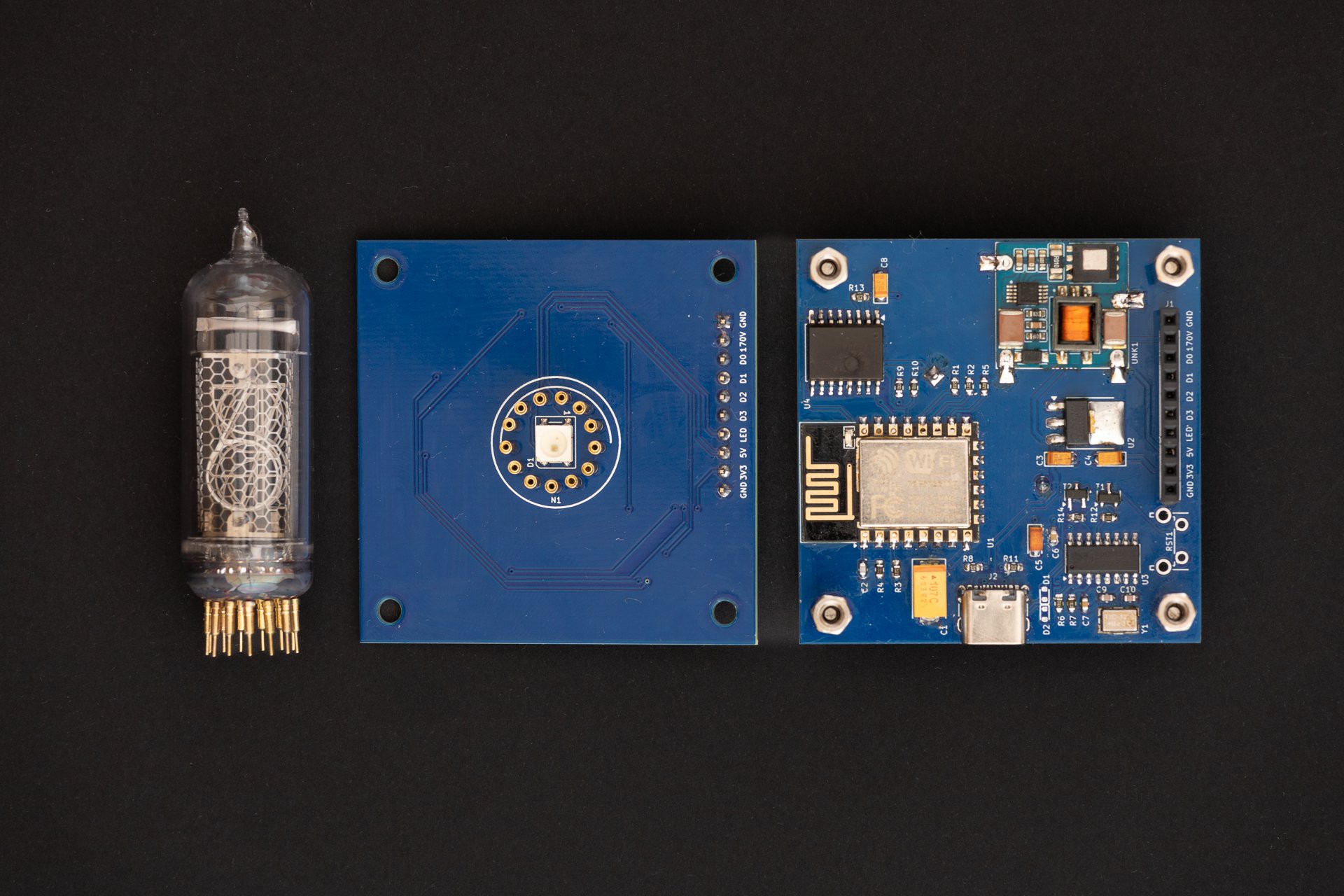

Hardware - new PCBs (thank you PCBWay)

01/31/2025 at 14:07 • 0 commentsA huge thank you to PCBWay for sponsoring this run of PCBs!

How does this story go?

A representative from PCBWay contacted me because he was deeply impressed by my project and offered to sponsor a batch of PCBs to test out their services.

Firstly, I was surprised since no one ever showed interest in my personal projects. He was very kind to explain what they offer through the sponsorship and we made a deal.

I have to be honest, I was a bit sceptical how this would go. It turned out they were very professional by sending the boards and paid all necessary costs including delivery. In addition to this, I have to praise simple and easy ordering through their website.

Since I recently moved to KiCad, it was a perfect opportunity to try out the PCBWay Plug-in for KiCad. It provides a simple way to place an order in just a few clicks. There is no need to bother with exporting gerber files, everything is automated. You just need to update the PCB specification and fill in the shipping information on the webpage. That’s it.

Another useful tool is PCBWay’s online gerber viewer, it is good for double checking all the exported files and to use images of PCBs in documentation.

The entire journey from placing the order to receiving the package took less than a week. Incredible! PCBWay did a superb job, PCBs are amazing.

![]()

Assembled PCBs:

![]()

Stacked PCBs:

![]()

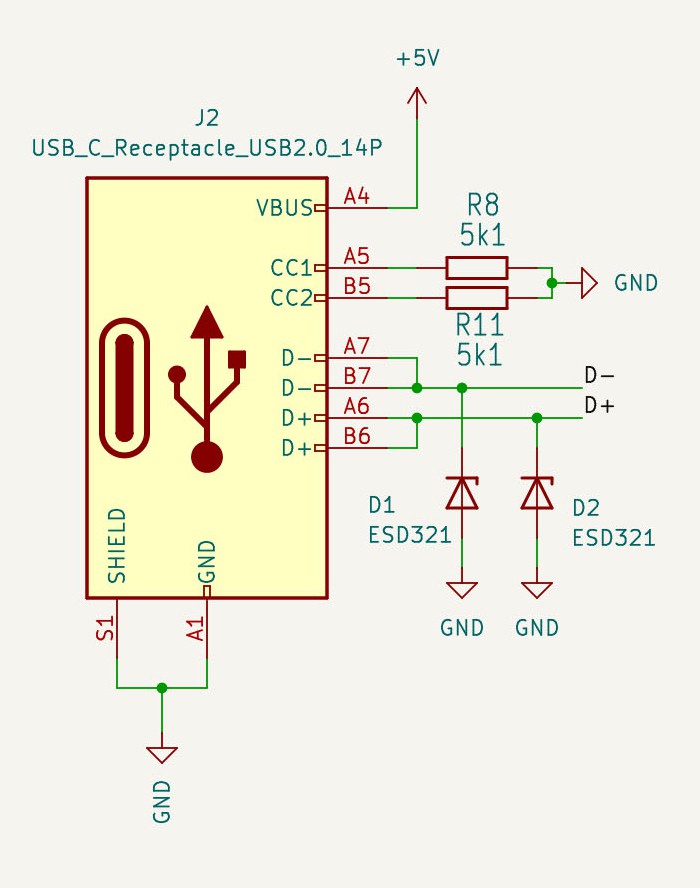

Updates on Control board

Micro USB connector has been replaced with a type C connector. Nowadays, it is much easier to find type C cables at our desks because almost all devices switched to it. Despite it being harder to solder this connector without stencils, I found this change a logical step to keep up with current trends.

Here is the updated part of the control board:

![]()

Control board schematic is updated in the project's details.

Lessons learned from this batch

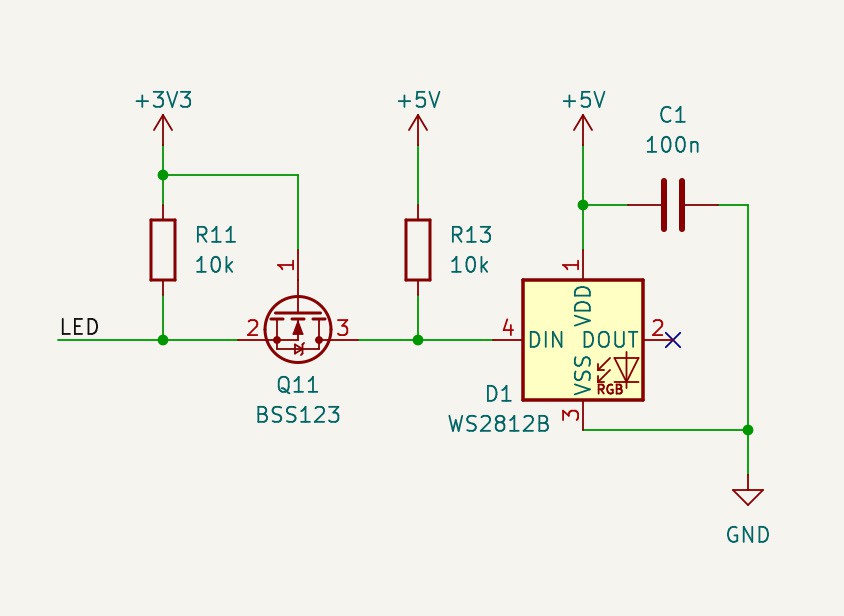

Weird behaviour of the WS2812B RGB LED:

![]()

I initially thought the problem was in micro USB connectors because the problem occurred with some cables. But, then I realised the problem might be in the fact that WS2812B is rated to 5V and the signal coming from ESP is 3V3. The LED worked on the breadboard while I was experimenting. I remember, I read somewhere that that’s fine… But, it isn’t. To fix this issue I’ve added a level shifter before the DIN pin of the RGB LED:

![]()

Here is my botched PCB:

![]()

-

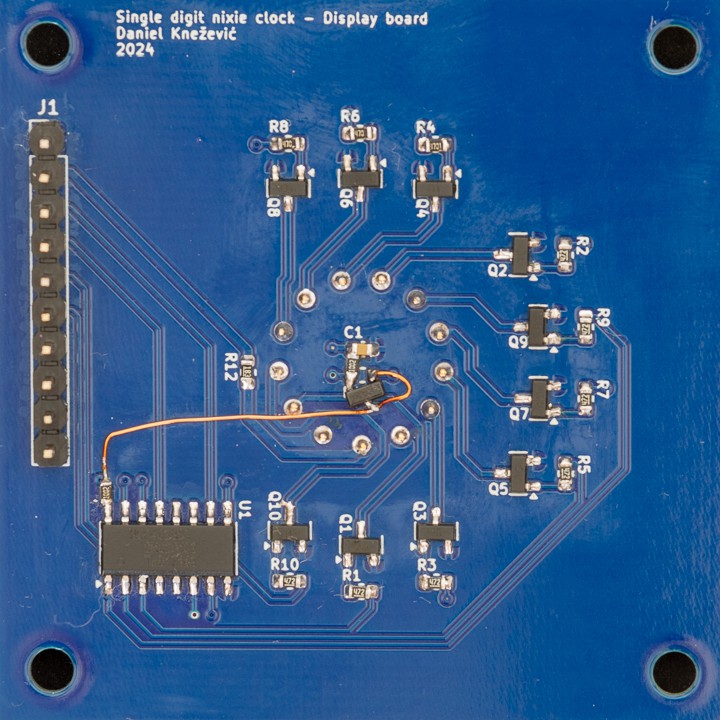

Hardware - Display board [v2]

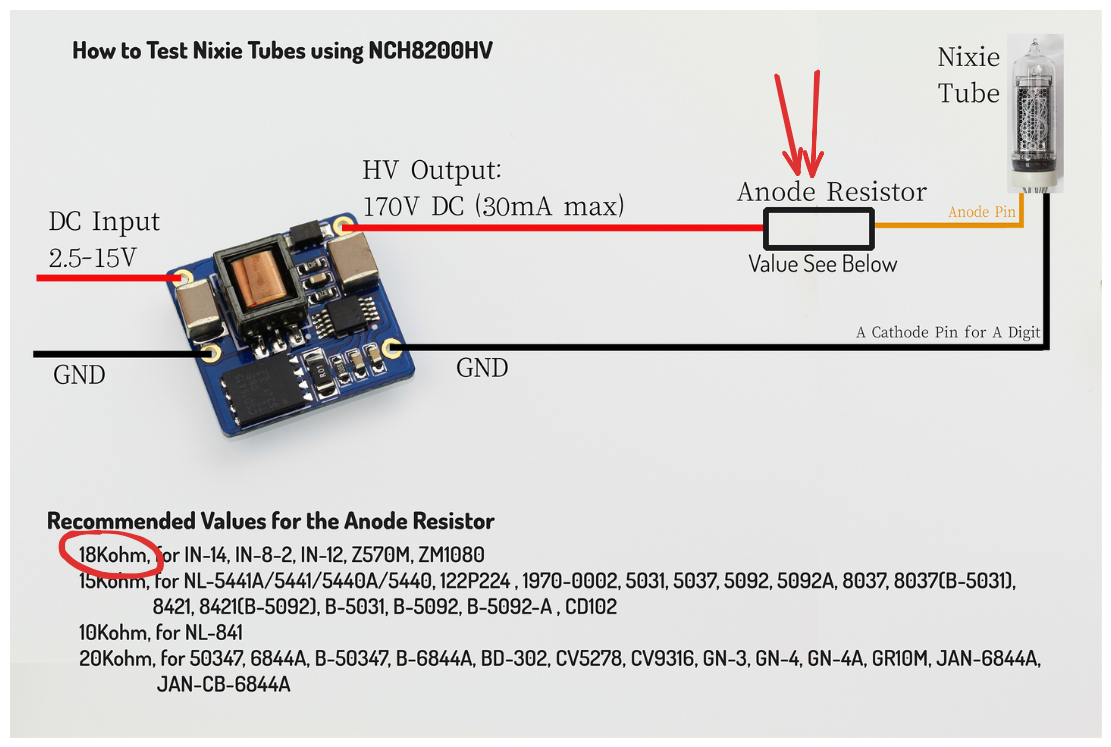

01/20/2025 at 13:24 • 0 commentsRecently, I decided to move schematic & PCB designs from the good old, but sadly dead EaglePCB to KiCAD. I found this exercise good for learning how KiCAD works. While I was replacing components with ones from KiCAD I double checked data sheets and docs… Documentation for NCH8200HV has a wiring diagram describing how to connect a nixie tube to the 170V supply module. In the picture below there is an anode resistor that is used as a current limiter. I completely missed that. That’s the reason why the digits were too bright. The second thing I learned is to never overcurrent Nixie tubes.

![]()

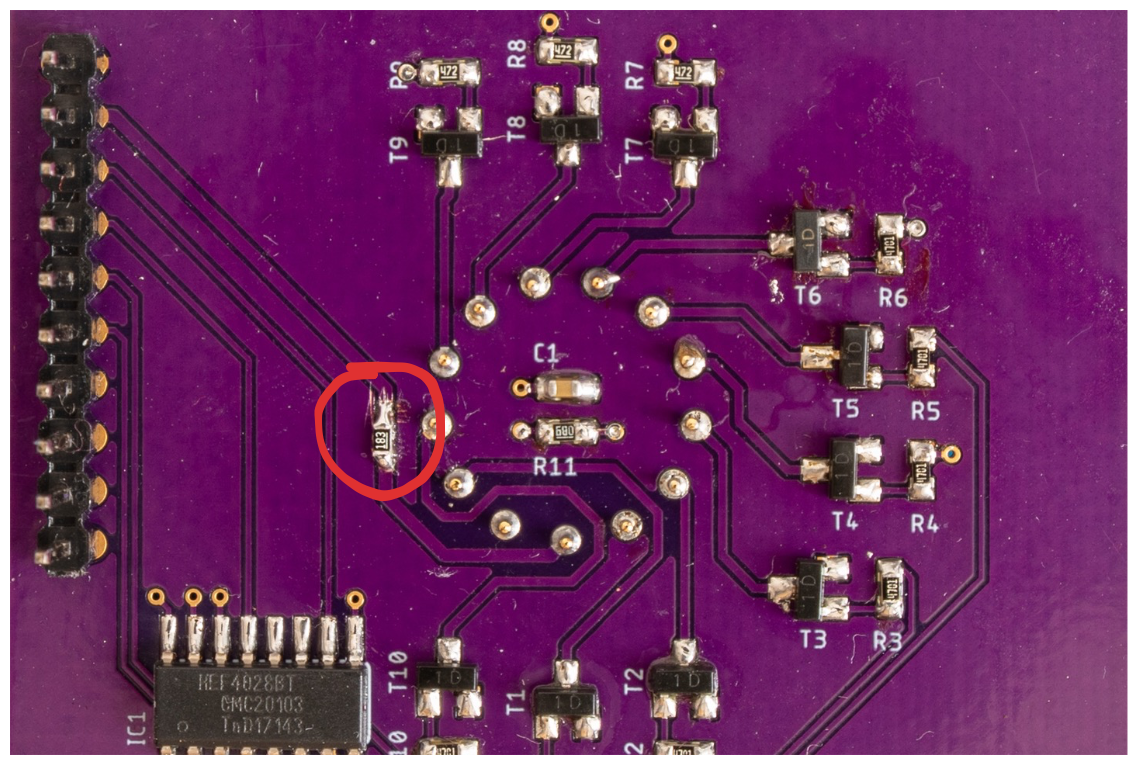

To solve this issue, I cut the 170V trace on the display board and soldered an 18K resistor in series:

![]()

Updated schematic is in the project's details.

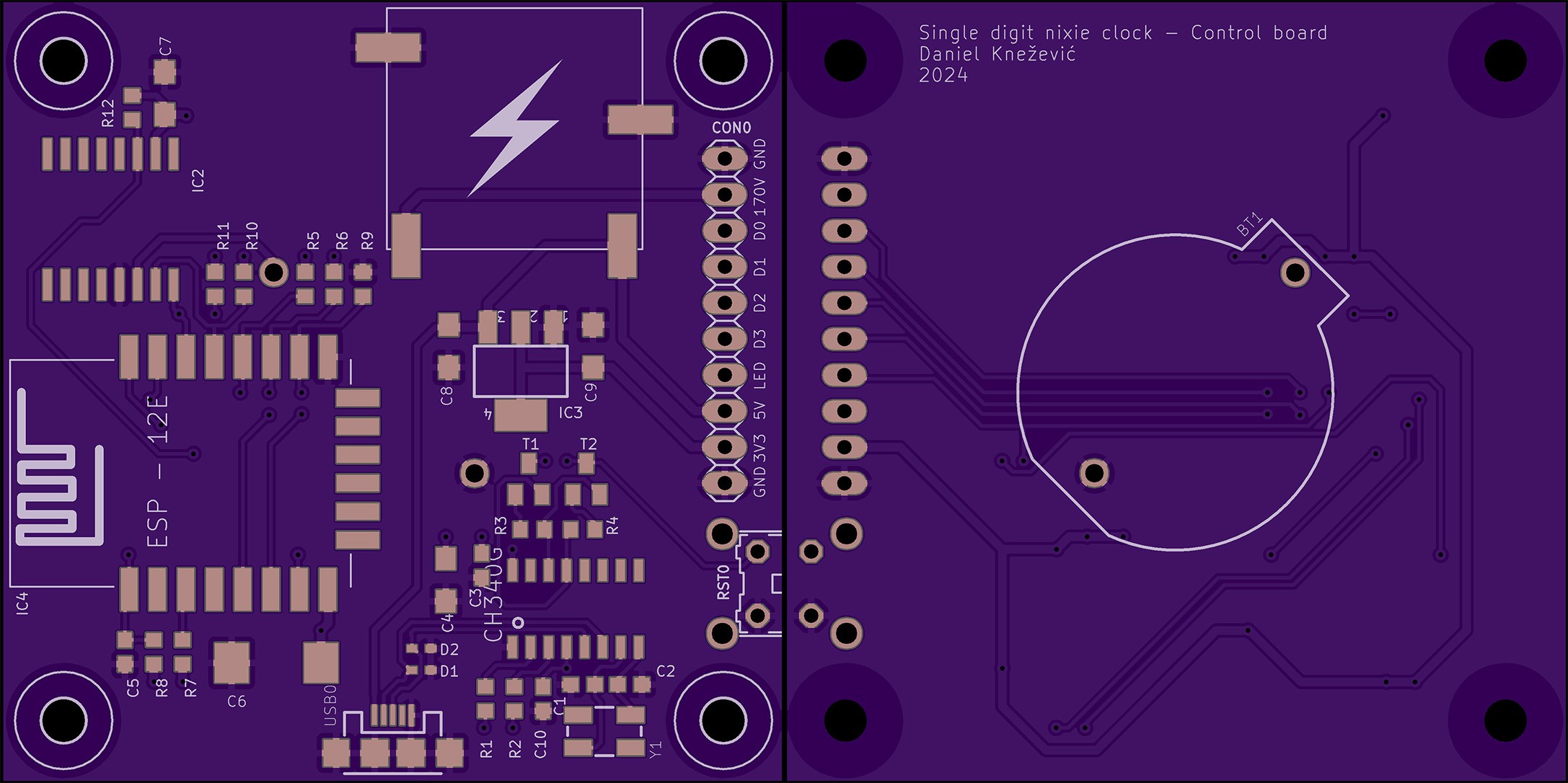

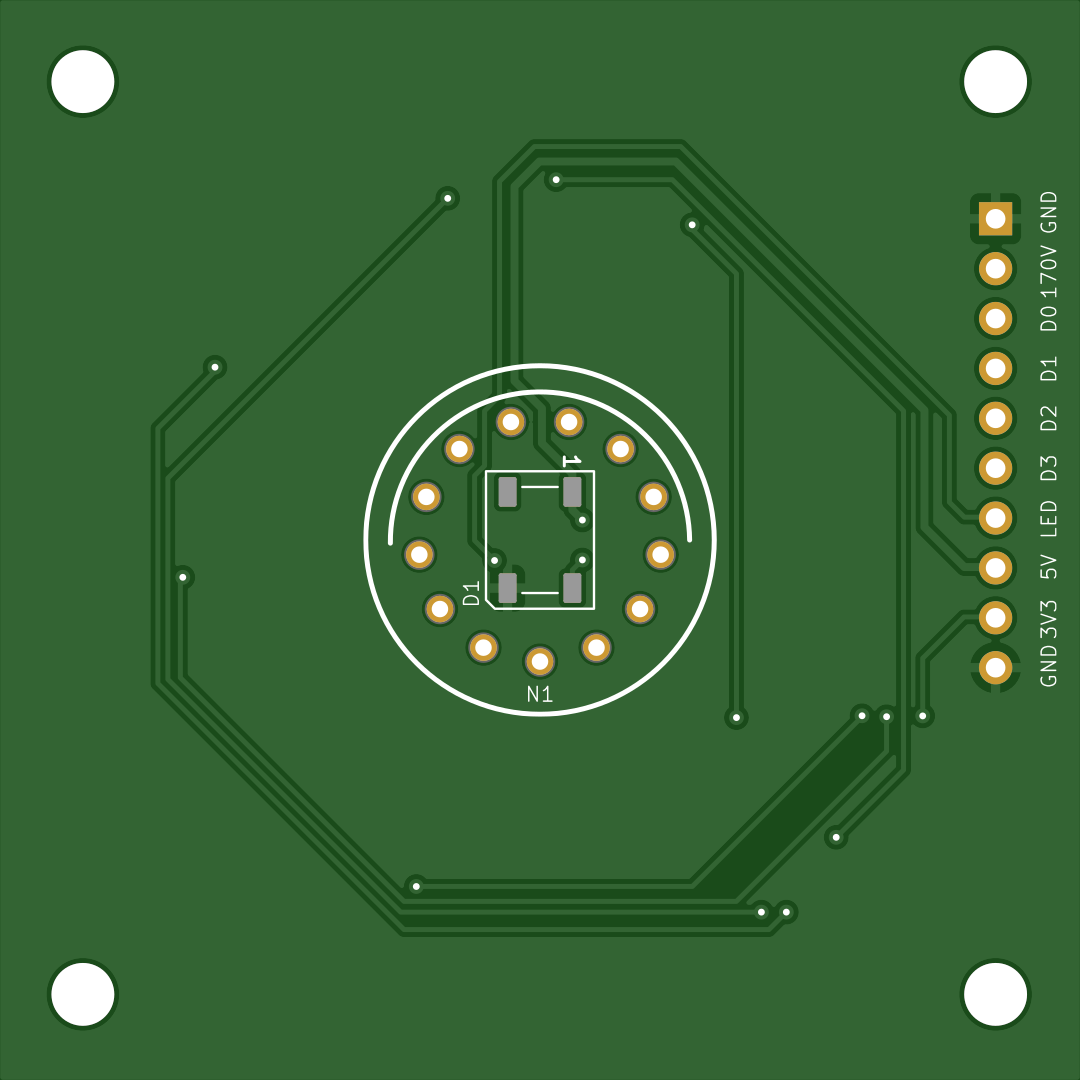

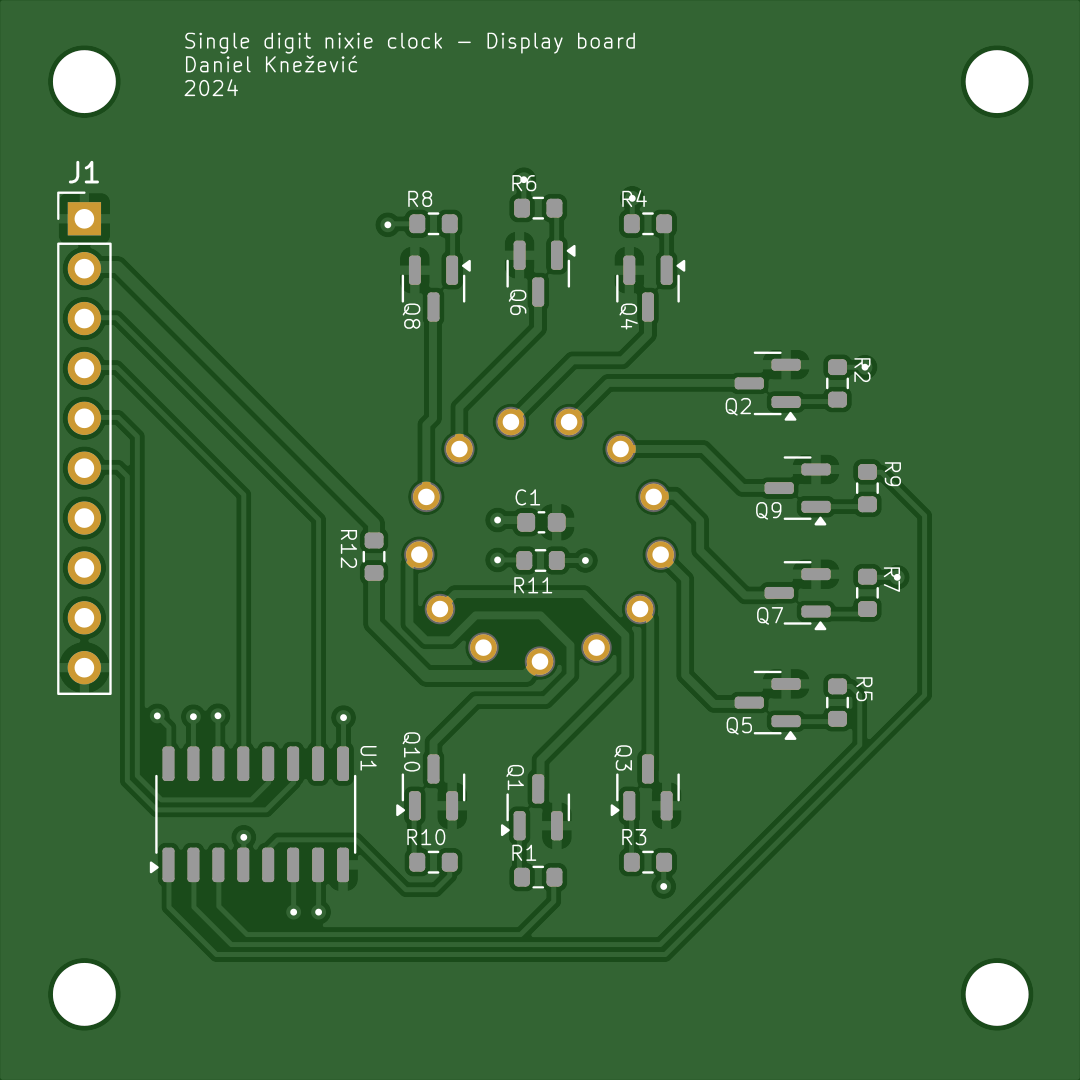

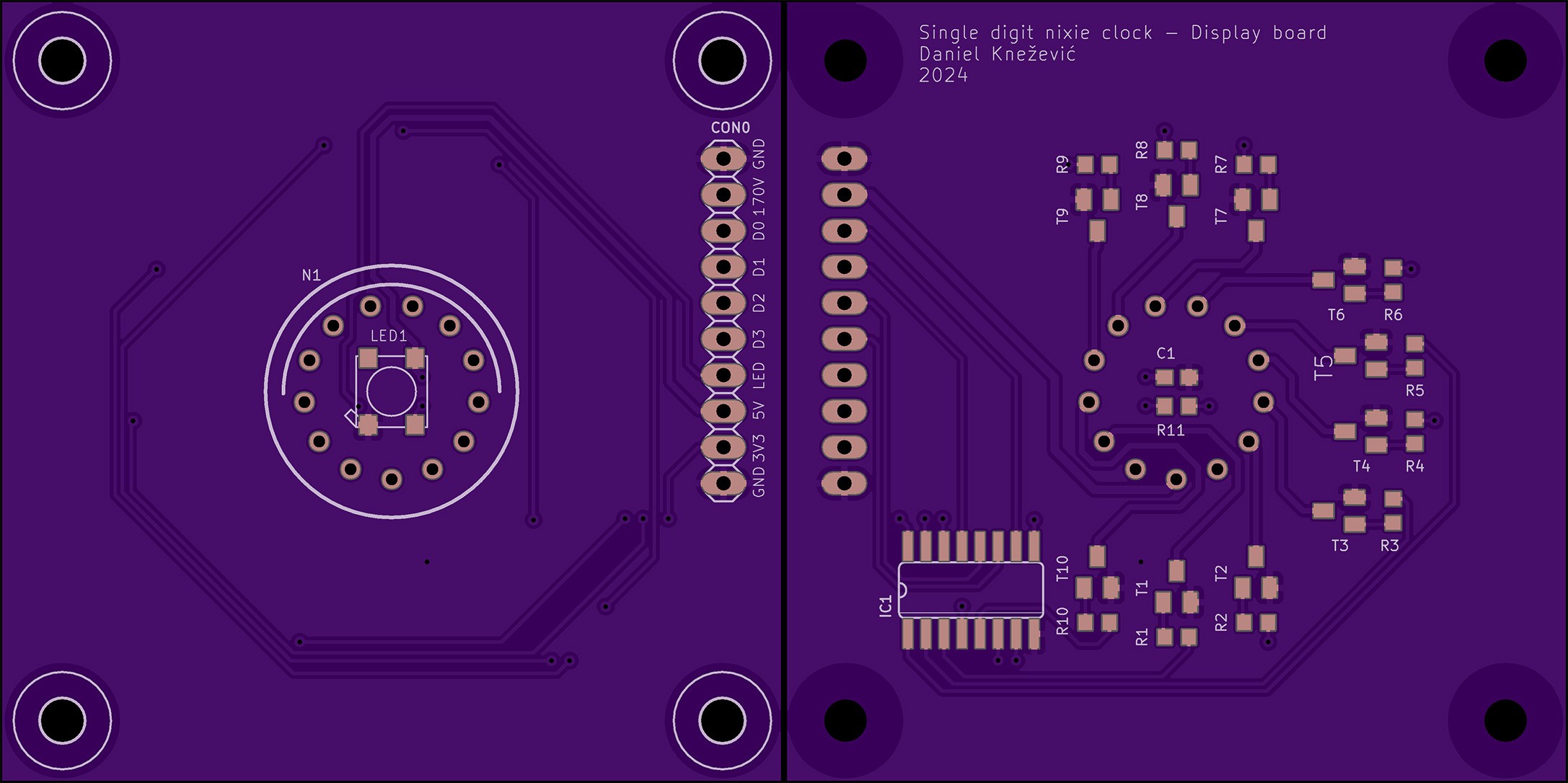

PCB

![]()

![]()

-

Web server

01/15/2025 at 16:31 • 0 commentsBackend

Backend is implemented using ESPAsyncWebServer.

Frontend design

Initially, the front end was implemented with jQuery mobile. Reason for choosing this framework was in its simplicity. It provides a simple way to create and control user interface components. One thing that always annoyed me was its low response time. It took too much time to load jQuery, jQueryMobile and theme resources. On top of this, this slow response time caused WDT resets.

One more thing, I just realised that jQuery mobile project is deprecated since October 7, 2021. Huh, when it comes to web related technologies, it looks like I'm living under a rock...

To solve these issues, I opted to completely re implement the frontend using plain HTML, CSS and JavaScript. The end result looks almost the same as the previous design or even better. Responsiveness and stability increased significantly. The only drawback is now in maintenance and extension. It is required to implement everything manually.

Size comparison

jQueryMobile implementation Custom implementation Improvement 404kB 32kB 1262,5% Performance comparison

Average loading time of 10 tries:

jQueryMobile implementation Custom implementation Improvement 8695mS 879mS 988% Note: The jQueryMobile implementation caused restart of the ESP 3 times.

Design comparison

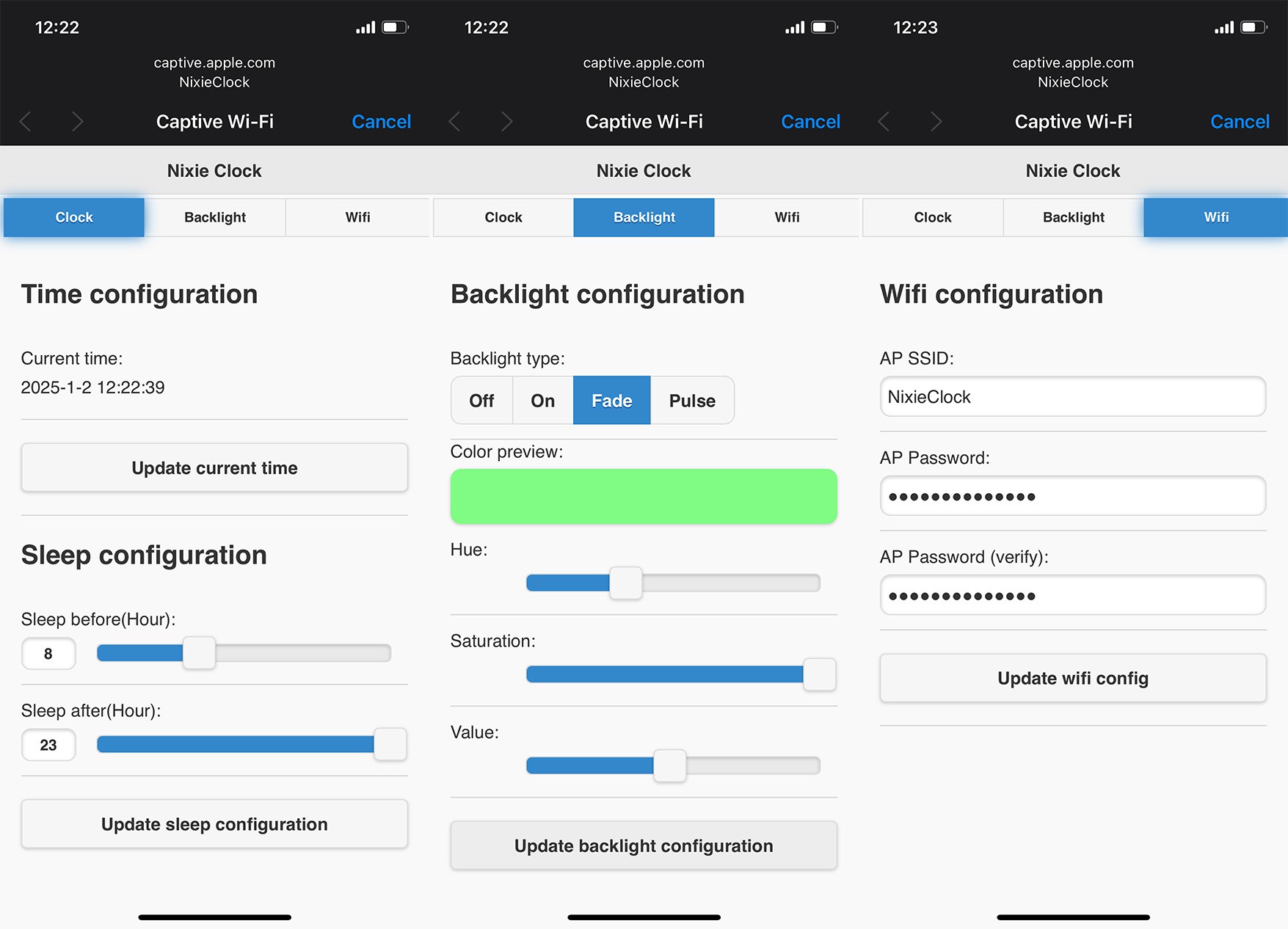

jQuery mobile design:

![]()

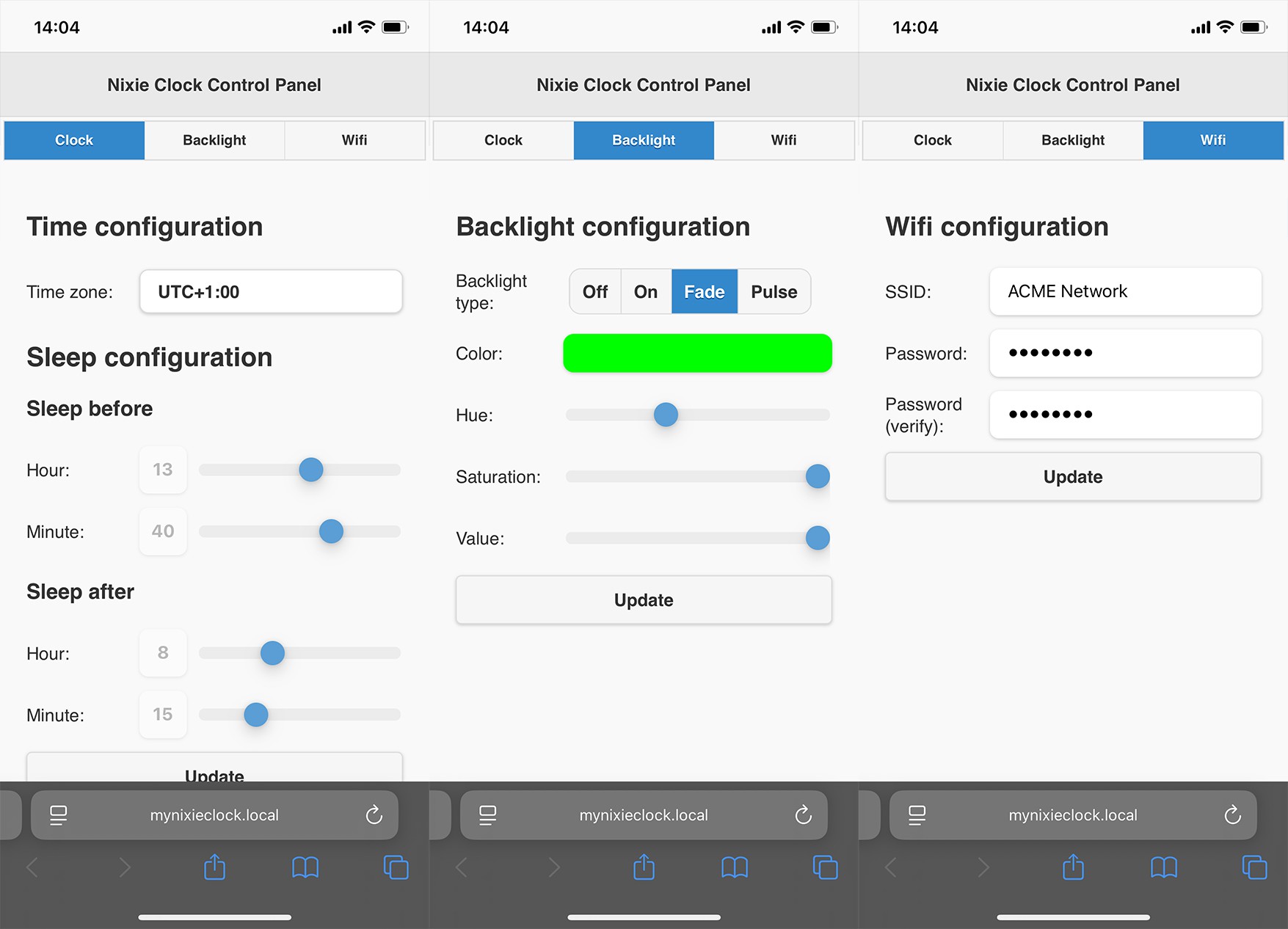

Custom design:

![]()

-

Hardware - Display board [v1]

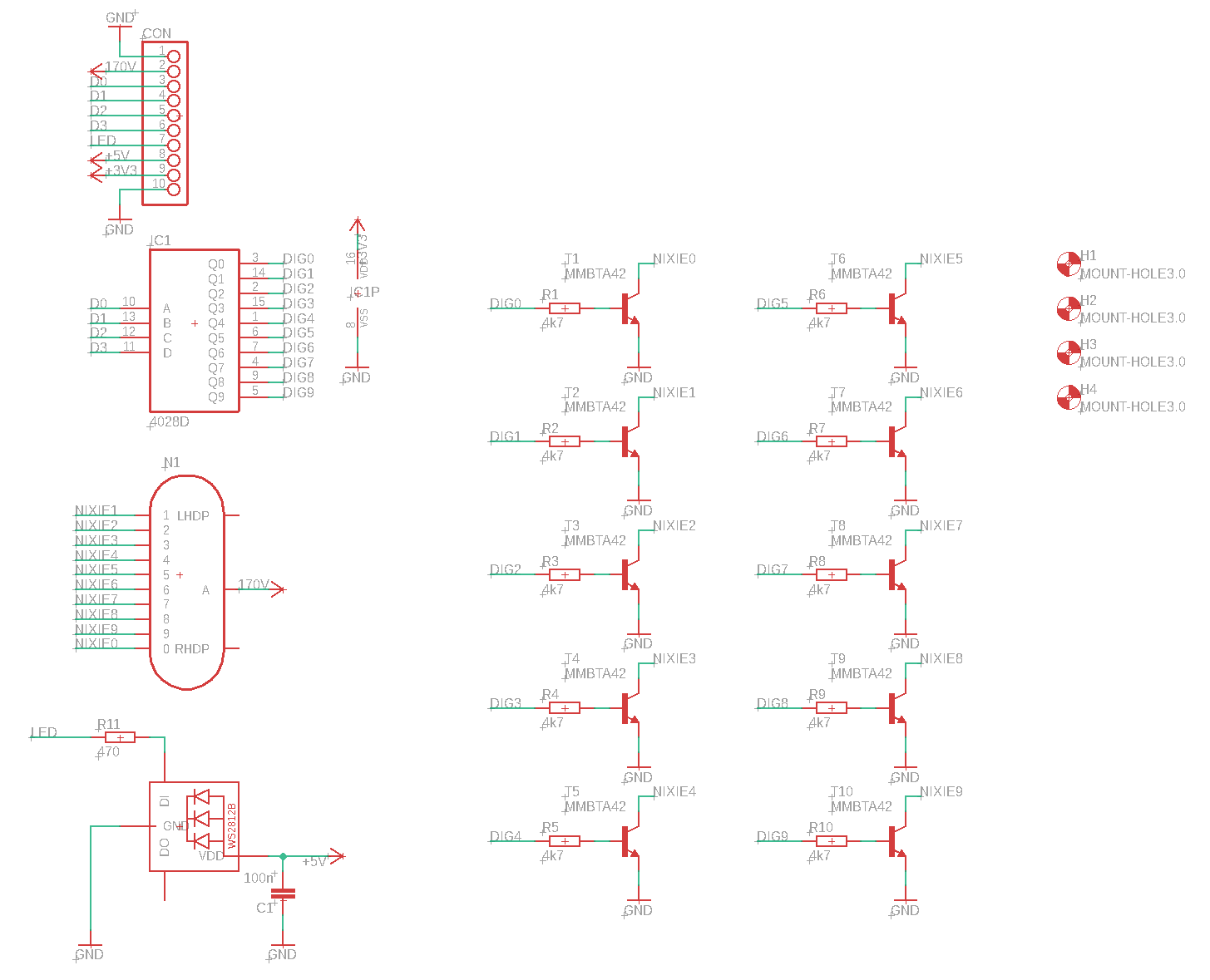

01/07/2025 at 10:58 • 0 commentsDisplay board uses a CD4028 BCD-to-decimal decoder. Its purpose is to reduce the number of required GPIO pins from 10 to just 4 for showing digits from 0 to 9. Compared to dedicated BCD to decimal decoder nixie drivers (like K511ID1), the CD4028 is a widely spread component and it is available in SMD package. Since CD4028 has a voltage range from 3.0V to 15V it is not compatible with nixie tube’s operating voltage of 170V out of the box. This problem is solved with MMBTA42, a high voltage transistor, rated to more than 200V.

The rest of the display board consists of a WS2812B RGB LED and a pin header used to connect with the control board.

Schematic

![]() PCB

PCB![]()

-

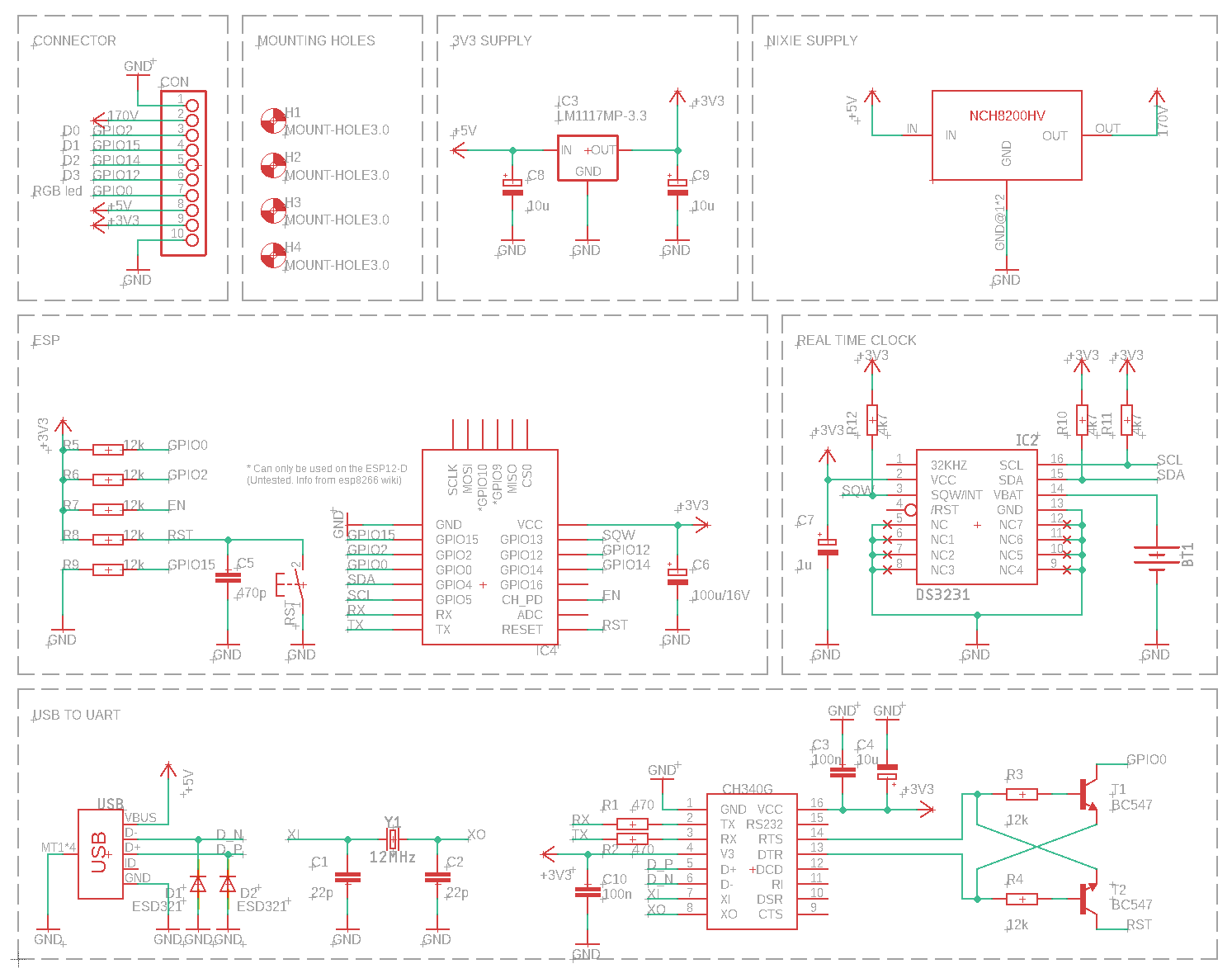

Hardware - Control board [v1]

01/03/2025 at 15:57 • 0 commentsFor proof of concept NodeMCU was connected with a DS3231 RTC module on a breadboard. This was enough to start working the firmware. Later, a PCB was created. The PCB is basically a re-packaged NodeMCU design connected with DS3231 and NCH8200HV high voltage boost module board.

![]()

Schematic

![]() PCB

PCB![]()

Single Digit Nixie Clock

A small project combining ESP8266 with a vintage Soviet Nixie tube from the 70s to create an artistic clock

Daniel Knezevic

Daniel Knezevic

PCB

PCB

PCB

PCB