Making a retro arcade that can simulate systems like the PS1, PS2, PSP, SEGA, Gameboy, and others without breaking a sweat was one of the best uses for this old SBC.

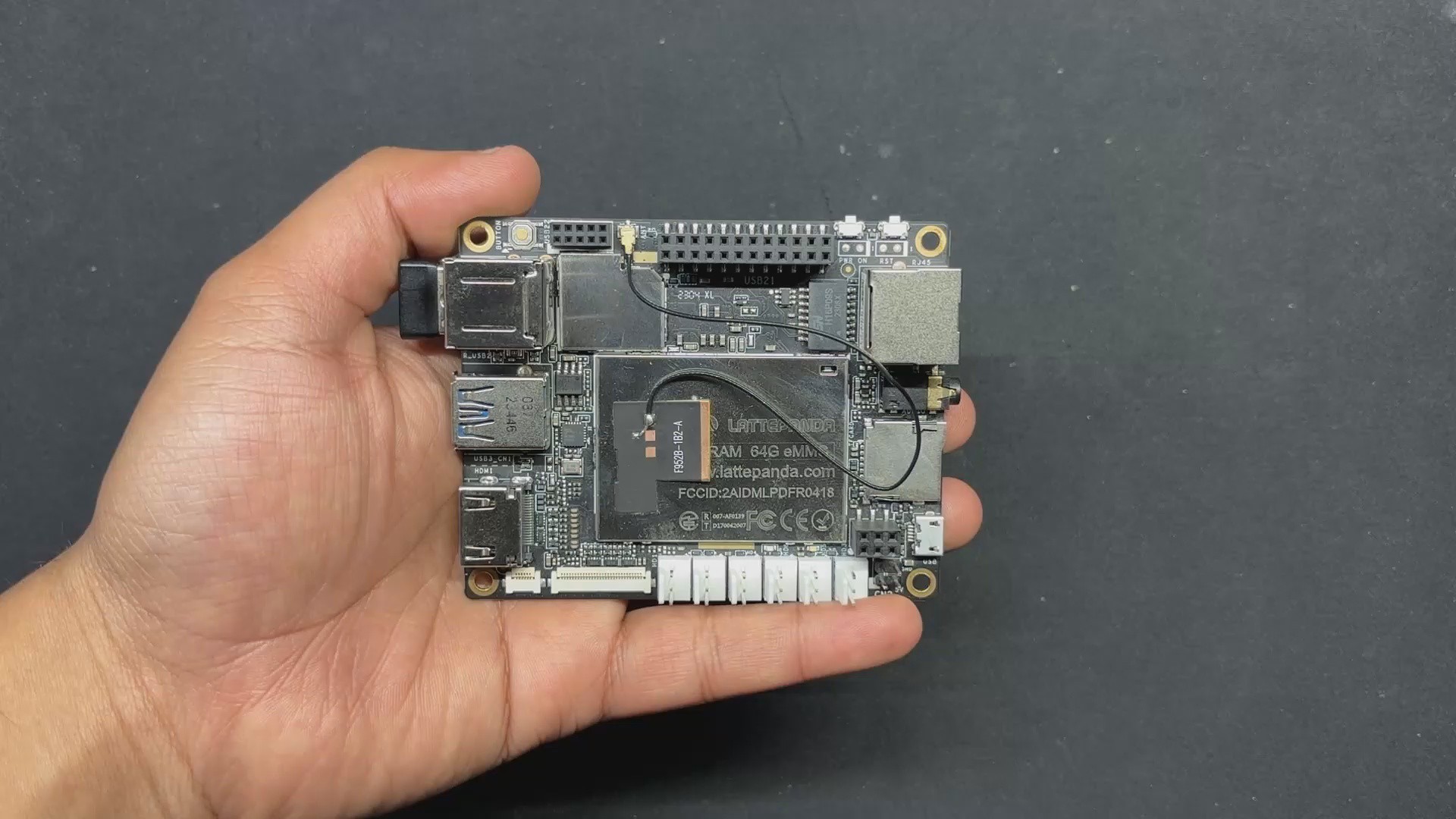

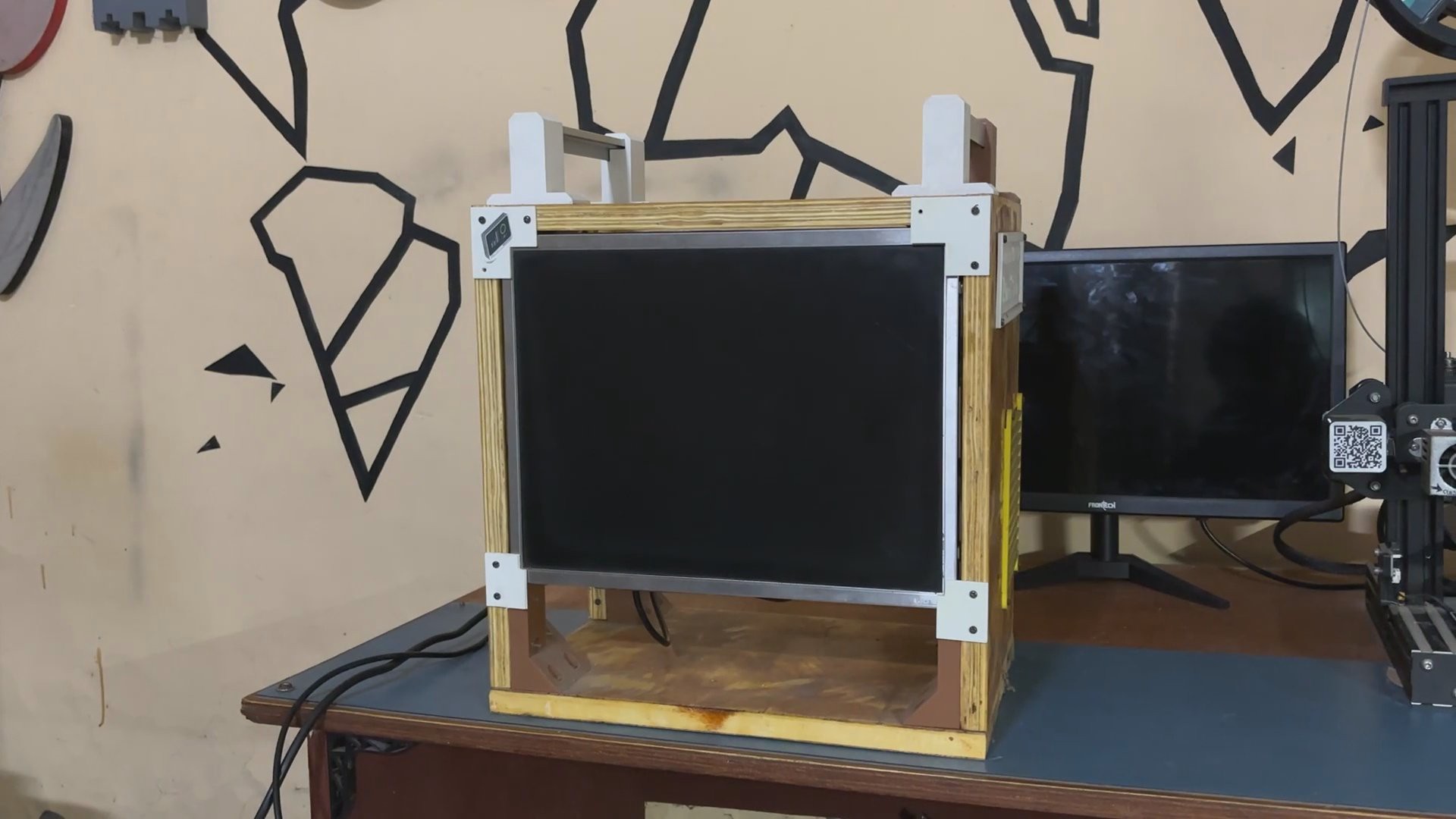

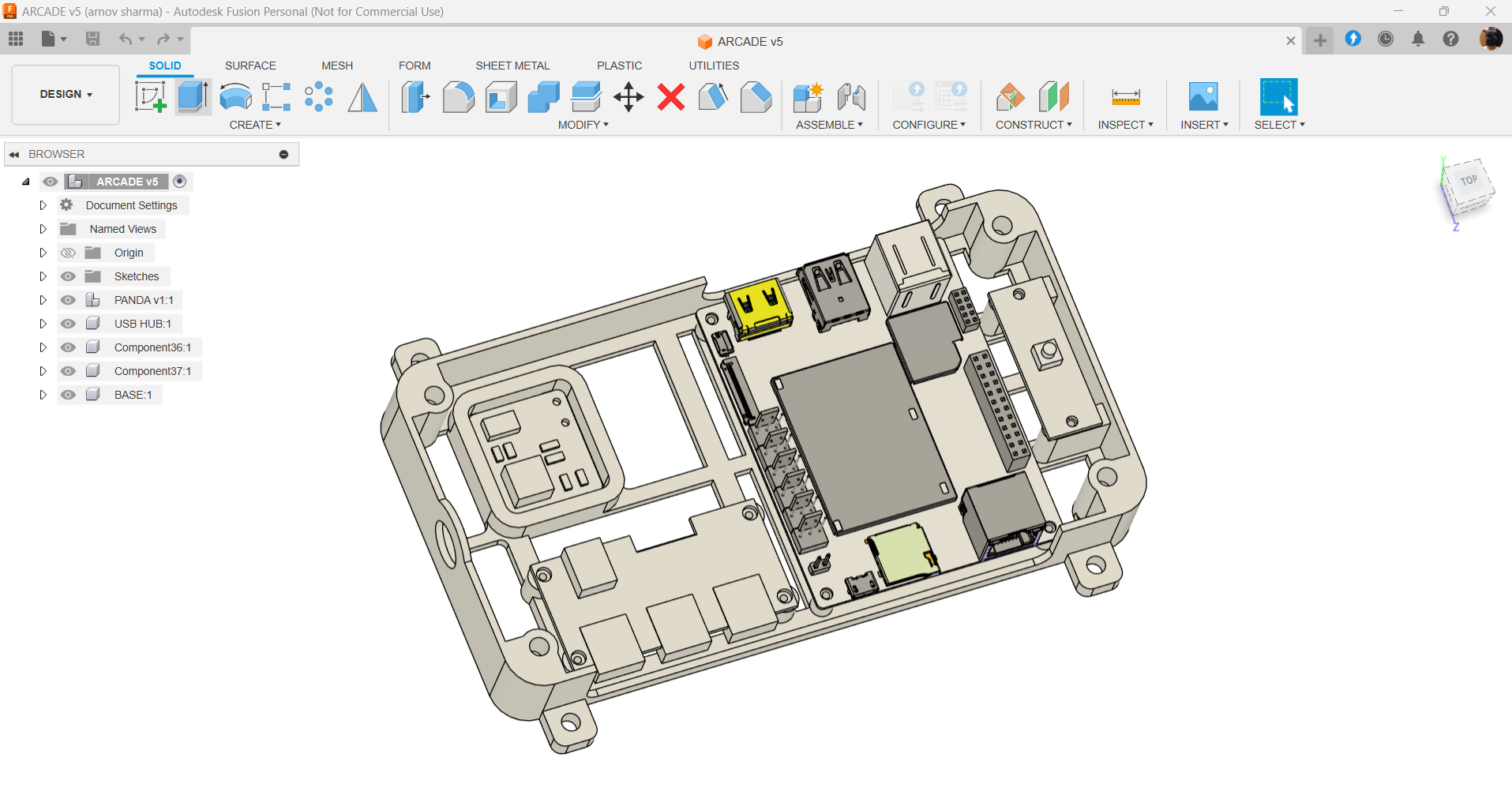

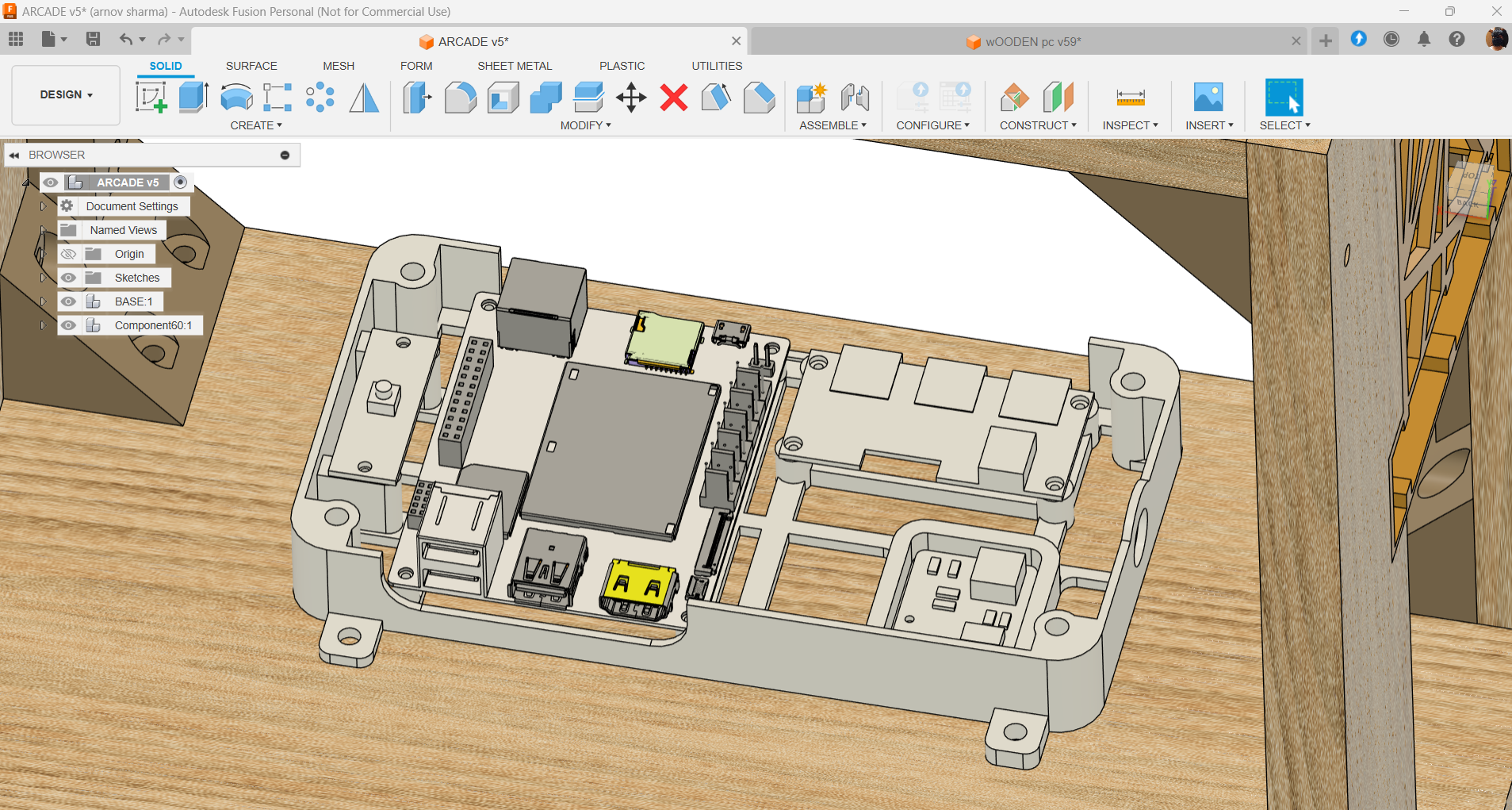

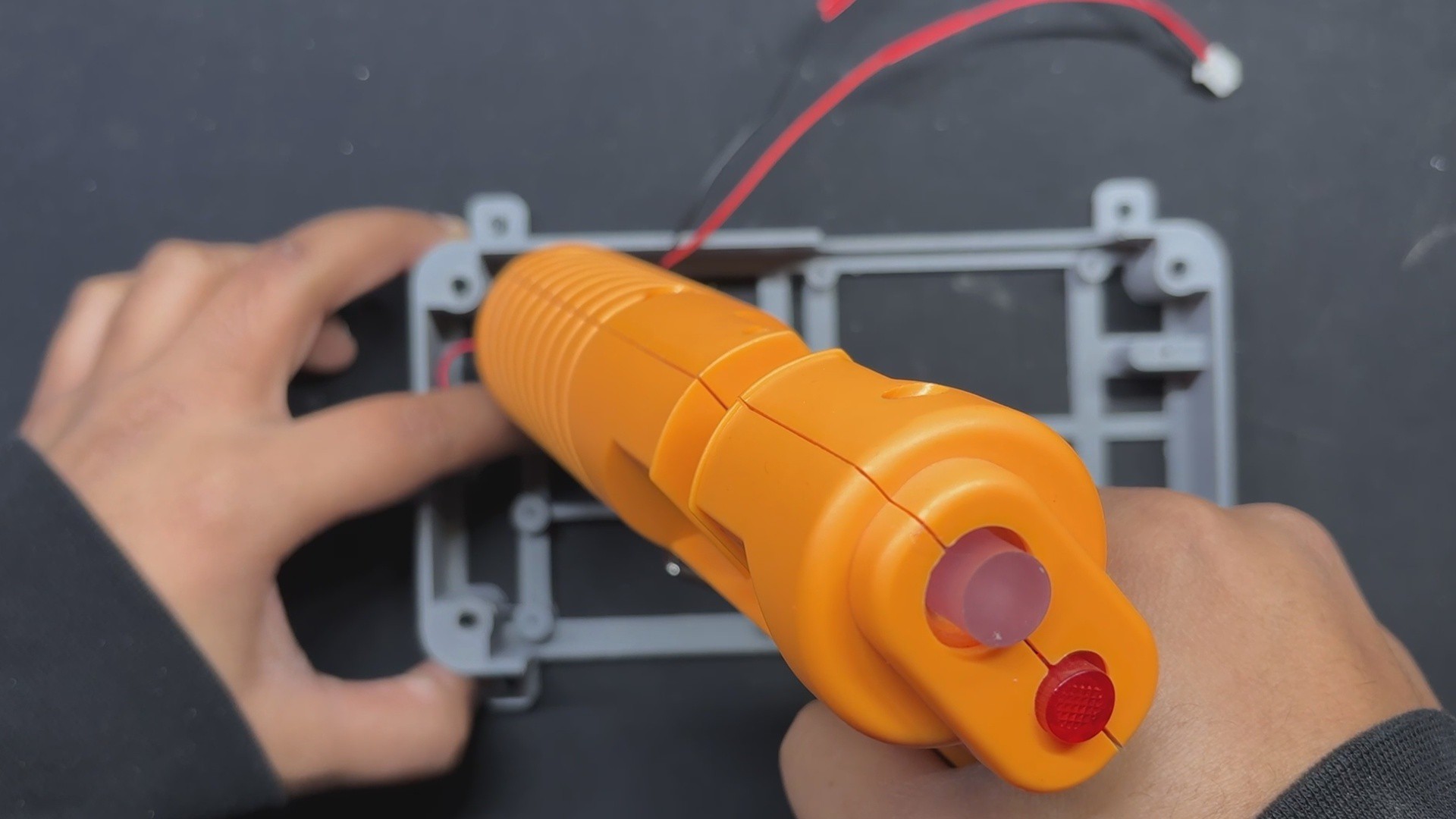

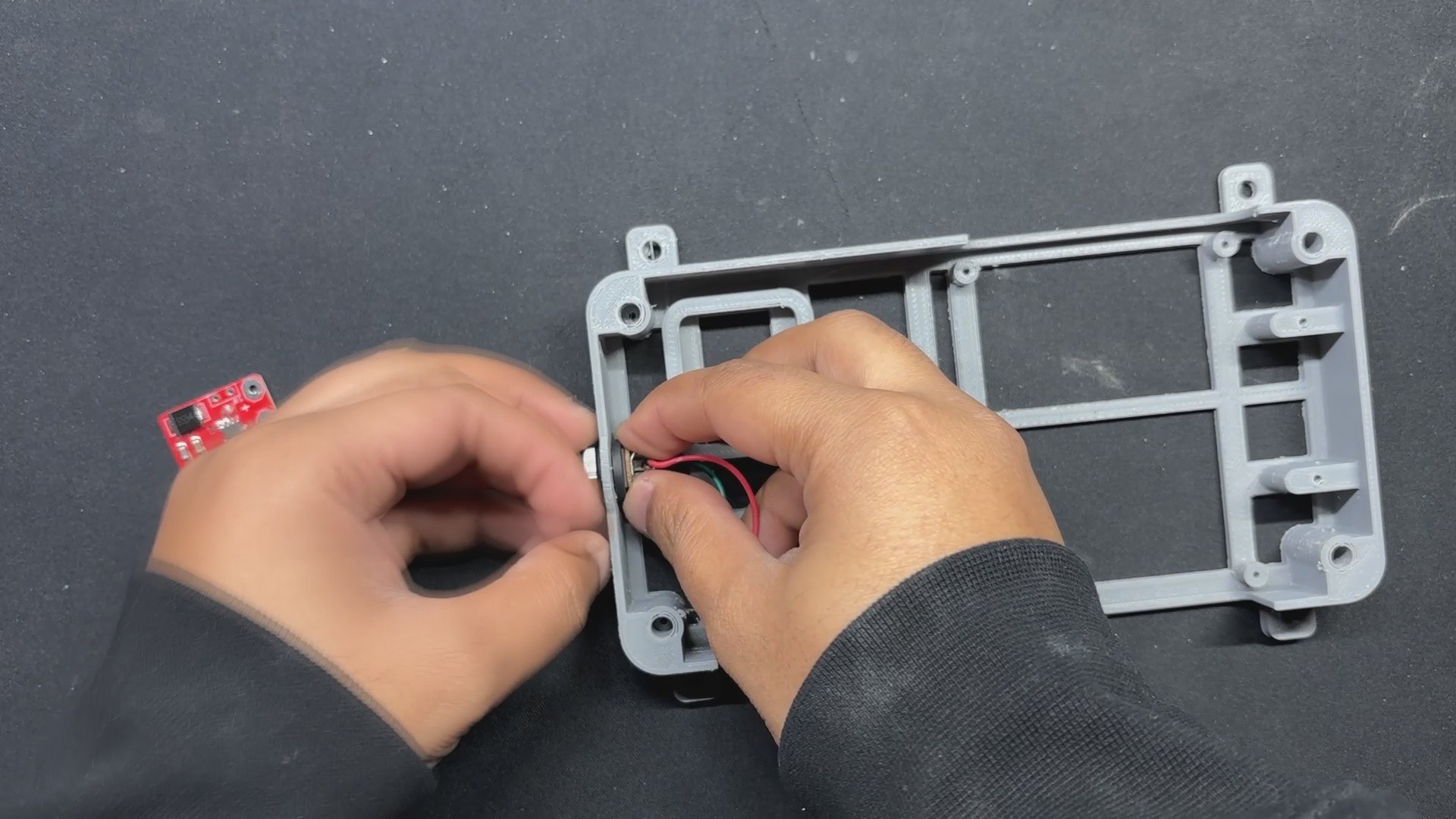

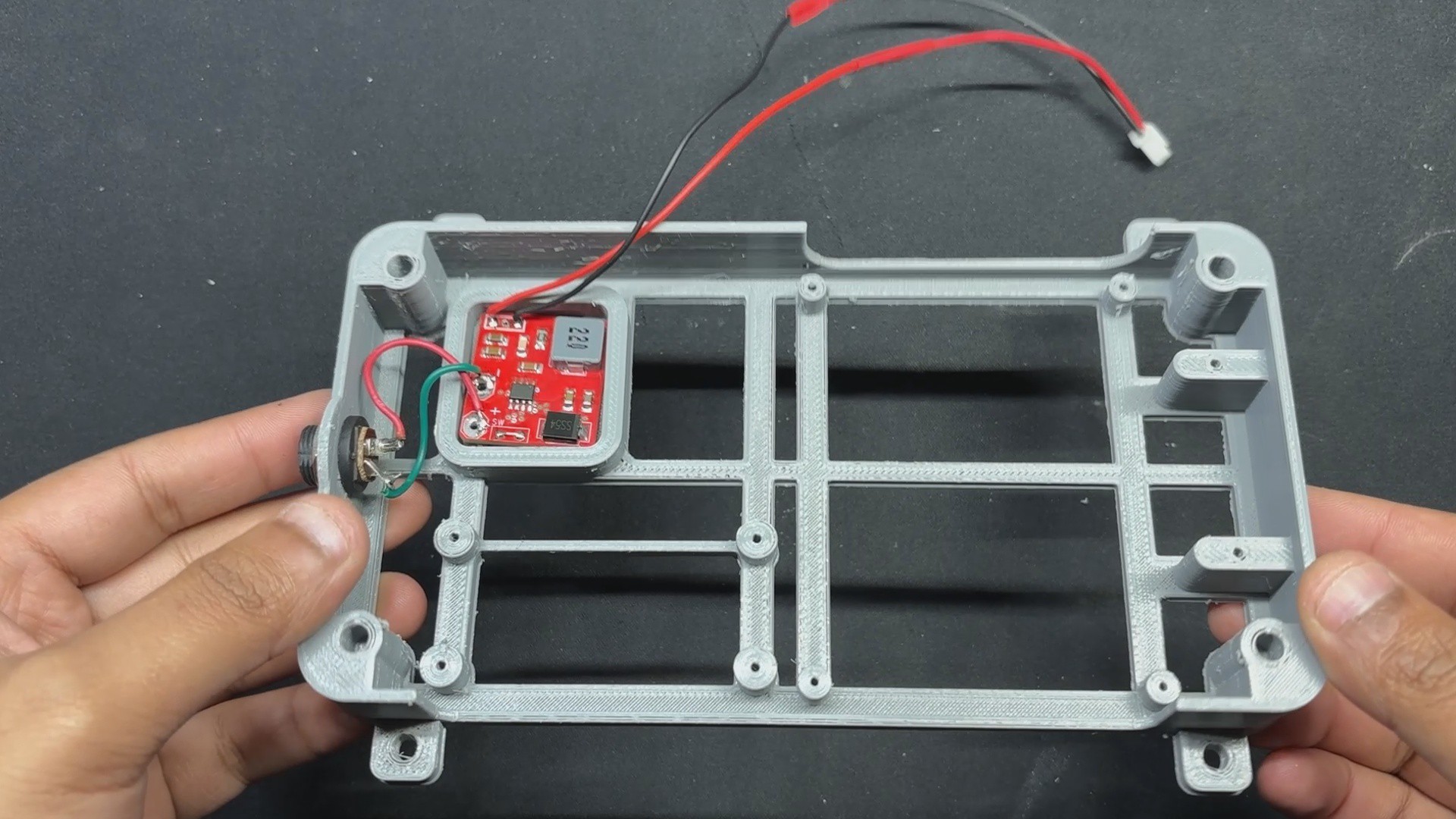

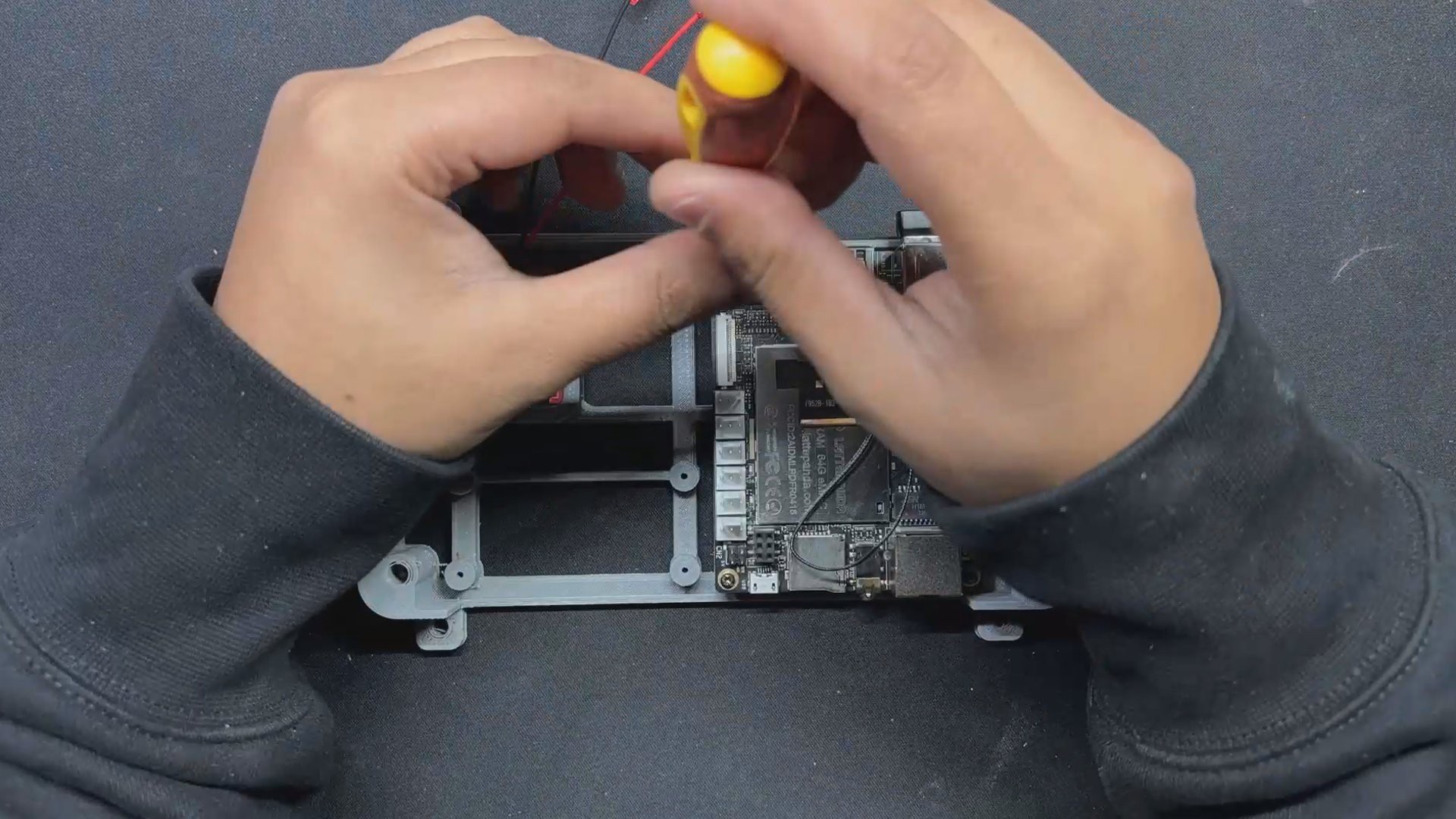

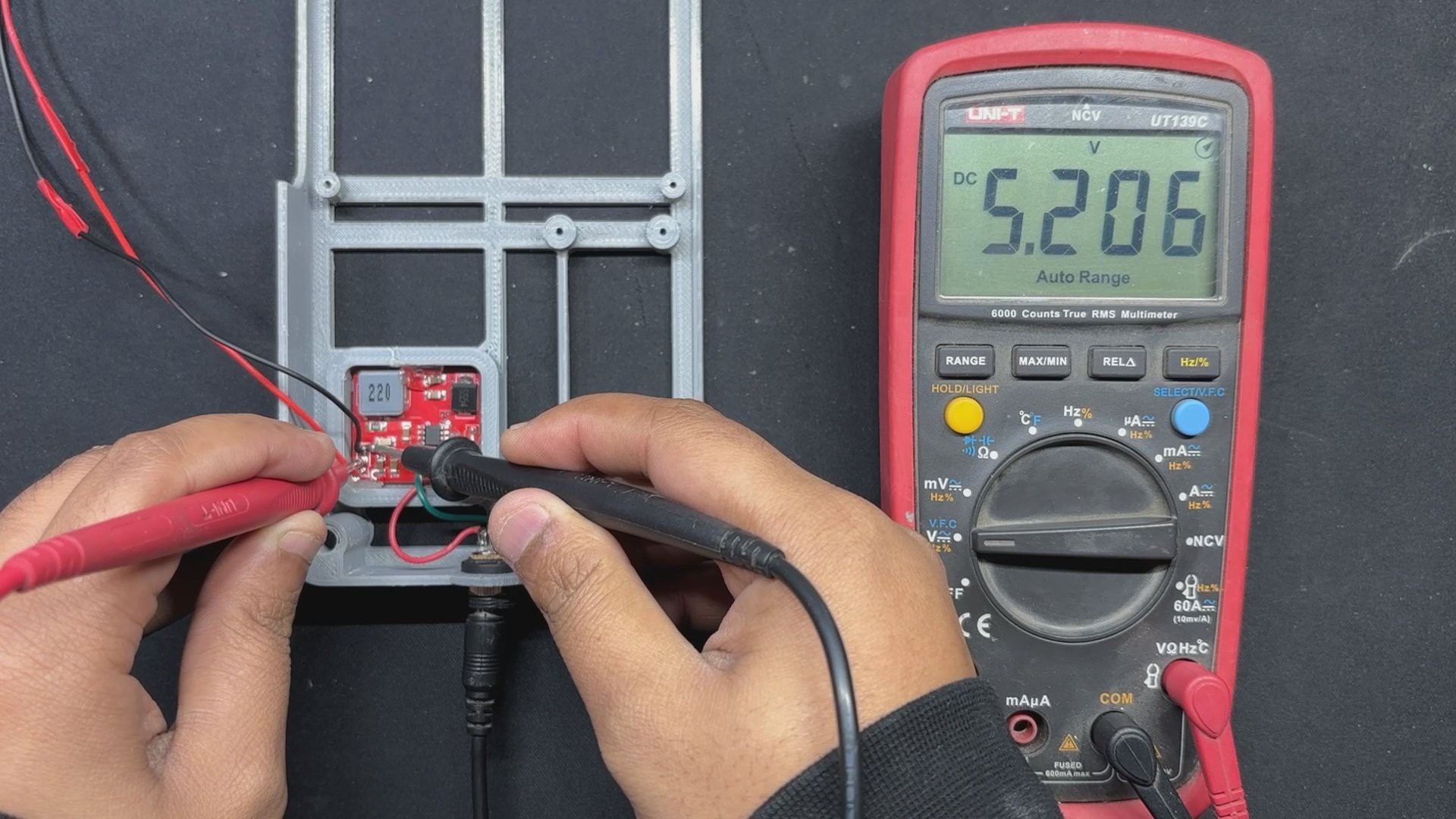

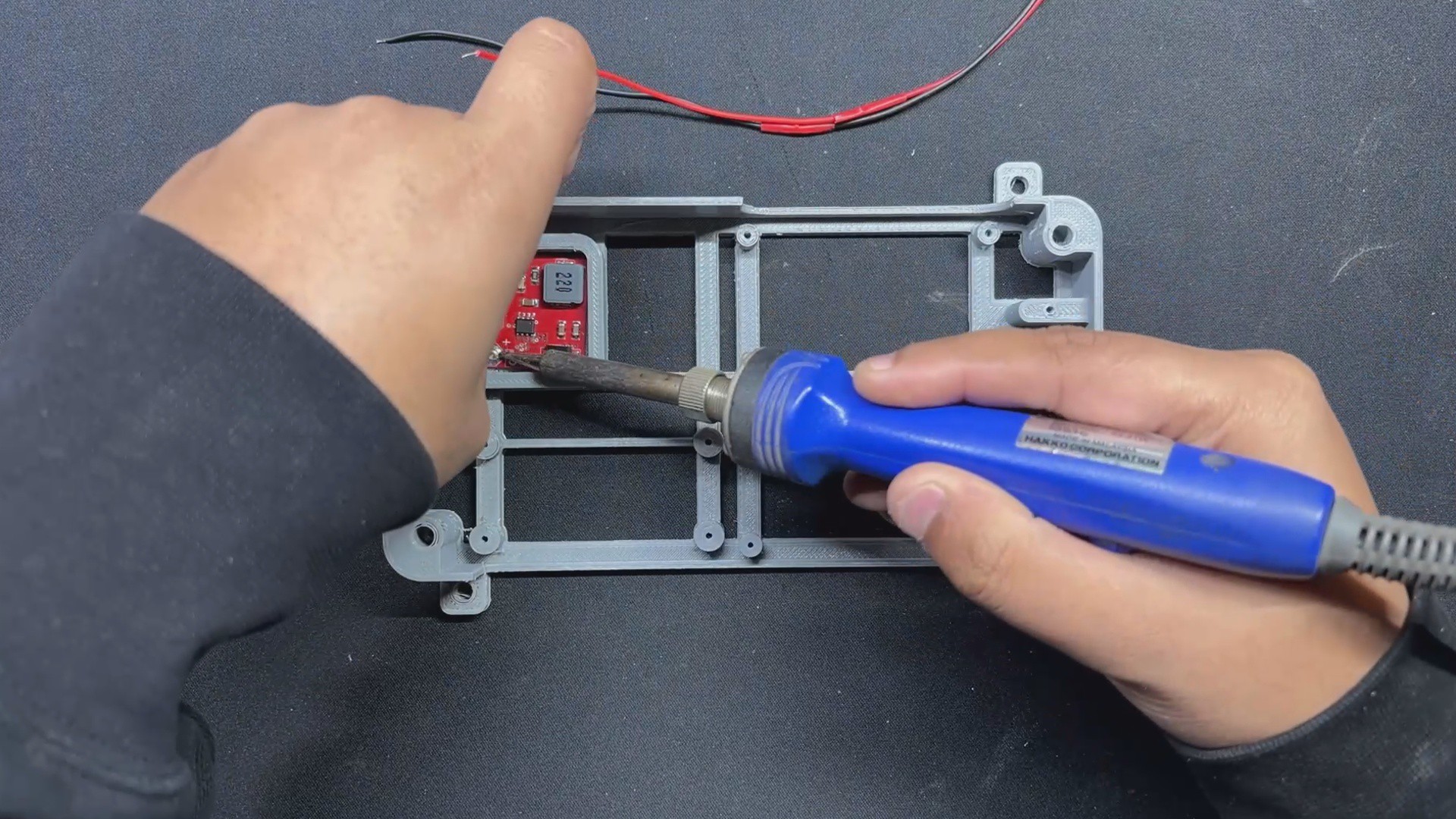

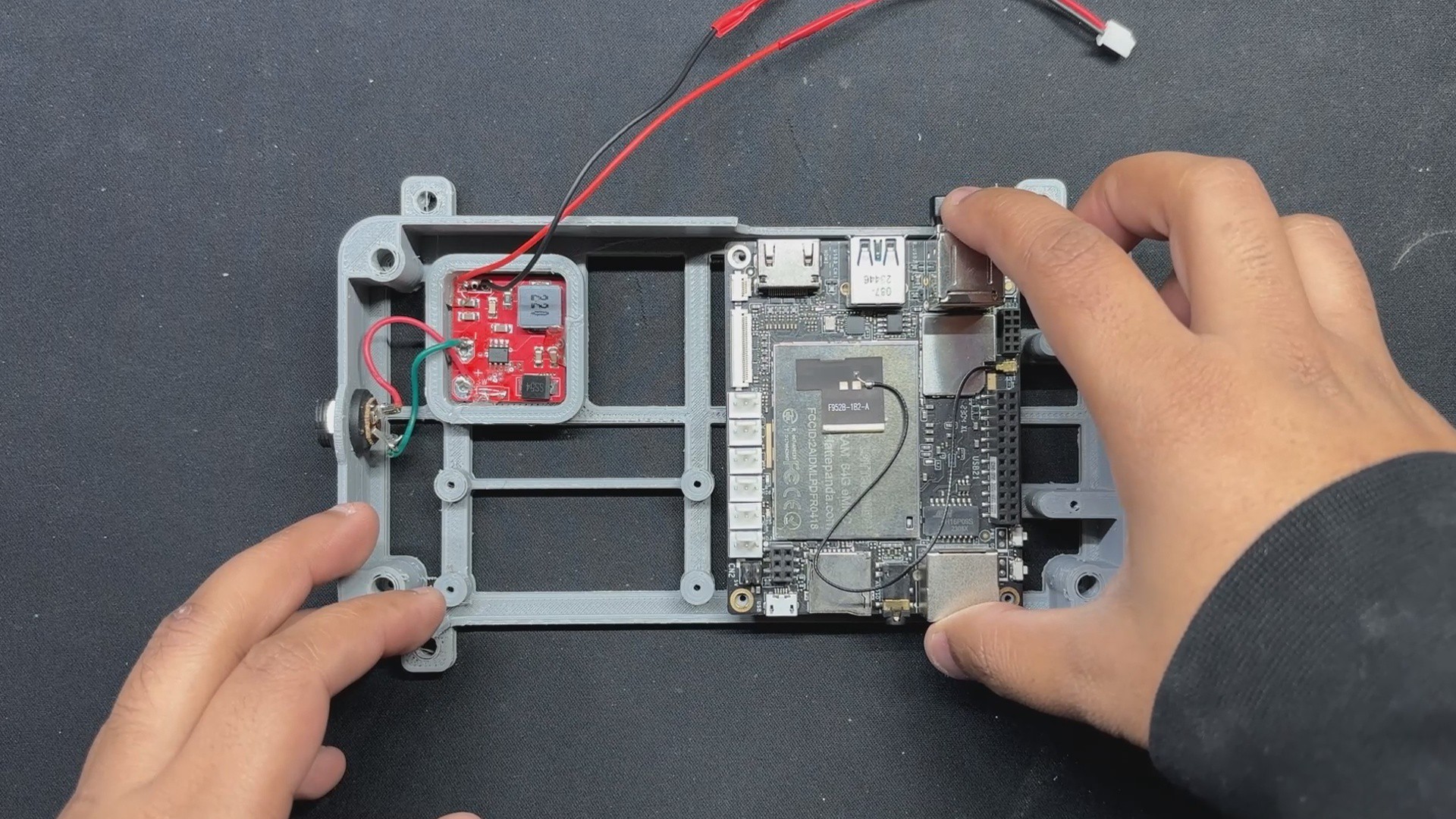

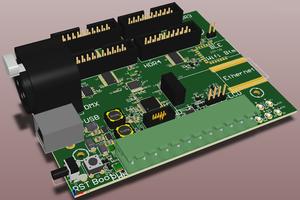

We created a compact box-like enclosure that holds the Latte Panda V1, a USB Extender Hub that allows us to connect multiple controllers to this device for multiple players, and a specially designed power circuit that requires 12V input and provides a steady 5V/3A output to operate the Latte Panda to its maximum capacity.

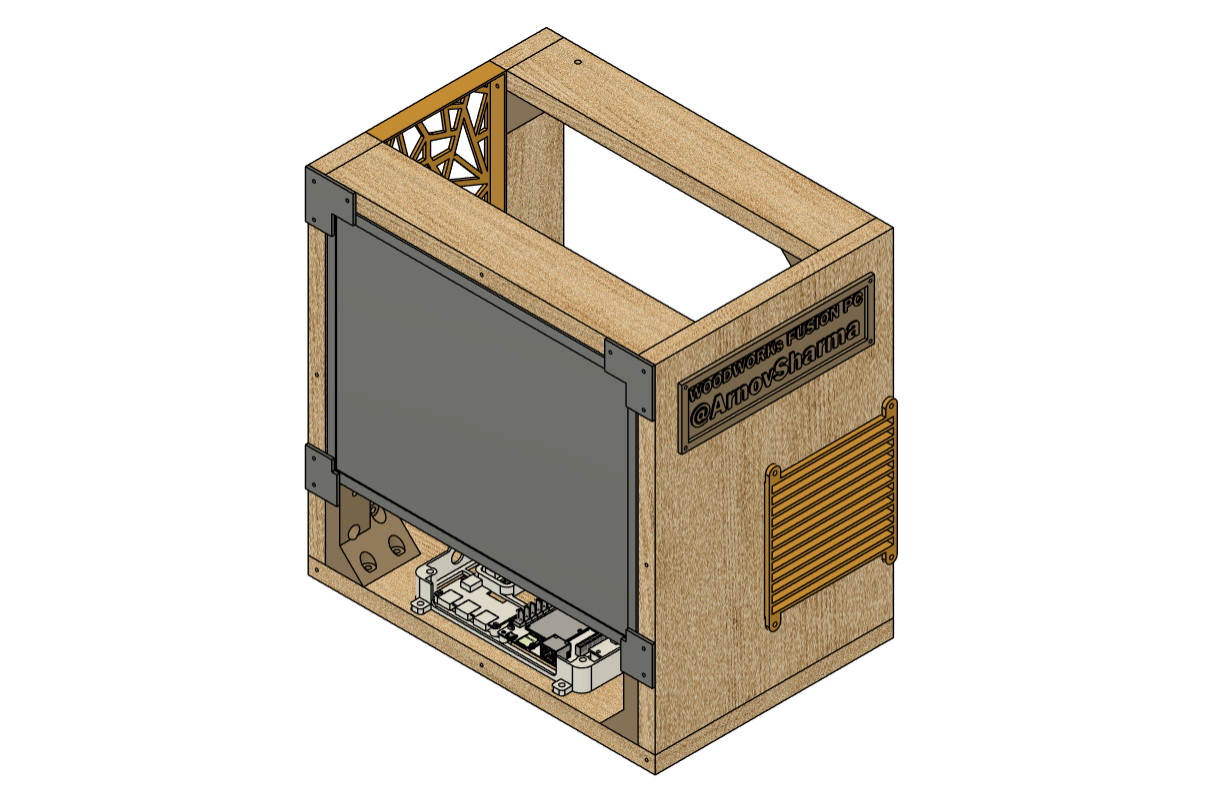

We used one of our previous projects, the woodwork fusion, for the project's body and screen. To provide room for the arcade box, the PC's motherboard and other components were taken out.

After that, we put our arcade box inside the PC frame and put everything together to create the ideal arcade system that runs Linux and Batocrea.

This article is about the whole build process of this project, so let's get started with the build.

LattePanda V1 x86 Single Board Computer

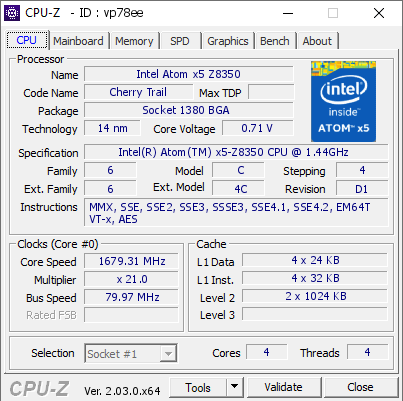

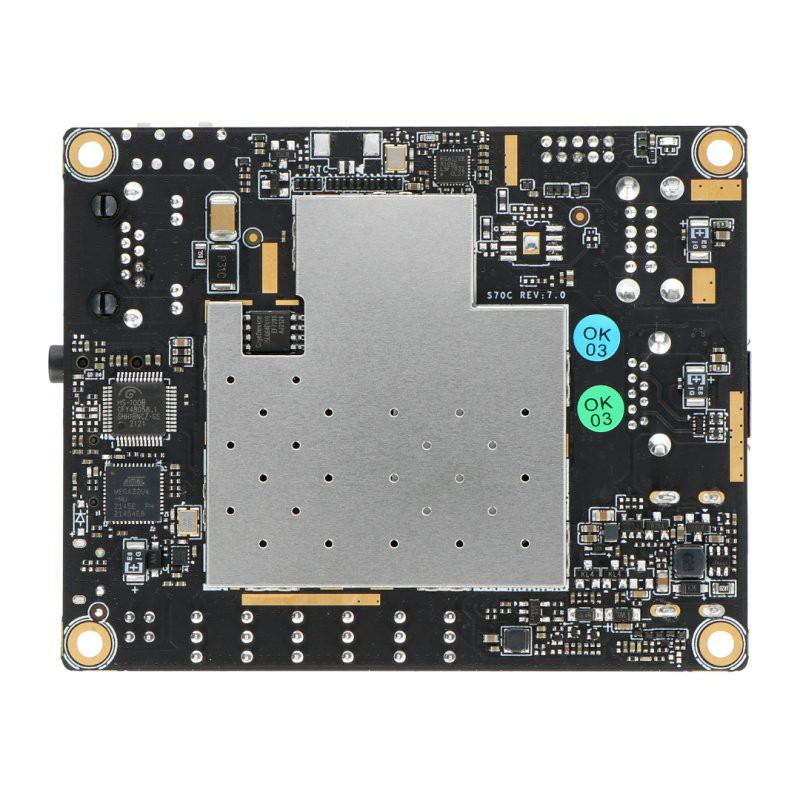

We opted to use the LattePanda V1, a single-board computer featuring an Intel Atom x5-Z8350 quad-core processor running at 1.8 GHz, 4GB of RAM, and 64GB of onboard storage, for our project.

This little device's x86 processor allows it to run a variety of Linux operating systems alongside Windows.

It comes with two varieties. 2GB RAM, 32GB storage, and 4GB RAM, 64GB storage; we are using the 4GB variant.

In terms of connectivity, this board has two USB 2.0 ports, one USB 3.0 port, HDMI output, onboard WIFI, Bluetooth 4.0, and an upgraded ATmega32u4 Co-processor that allows us to add sensors and modules. In other words, we can use the onboard Co-Processor as an Arduino device.

For more information about the SBC, you can visit the wiki page published by DFrobot, the company that made this device.

Power Source Circuit

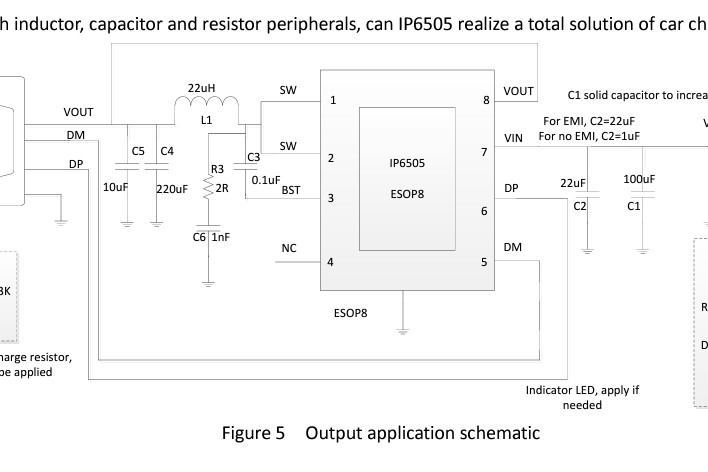

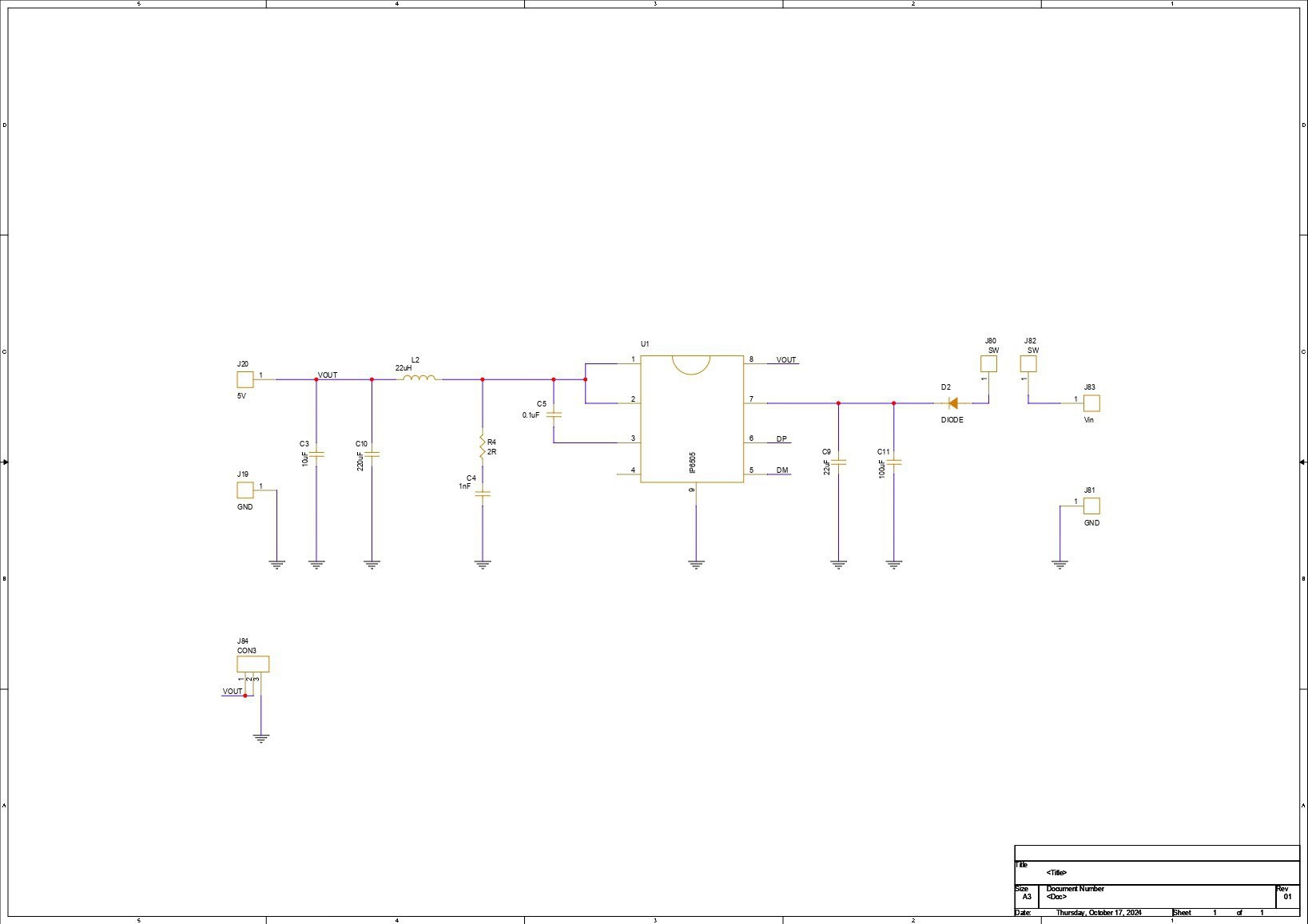

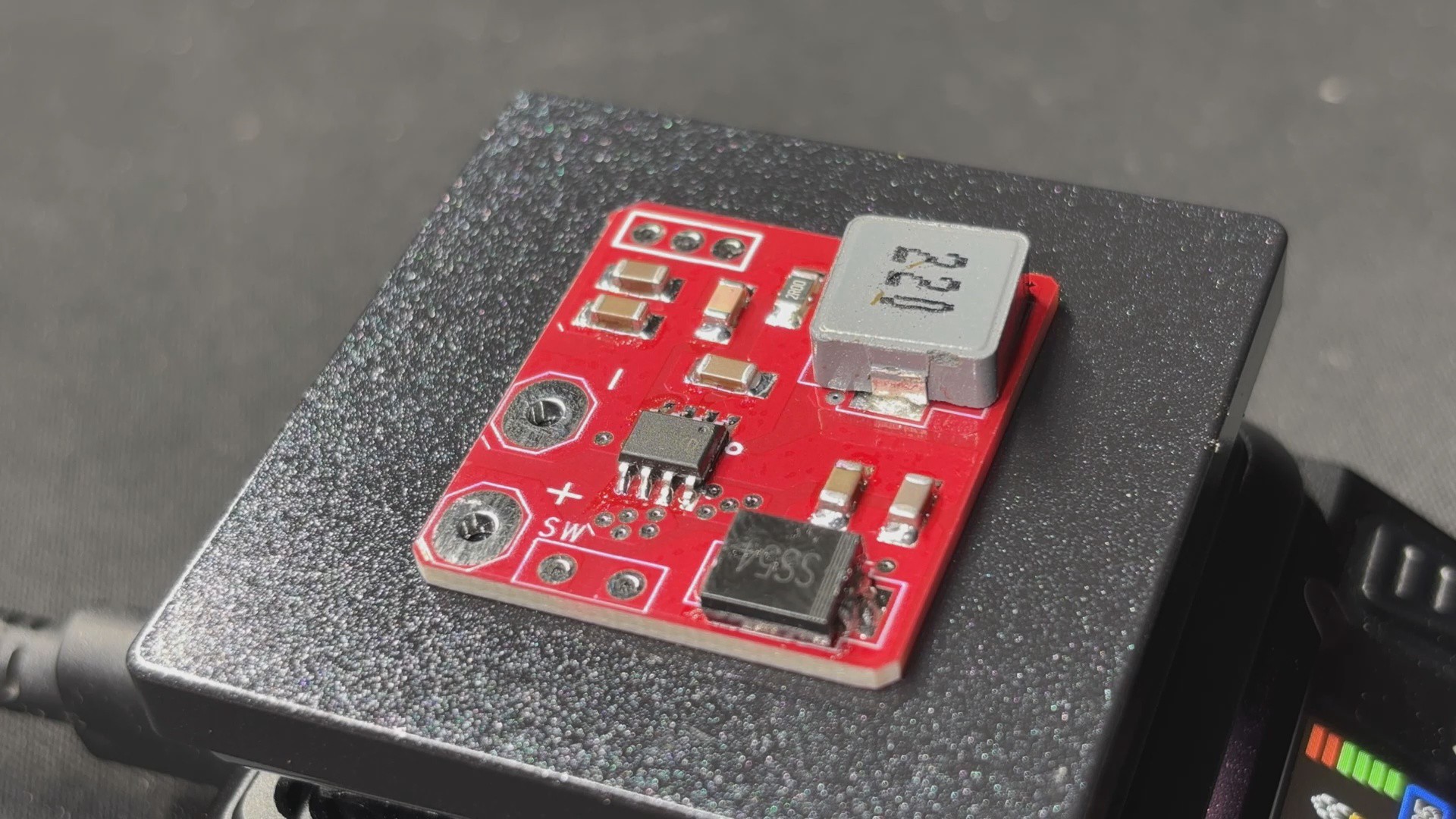

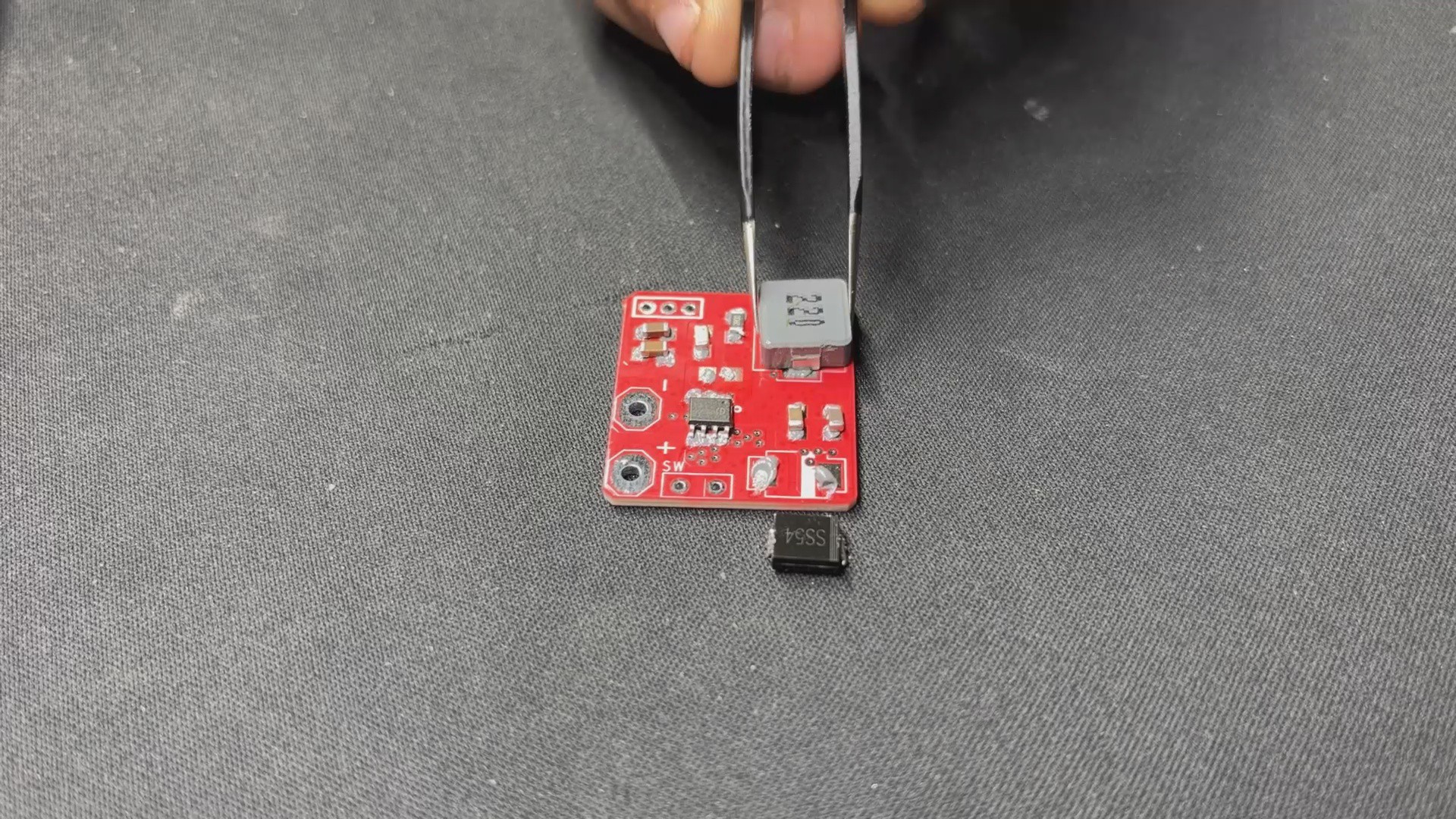

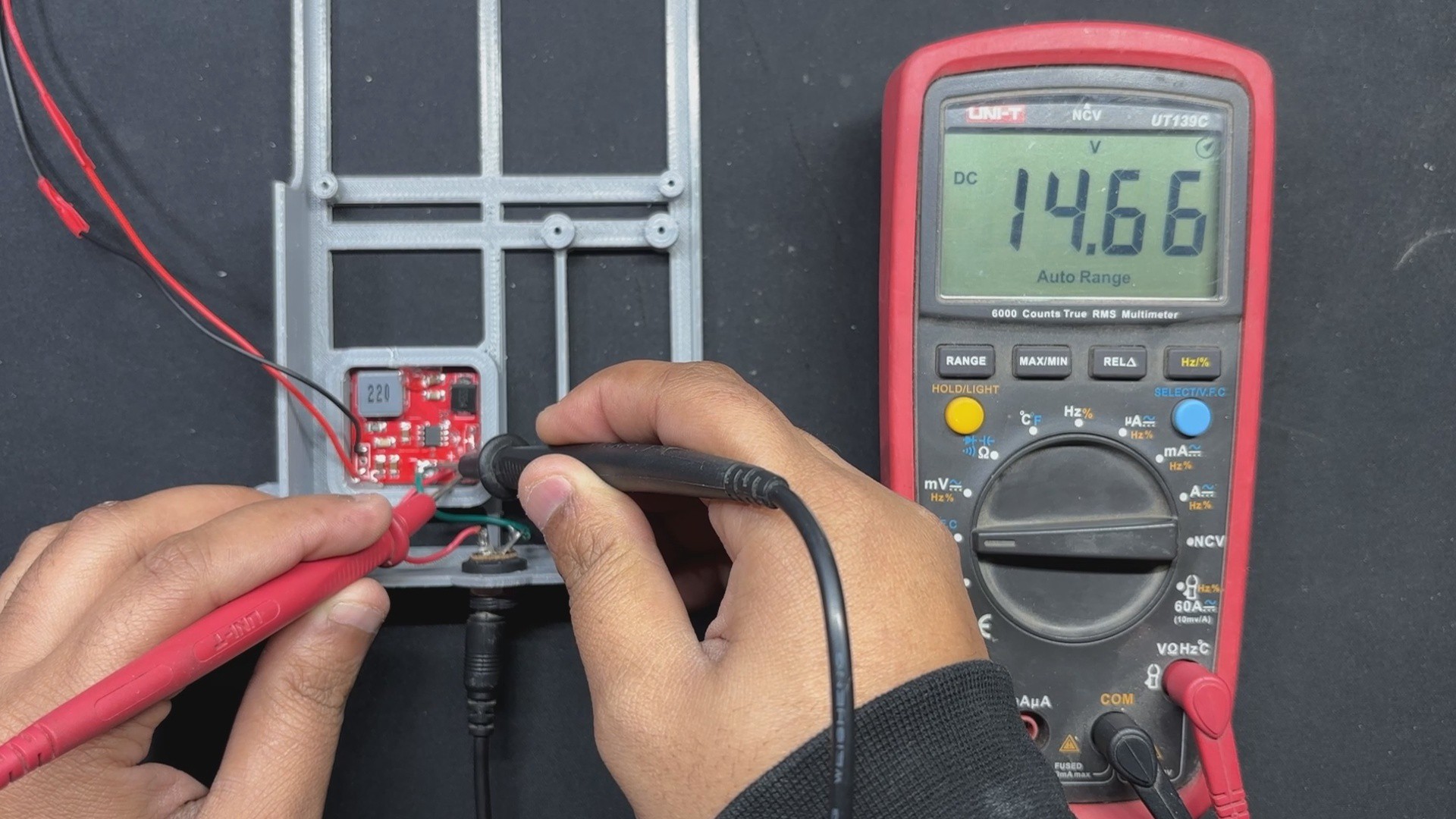

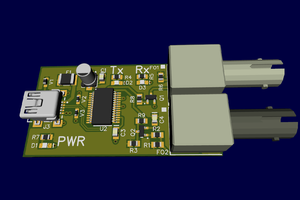

For the power circuit, we opted for a Buck Converter setup in which we have chosen the IP6505 IC, which is a step-down converter with an inbuilt synchronous switch that can handle an output of up to 10A for fast charging protocols. This is the project's main appeal.

An integrated power MOSFET with an output voltage range of 3V to 12V and an input voltage range of 10.5V to 28V is a feature of the IP6505. By automatically altering the voltage and current in accordance with the recognized rapid charge protocol, it can produce up to 24W of output power, which is plenty for our Latte Panda V1.

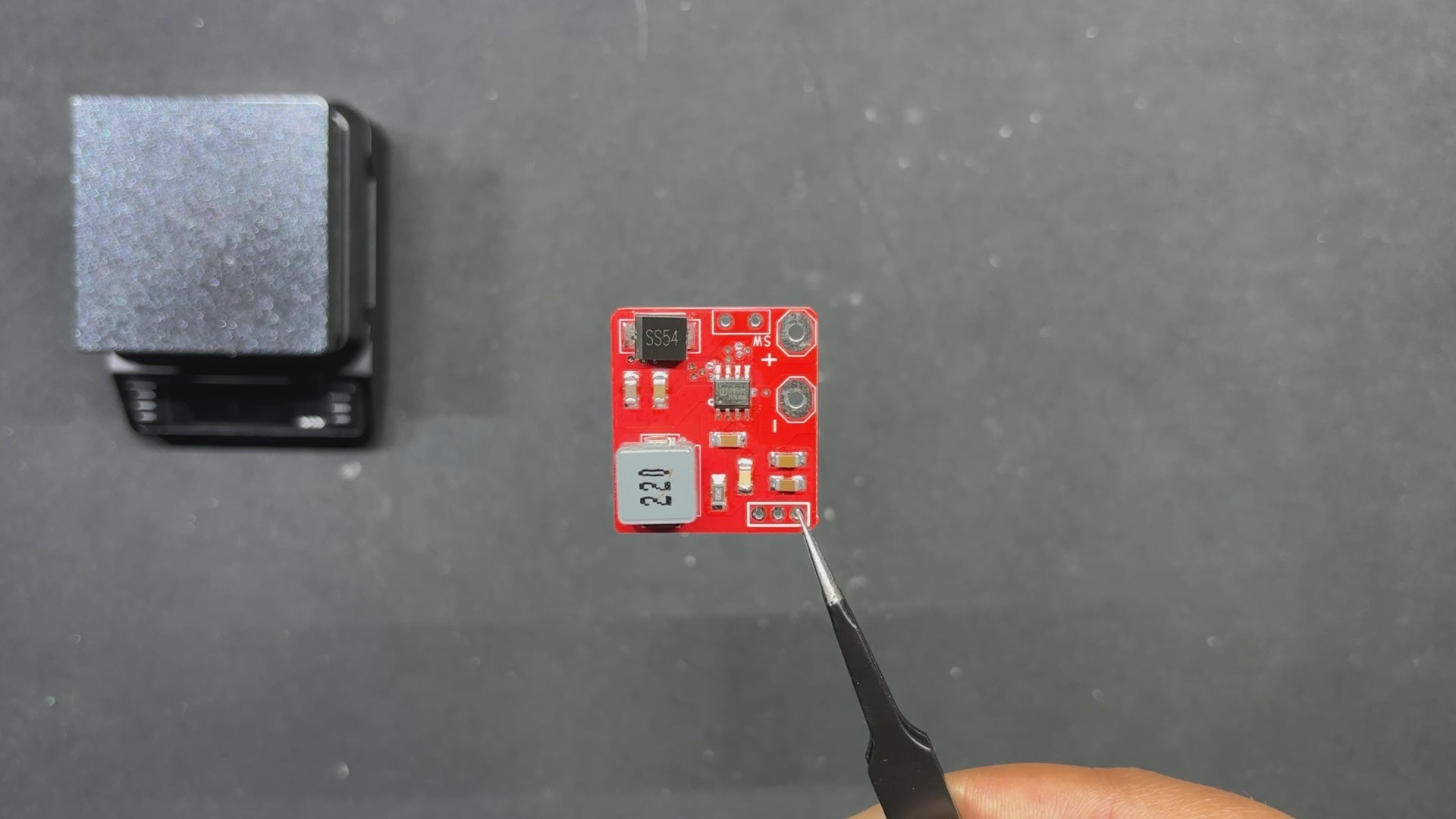

We produced a little Buck converter board with this setup because we had previously used it and found it to be quite easy to work with.

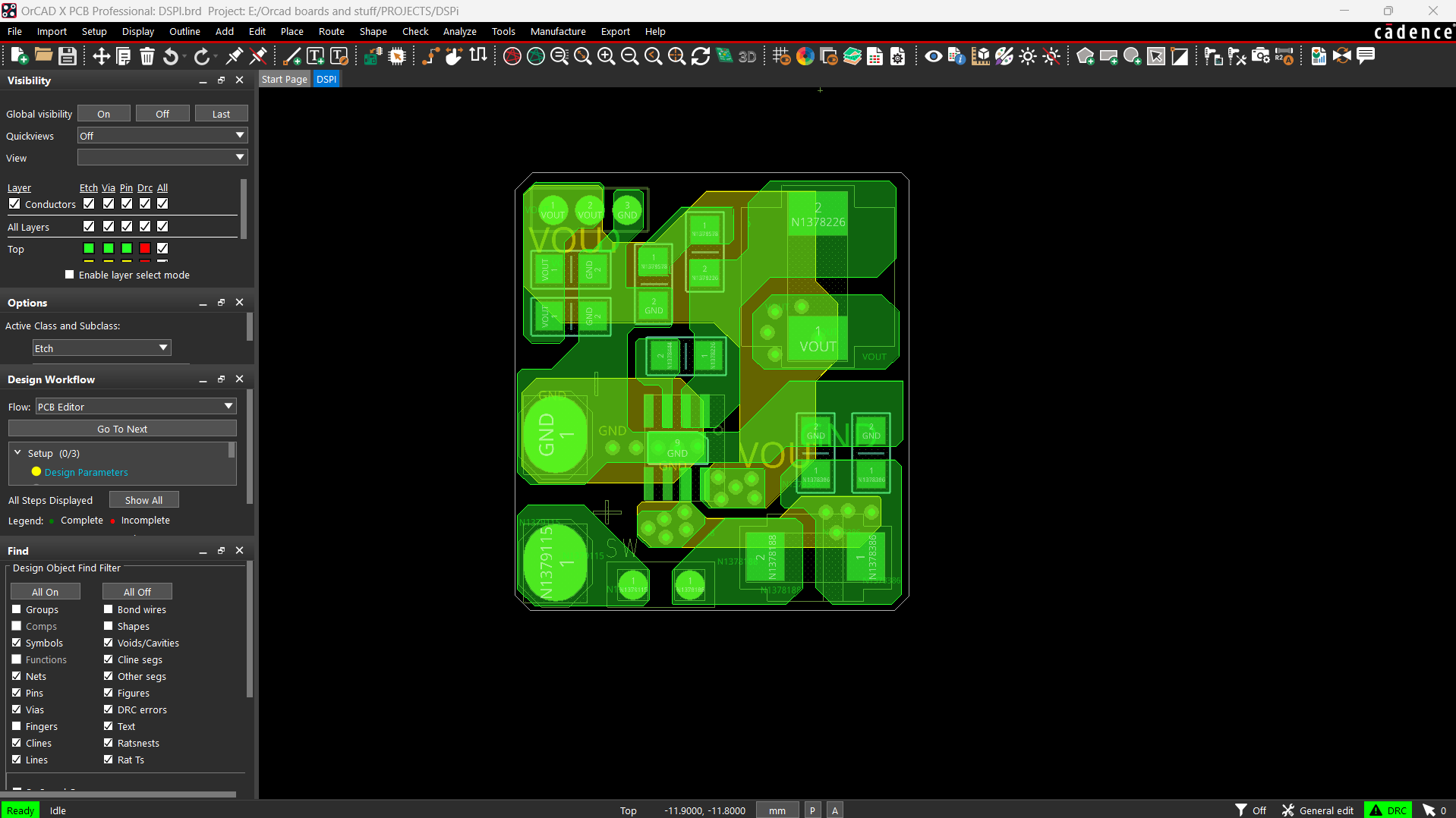

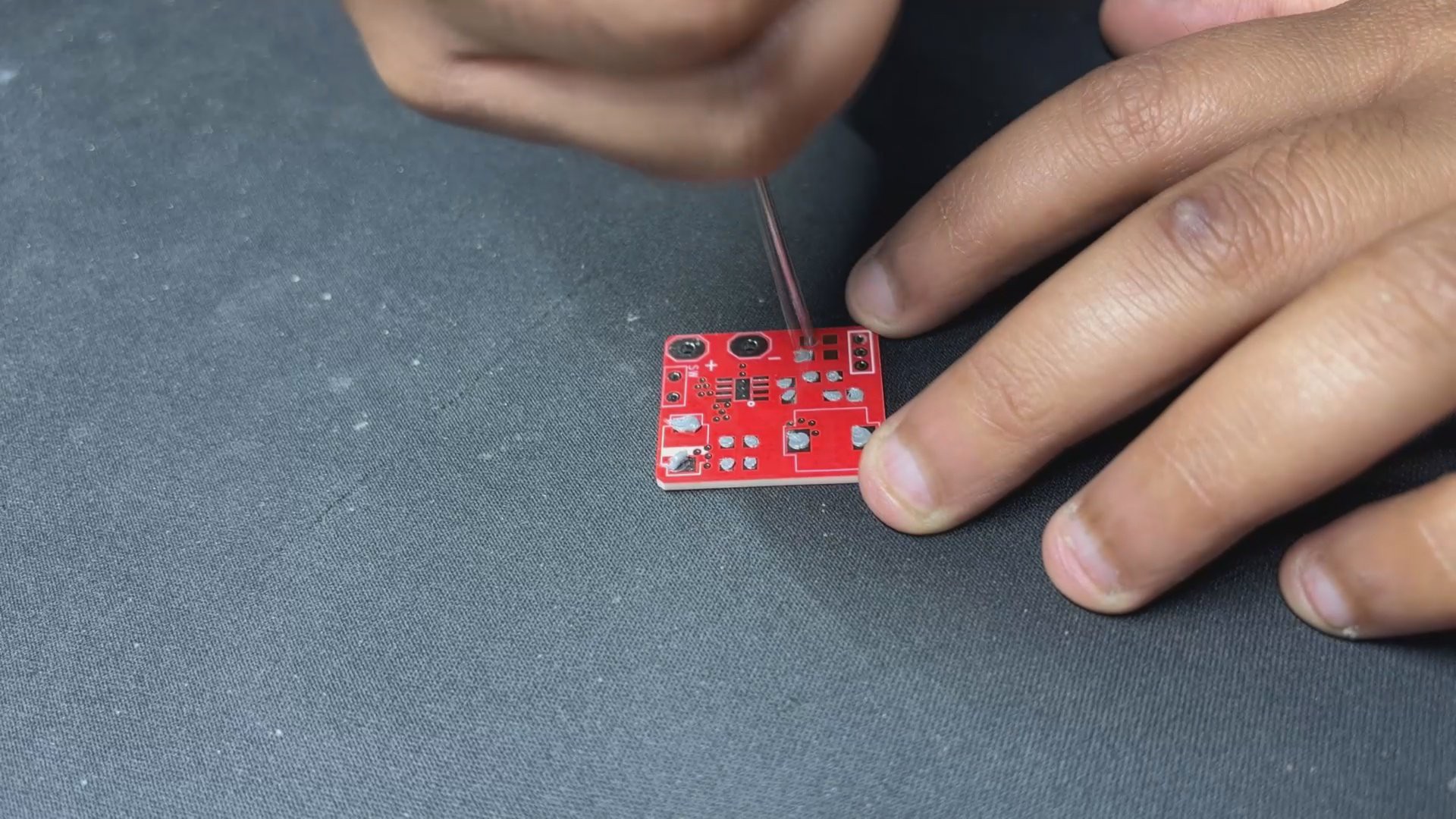

The schematic was originally created and set up using the datasheet's example layout. All of the components on this board are surface mount, which minimizes the need for manual soldering, including the mounting of through-hole components.

PCBWAY Service

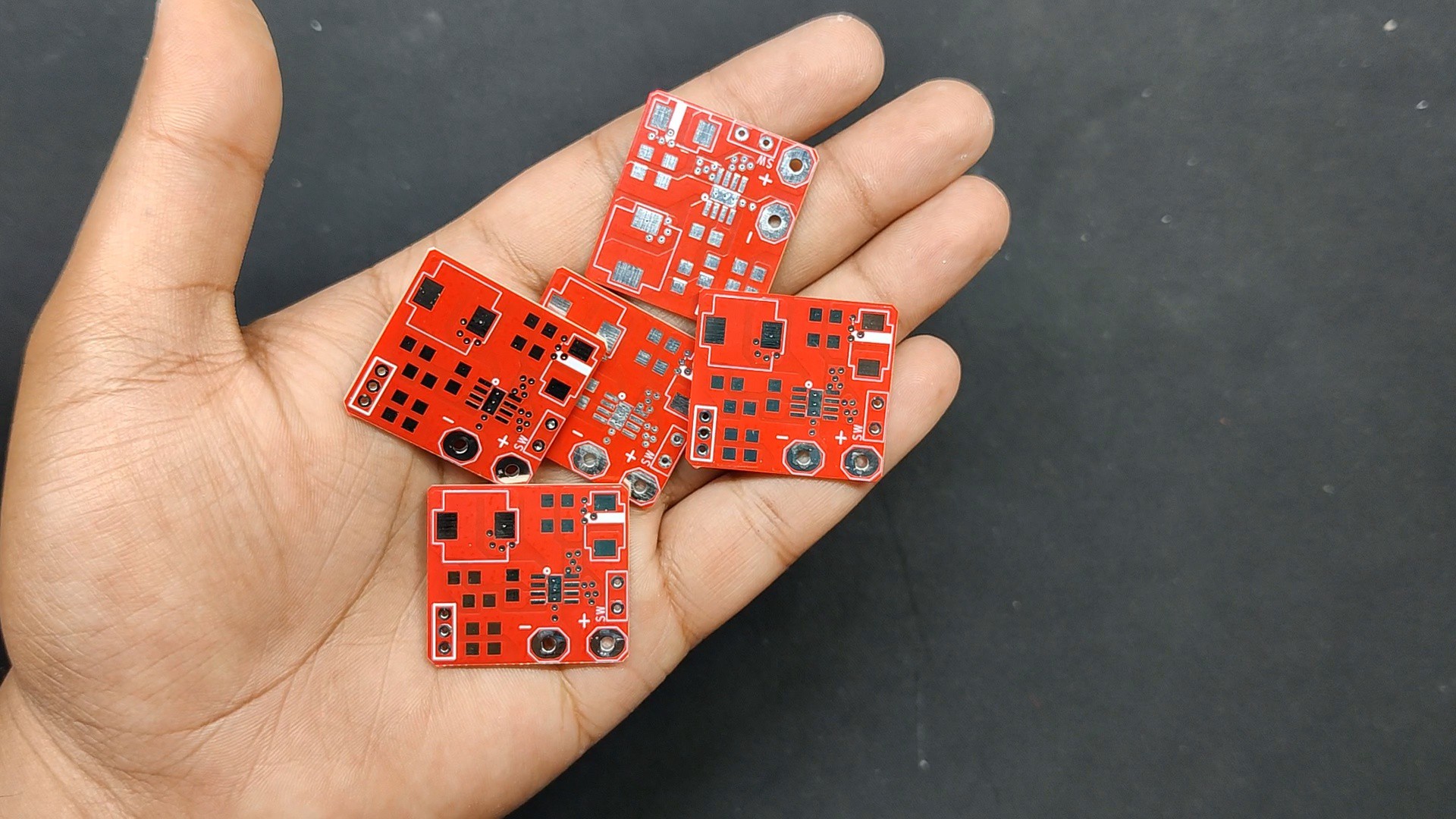

After completing the PCB design, we export the Gerber data and send it to PCBWAY for samples.

We placed an order for a Red Soldermask PCB with white silkscreen.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

Over the past ten years, PCBWay has distinguished itself by providing outstanding PCB manufacturing and assembly services, becoming a trusted partner for countless engineers and designers worldwide.

Their commitment to quality and customer satisfaction has been unwavering, leading to significant growth and expansion.

You guys can check out PCBWAY if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma

Oliver Scholz

Oliver Scholz

Ben Holmes

Ben Holmes

James

James