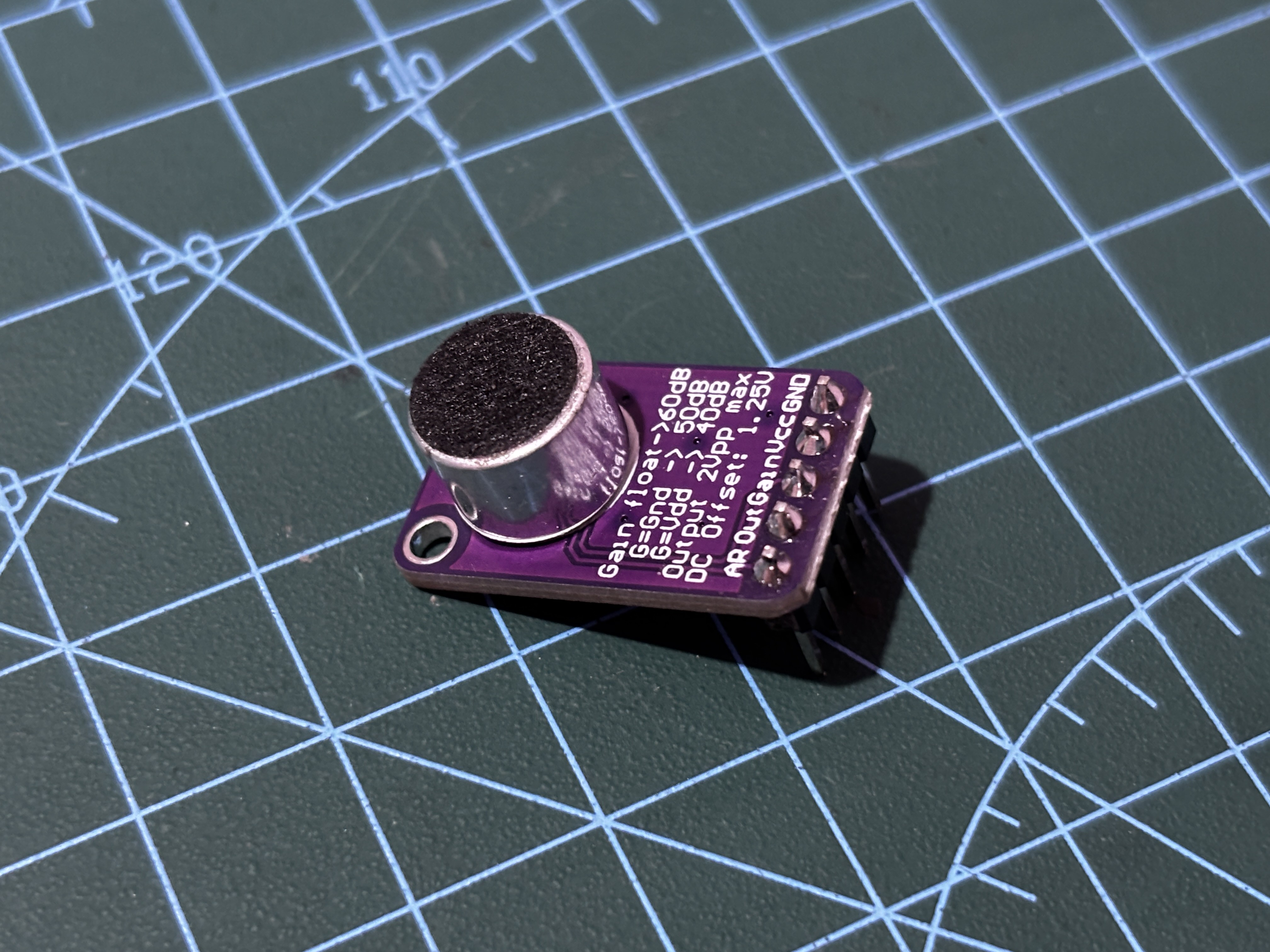

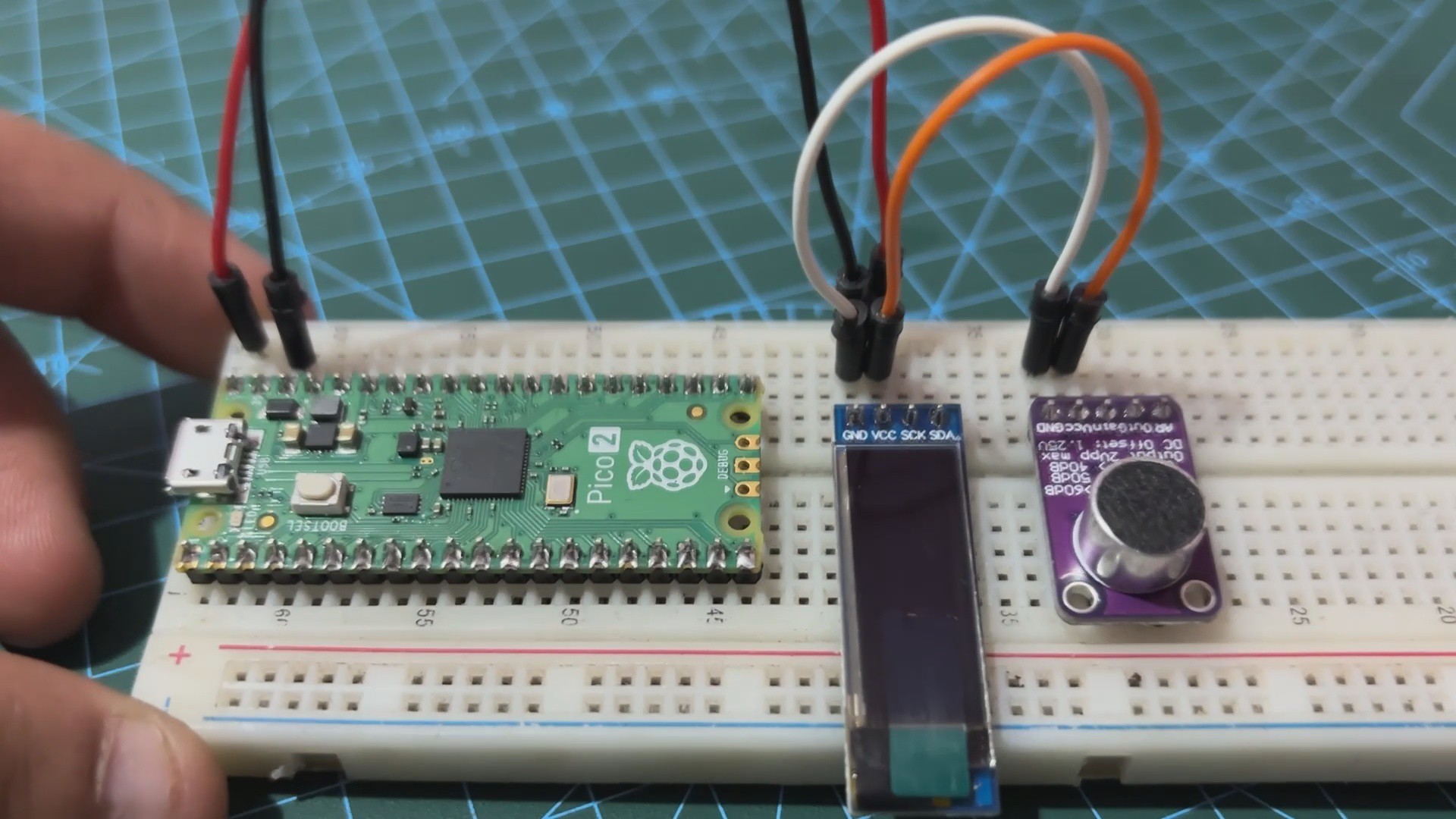

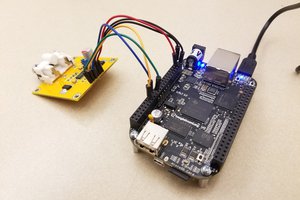

MAX9814

The MAX9814 is a high-performance microphone amplifier module designed for applications requiring precise audio capture and amplification. It features Automatic Gain Control (AGC), which dynamically adjusts the amplification level to accommodate varying audio input levels, ensuring consistent and high-quality output.

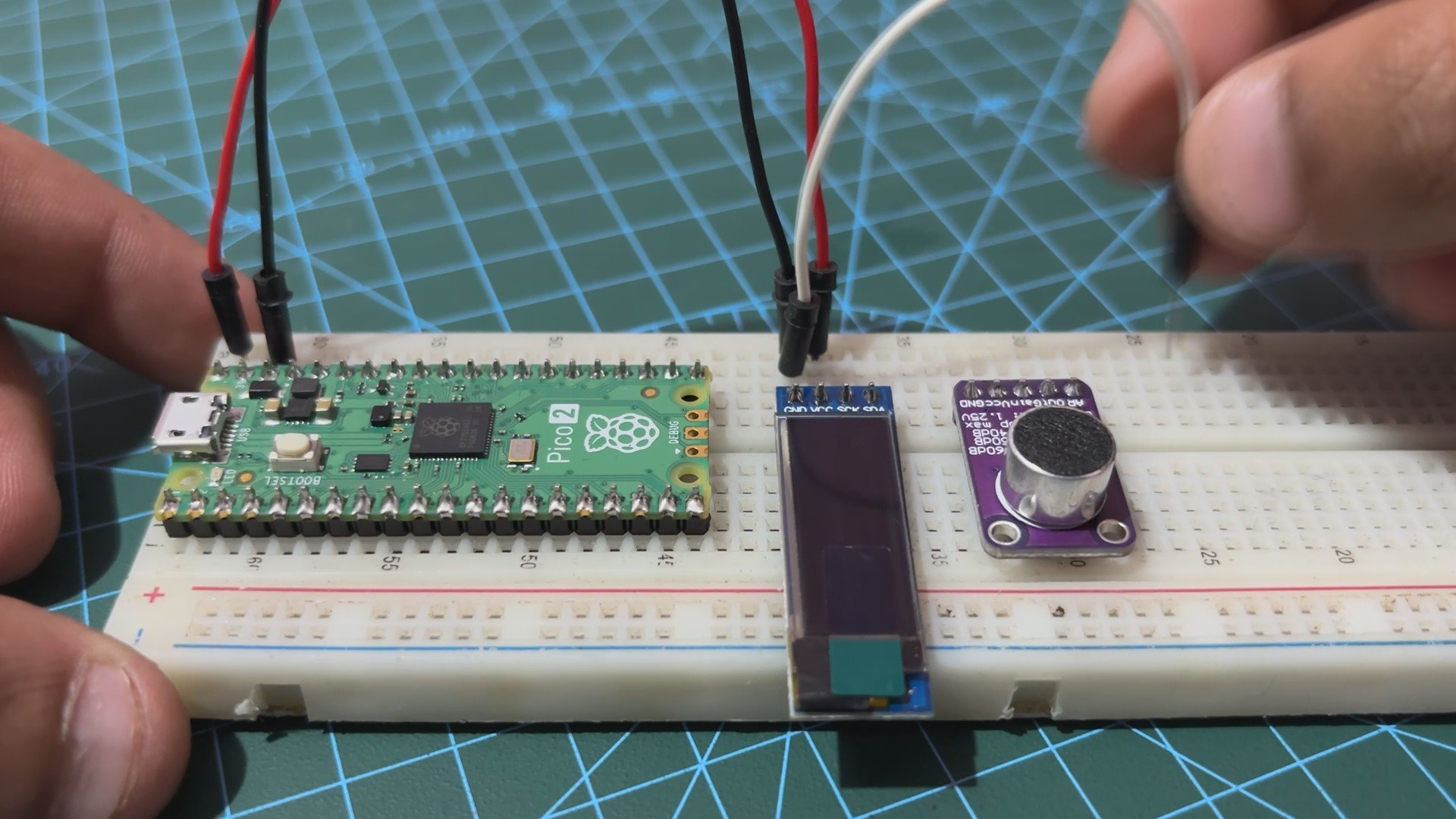

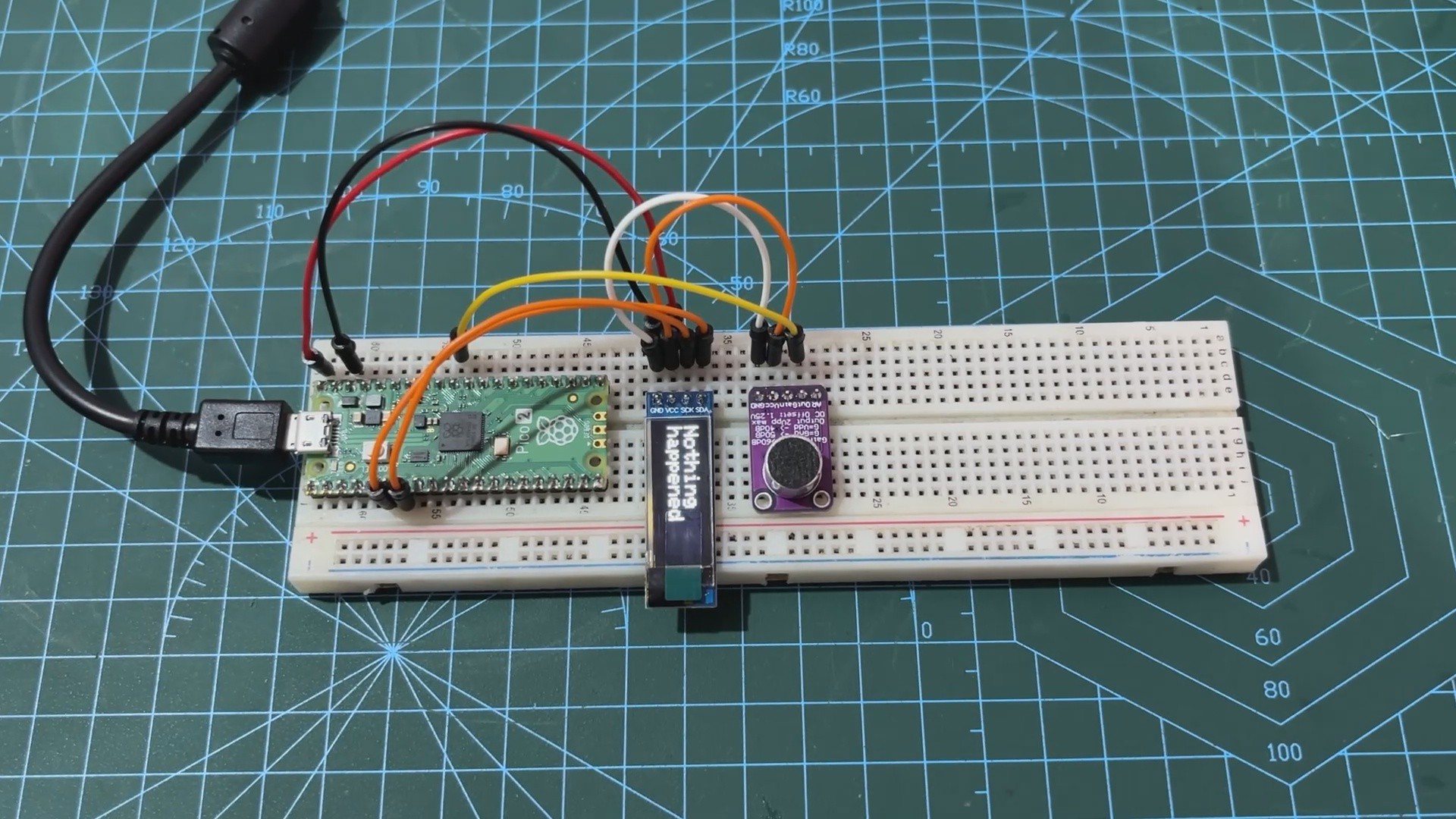

We use MAX9814 in our Clap Switch project because of the AGC, which dynamically adjusts the gain to ensure consistent audio output, even in varying noise environments. This means it can accurately detect claps regardless of background noise levels. Additionally, its low input-referred noise density and low Total Harmonic Distortion (THD) ensure that the audio signal is clear and precise, making the detection of clap sounds more reliable.

It operates on 2.7V to 5.5V, consumes around 3mA, and offers a 2V peak-to-peak output on a 1.25V DC bias, covering a frequency range from 20Hz to 20kHz. With a low input-referred noise density of 30 nV/√Hz and a THD of 0.04%, it ensures clear, high-fidelity audio. The amplifier supports programmable gain settings of 40dB, 50dB, and 60dB, provides a 2V microphone bias, and works in temperatures from -40°C to +85°C, packaged in a compact 14-pin TDFN.

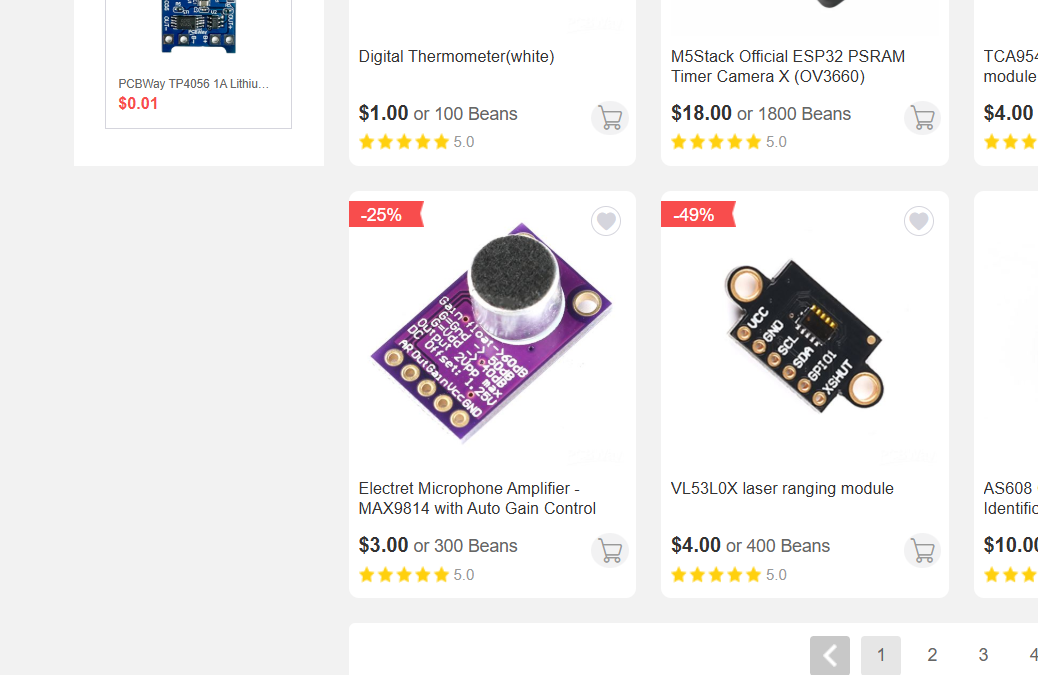

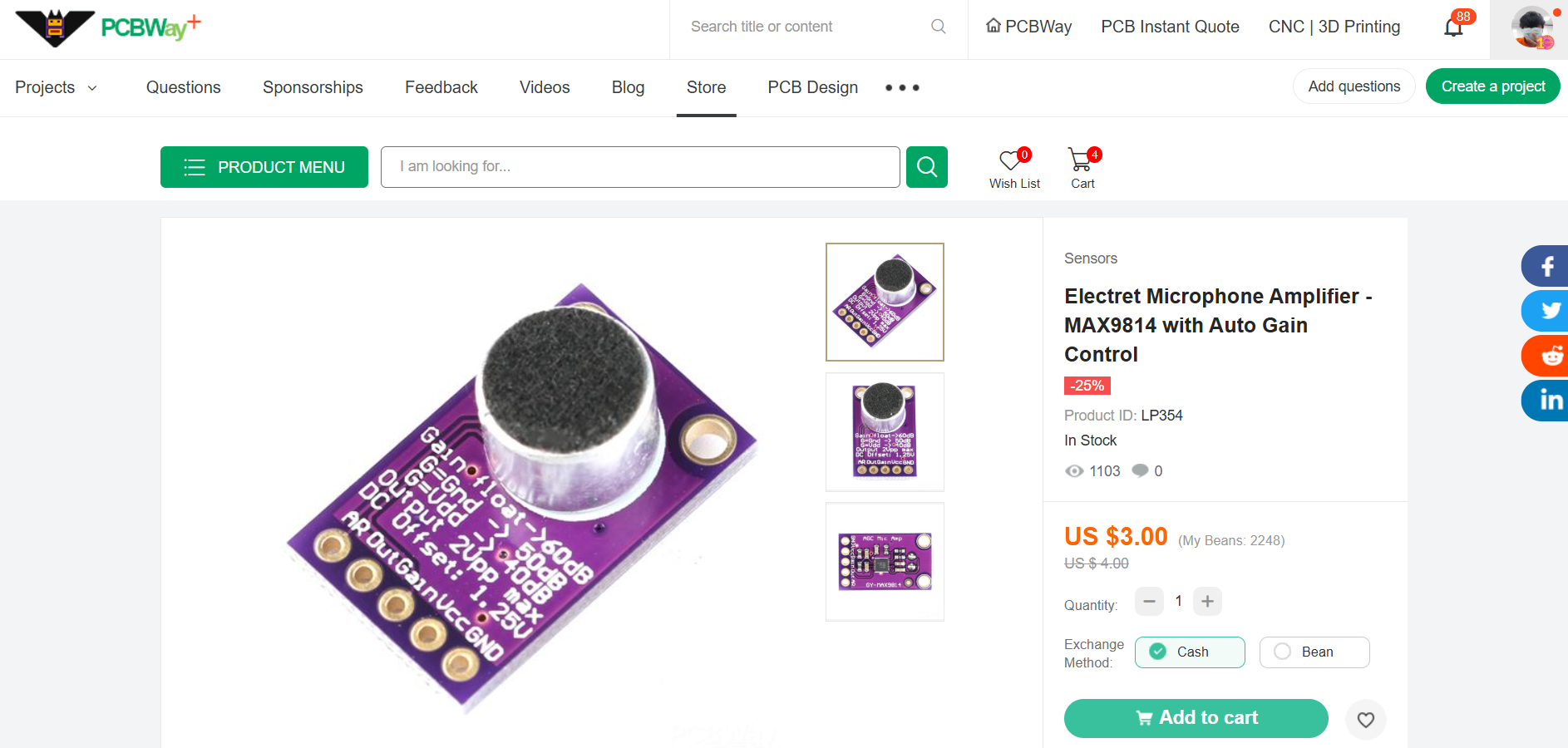

PCBWAY GIFTSHOP

As for sourcing the MAX9814 Microphone Amplifier module along with PICO 2 we used in this project, we got them from PCBWAY's Giftshop.

https://www.pcbway.com/project/gifts_detail/Raspberry_Pi_Pico_2_a84bd81f.html

PCBWAY gift shop is an online marketplace where you can get a variety of electronics modules and boards for their genuine price, or you could use the PCBWAY currency, which is called beans.

You get beans after ordering something from PCBWAY as reward points, or you can also get them by posting any project in the PCBWAY community.

Also, PCBWay is hosting its 7th Project Design Contest, a global competition that invites electronics enthusiasts, engineers, and makers to showcase their innovative projects. The contest provides a platform for participants to share their creativity and technical expertise with the broader community.

This year’s competition includes three major categories: electronic project, mechanical project and SMT 32 project

With prizes awarded for the most exceptional designs, the contest aims to inspire and support innovation, making it an exciting opportunity for both professionals and hobbyists to gain recognition and connect with like-minded creators.

You guys can check out PCBWAY if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma

Logan Cummings

Logan Cummings

GaryGru

GaryGru

JangoJungle

JangoJungle

Sebastian

Sebastian