-

Final Thoughts: A "Successful Disaster"

06/28/2025 at 01:02 • 0 commentsDid it work? In some ways - yes. In others - no.

![]()

The RC car drove, spun, crashed, and broke, but each failure taught me something invaluable.

![]()

While plastic filament has come a long way, it still can’t match metal for durability.

![]()

-

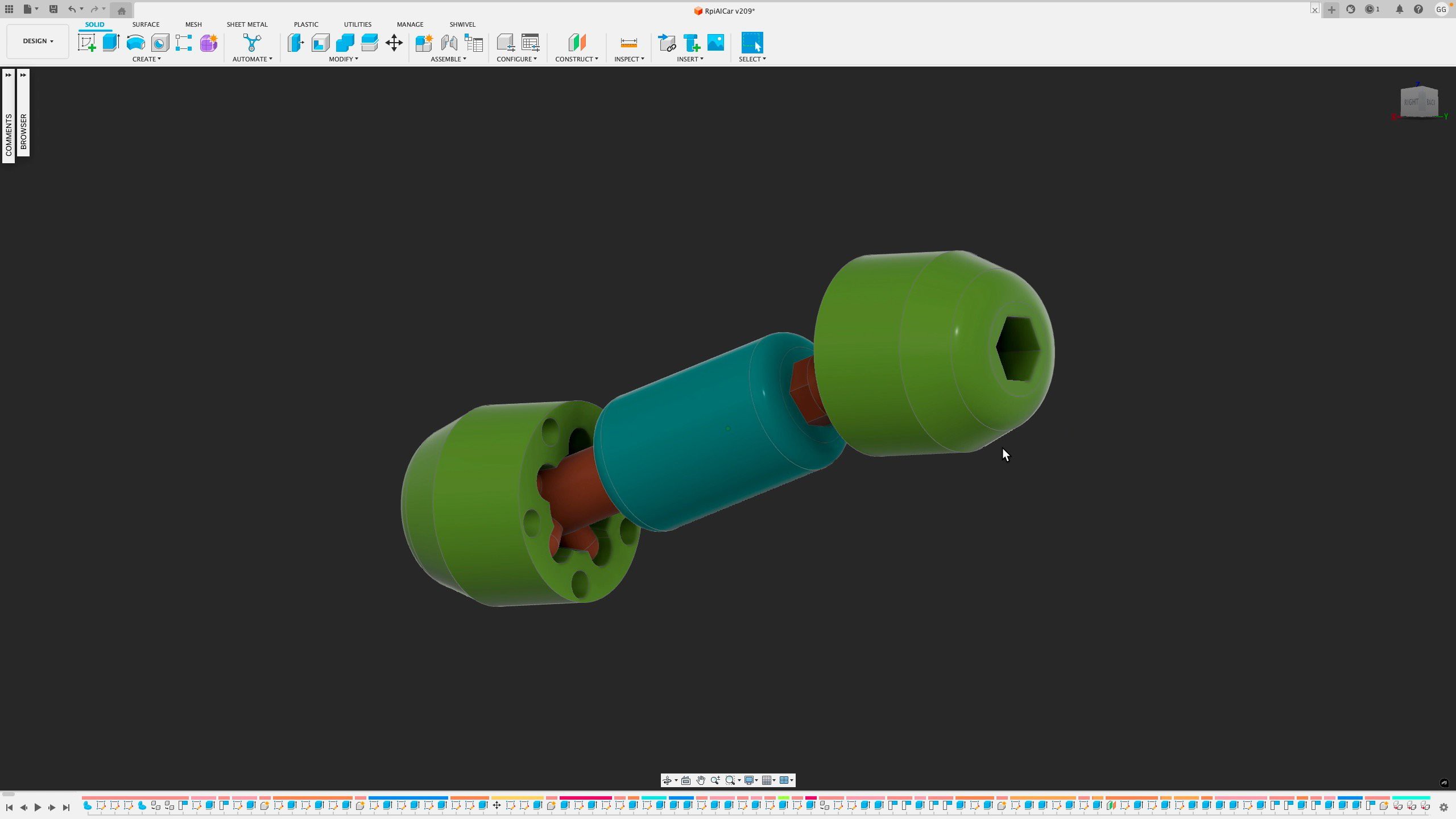

Final Fixes: CV Joints & Reinforcements

06/28/2025 at 01:01 • 0 commentsStill one wheel failed mid - run due to a U-joint issue.

![]()

I replaced it with a CV joint—stronger, more reliable. After reprinting, the entire system was ready for one last test in the wild.

![]()

![]()

-

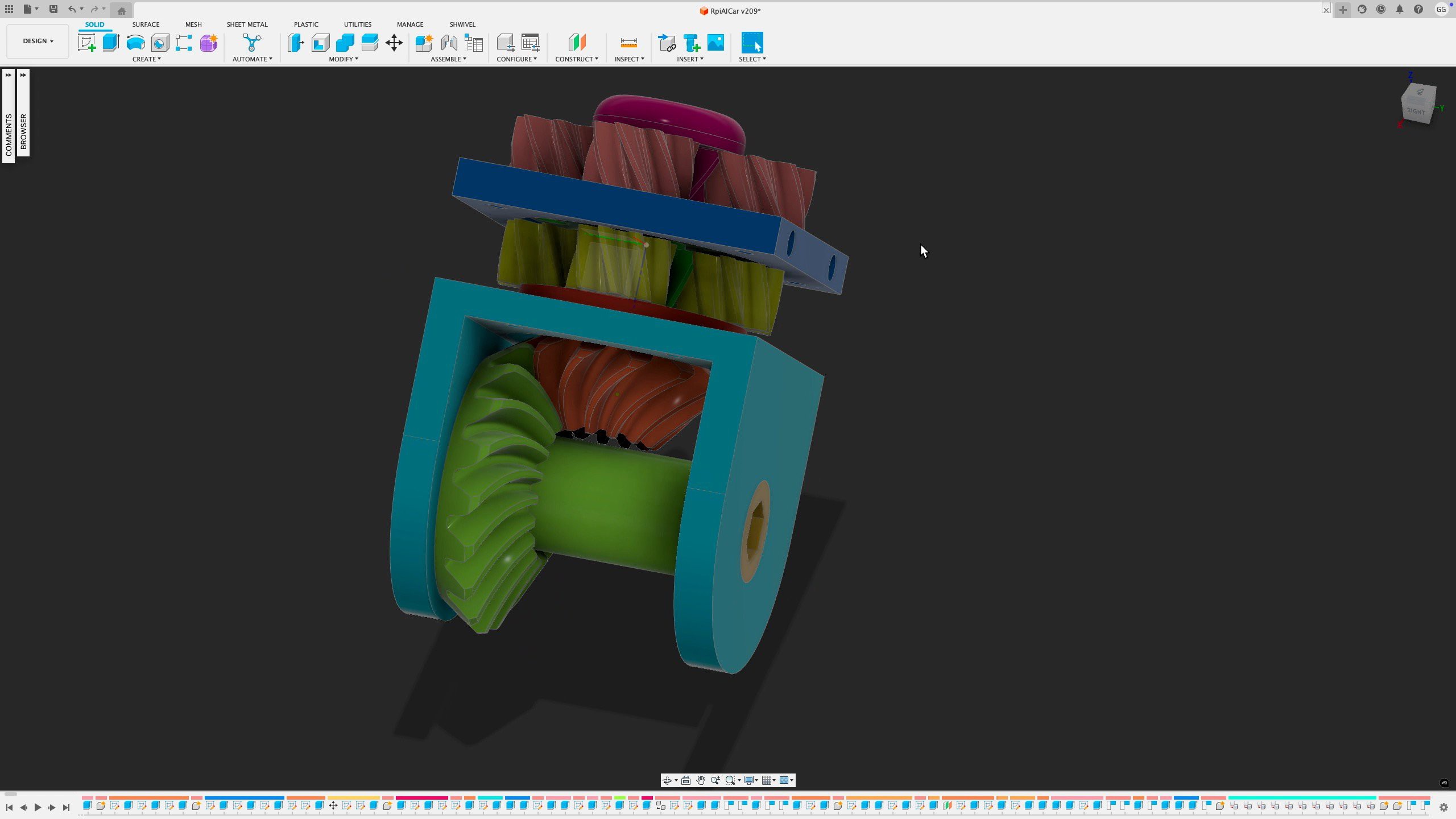

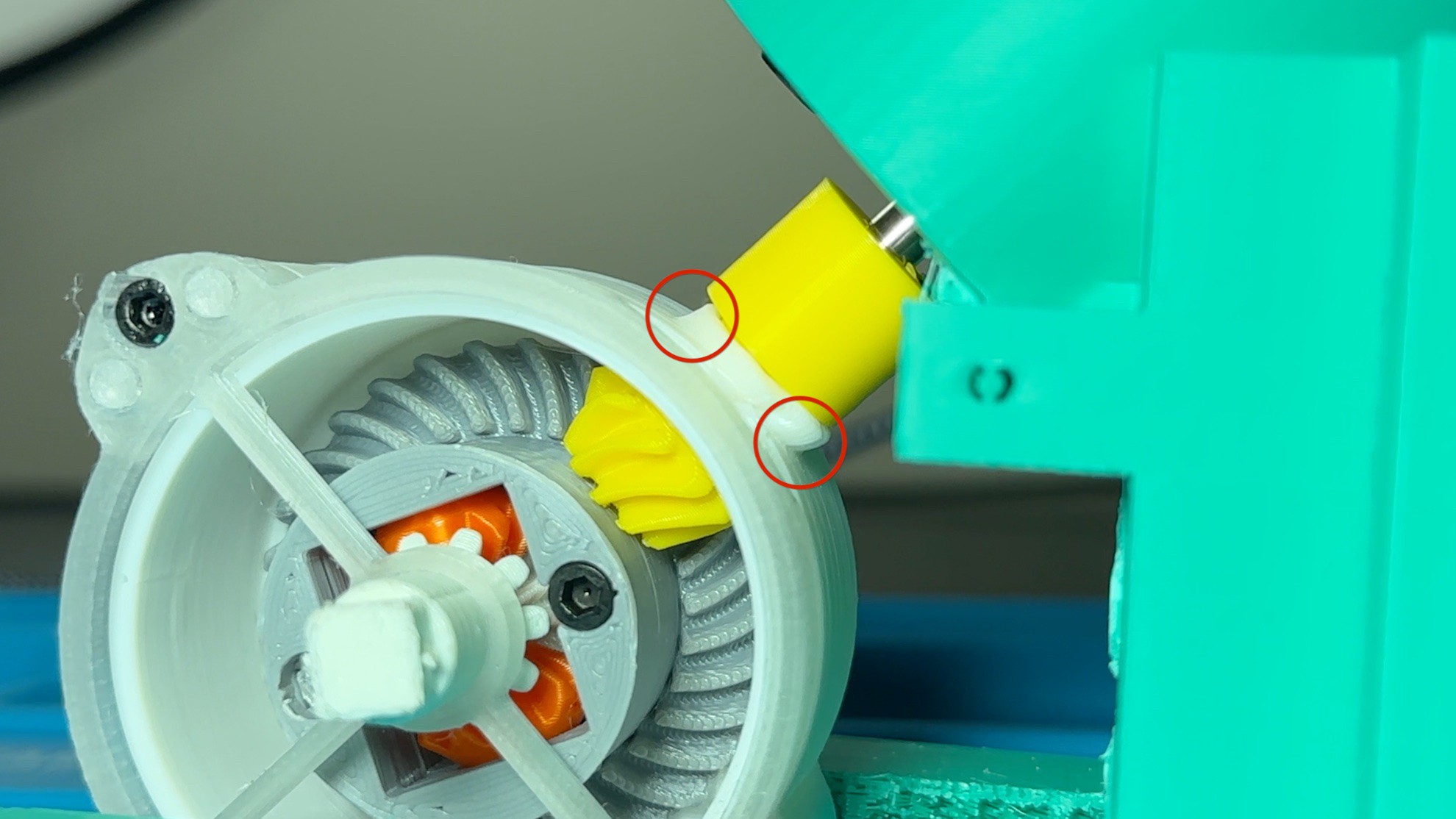

A Grass Cutting Test & Differential Failure

06/28/2025 at 00:55 • 0 commentsNext obstacle: grass. Total fail—the plastic differential shredded both pinion and ring gears.

![]()

But failure led to innovation: I swapped to a multi-stage planetary gear reduction and temporarily locked the rear wheels together. It worked, though imperfectly.

![]()

![]()

-

Outdoor Trials: Snow, Cliff Jumps & Broken Bones

06/28/2025 at 00:52 • 0 commentsFirst test: snow. Gorgeous—until I pulled full power and sent the car off my deck.

![]()

![]()

![]()

The result: a shattered wheel arm.

Fixed with a PETG replacement, but a few minutes later the pinion lost teeth again.

![]()

-

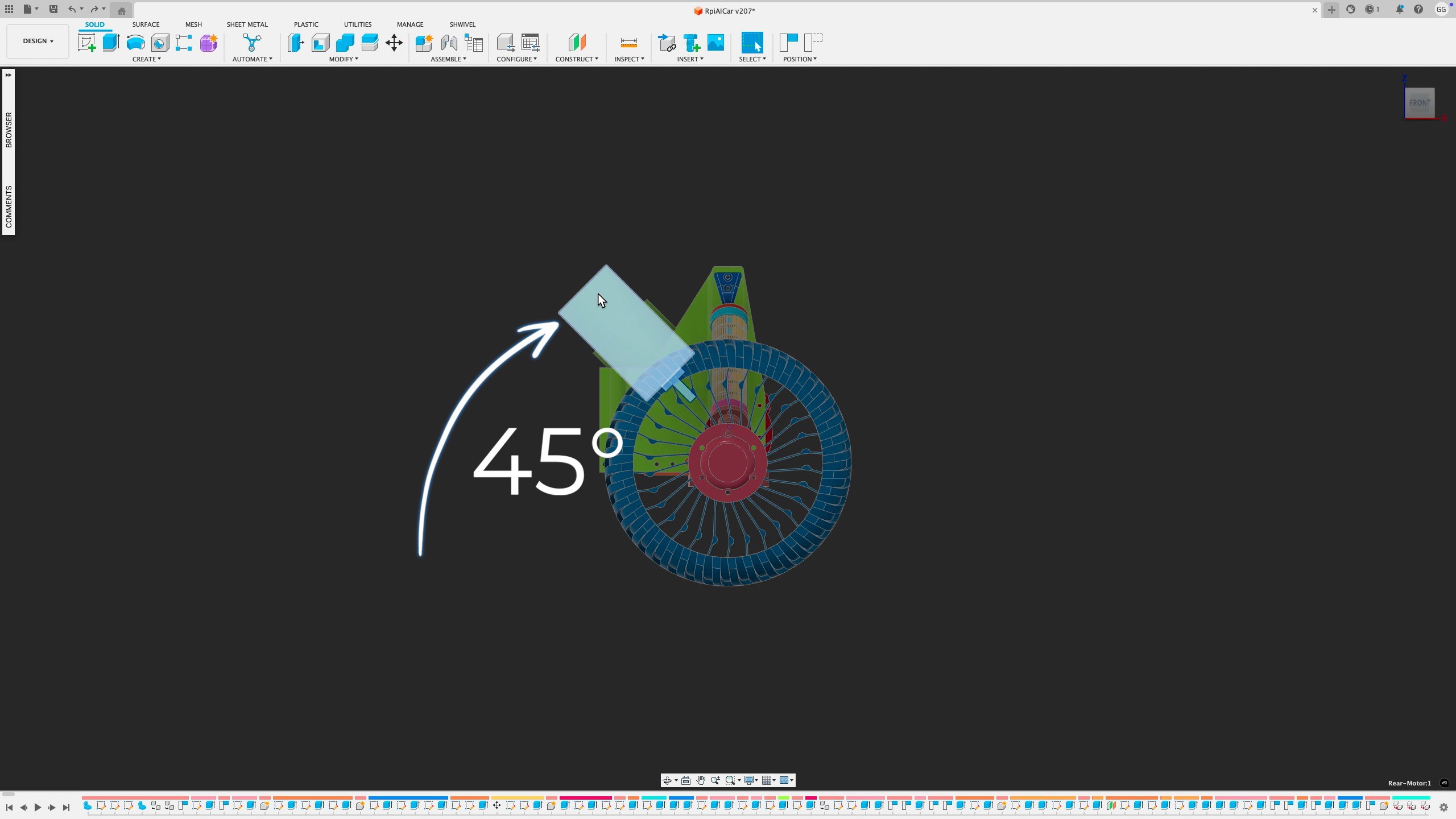

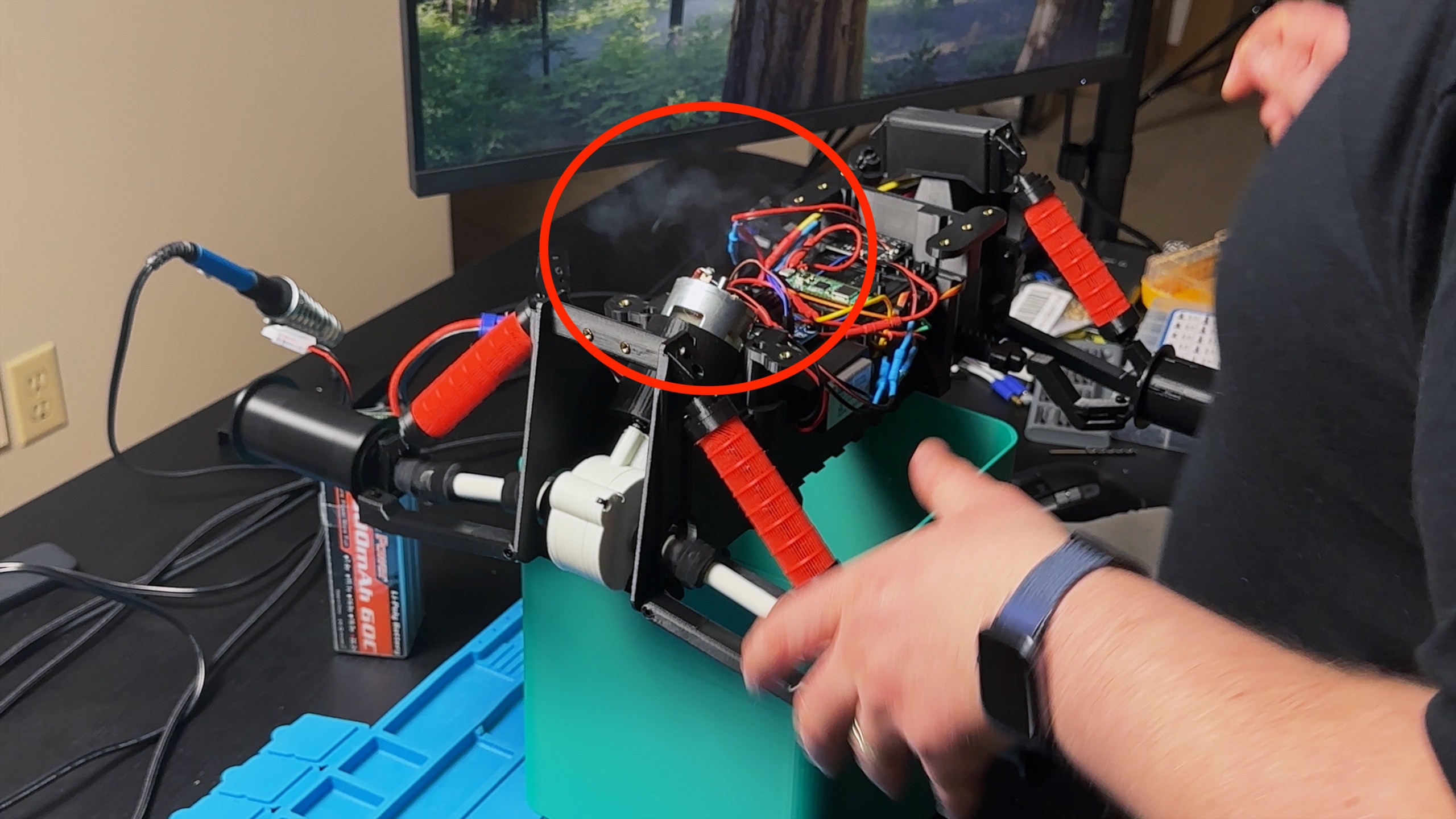

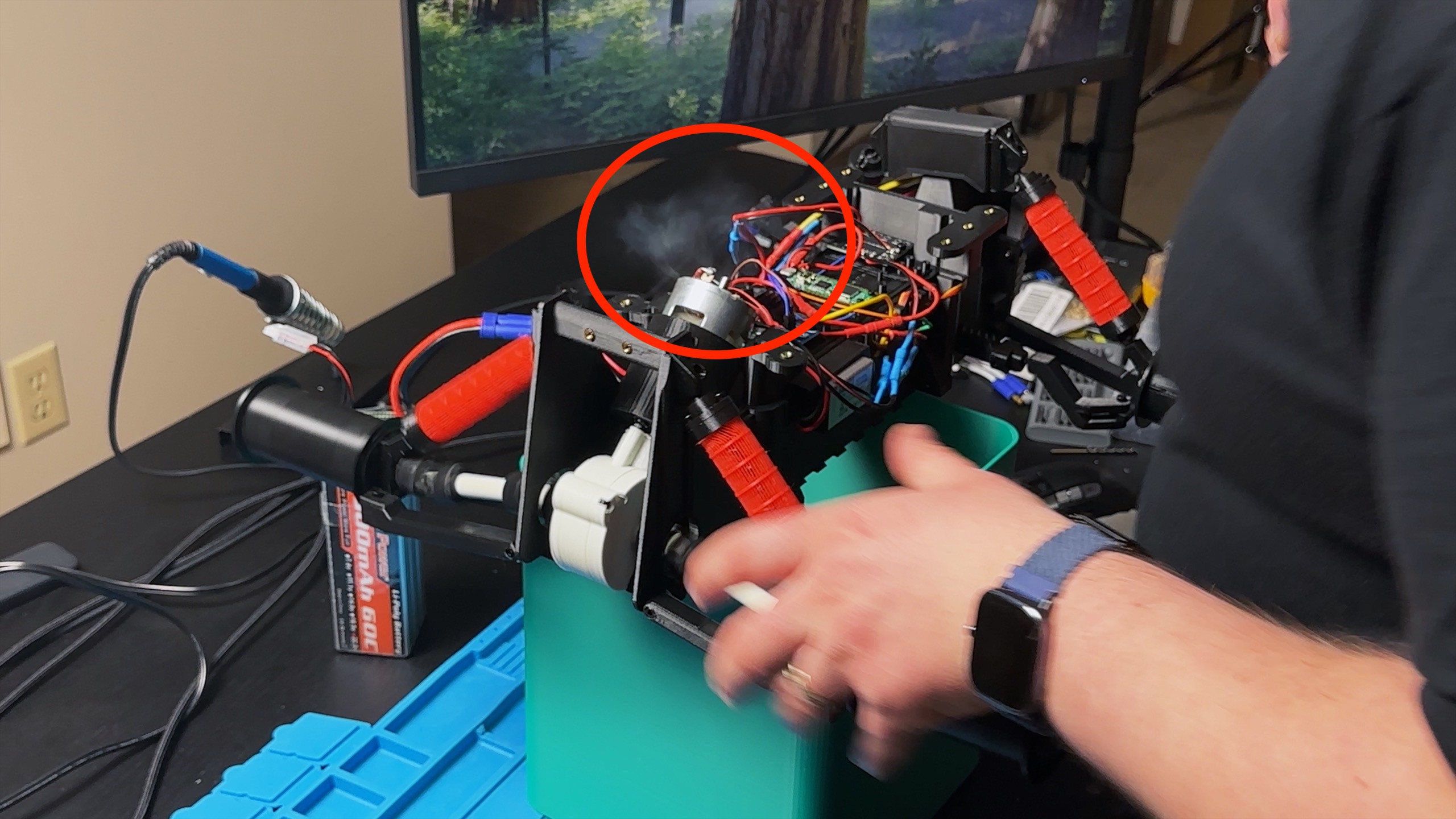

Motor Power & Unexpected Blasts

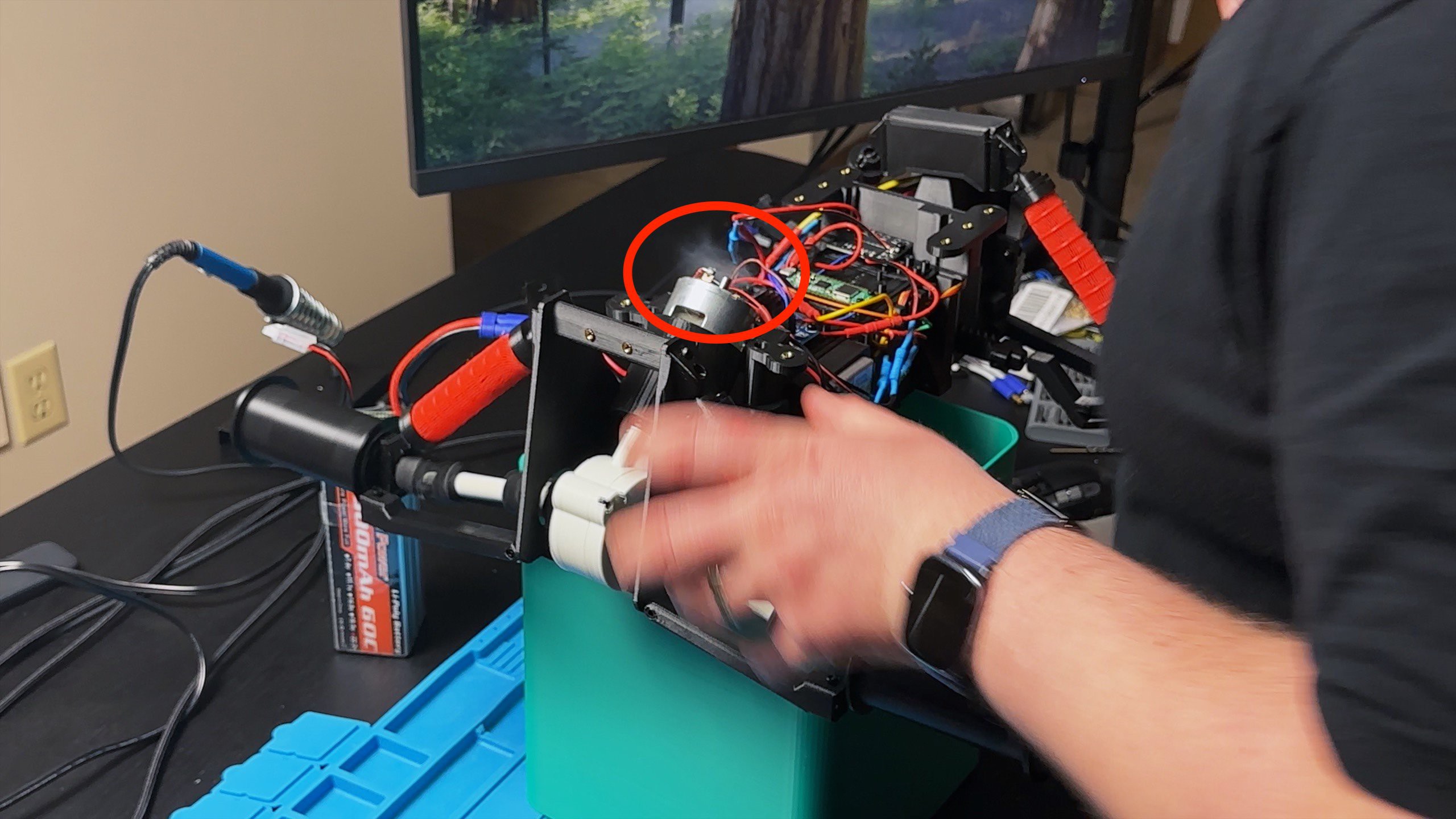

06/28/2025 at 00:50 • 0 commentsA 775 brushed motor at 45° angle powered the car, driven via an H-Bridge.

![]()

On the first test, it seemed to work—until I heard a pop: the H‑Bridge blew up (twice). It lacked thermal protection and failed under load, so I upgraded to a more robust controller.

![]()

![]()

![]()

-

Suspension Without Springs

06/28/2025 at 00:48 • 0 commentsWithout metal, I crafted a suspension using stacked TPU disks and ball joints. Surprisingly, it handled rough terrain better than expected—until it didn’t.

![]()

-

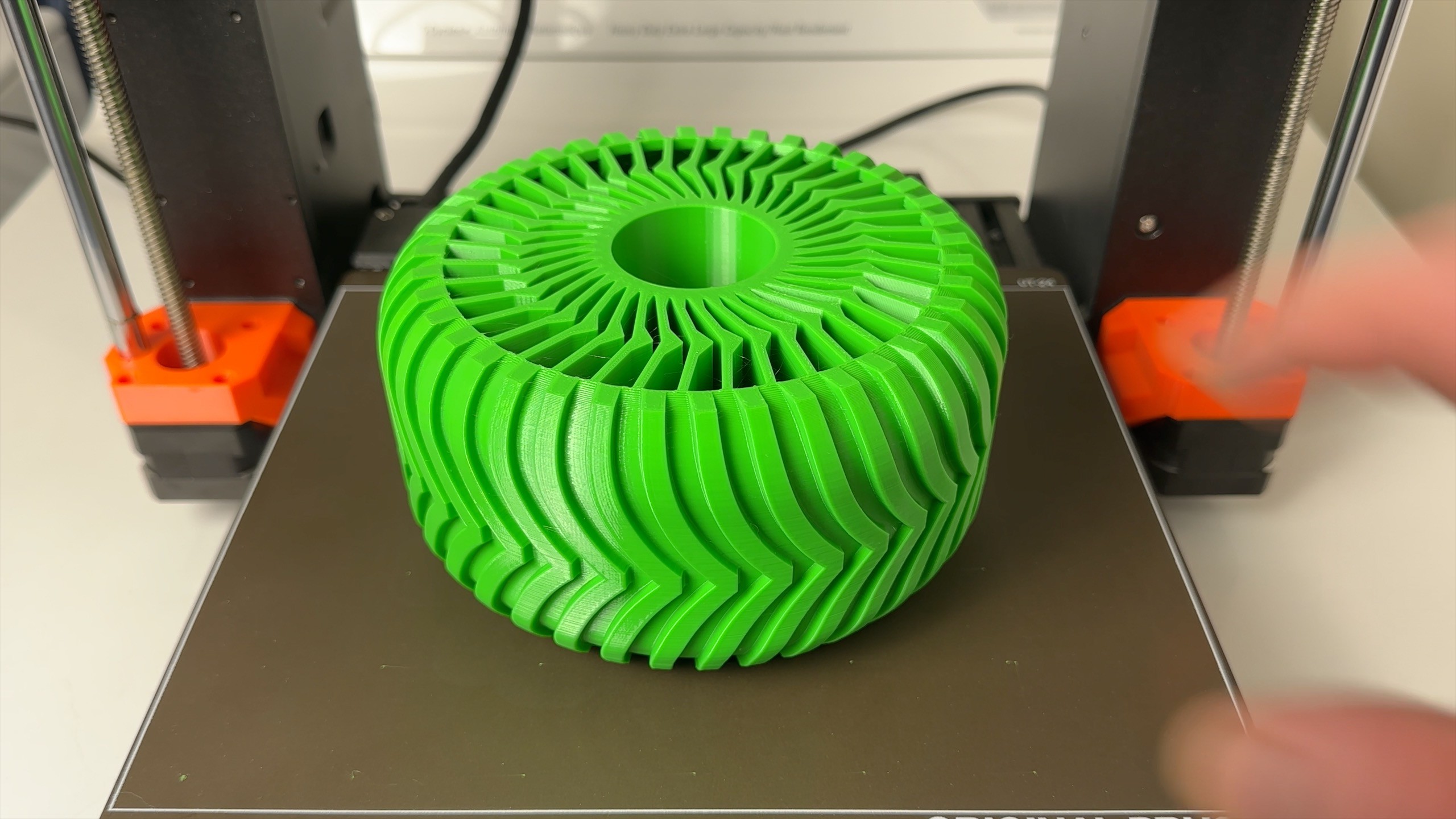

The Wheels: Airless & TPU

06/28/2025 at 00:47 • 0 commentsI designed almost 6-inch tires inspired by Michelin’s airless concepts, all printed in TPU. They turned out great—each tire took around a day to print. Bearings were added early to ensure smooth rotation.

![]()

![]()

-

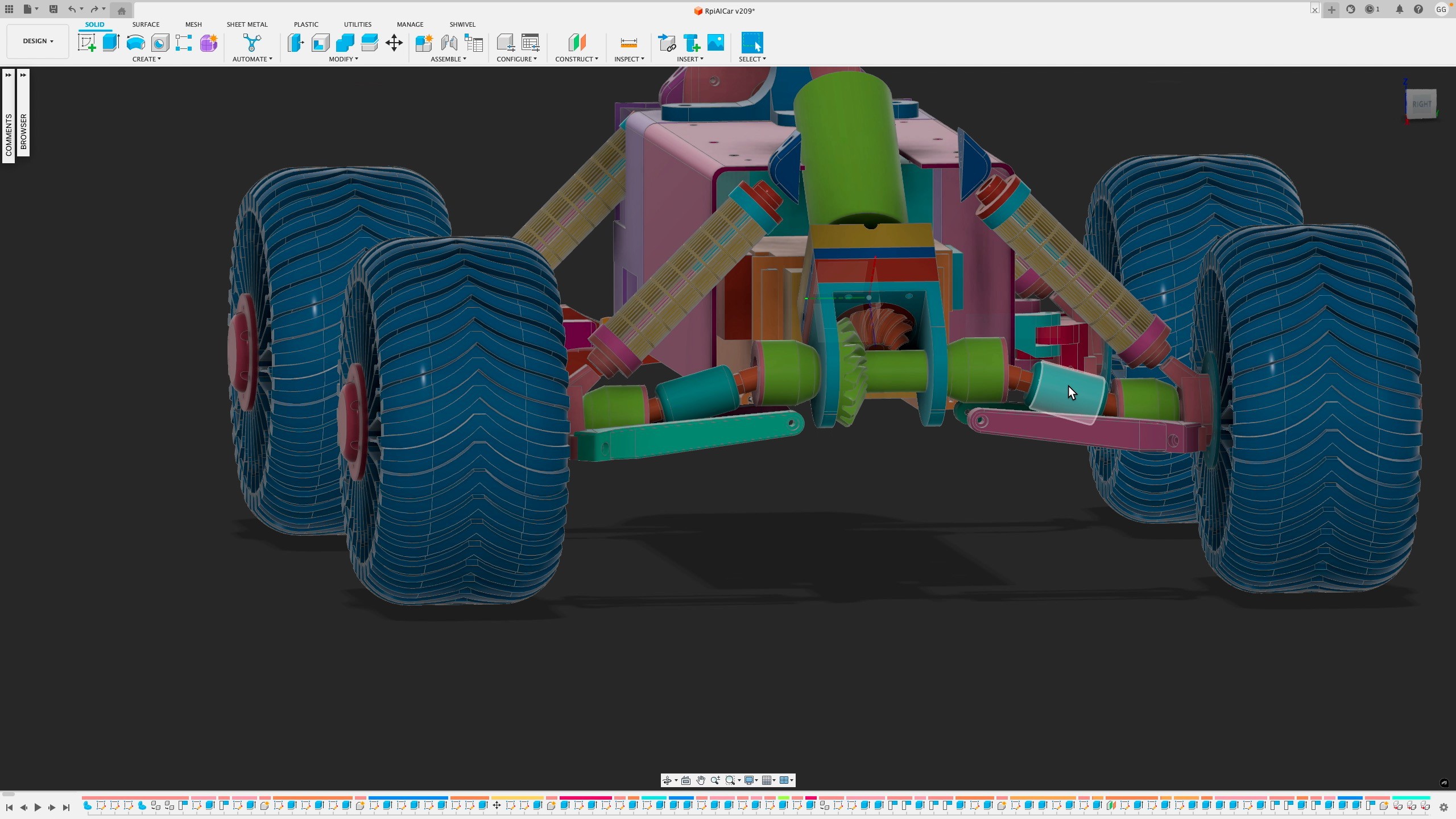

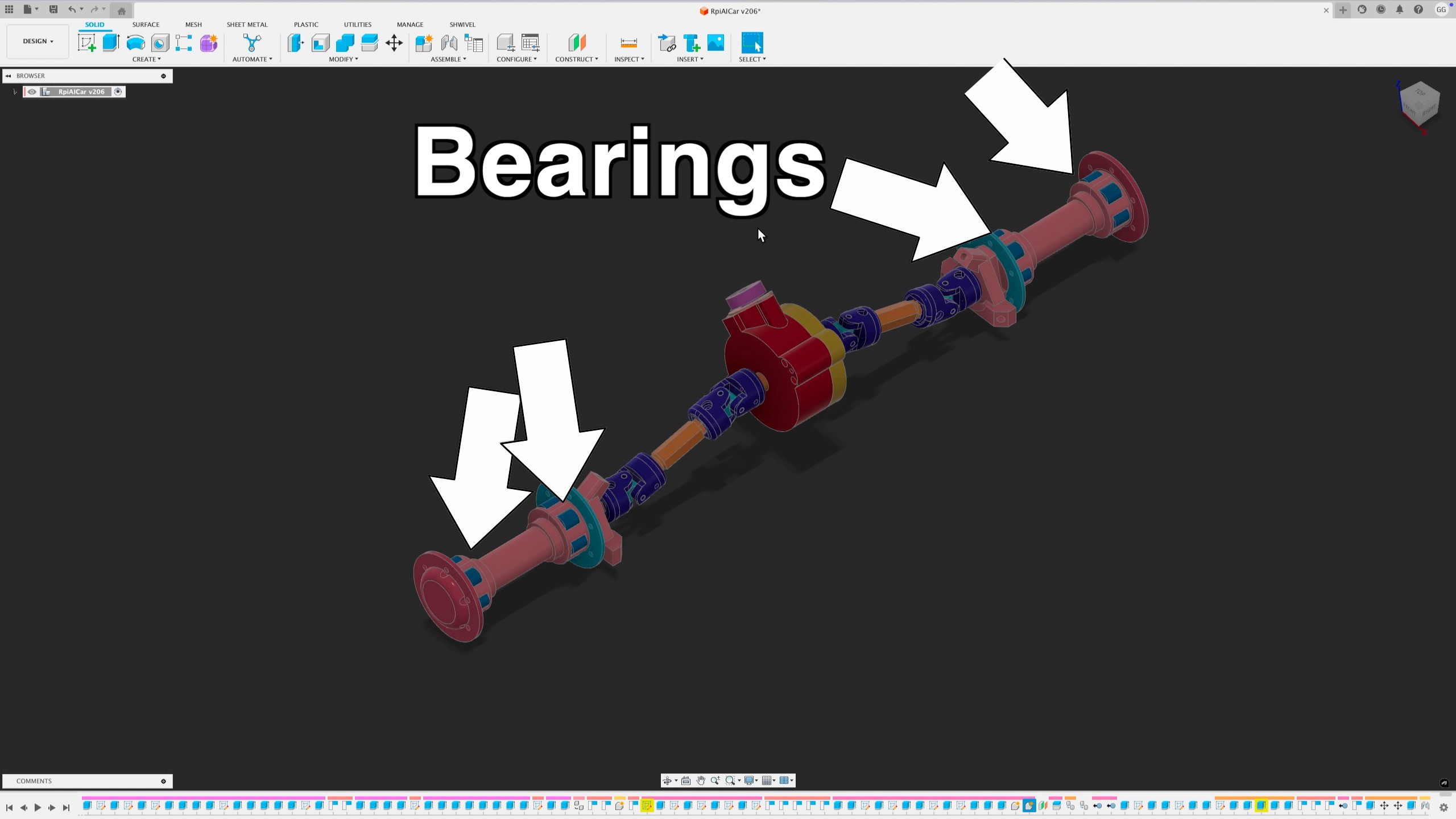

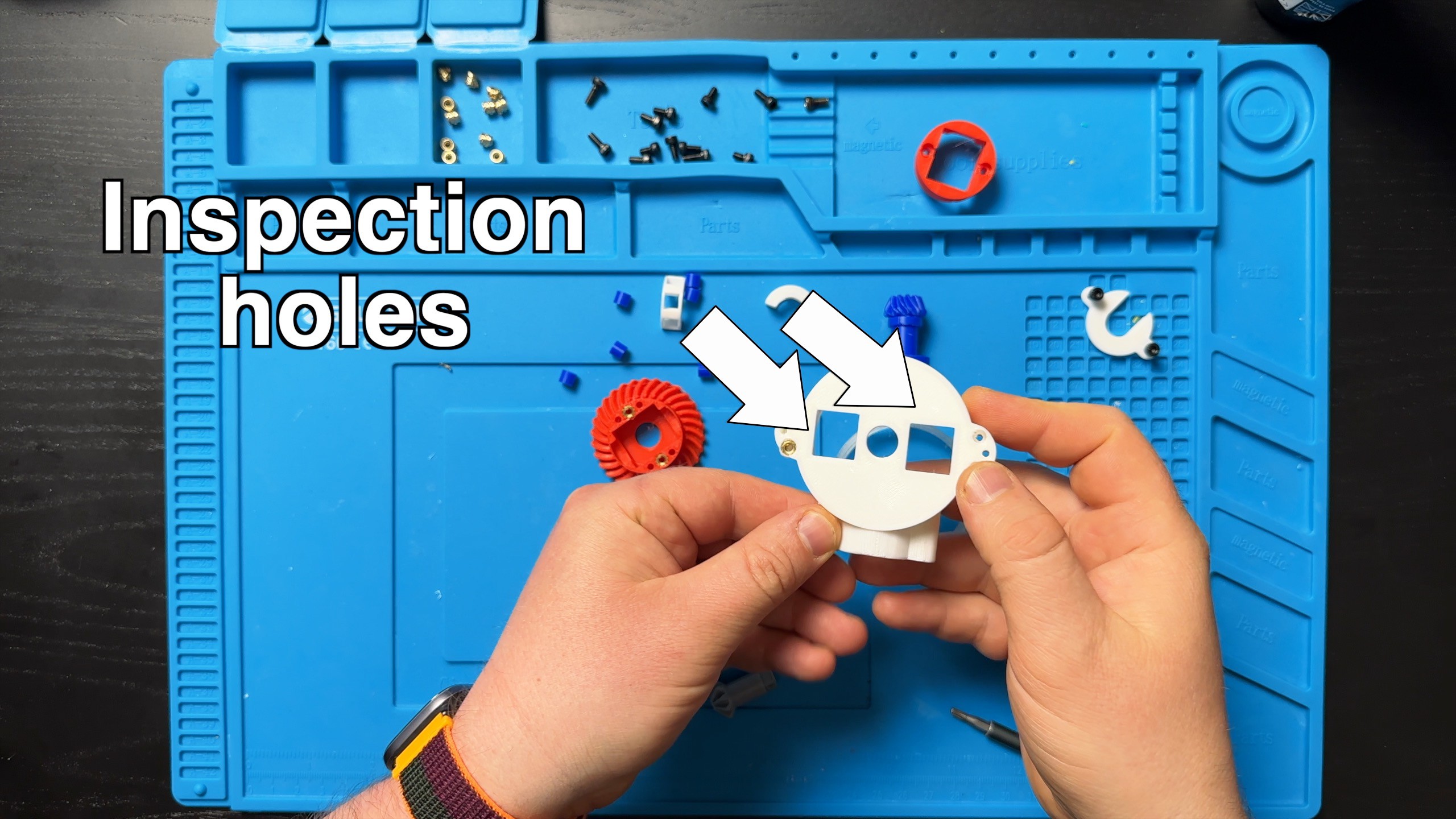

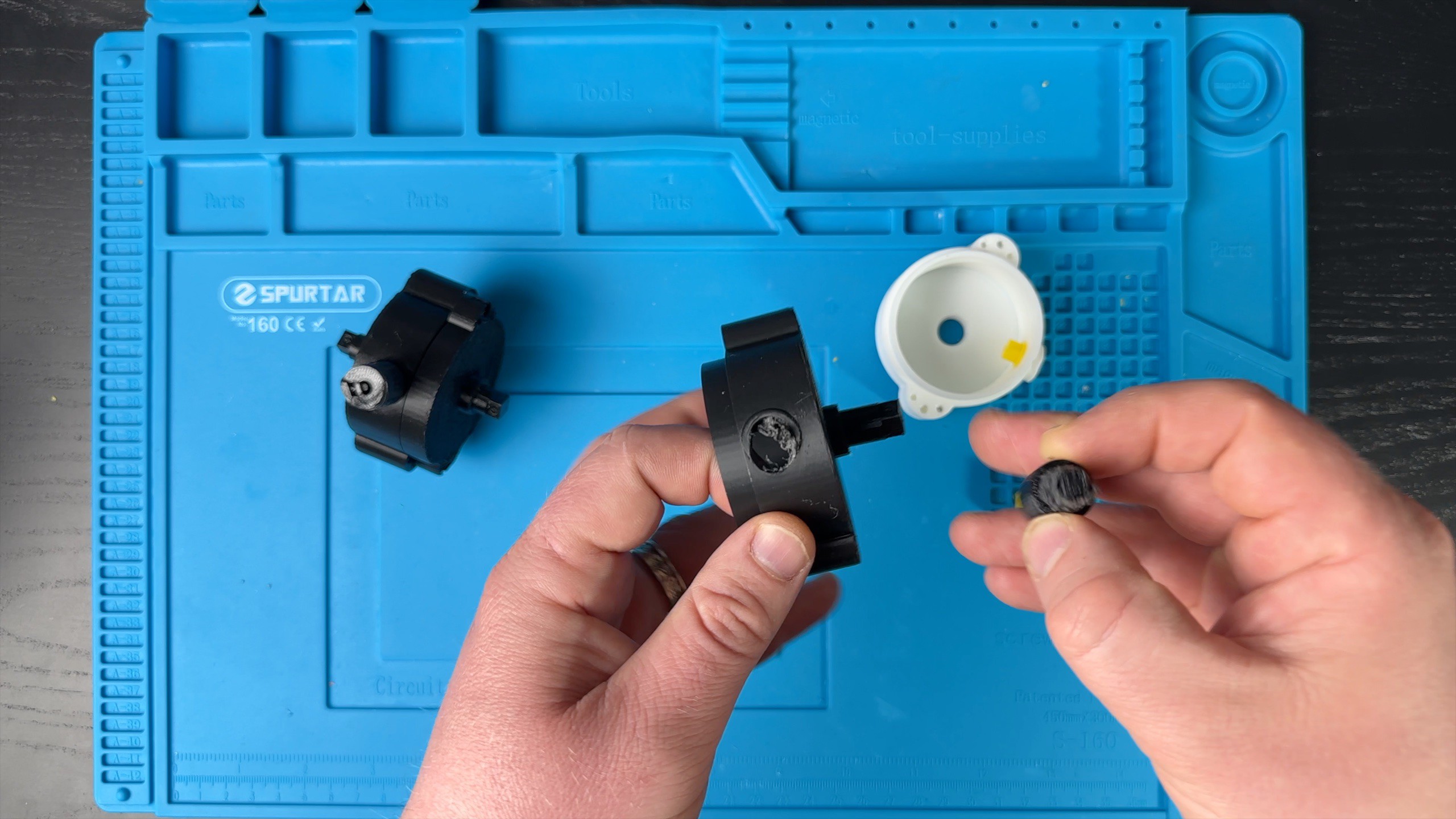

Stage 2: Bearings to the Rescue

06/28/2025 at 00:45 • 0 commentsNext, I added bearings to reduce friction and even added observation holes to monitor the setup.

![]()

With vents, it worked temporarily, but failed while sealed. After dozens of iterations (and switching to stronger nylon filament),

![]()

![]()

the differential finally survived long enough to move on.

-

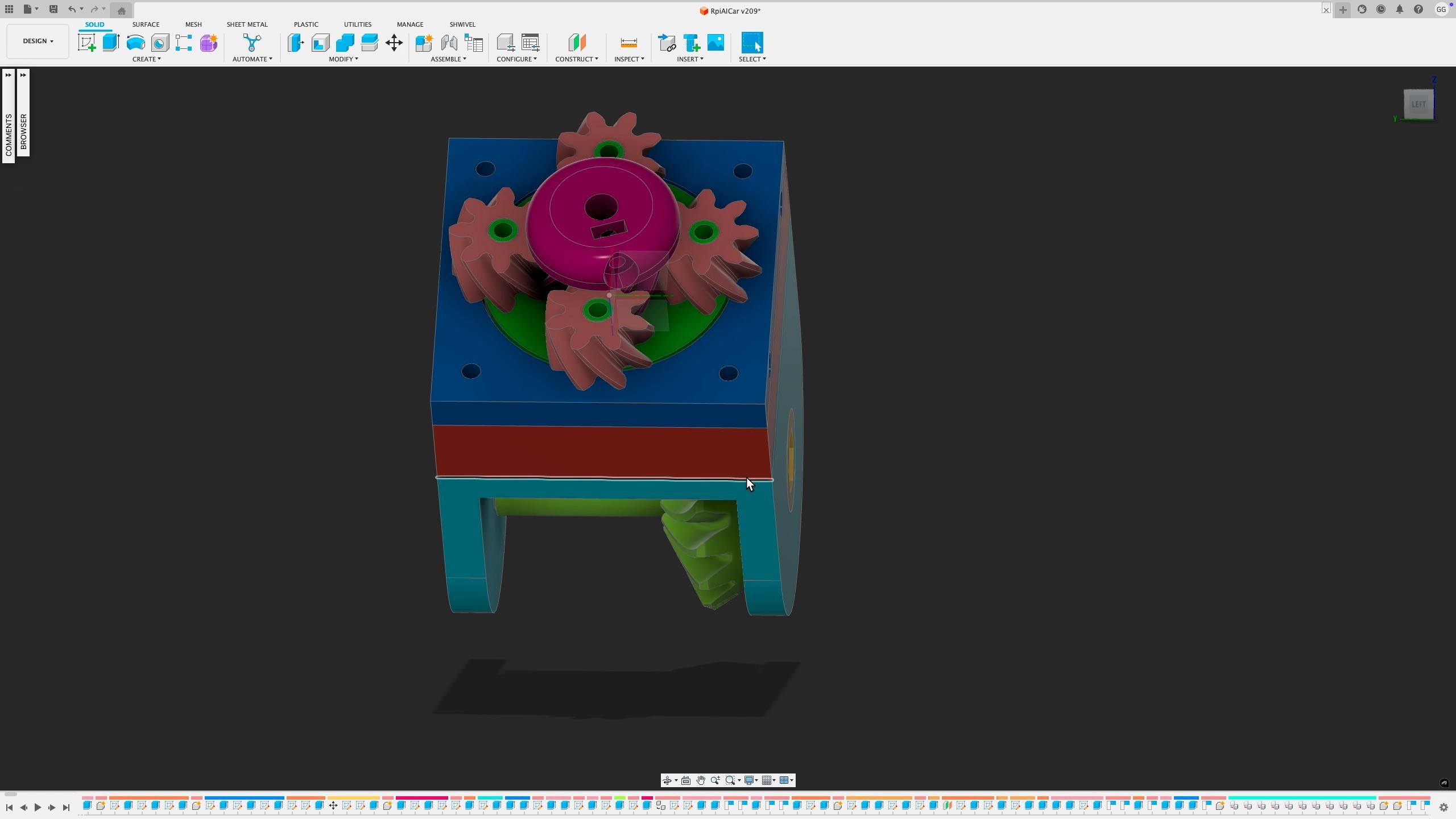

Stage 1: Differential Drama

06/28/2025 at 00:43 • 0 commentsI began with a planetary-style differential designed in Fusion 360. But when I tested the first PLA prototype, it melted almost immediately. After just ten seconds of operation, the pinion gear stalled, the case warped, and the shaft fused to the plastic. PLA failed; so did PETG. Heat + friction = melted mess.

![]()

![]()

3D Printed RC car (1-5 scale)

Can You 3D Print an Entire RC Car? I Tried — And It Blew Up (Literally)

Eugene Tkachenko

Eugene Tkachenko