-

Over torque...

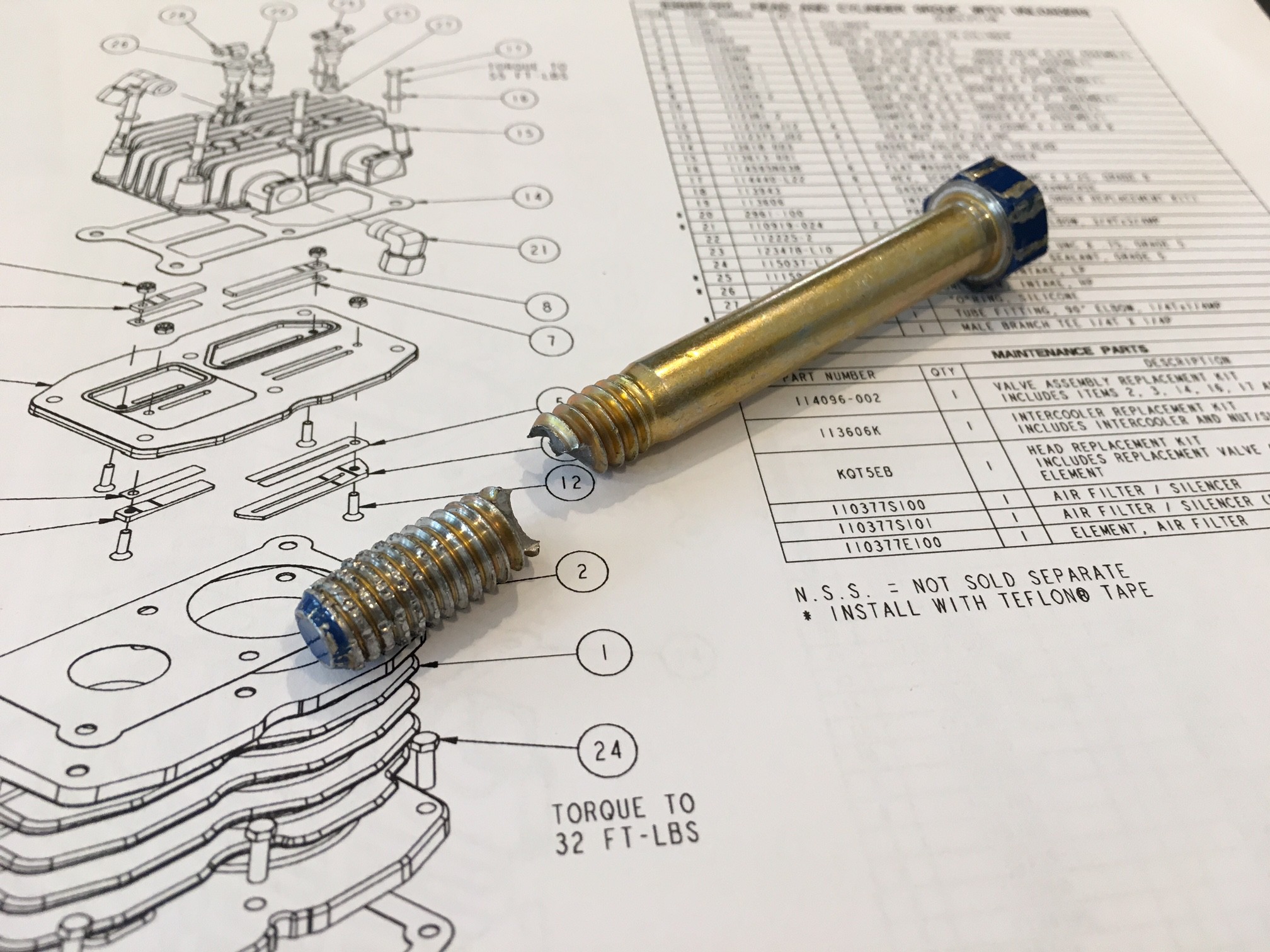

03/20/2017 at 17:59 • 0 commentsScheduled maintenance on the compressor says that after one hour of operation, you check the belt tension and verify the cylinder head bolt torque.

Not sure if it was the torque wrench (not likely), the bolt (even less likely) or the operator (highly likely) that failed, but this was the end result after the first bolt...

So, minor setback.

Fortunately, the parts lists and maintenance drawings from Quincy are immaculate, so I know exactly what needs to be replaced: Grade 9, 3/8-16 UNC hex bolt, 3 1/4" long. Should be a quick fix...

*** UPDATE ***

Credit where credit's due, DesignLab intern @Trey Weber did the torquing and let me know as soon as I got in this morning. So I went down there to see for myself what happened. Honestly? I gotta think it's a defective bolt. It's impossible to not-notice a 55ftlb click on a torque wrench, since it's more of a jarring snap than a regular click.

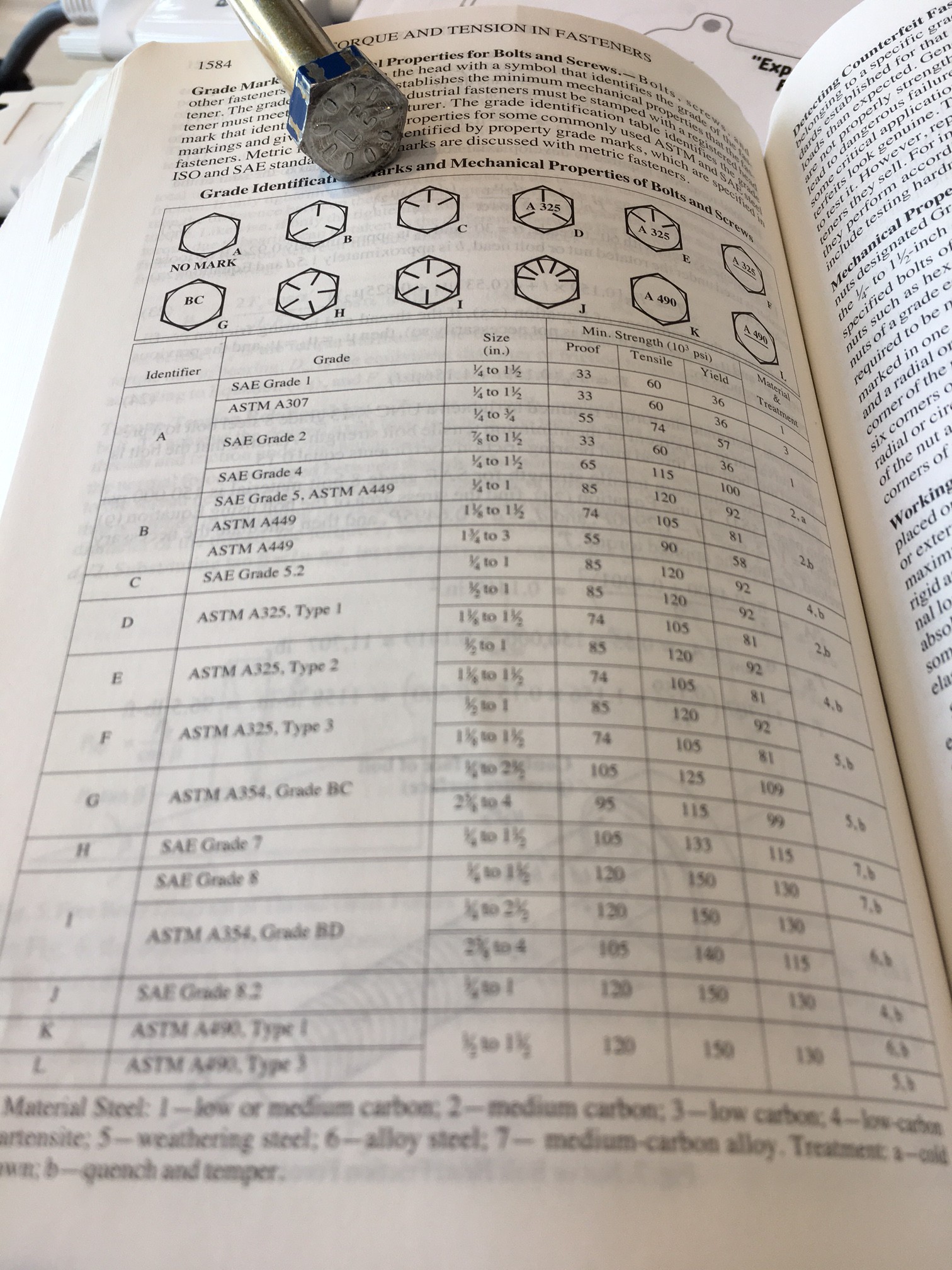

And further, it's a Class 9 bolt.

Class 9 is a little baffling to me, because my Machinery's Handbook doesn't list it as either an ASTM or SAE standard. In fact, it seems like "Class 9" is a way for manufacturers to make a bolt that they can say is "stronger than any regular bolt" or something like that. For examples, google the "L9 Fastening System". Basically, this bolt is rated at having 180,000 psi of tensile strength.

![]()

Essentially, the cast iron head should have stripped out waaaaaay before this bolt snaps.

I torqued the next bolt over in the pattern and it clicked at 50ftlbs, but required another 1/8 of a turn at 55ftlbs. So the wrench is working right. I suspect, ultimately, this was just a crap bolt.

Replacement ordered from McMaster-Carr... should be able to swap it out this afternoon.

-

Delivering Air

03/15/2017 at 21:32 • 0 commentsAn injection molding machine isn't much good without the compressed air that makes it run. The spec for the Morgan G-125T is...

The minimum compressor required to adequately operate a Morgan-Press is a one horsepower, two-stage compressor with a 30 gallon holding tank rated to maintain on/off pressures at 120 to 150 psi. The flow rate should be a minimum of one scfm. This is for dedicated usage by one machine. For light duty applications, a smaller compressor with less holding tank may suffice.

It seemed to me that it would make more sense to invest in a proper compressed air system for the lab as a whole, than simply delivering enough air to run the injection molder. At a minimum, I would want to run the injection molder and the FogBuster mist coolant system on our Tormach PCNC1100 simultaneously.

The Morgan needs 150 PSI and the FogBuster needs far lower, 20 PSI, but really, it's not the pressure but the volume of air that they need to chug that could be the problem. Both systems require 1 SCFM (standard cubic feet per minute) to operate correctly, and you really don't want that to bog down when the compressor has to kick on.

Ultimately, after a significant amount of research, I settled on the Quincy QT-5 80 Gallon compressor. The large receiver tank should be sufficient to act as a buffer for having multiple tools running off of the system at the same time, and the 5HP motor is able to generate 17.7 SCFM! I think we'll be fine.

When the thing showed up though... I wasn't quite ready for the size, even though I knew it was coming...

![]()

![]()

I don't think those pictures really do it justice... it stands 54" tall! I had no idea how I was going to get it off the pallet let alone moved to where I was going to have the electrician hook it up. Fortunately for me, the electrical contractor I've been working with, Larry Butler of Larry Butler Electric, took care of all of it for me. One minute he was looking at it sitting on the pallet, and when I got back from lunch, he had it moved over to the wall and was getting the power whip ready for it. Within two days, he had it mounted on vibration dampeners, bolted to the concrete with 3/4" bolts, and hooked up to 208V.

![]()

![]()

The compressor has a pretty well defined break-in process we have to follow to ensure that the piston ring seal correctly, the belt from the motor to the compressor is correctly tensioned, and that the cylinder heads are appropriately torqued, but after about 10 hours of run time, we should be ready to put it into production.

Next step ... installing the compressed air plumbing.

-

To Catch Everyone Up...

03/15/2017 at 20:55 • 0 commentsIn late November, we had our Morgan Industries G-125T and accessories delivered! It arrived in a coffin sized crate, that presented a bit of a challenge: how do you get a 400 pound injection molding machine out of a crate when it was shipped horizontally and needs to be lifted onto a workbench - particularly when you don't have a ceiling crane or hoist to use.

![]()

Well, as it turns out the solution to that is teamwork! I roped in a group of operations staff from the Supplyframe corporate office and together we cajoled, connived and eventually convinced the Morgan Press to take up residence on its new workbench here in our loading dock.

One careful lift at a time, the DesignLab welcomes its new baby, a Morgan Inudstries Injection Molding Press! pic.twitter.com/esvwZaKoNJ

— SupplyframeDesignLab (@SupplyframeDL) January 4, 2017A little more careful moving and sliding... and the purchase of one substantially more stable work platform from McMaster-Carr later, the press was located and ready for hookup.

![]()

Morgan Industries G-125T Injection Molding Machine

A project that documents the installation, preparation and testing of the DesignLab's new Injection Molder

Supplyframe DesignLab

Supplyframe DesignLab