-

Updated Drive System

06/17/2017 at 17:59 • 0 commentsAfter much introspection, it looks like I am going to make some changes:

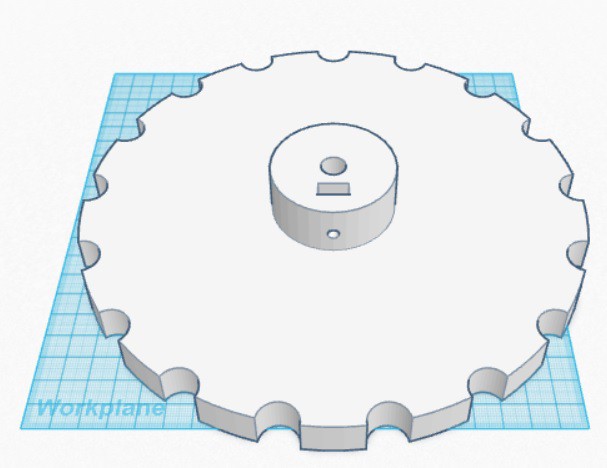

- 3D Printed drive and idler sprockets at 17 teeth instead of 11

- 3D Printed road wheels (yes, printed), but also at 17 teeth, that will raise the chassis of the tank higher off the ground.

- Move forward with making the tank based on a metal frame instead of a wooden one. 2 of the 2x4s will be recycled as longitudinal support members

- Fiberglass surfaces so that the batteries can be mounted inside the frame cavity

Plastic wheels and sprockets will save the track a lot more, and based on initial estimates will suffice for prototyping. They may not handle heavy duty operations, but it's pretty easy to cast aluminum replacements afterwards. I do intend to print in PLA at 100% in-fill.

Here's an image of the sprocket/idler:

-

Keep the Motors...says everybody!

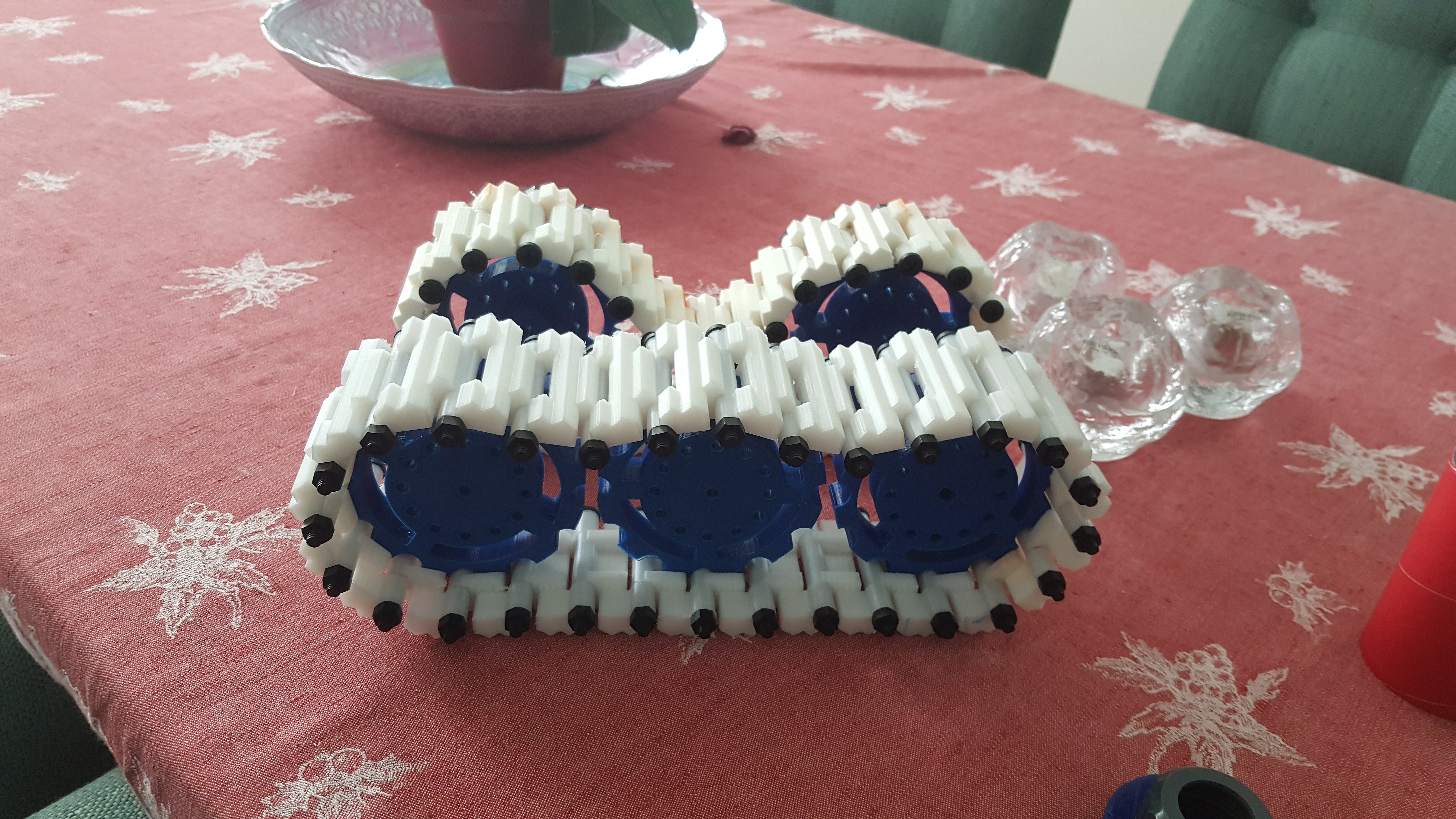

05/02/2017 at 02:18 • 0 commentsEveryone who commented on the Hackaday article is saying I should stick with my 1KW motors. So I went back to the drawing board amd redid a few things. I think I can, I think I can. Meanwhile, as I wait for the tank to return from April's STEM Faire, I started mocking up an idea for eliminating the need to tension the tracks beyond a certain point. That does involve letting the track 'sit' on the road wheels. I will be testing this idea in miniature....here's a picture:

-

GoKart Tank Story featured on Make Magazine

04/07/2017 at 00:56 • 0 commentsI wrote an article for Make on the tank and you can read about it here:

http://makezine.com/2017/04/05/gokart-tank/

Enjoy!

-

Metal Frame Idea

04/07/2017 at 00:51 • 0 commentsI am debating V2.0 of the tank to abandon the wooden frame and go with all metal. Here's what I am considering:

When I moved all my servers from my CoLo, I also brought back all these rails from the server rack made of 1/8" powder coated steel. These are L shaped rails that have one piece that slides into the other so that you can adjust it for different length/depth racks. I have maybe 10 of these things (for 5 servers). These aren't the ball-bearings sliding rails. They are fixed. They are strong, heavy duty, very solid. I measured them up and I have enough to make a pretty big and solid metal frame to replace the wooden one. I also have a lot of sheet metal from my airplane builds, tons of rivets and of course my drill. I think I can make a solid frame out of these left over materials that I would otherwise have to give away or sell off for peanuts. Yeah, I think it's viable. In addition, I have 2 dead 4U servers I had custom built years ago. The cases themselves are also steel. Bolt those onto the frame and you have a full enclosed box frame that is rigid and hollow AND fireproof. My thinking is that I can make a box frame with panels and a hollow space to install batteries, electronics and whatever else I need using recycled computer junk and still make it look good. Here is a grainy picture of the tank with one rail laying on it.

And here is one of those cases. Pretty hefty.

What do you think?

-

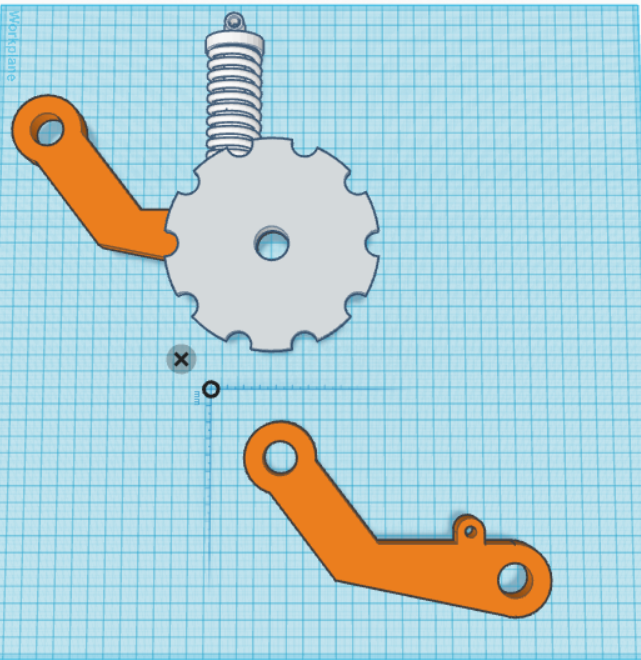

Suspension Arm Prototype is done

04/07/2017 at 00:37 • 0 commentsI have refined the suspension arm after 3 prototypes. 2 arms side by side with the shock in between. Bearings press fit and epoxied in place and we are ready. The arms themselves are 3D printed. And when I tell you they are rigid, they are super super rigid. Before I mount them, I will treat them all with XTC3D to weatherproof and of course make them even stronger.

-

Suspension!

04/01/2017 at 03:35 • 0 comments -

It Lives!

03/20/2017 at 17:23 • 0 commentsPhew. All done and ready for the Maker Faire. And it runs and runs great! In the end, I learned:

1) My choice for track works well in one direction only. Going in reverse throws a track

2) 2.5HP is not enough

3) I over engineered it in the effort to make it 'Heavy Duty'. I should have stuck to a metal body

4) I would use straight through axles for the road wheels. I have 16 pillow block bearings there. Each weights close to 3lbs. I could do fine with axles and 8 bearings instead.

5) The lexan sprung bogie is not strong enough for heavy duty work. I have to switch to metal

6) Electric is not the way to go for something this heavy. The motors are way too heavy and the 8 batteries are killer in terms of weight.

But...I love it!