What is the WEEDINATOR?

The WEEDINATOR is a collection of modules to enable autonomous weeding of rows of vegetables by a robot tractor. It is not limited to weeding and can be adapted for planting and other functions.

What are the main components of the WEEDINATOR?

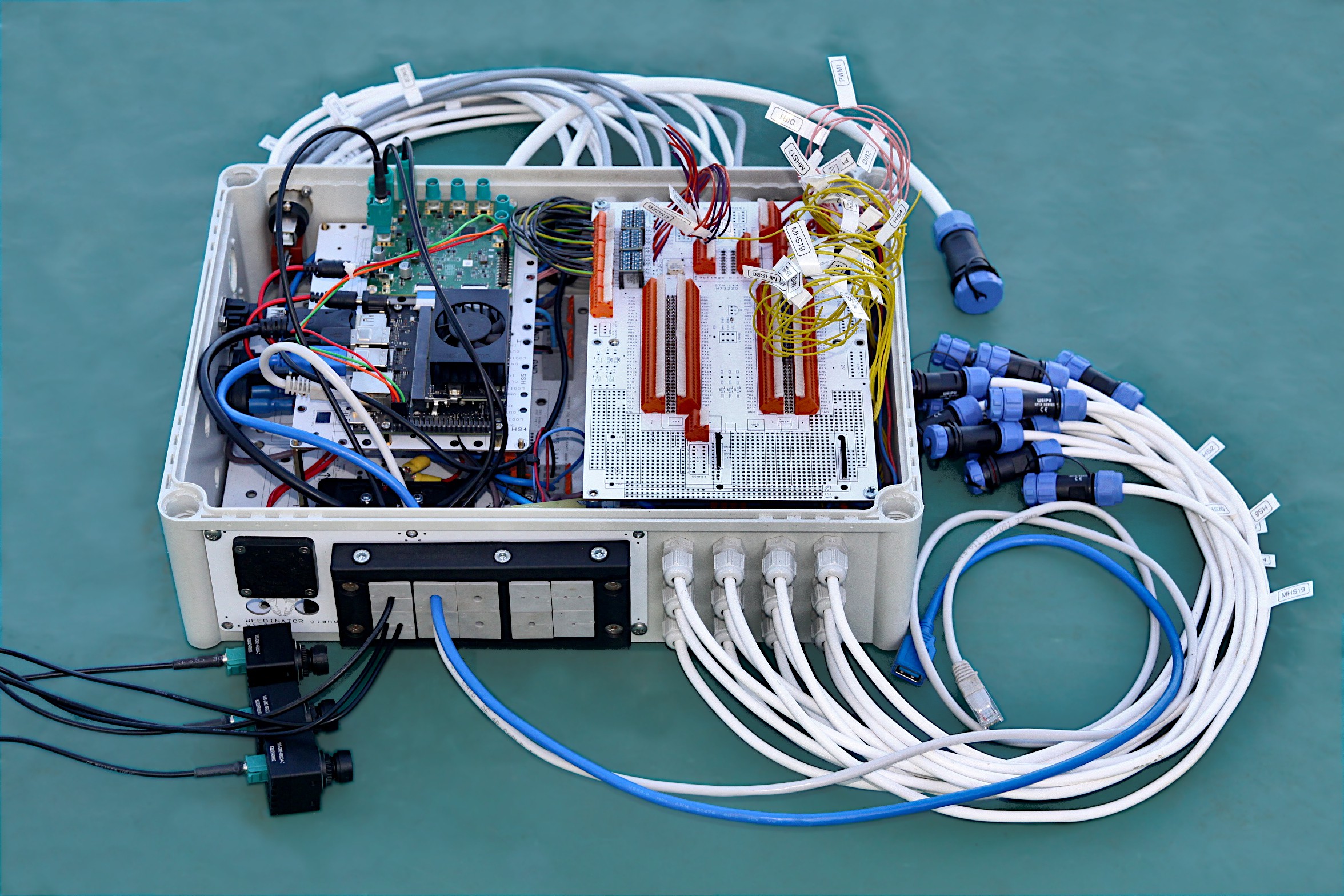

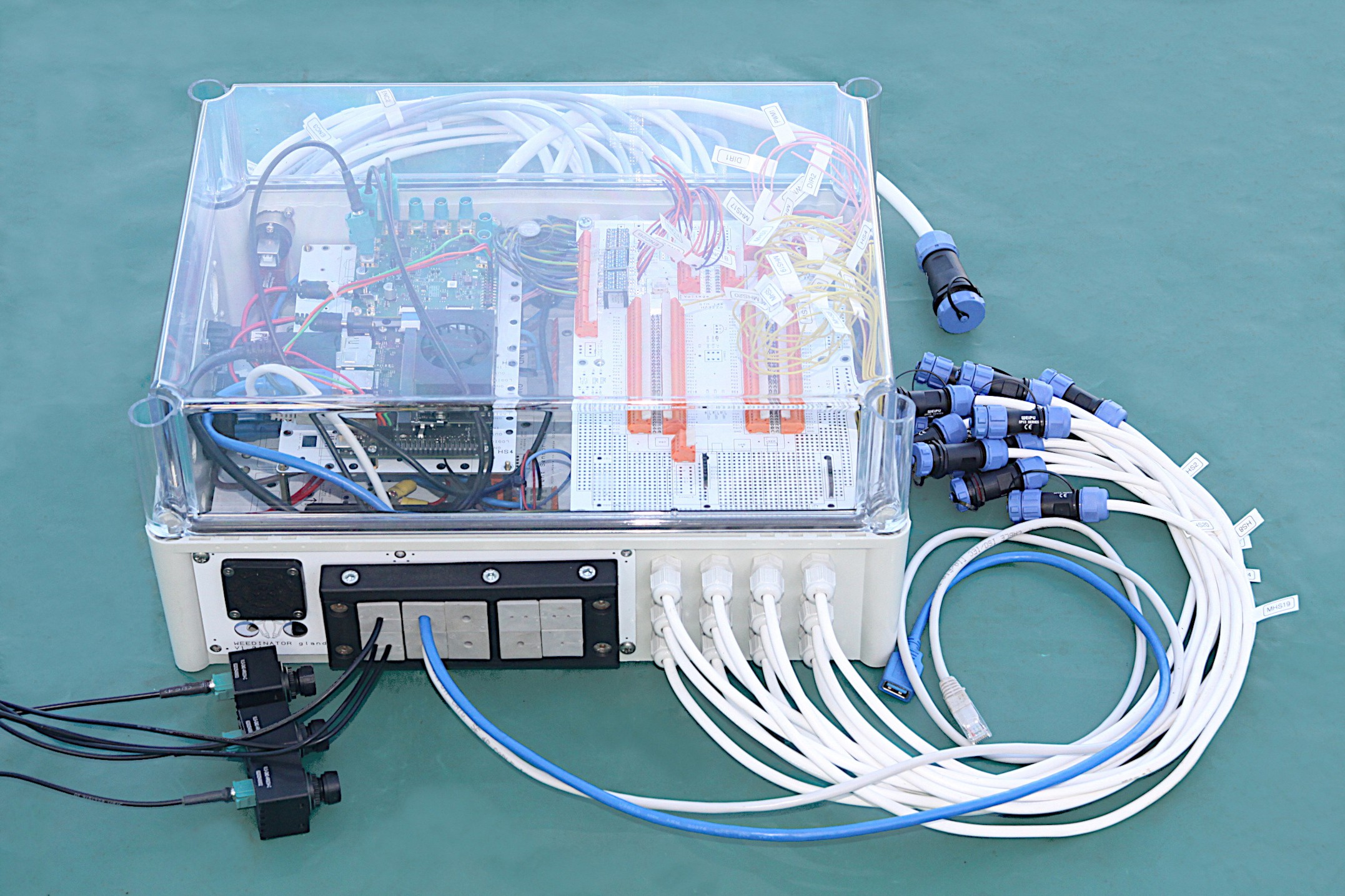

We call the 3 primary control modules Control Box 1, Control Box 2 and Safety Cameras. Box 1 is an infinitely hackable hardware system with a high end STM MCU, a set of automotive relays and automotive grade high side switches. Other sub modules in Box 1 include motor controllers and a 10 way fuse box. Box 2 can be configured in a similar way to Box 1 but would normally include a small board computer (SBC) for communication via 4G and crop detection with cameras and machine learning. WEEDINATOR Safety Cameras is a module for detecting the presence of people and a robot would normally have at least one at the front and back.

There is also a hydraulically powered cultivating (weeding) implement for towing behind the tractor.

More info to follow - watch this space!

Sponsored by PCBWay - the best quality and most reliable: https://www.pcbway.com/ . Other manufacturers exist, but we had quality issues with some of them.

Apart from the primary control system we are working on the cultivating implement, which has an Ai camera attached that scans the grids of crops as in the video below:

This video shows how we've combined traditional, CPU intensive, Open CV type computer vision systems with modern YOLO26n Ai image inference to try and recognise, and predict, the position of grids of seedlings. The idea is to try and predict when there is a gap between the crops to momentarily stop the cultivator implement in the Y axis and quickly send a set of hydraulically driven rotating claws across the X axis, and back again. The red horizontal X axis line acts as a trigger point and when the system detects that a weighted combination of the inferred Ai driven grid center and the traditional CV grid center overlap, or are close enough to one another, a data point is added to the data array. The system is able to detect the next grid center which is useful if the system misses a trigger point. It's not perfect yet and you can see it does actually miss one prediction, but as long as it gets most of them, this should be ok.

GOAT INDUSTRIES

GOAT INDUSTRIES