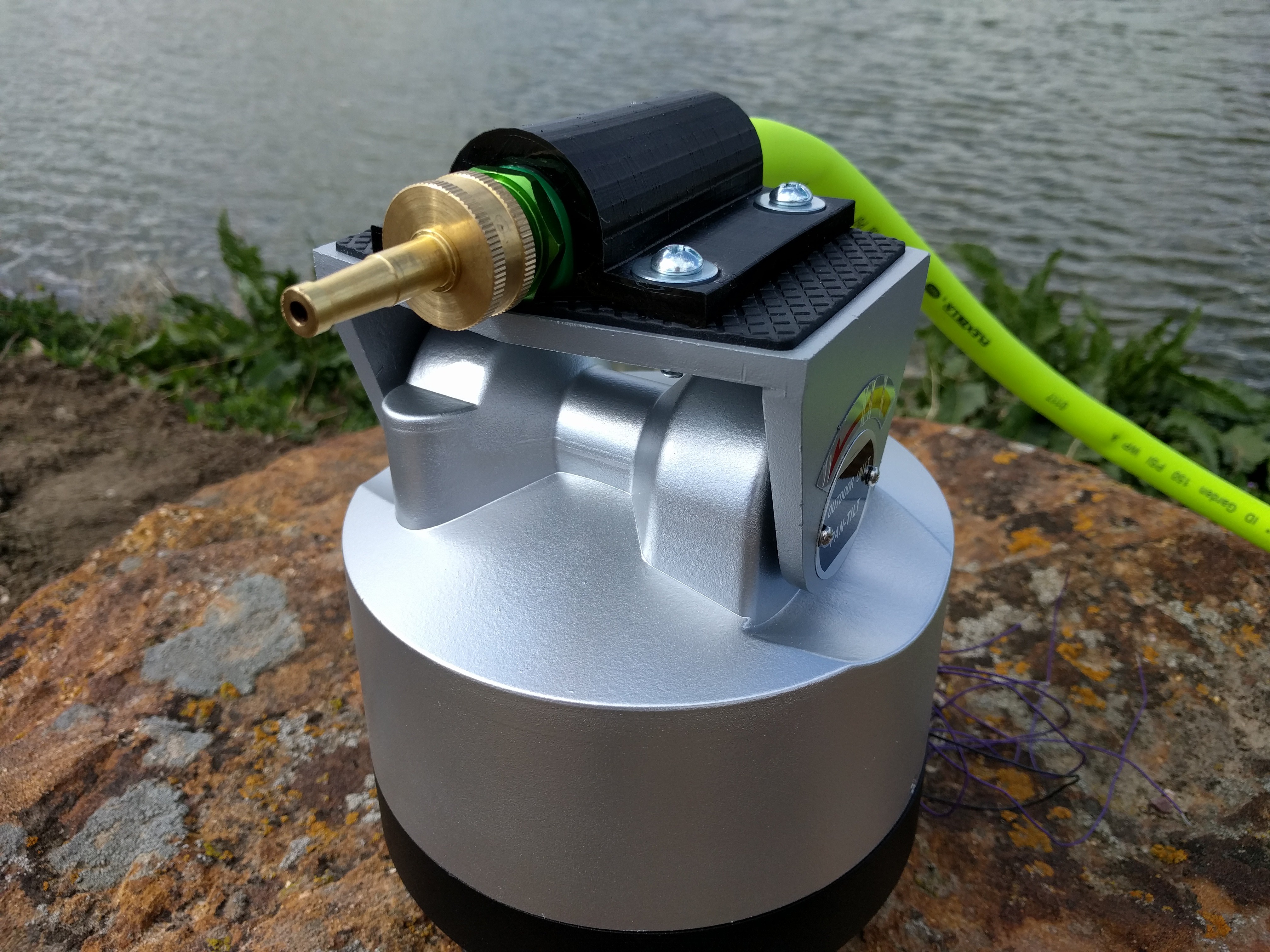

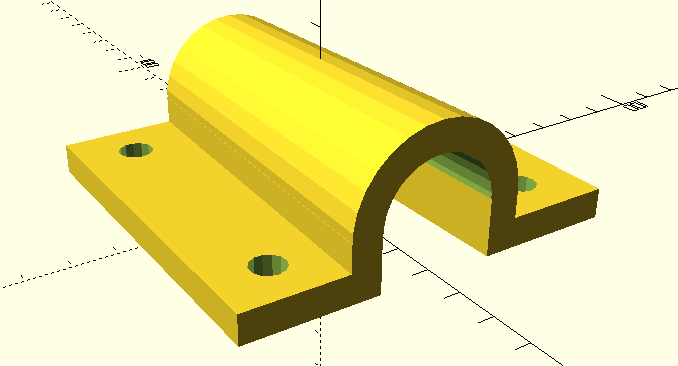

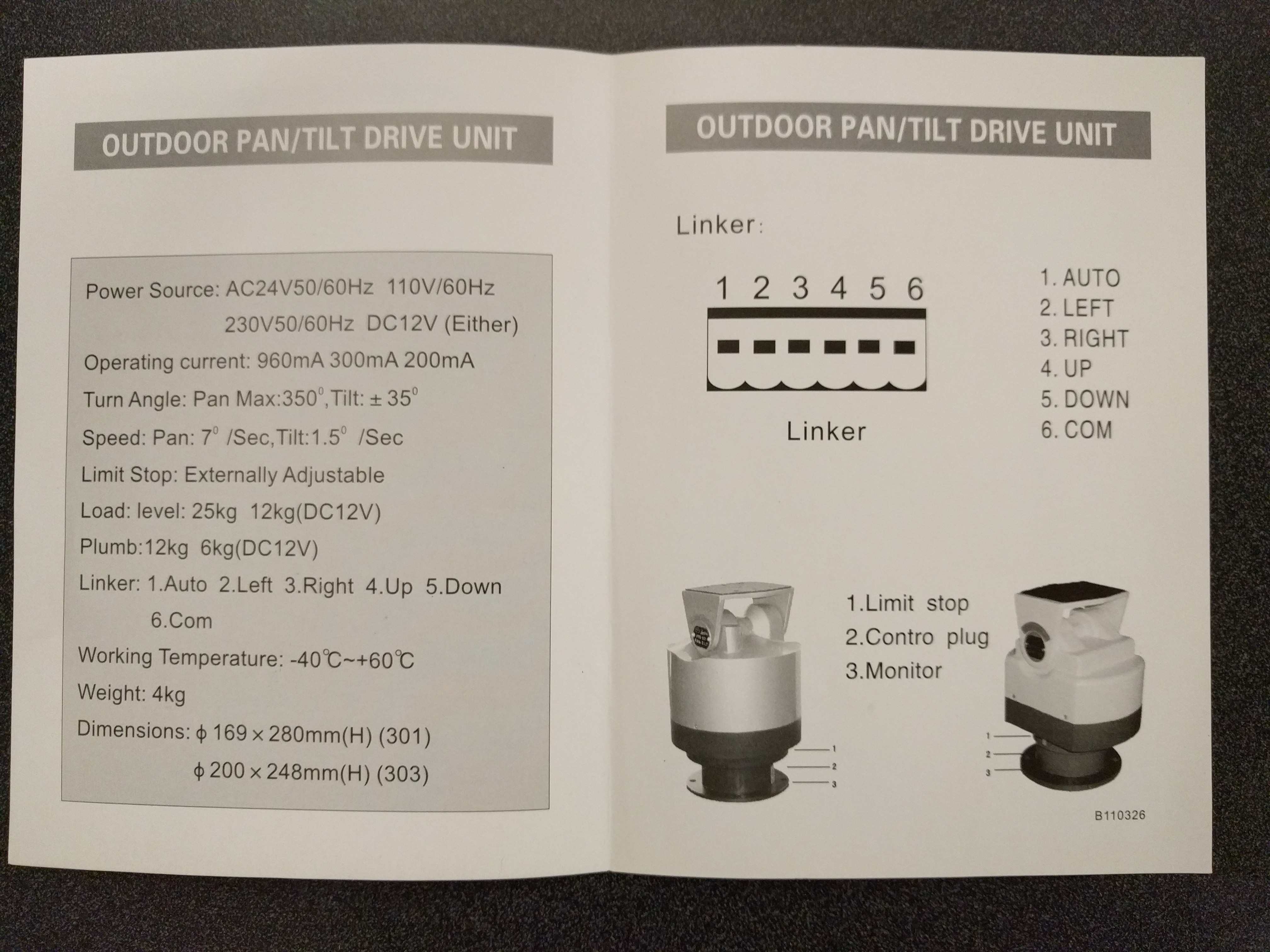

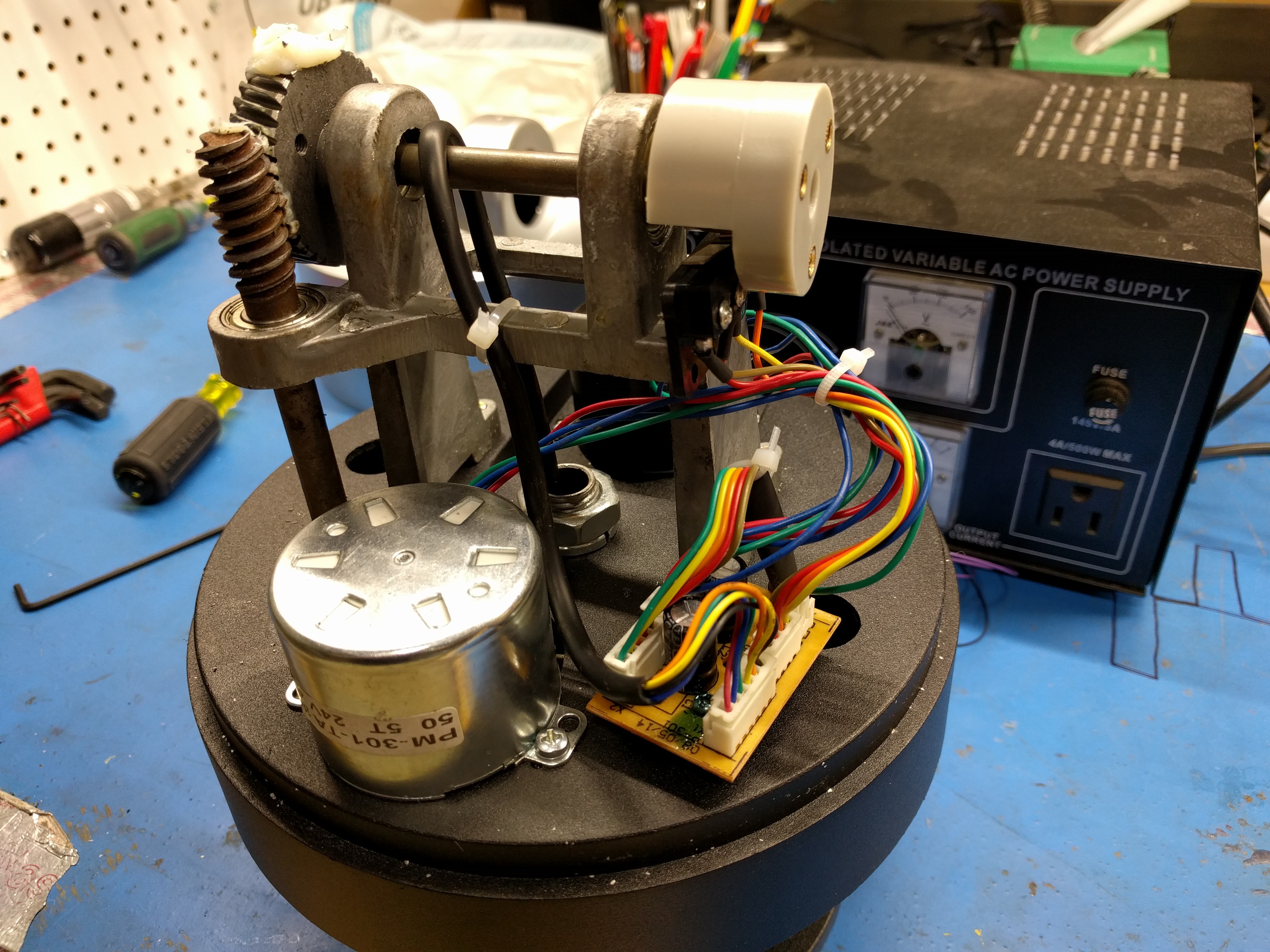

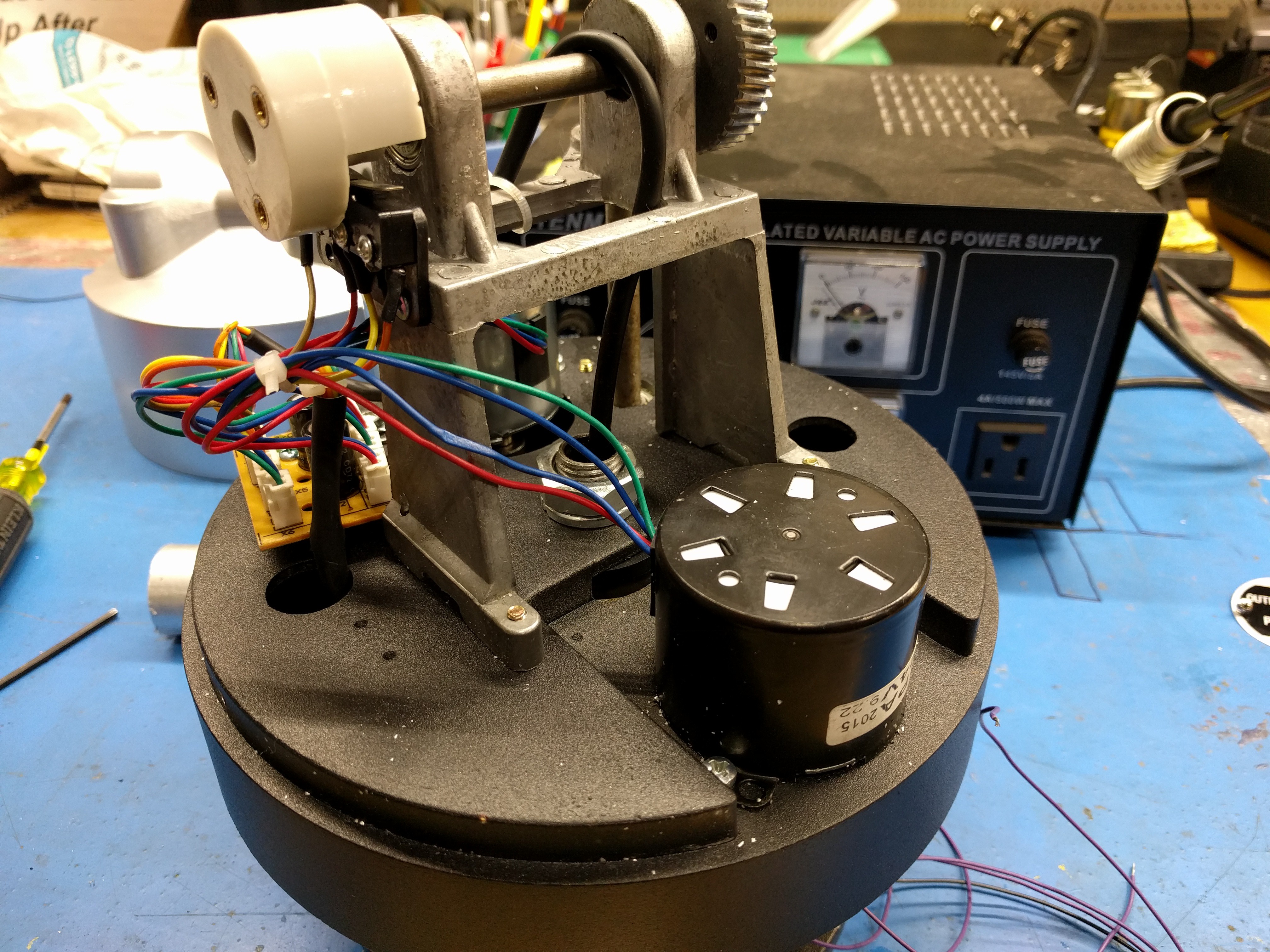

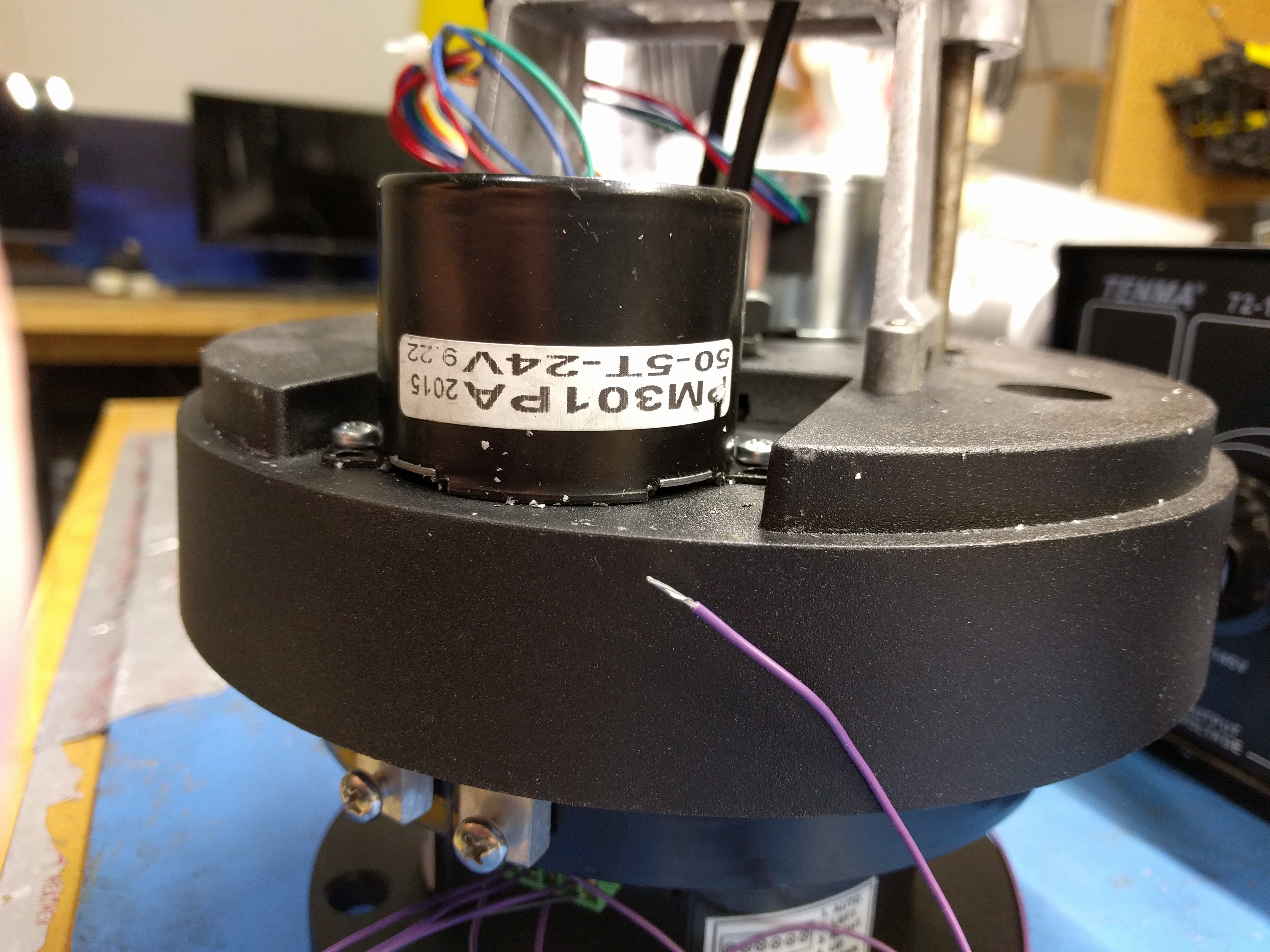

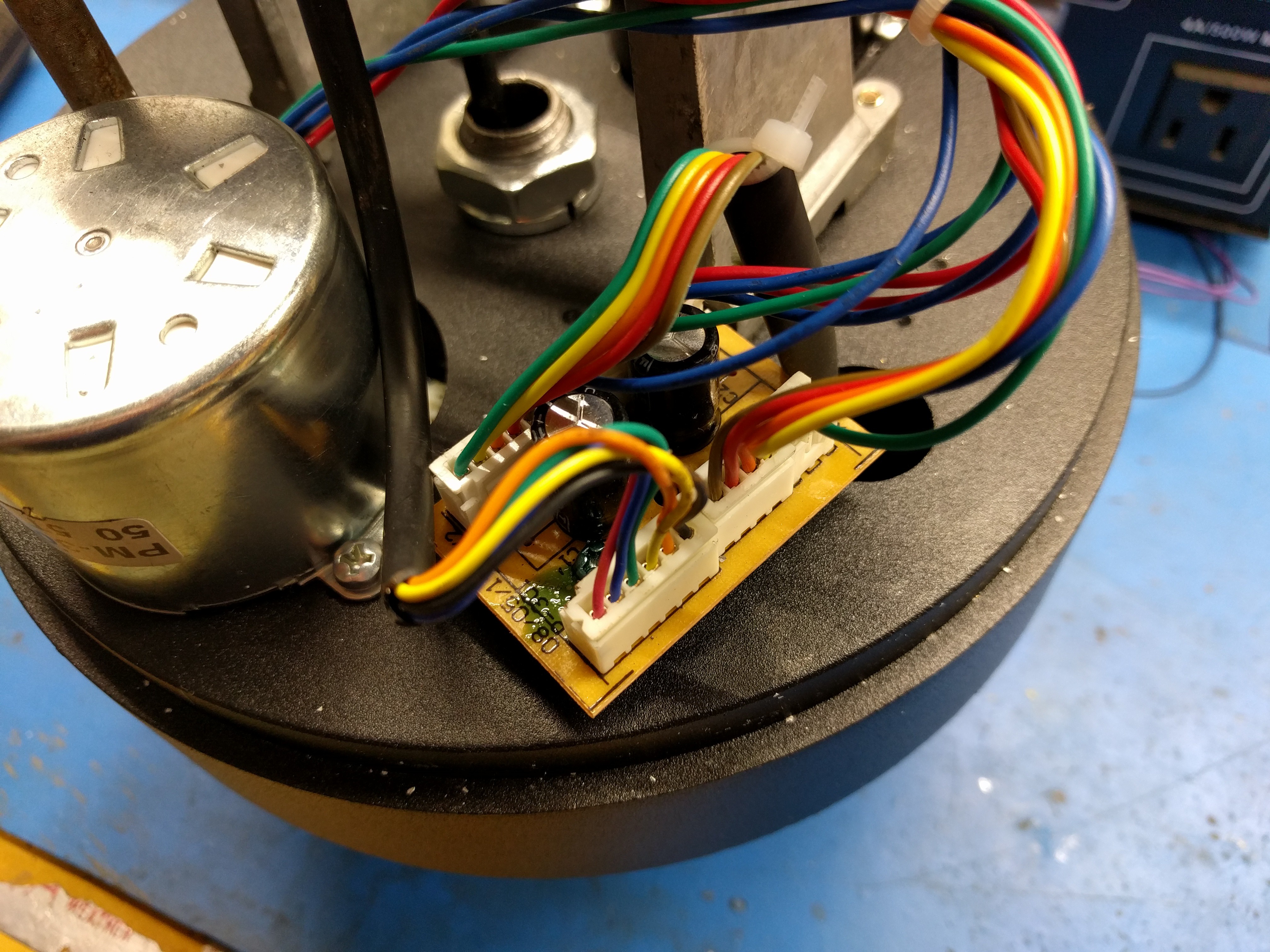

The intention of this project is to use as many low cost off-the-shelf components as possible. Starting out with the lowest cost heavy duty outdoor pan/tilt stage I could find, plus a regular irrigation solenoid valve. Both parts are well-reviewed and are outdoor rated, so I don't need to try and re-invent the mechanical parts.

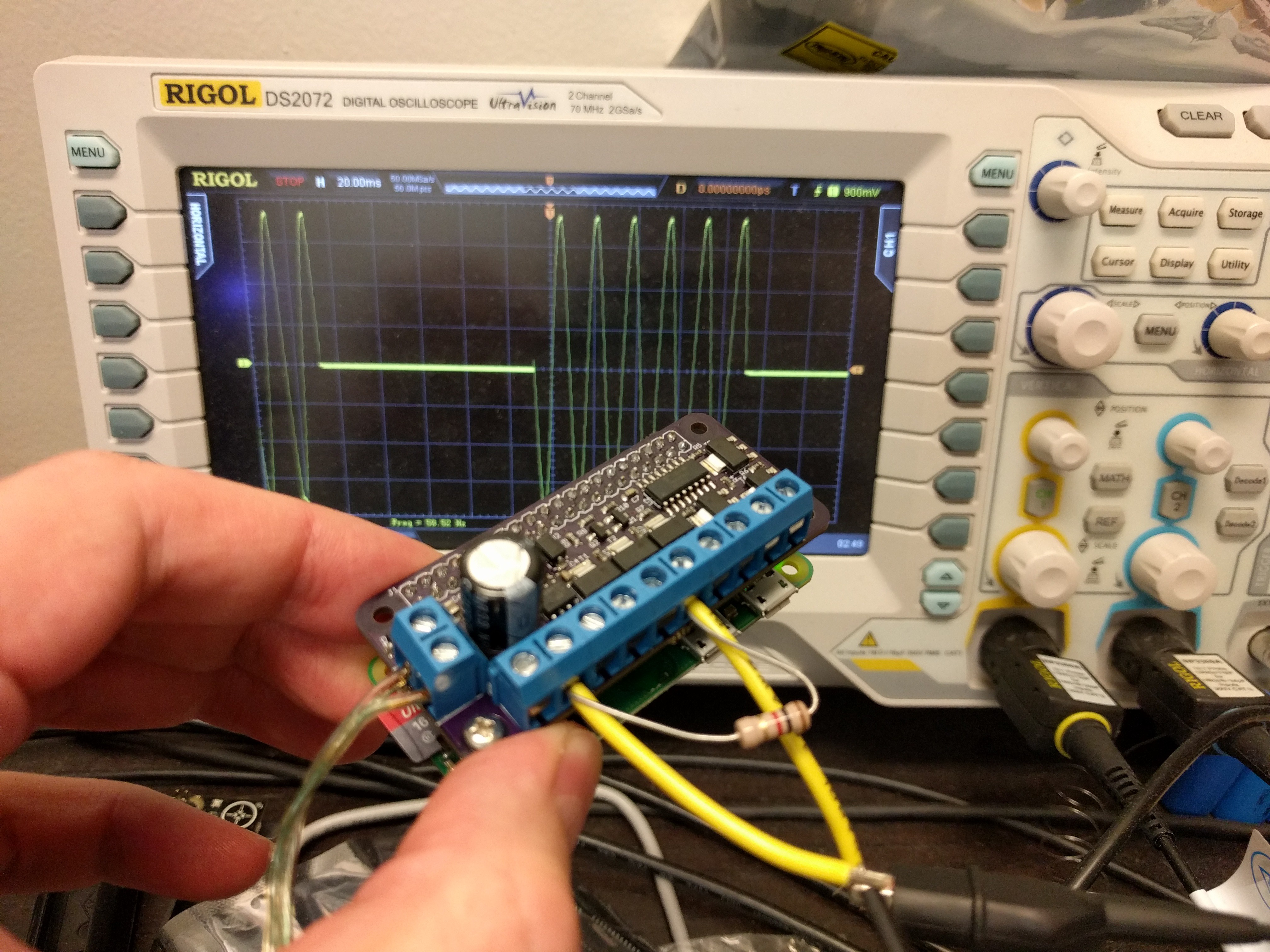

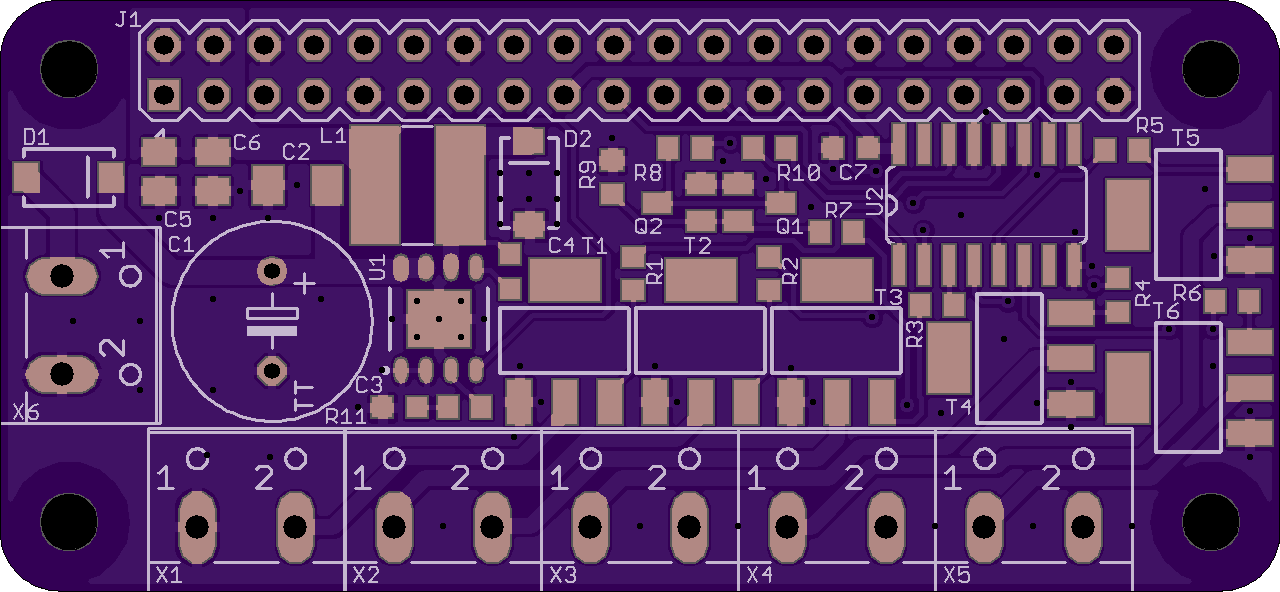

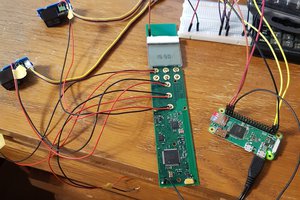

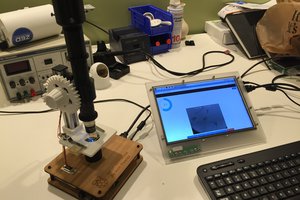

I will probably build some custom electronics to control these components from a Raspberry Pi.

The idea for setting it up is that the user would turn on the water and then manually control the valve, guiding it along the outline of the polygon that makes up the boundary of the area to be watered. Software would then simplify the polygon and calculate a fill pattern (or maybe two fill patterns crossed for better coverage), and move the spray along the calculated pattern across the lawn, taking into account the wider, less dense spray in the distance compared to the narrow, hard spray close to the spray head.

The goal is to cover the lawn evenly, and reduce overspray on sidewalks and driveways as much as possible, to use the minimal amount of water necessary to achieve the goal of keeping my lawn green through the summer. Other smart features such as scheduling based on time and weather forecast, integration with humidity sensors etc. may be added as the project progresses, but the first goal is even, accurate watering to significantly reduce waste associated with traditional sprinkler systems.

Patrick Van Oosterwijck

Patrick Van Oosterwijck

Psycho

Psycho

Alan

Alan

jdelbe

jdelbe

Great project Patrick!

You've been putting a lot of thought into it. Love what you did. Since you disassembled the Defender, do you know if the motors are stepper motor or dc motor?

Thanks!