-

Waving Arm for Blinky

04/20/2017 at 00:21 • 0 commentsI ran across a cool project, "Poppy", an open source bi-ped robot complete with all manner of 3d print files and instructions. I printed one hand and arm--then knew that Blinky needed this to provide a friendly "wave."

![]()

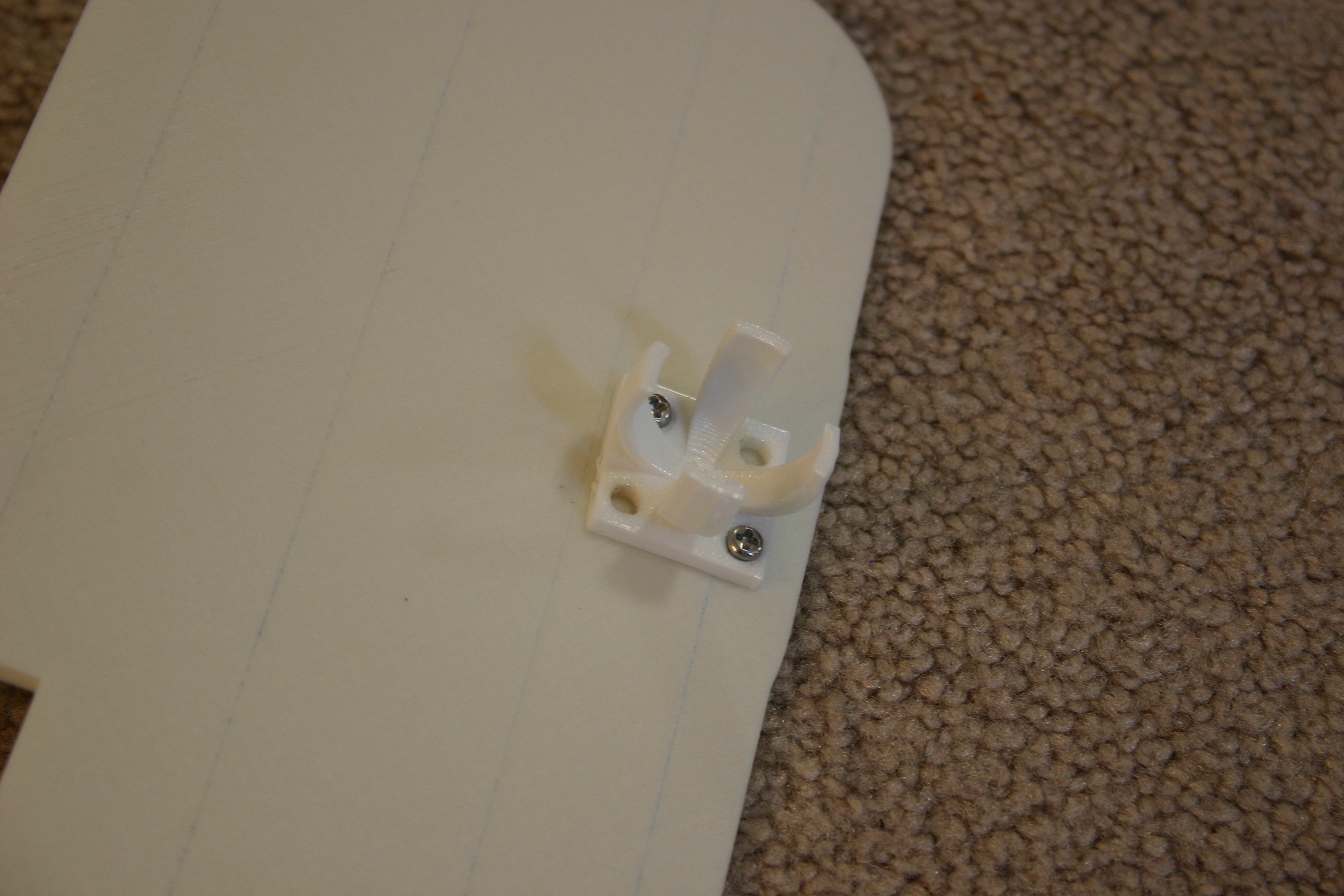

I slid the hand into the arm and fastened them together using 2-56 machine screws.

![]()

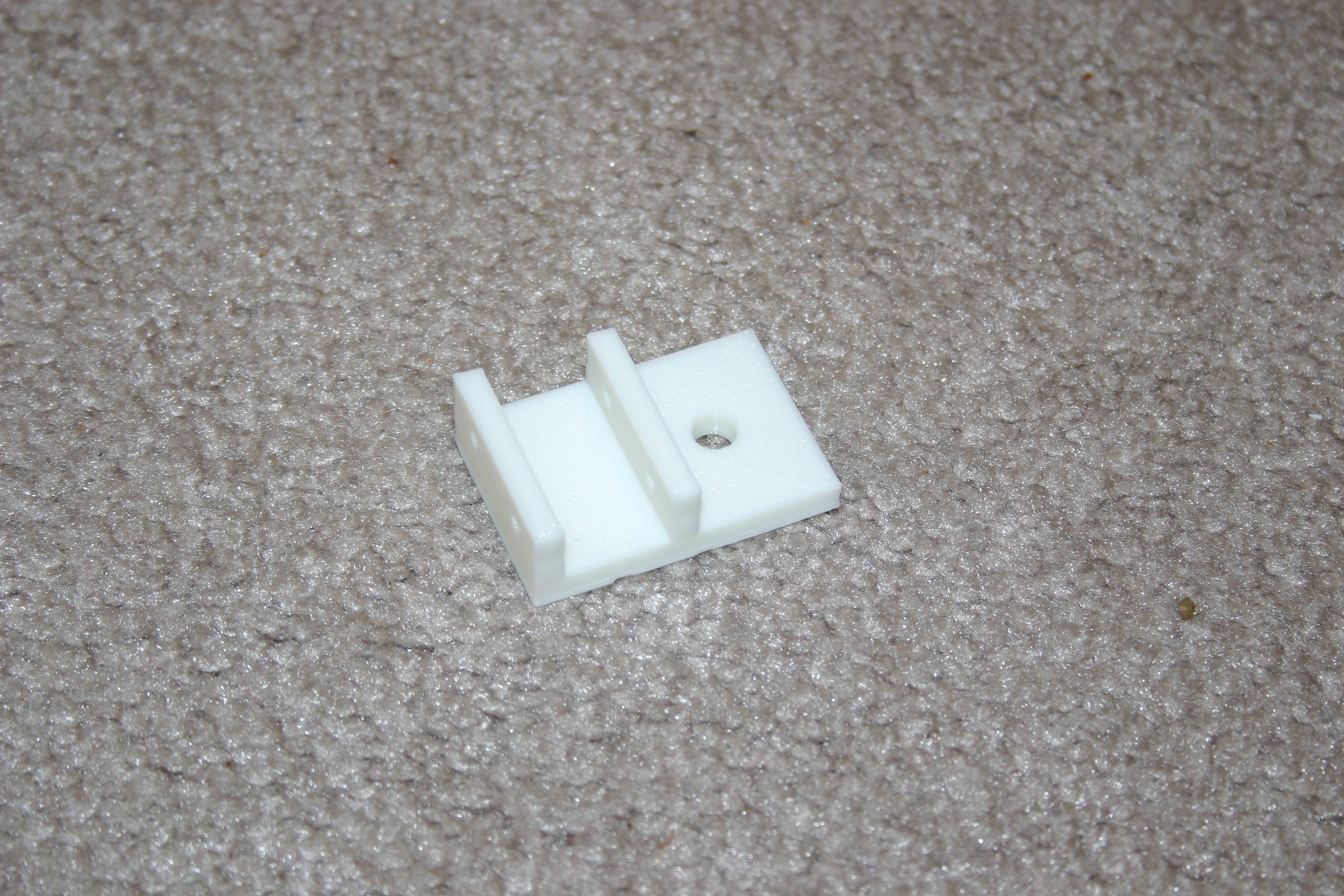

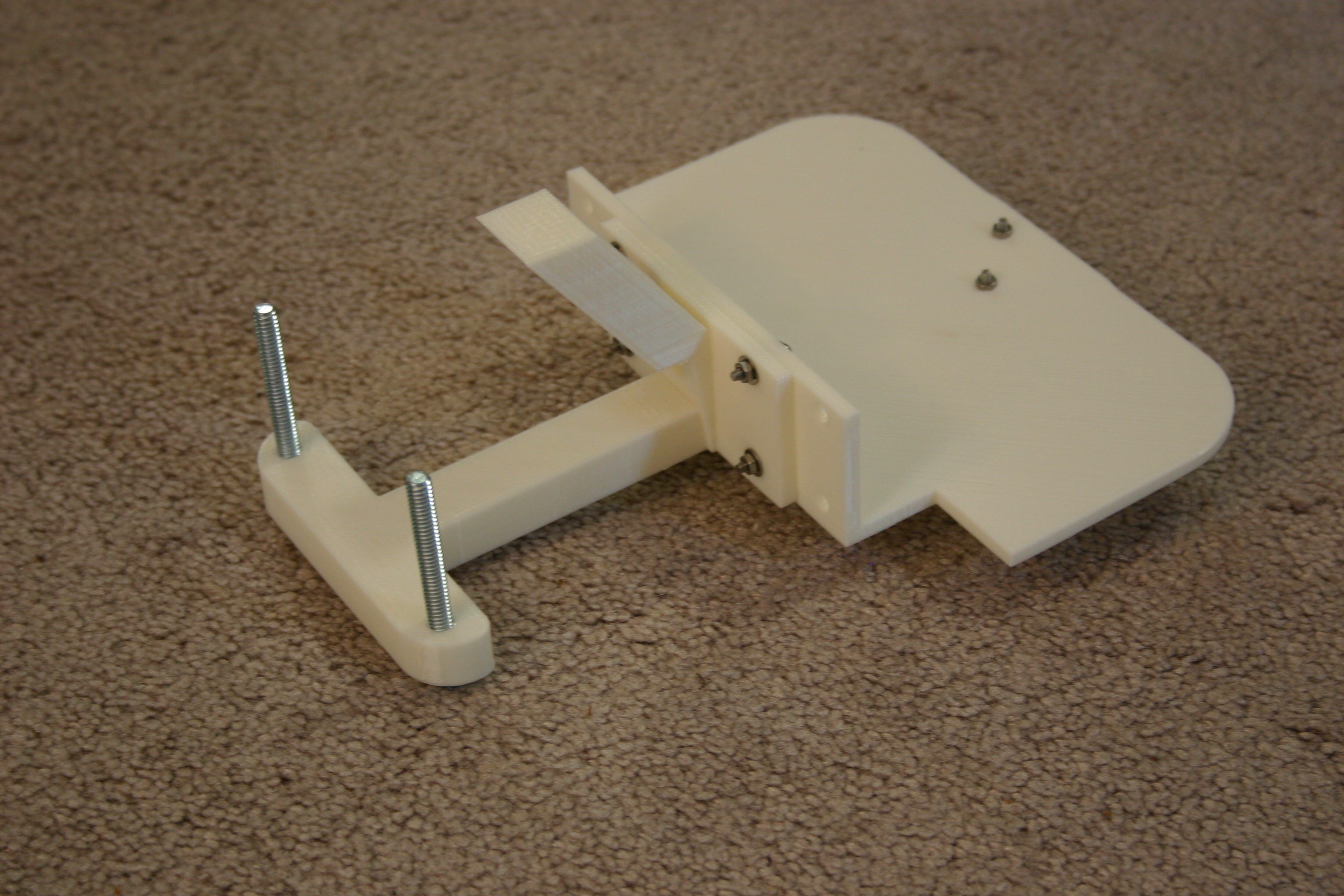

I attached the arm to a servo horn using 2-56 machine screws and nuts.

![]()

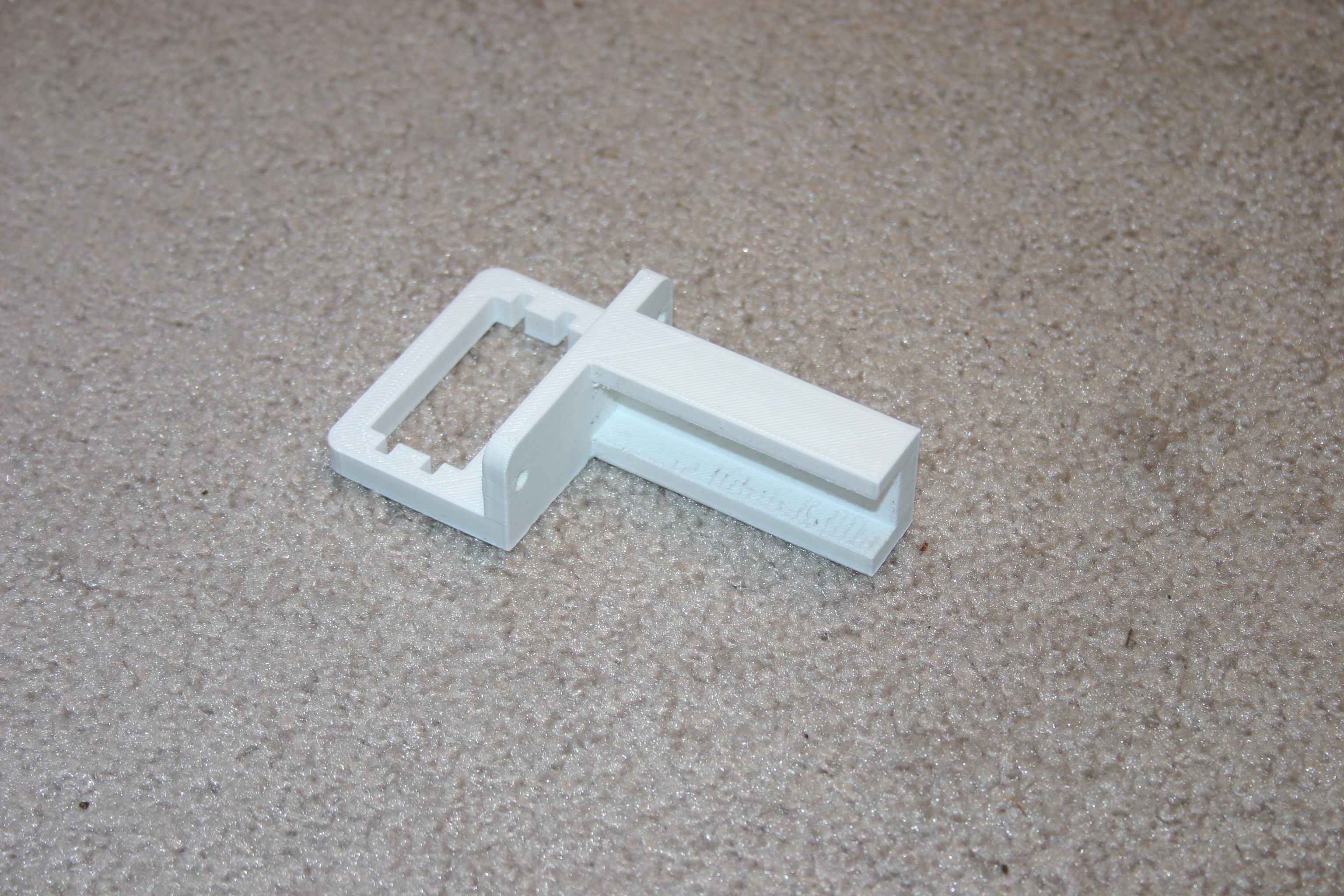

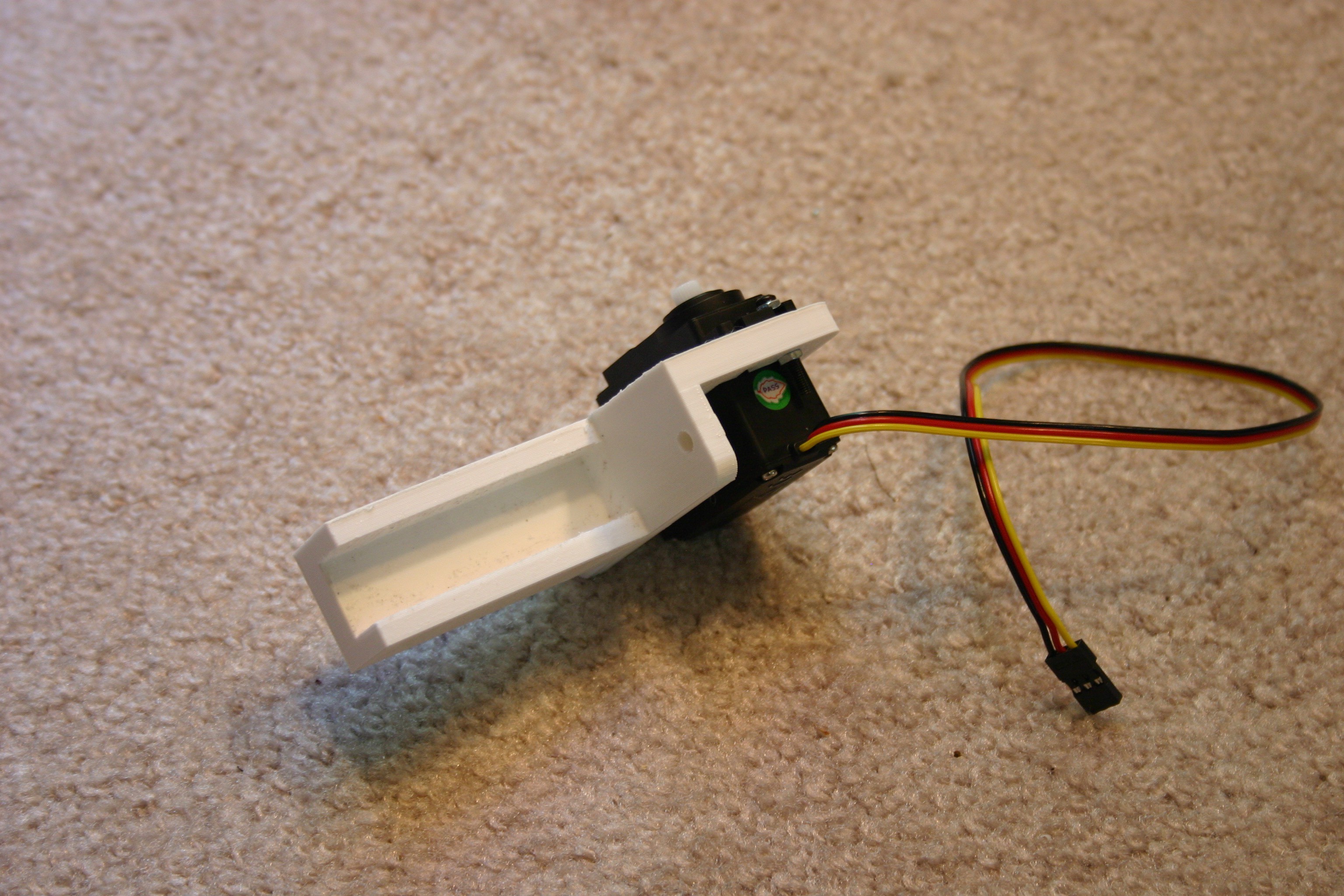

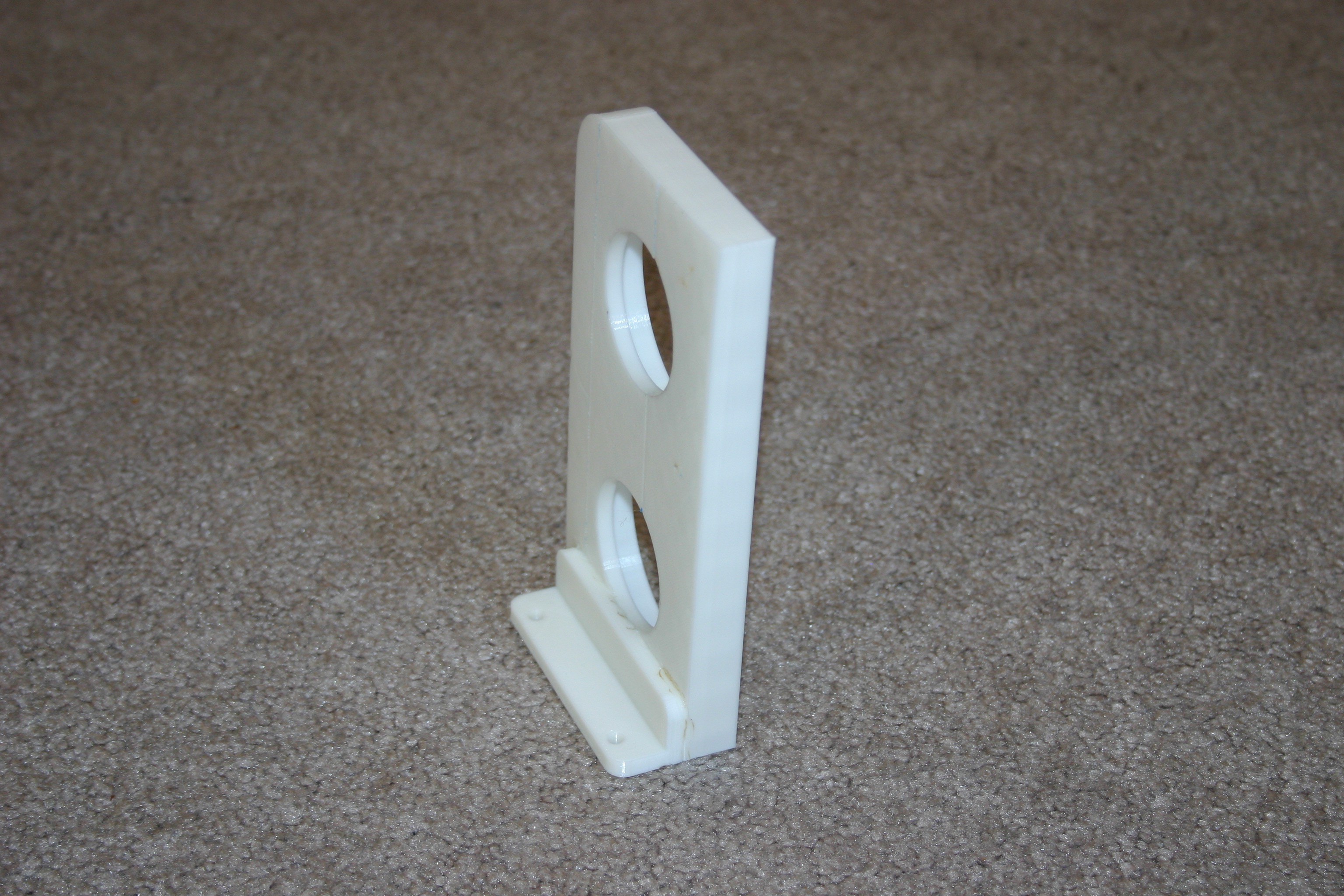

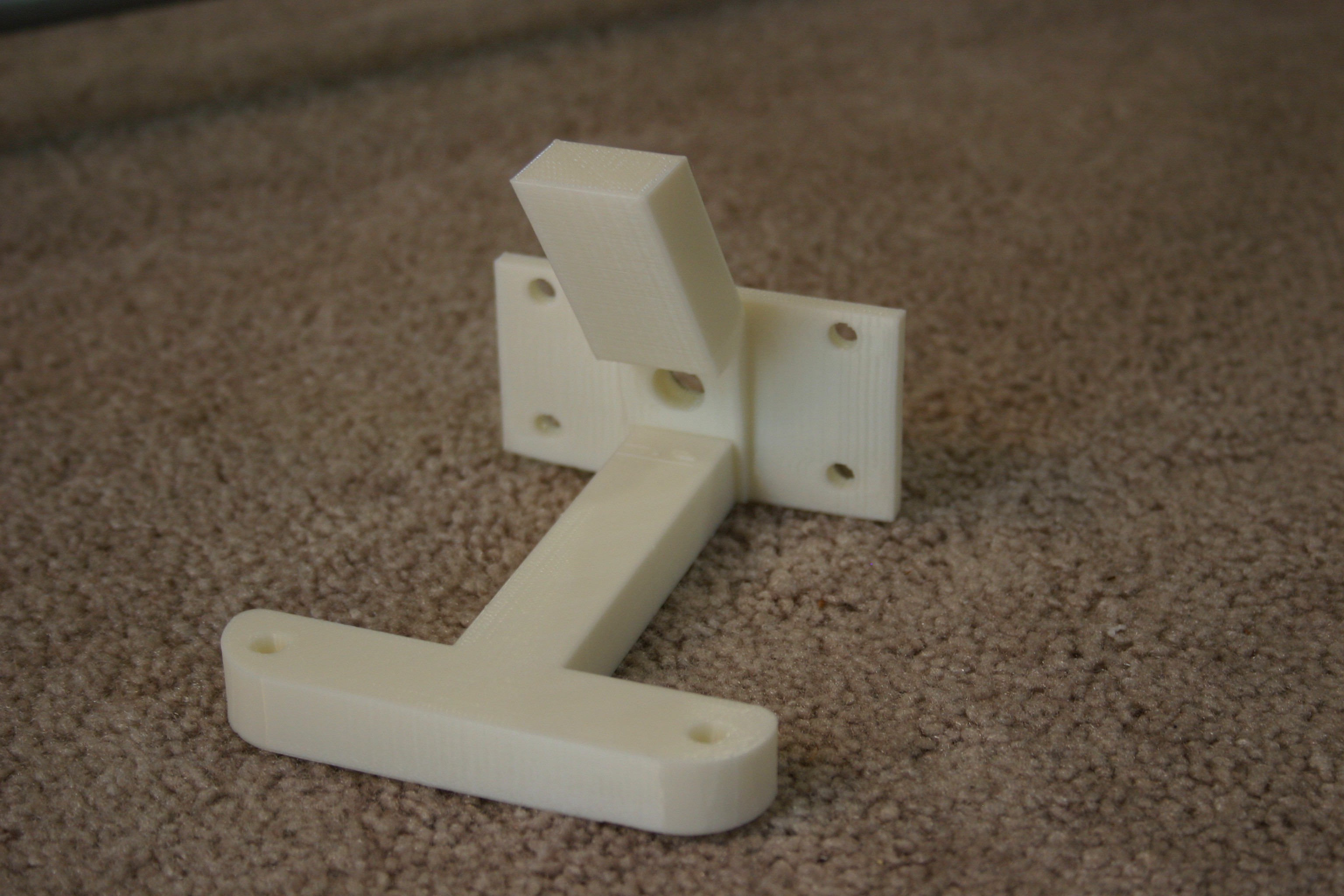

I printed a bracket to hold the servo motor and attach to the ultracapacitor frame.

![]()

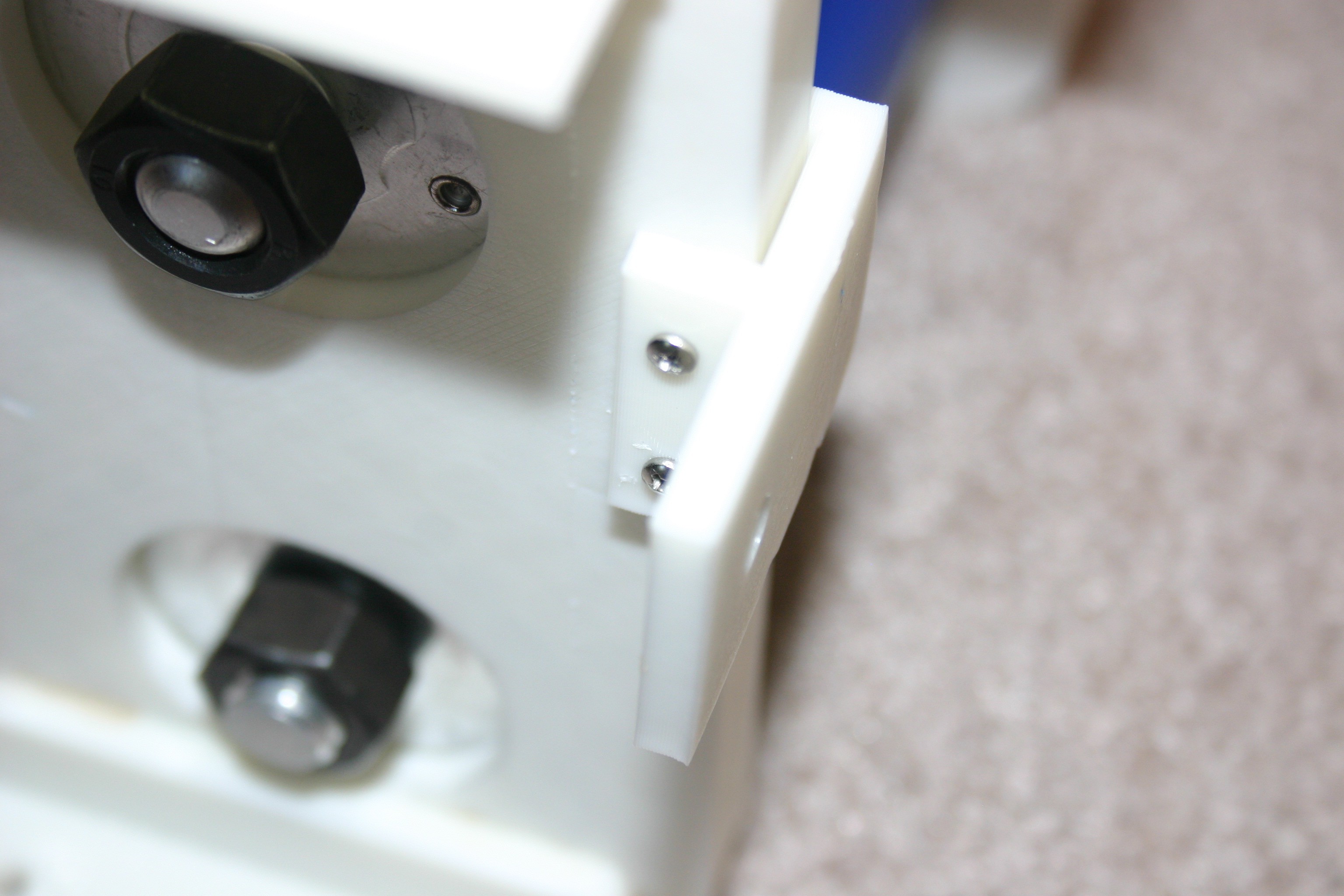

I placed the servo motor in the frame and secured it with 2-56 machine screws and nuts.

![]()

I attached the arm to the servo motor using the servo horn screw.

![]()

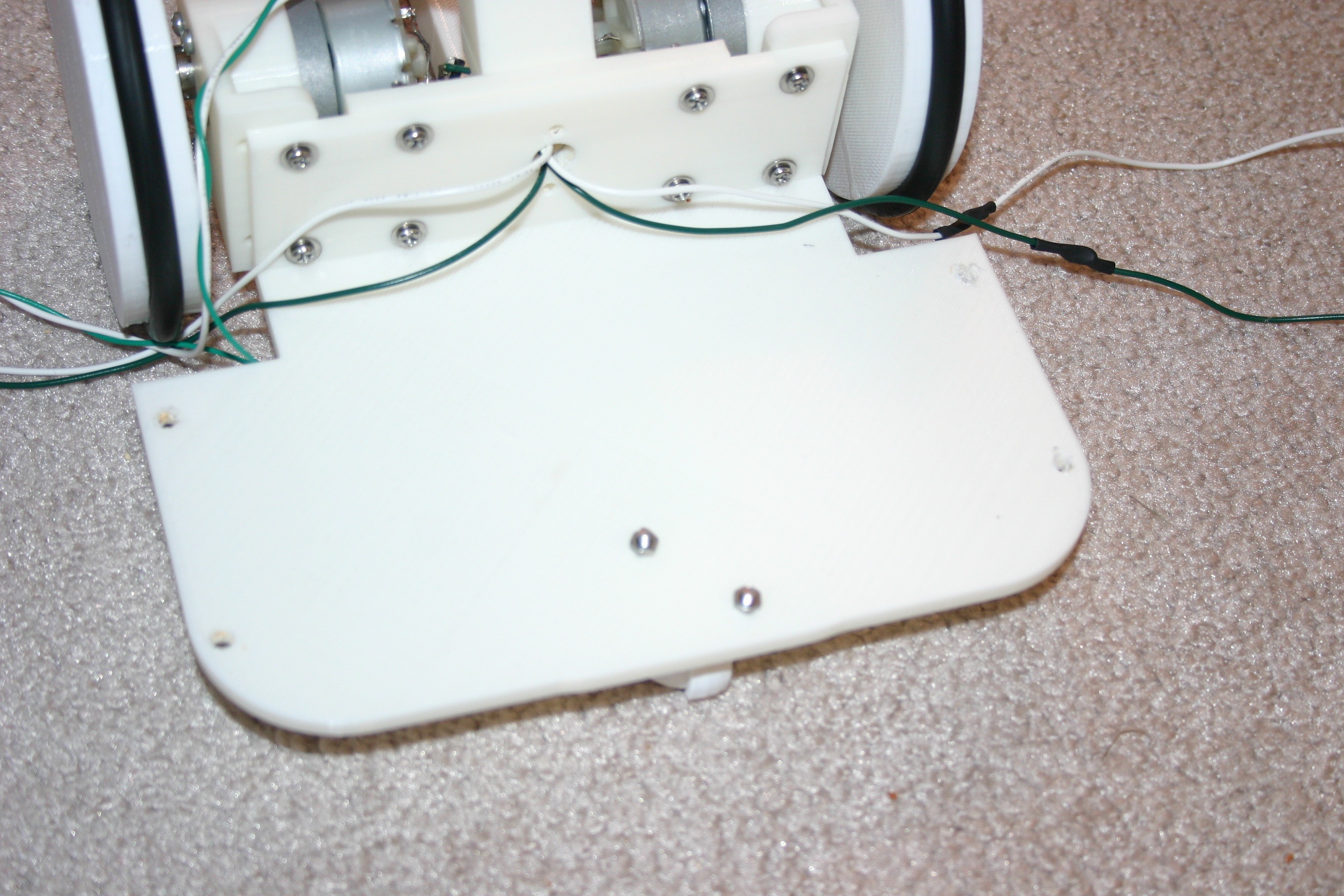

I press fit the bracket onto the back of the ultracapacitor frame. I'll secure it and work out the control electronics and software in a later phase.

![]()

-

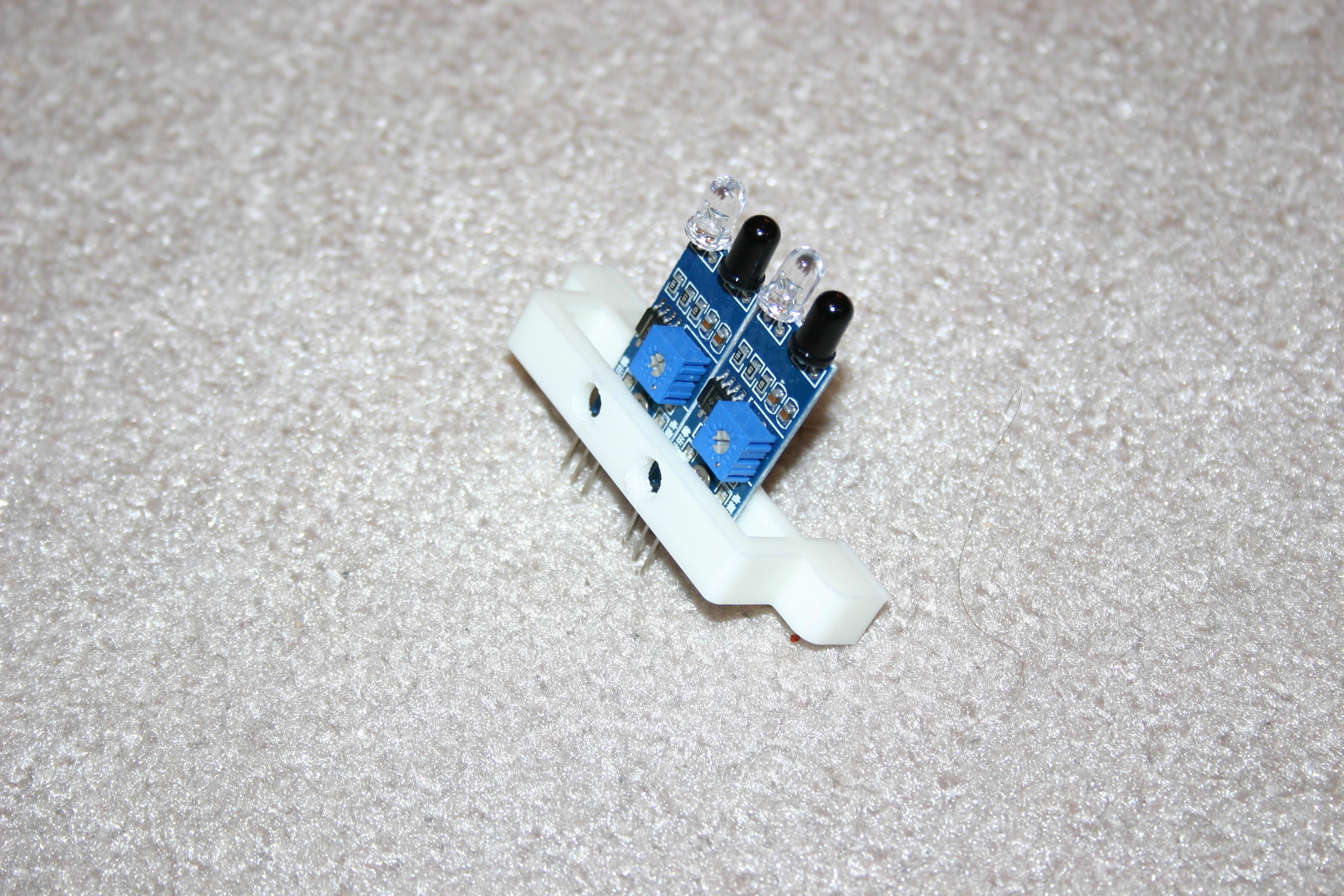

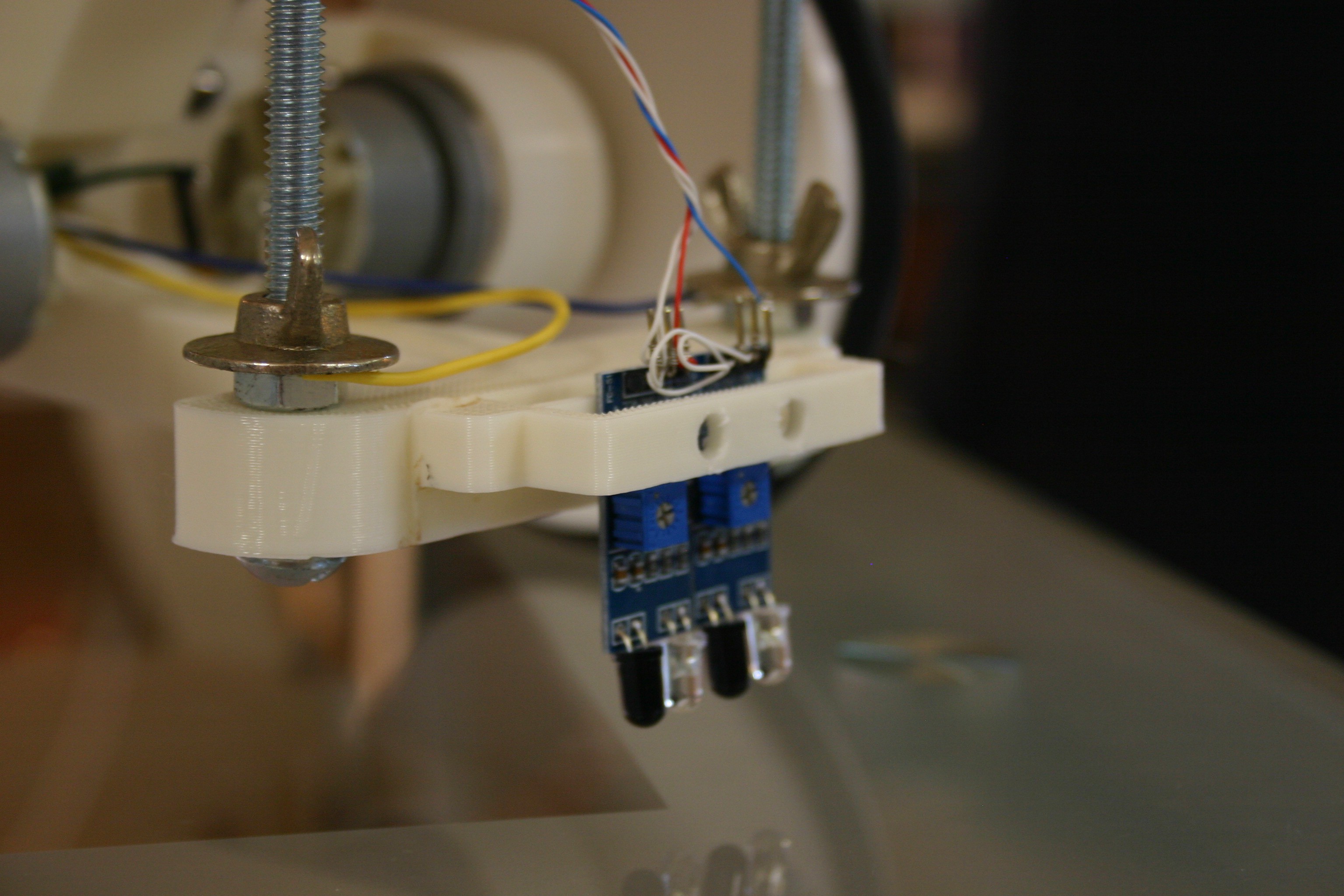

Line Detect Sensor

04/19/2017 at 17:56 • 0 commentsIn this step I am adding two infrared line detectors--part of the homing system to reach the charging station.

First, the sensors are mounted to the line detect holder.

![]()

Next, the holder is melted to the front bumper of Blinky.

![]()

-

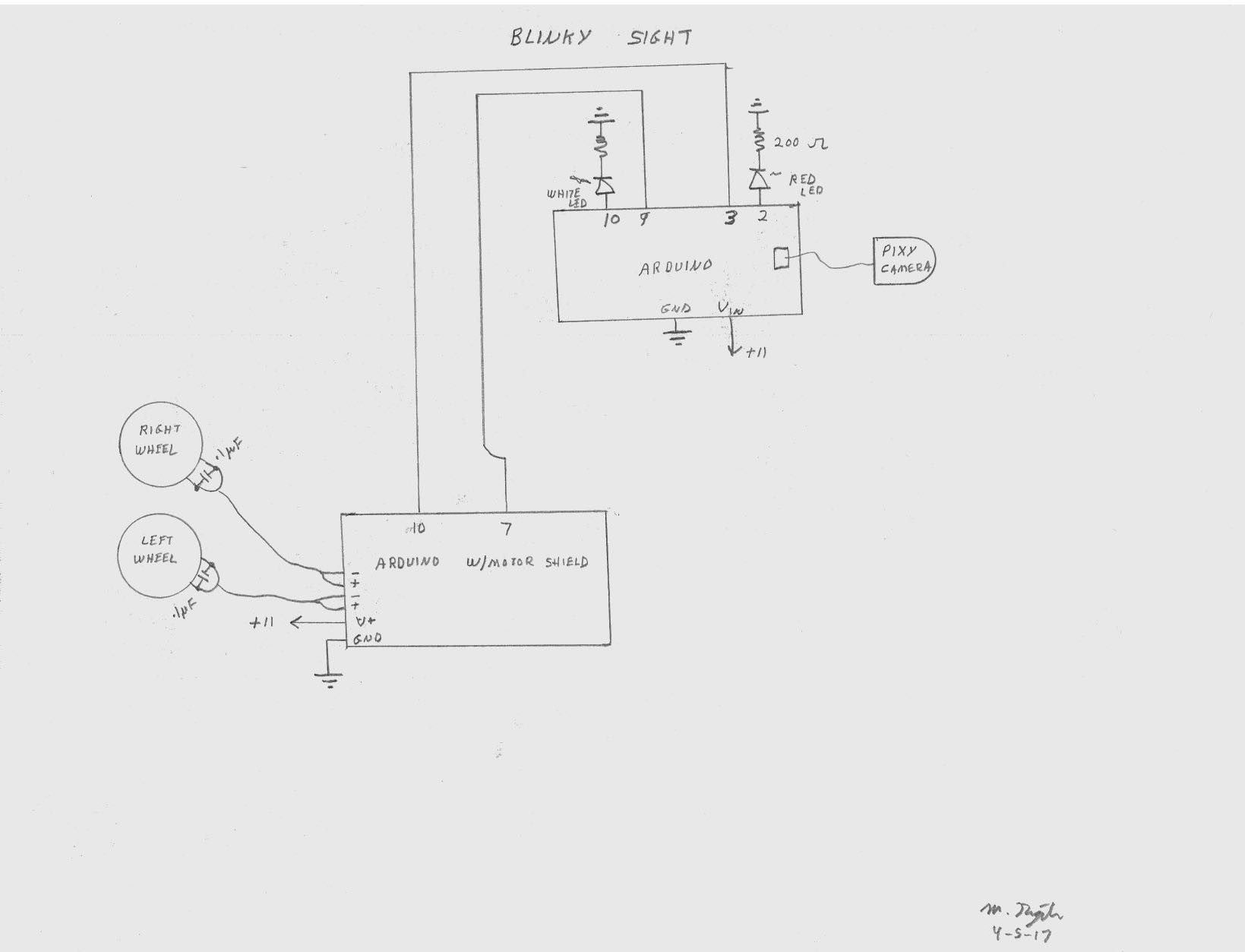

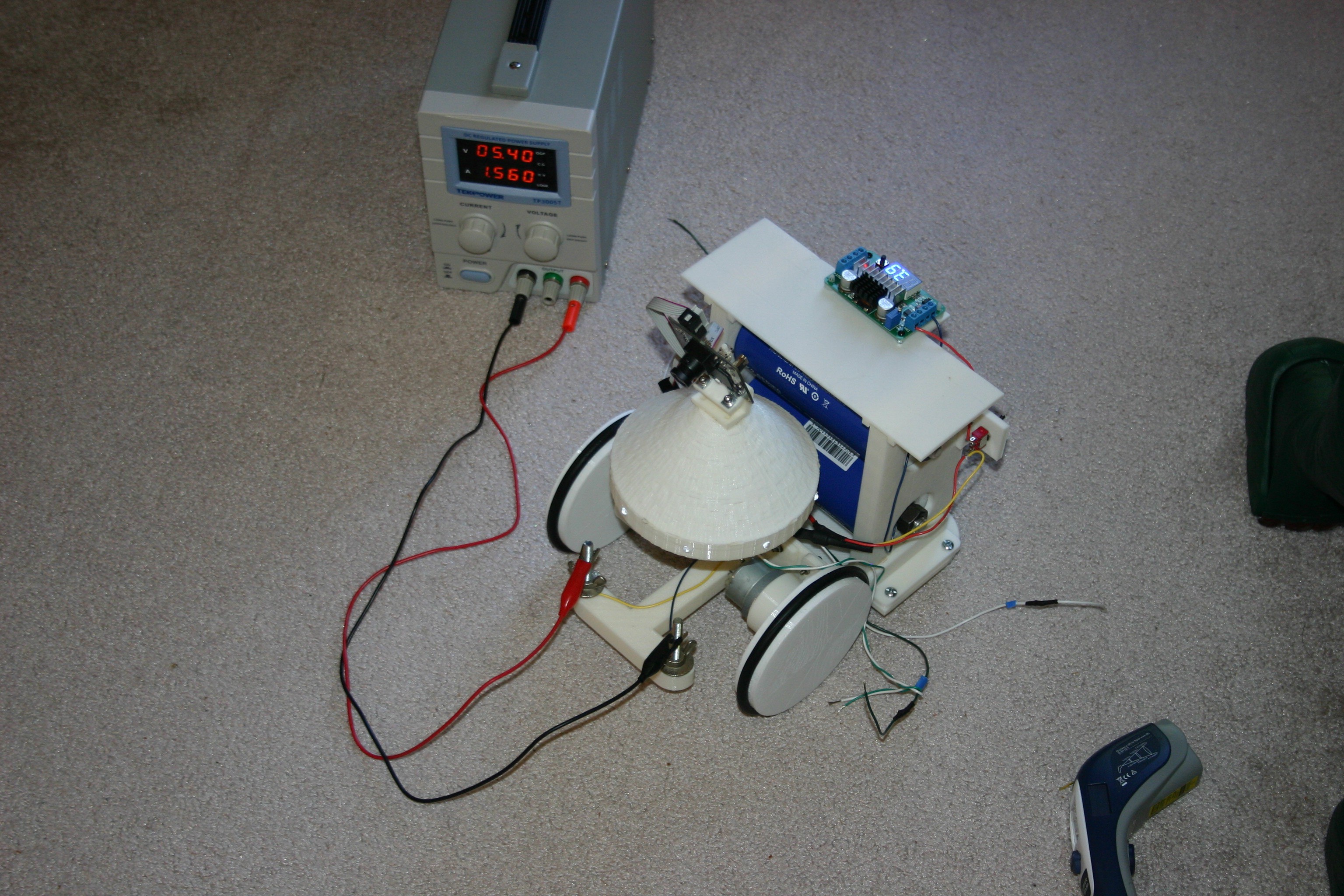

Moving Toward Home

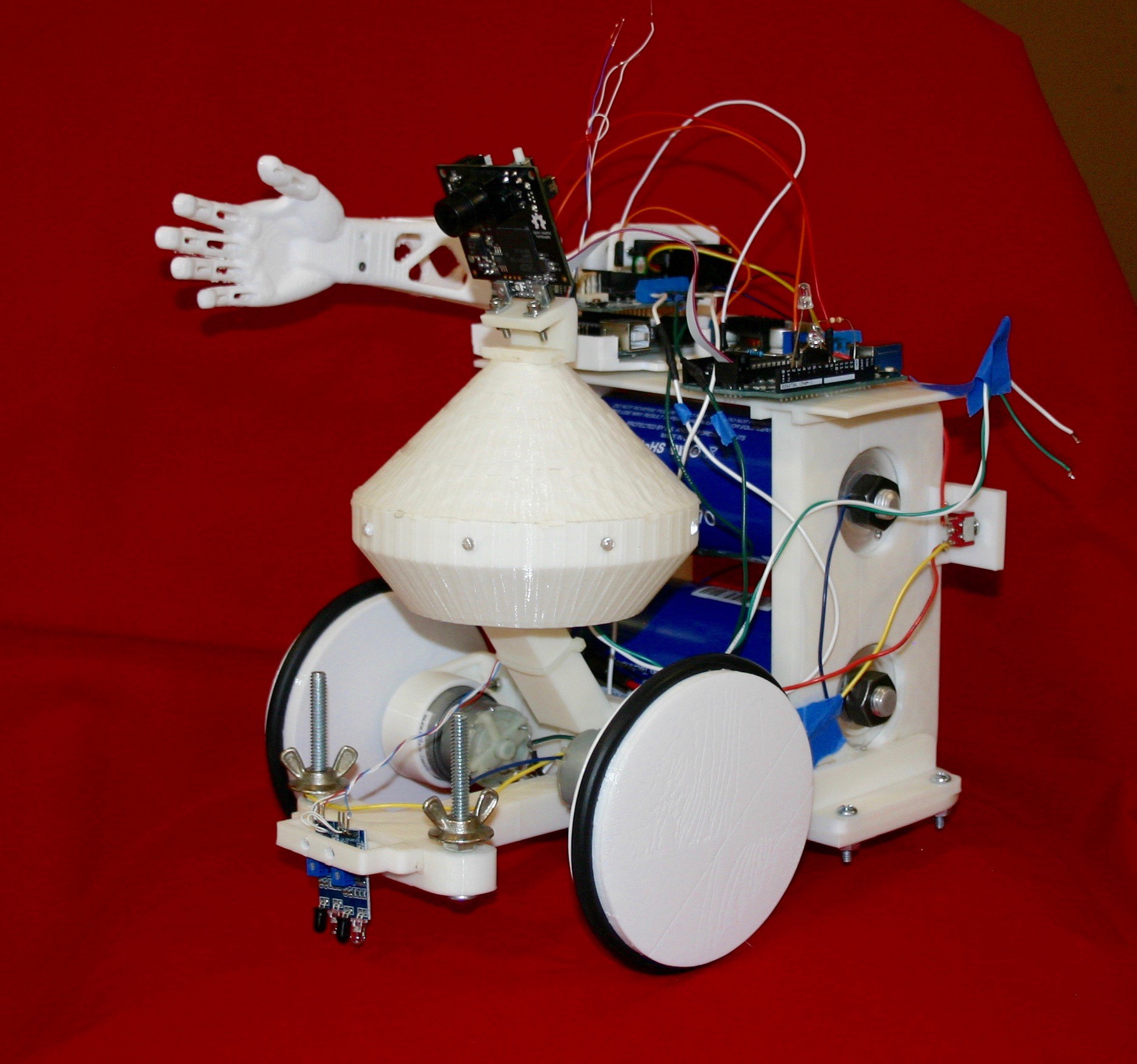

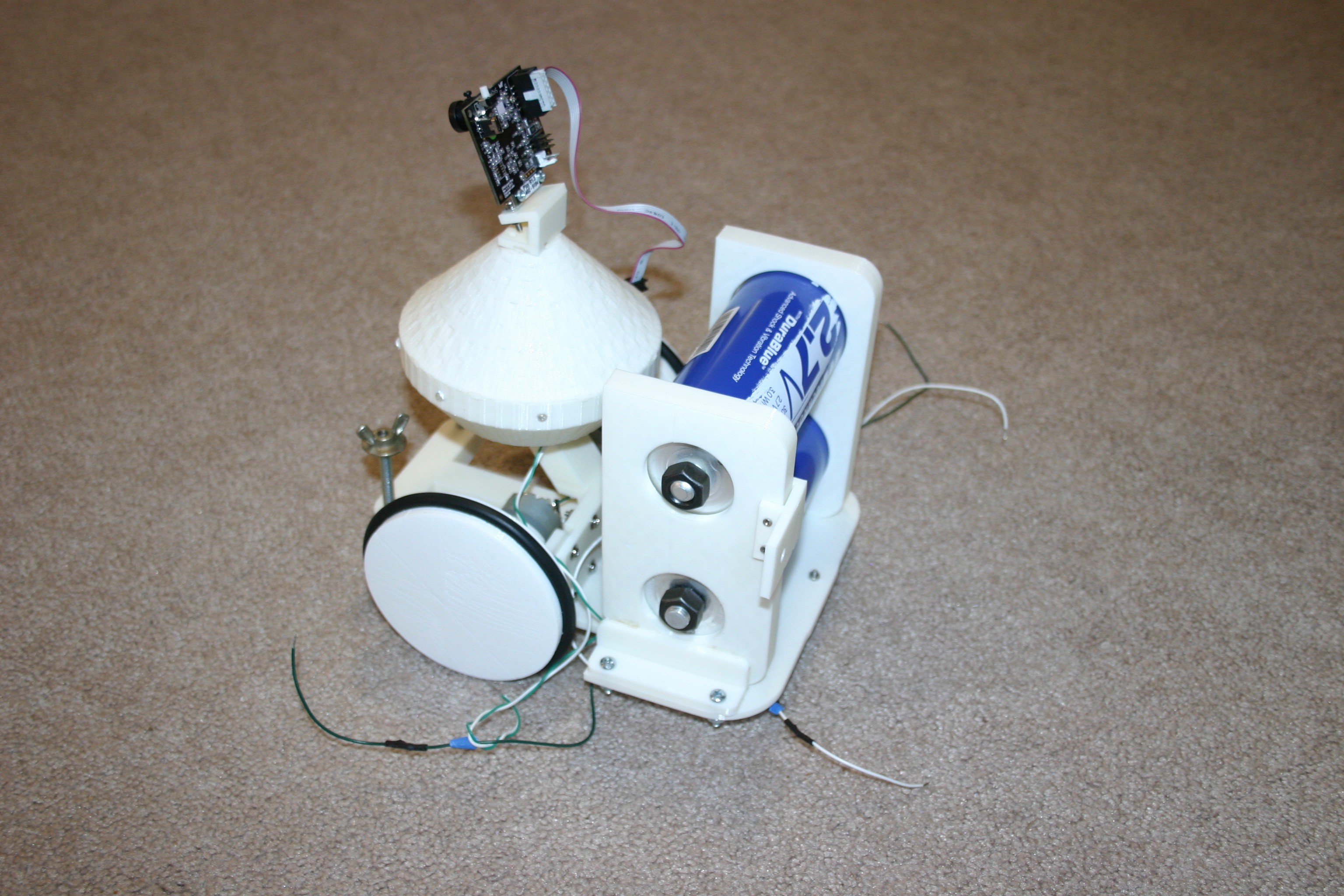

04/05/2017 at 17:22 • 0 commentsBlinky now has vision and is able to move toward a "home" target.

The camera is connected to the motor controller according to the schematic below.

![]()

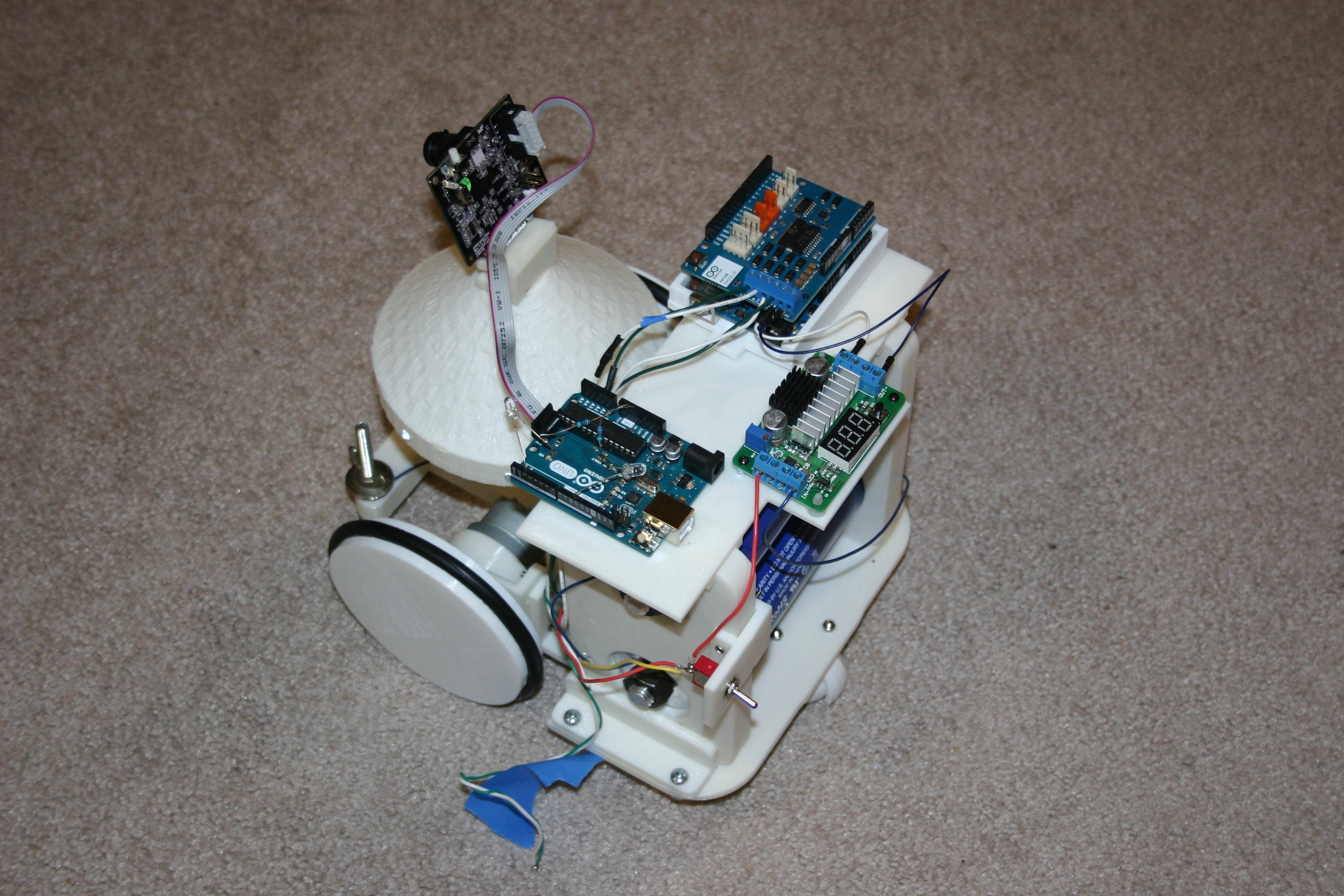

Here's what the top of Blinky looks like with his two Arduino controllers.

![]()

We're not approaching the target color in a controlled manner that would allow for docking--but stay tuned. The vision and motor sketches for the Arduinos are posted on this site.

-

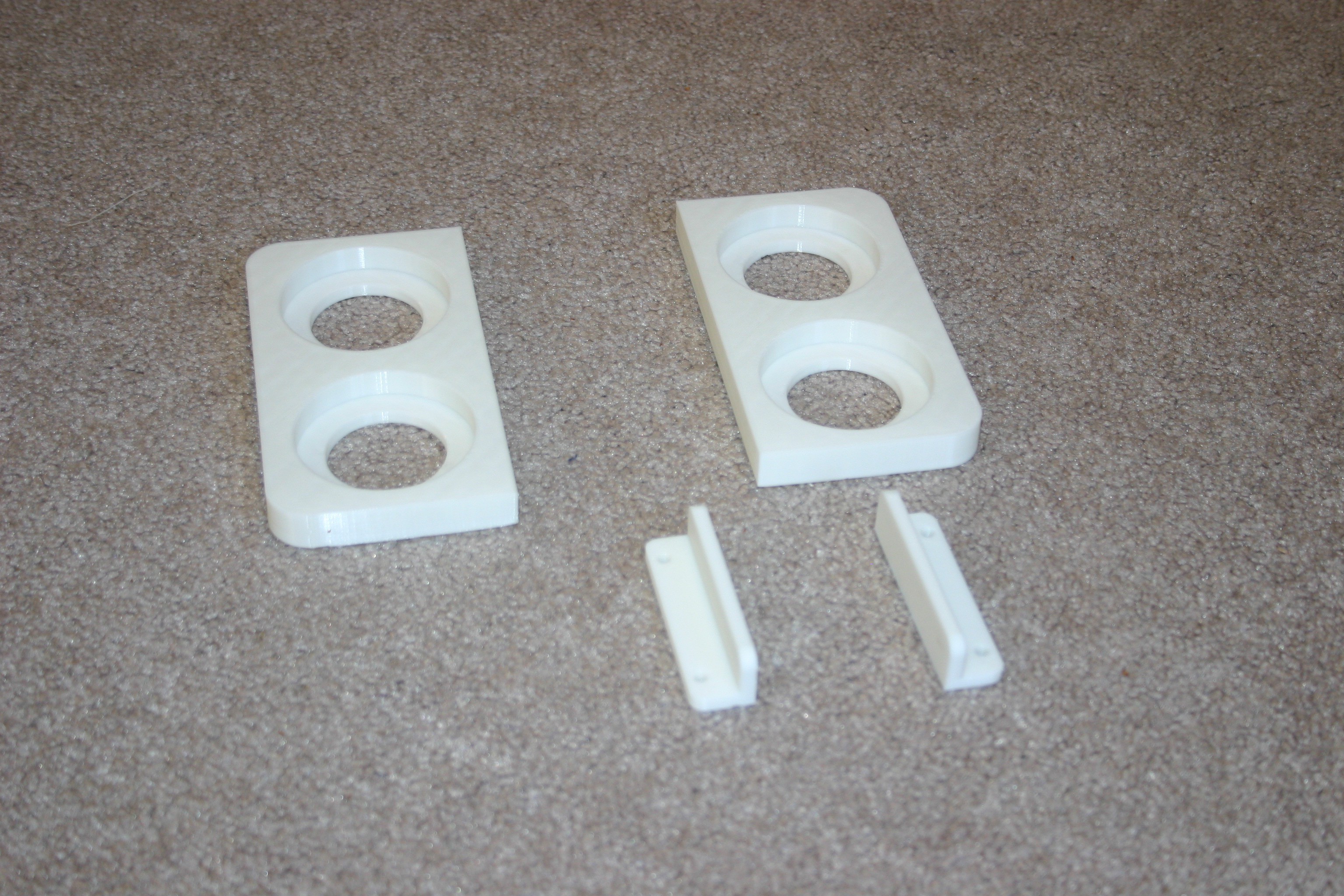

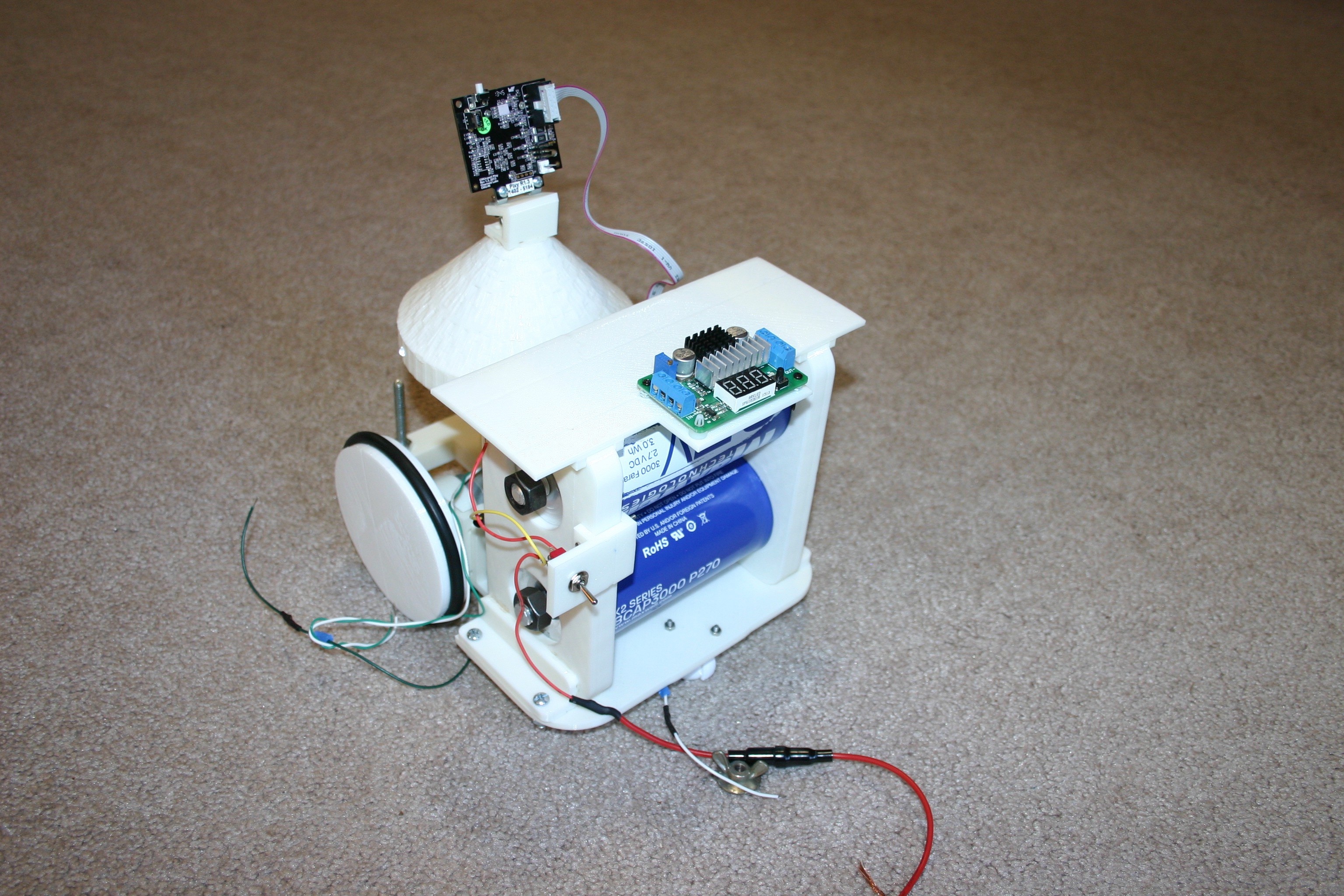

Power

04/02/2017 at 18:51 • 0 commentsToday I work at providing onboard power for Blinky. Print two "ultracap ends" and two "ultracap screw bases."

![]()

Melt the screw bases to the ultracap ends.

![]()

Insert the capacitors and place the assembly onto the chassis of Blinky. Mark the holes for drilling in Blinky's chassis.

![]()

Drill the holes in the chassis.

![]()

Print the switch holder.

![]()

Drill holes and mount the switch holder to the left rear portion of the capacitor holder.

![]()

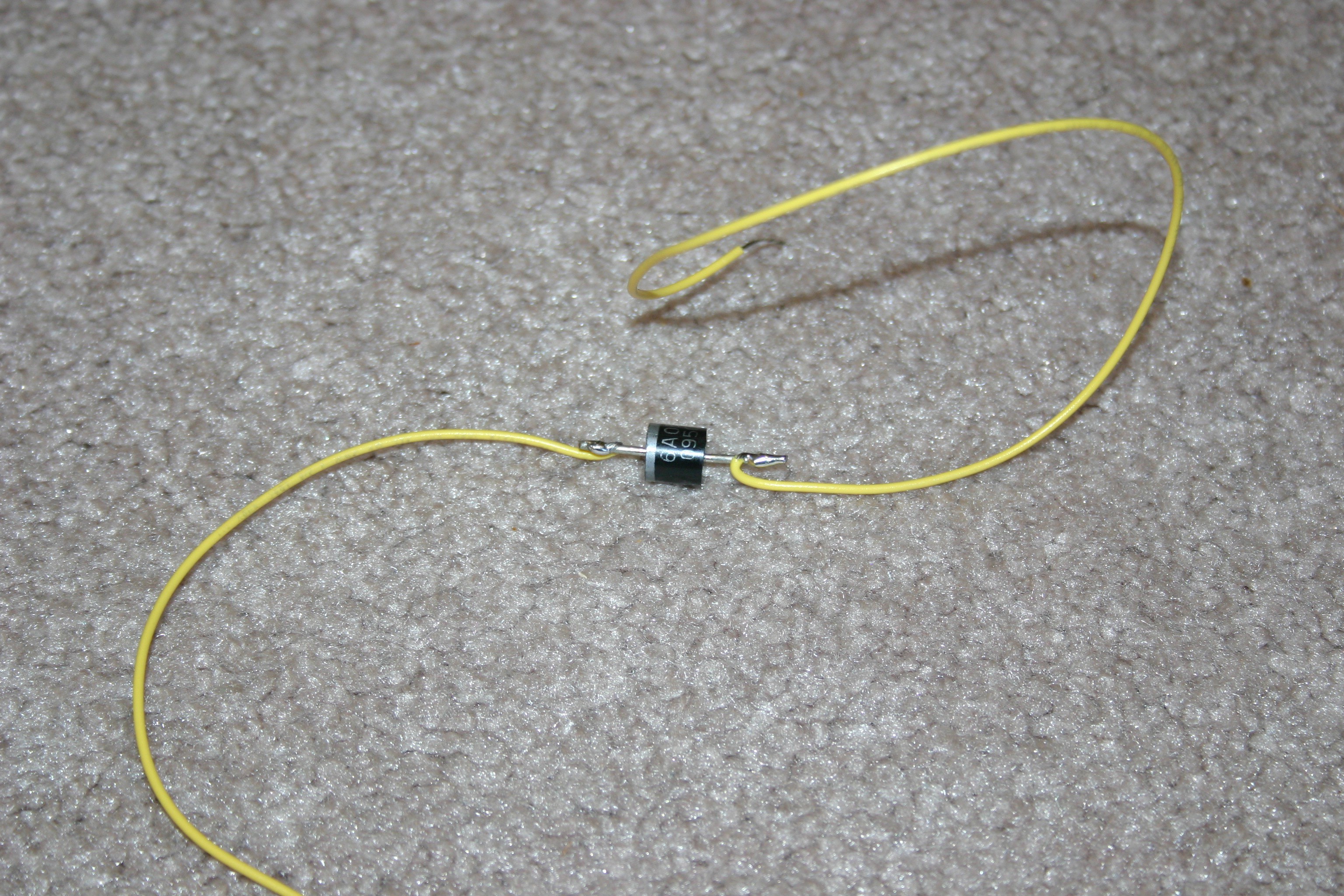

Solder a diode (blocking diode from capacitor to charging post) in the center of a connector wire.

![]()

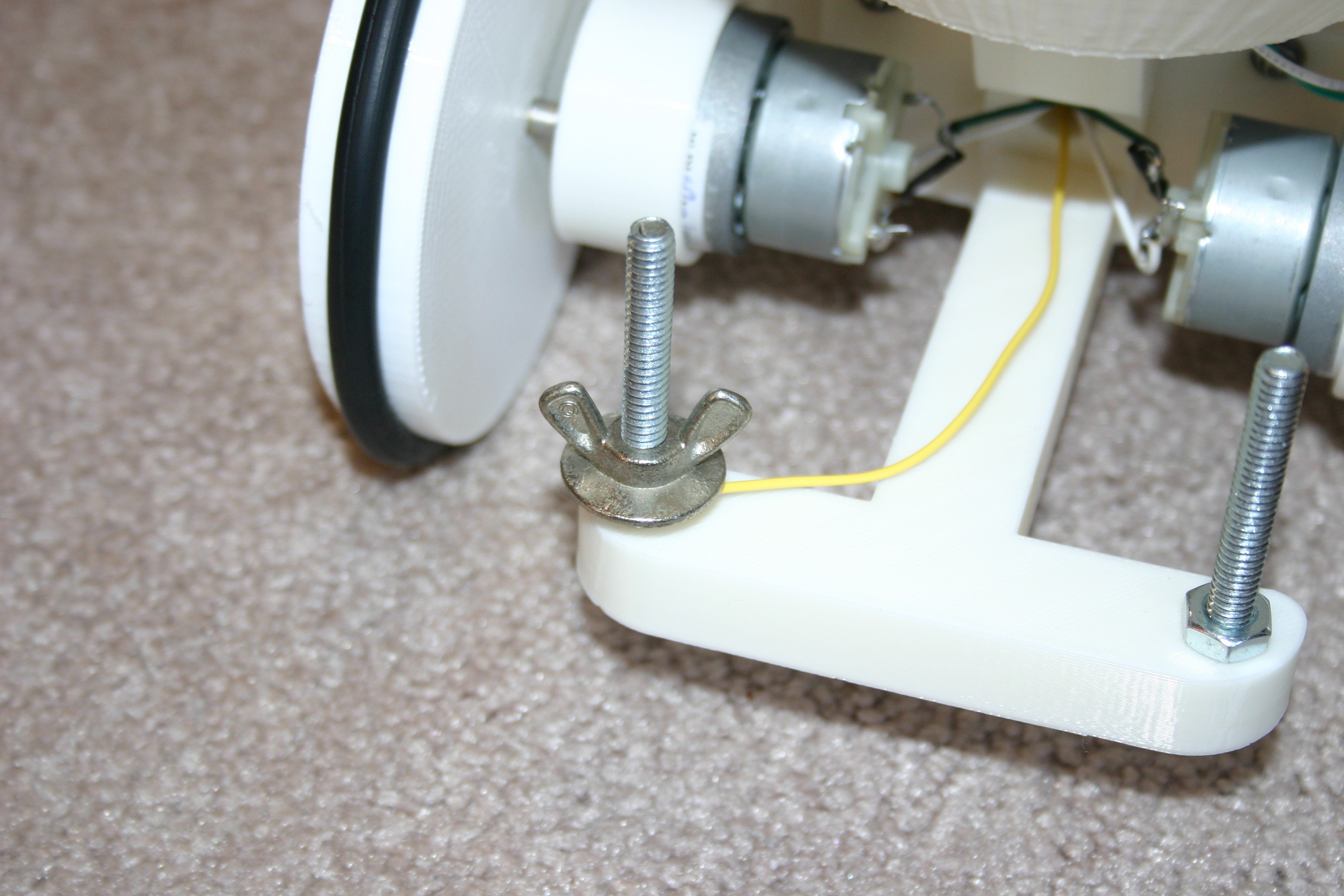

Fasten the anode end of the wire to the right front charging post.

![]()

Secure the capacitor assembly to the chassis with nuts and bolts.

![]()

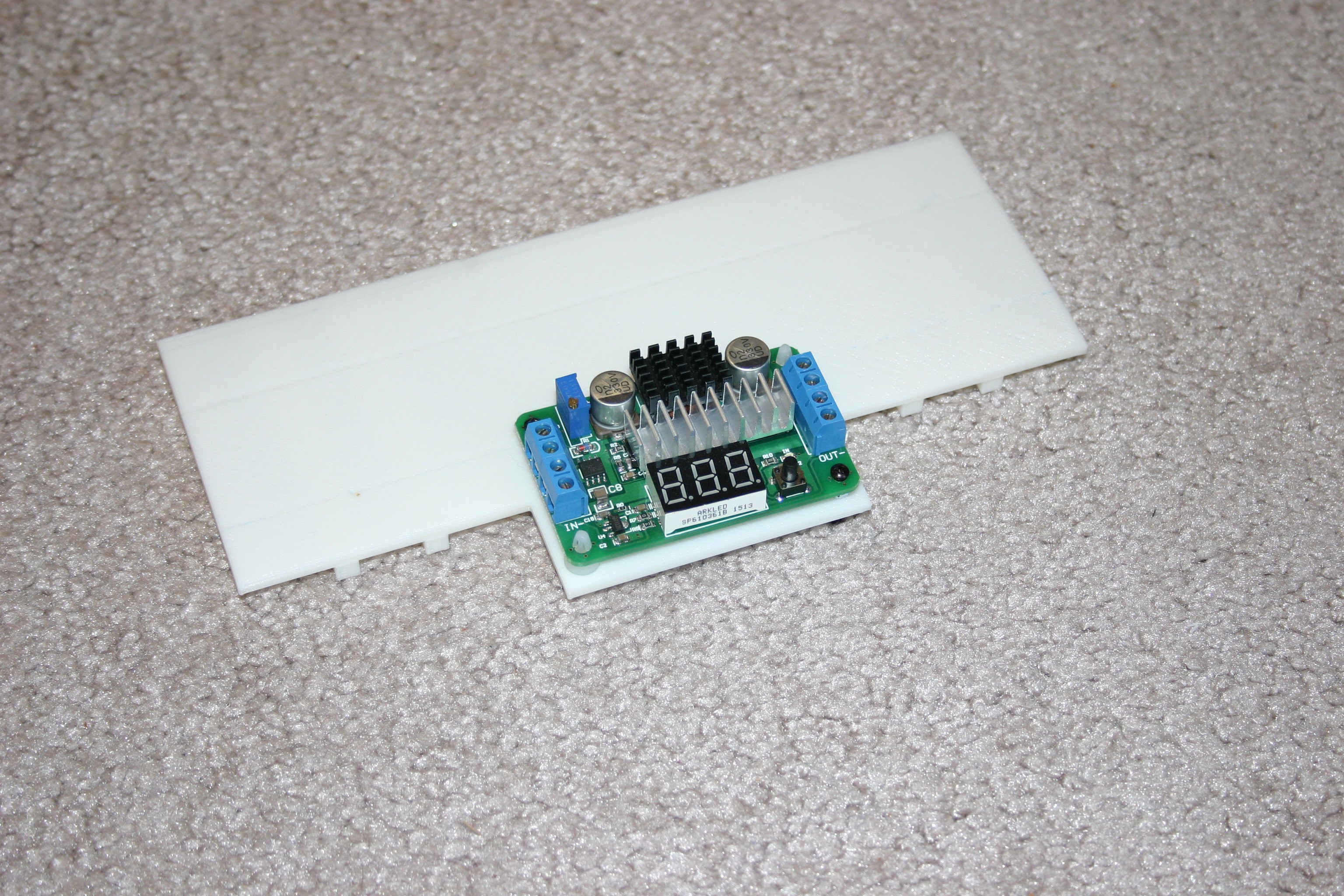

Print the top bracket and fasten the dc to dc converter to the bracket.

![]()

Place the bracket on top of the capacitors. Install the on/off switch in the switch holder.

![]()

Connect the capacitors, diode and dc converter as shown in the schematic (see overview schematic in details section), then charge the capacitor.

![]()

-

Blinky Head

03/31/2017 at 20:05 • 0 commentsBlinky's head started as a "flying saucer toy" design for Santa's Shop (Santa's Shop will be upgraded and placed on public display in the Brightway Insurance window in Gainesville, Fl during December of 2017). I tried to make the flying saucer "float invisibly" using magician's thread (which is pretty darn hard to see), but the thread will only support about 1.5 grams of weight. Instead of floating, the flying saucer will "rise and land" by means of a linear actuator (under construction right now).

I have digressed. Blinky's head is composed of a lower piece as shown below:

![]()

The holes for the leds are a little small and need to be drilled or reamed out. Using wire wrap wire, I connected eight multicolor fast blinking leds in parallel, then pushed them through the holes in the base piece.

![]()

I soldered the wire wrap wires to about 10 inches of connector wire and drilled a hole in the bottom of the base through which the connector wires are routed.

![]()

Print the top of the saucer head:

![]()

Print the camera base:

![]()

Melt (use soldering iron) the camera base to the top of the saucer (head).

![]()

Melt the top of head assembly to the bottom of the head.

![]()

Fasten the camera to the camera base using M3 x 12 machine screws and nuts.

![]()

Fasten the head assembly to Blinky's chassis by melting the pieces together.

![]()

-

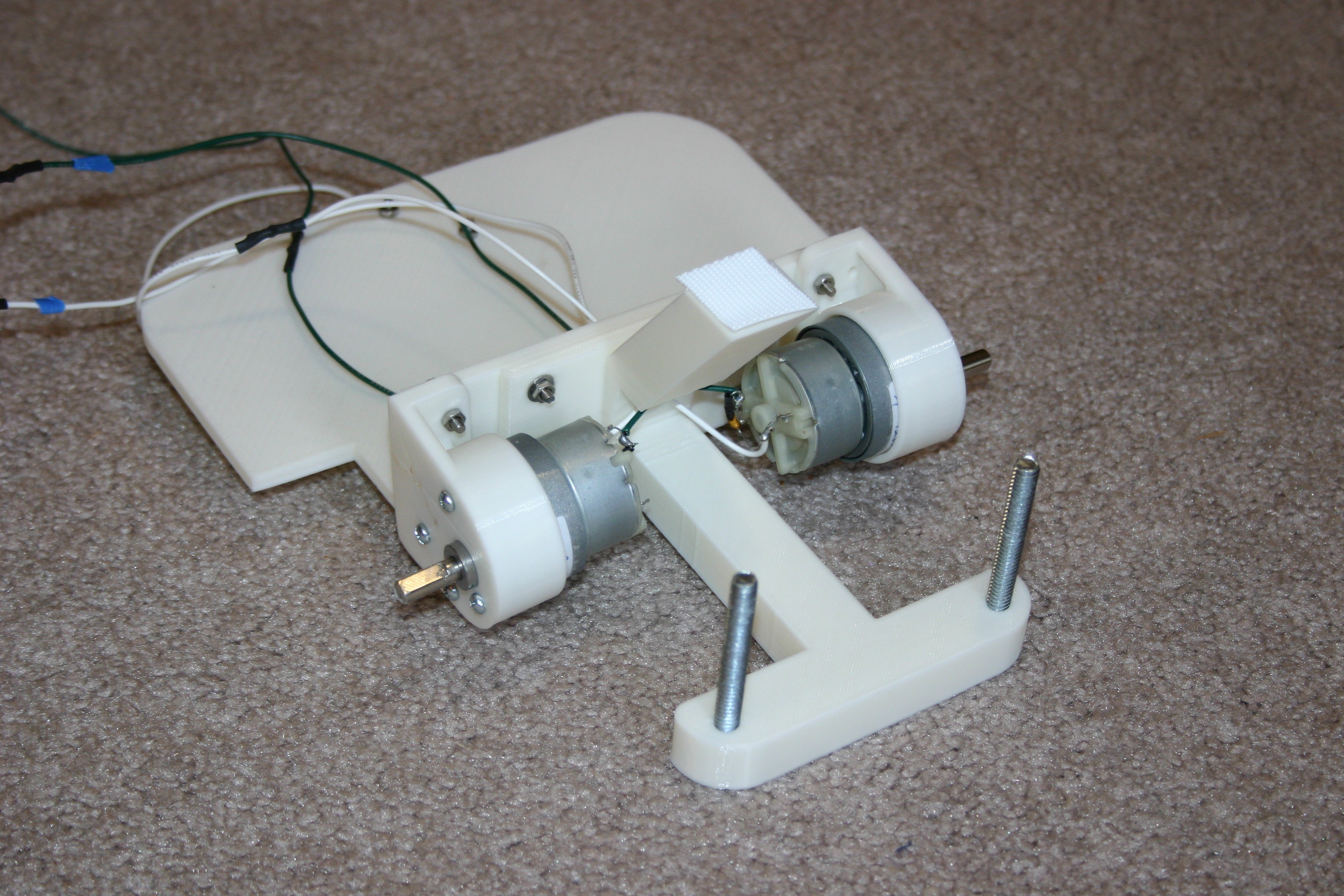

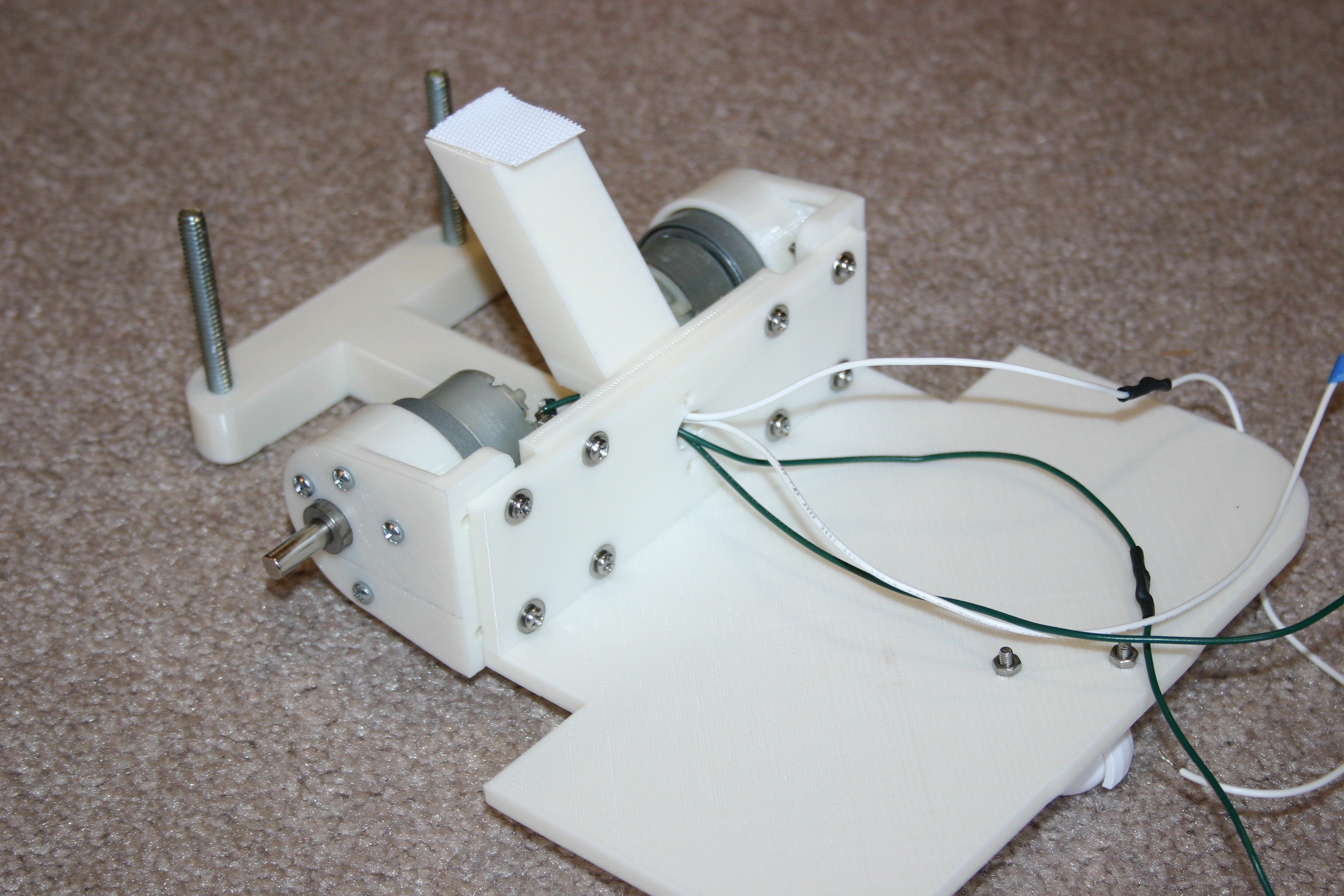

Wheels

03/30/2017 at 23:24 • 0 commentsIn my previous projects, I purchased metal brackets to mount the motors. I considered designing my own bracket for 3d printing, but I usually search thingiverse.com first and I found a great bracket here:

Print two of these brackets.

![]()

Mount the motors to the brackets using M3 x 6 machine screws.

![]()

Solder a .1 microfarad capacitor across the motor leads.

![]()

Mount the motors to the body using machine screws and nuts.

![]()

Route the wires through the hole to the back of the assembly.

![]()

Print two wheels (at least 50% infill) and push the Eureka vacuum belts (tires) onto the wheels.

![]()

Push the wheels (friction fit) onto the axles.

![]()

-

Add Bumper/Charge Pickup to Base

03/28/2017 at 18:56 • 0 commentsPrint the bumper/charge rod piece.

![]()

Drill a hole in the base to match the hole in the bumper piece (for future wire routing).

![]()

Fasten the bumper and the base together with machine screws.

![]()

Obtain (2) 1/4 inch by 2 1/2 inch bolts.

![]()

These thread into the bumper piece (they will be the charging rods for Blinky).

![]()

-

The Base

03/28/2017 at 14:08 • 0 commentsPrint the base at 30% infill.

![]()

Drill two holes (yes, I should have designed them into the base--but I'm not perfect), then secure the caster base using m3 machine screws.

![]()

Push the caster ball into the caster base.

![]()

Blinky, the Companion Robot

Blinky, a robot, lives with you, feeds itself and will--when asked--report that you have been seen moving around.

Mike Rigsby

Mike Rigsby