-

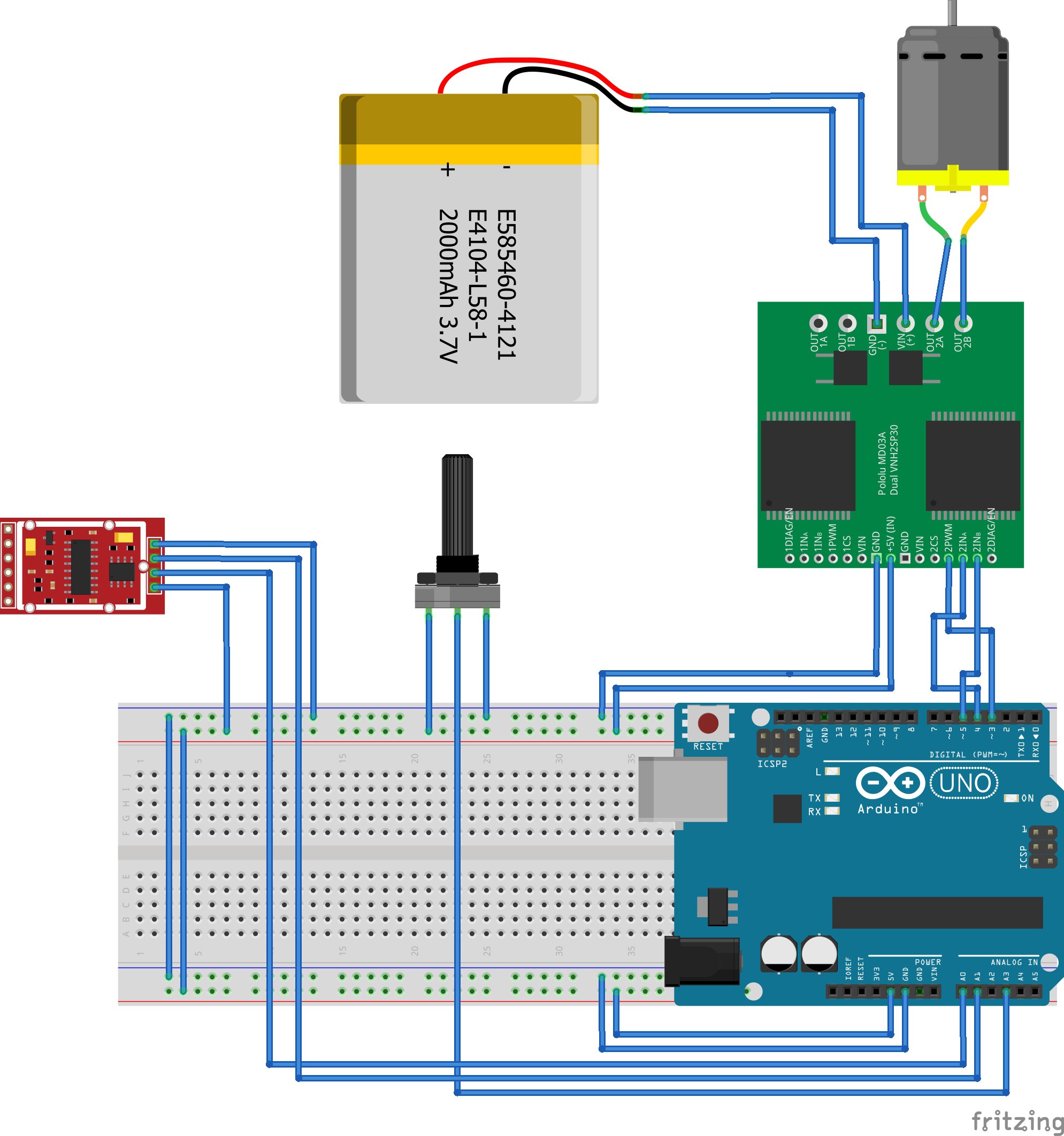

Schematics

10/21/2017 at 12:51 • 0 comments![]()

A schematics. I never got to make a PCB, but that doesn't mean you shouldn't. It's actually very easy, as you can see that there are no resistors, diodes etc.

For components and links go to PARTS LIST.

-

SOFTware

10/21/2017 at 10:38 • 0 commentsCode? Well if I knew how to make a good program that runs it.. I spoke to a friend of mine that is extremely good in electronics and programming, and he said that the most optimal solution to intuitive control would be to insert strain gauge in your bones. But in this world that is not possible and probably never will be. So there's that.

See, the problem is that the ExoArm must read the weight of object you lift before it even tries to assist you in lifting. And that is so hard. So hard. Weight changes depending on the angle of fore arm, how your arm is angled in respect to earth, etc. I'm not saying it's impossible, but it would really take some time to make this happen.

SO if you are looking to make one yourself, and are not that good in programming you should just use 2 buttons. It's astronomically easier.

MUSCLE SENSOR:

Short answer. No. Why? Because.

Just kidding. I tried using it and it did not work as I thought it will. Not even a bit. See the problem is that when you put the electrode on your biceps, you can trigger it just by stretching your skin. it causes so much electricity that it false triggers and device thinks that you send a muscle signal. So when the Exo-Arm is fastened to your arm, the belt will stretch your skin, especially at the biceps. What happens? Exo-Arm flexes, but does not let go, because it thinks you're still sending signals to the biceps when the only signal is your stretched skin, if that makes any sense.

Where to put all electronics?

I spend so much time trying to come up with a decent place. Perhaps a good starting point would be a little "backpack thingy" that sits on your shoulder or maybe even a small backpack. See the problem are batteries. They are rather heavy and make things difficult. We must also keep in mind that this should be as low cost as possible, so no fancy ExoBacks or similar things.

-

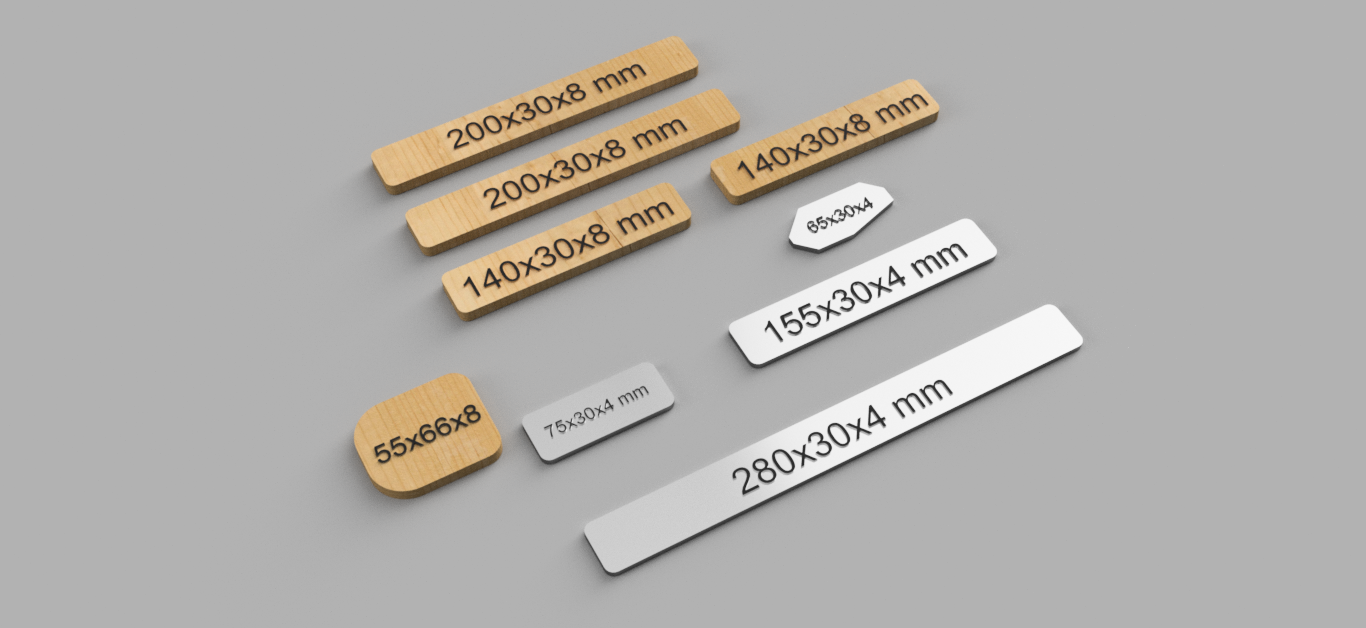

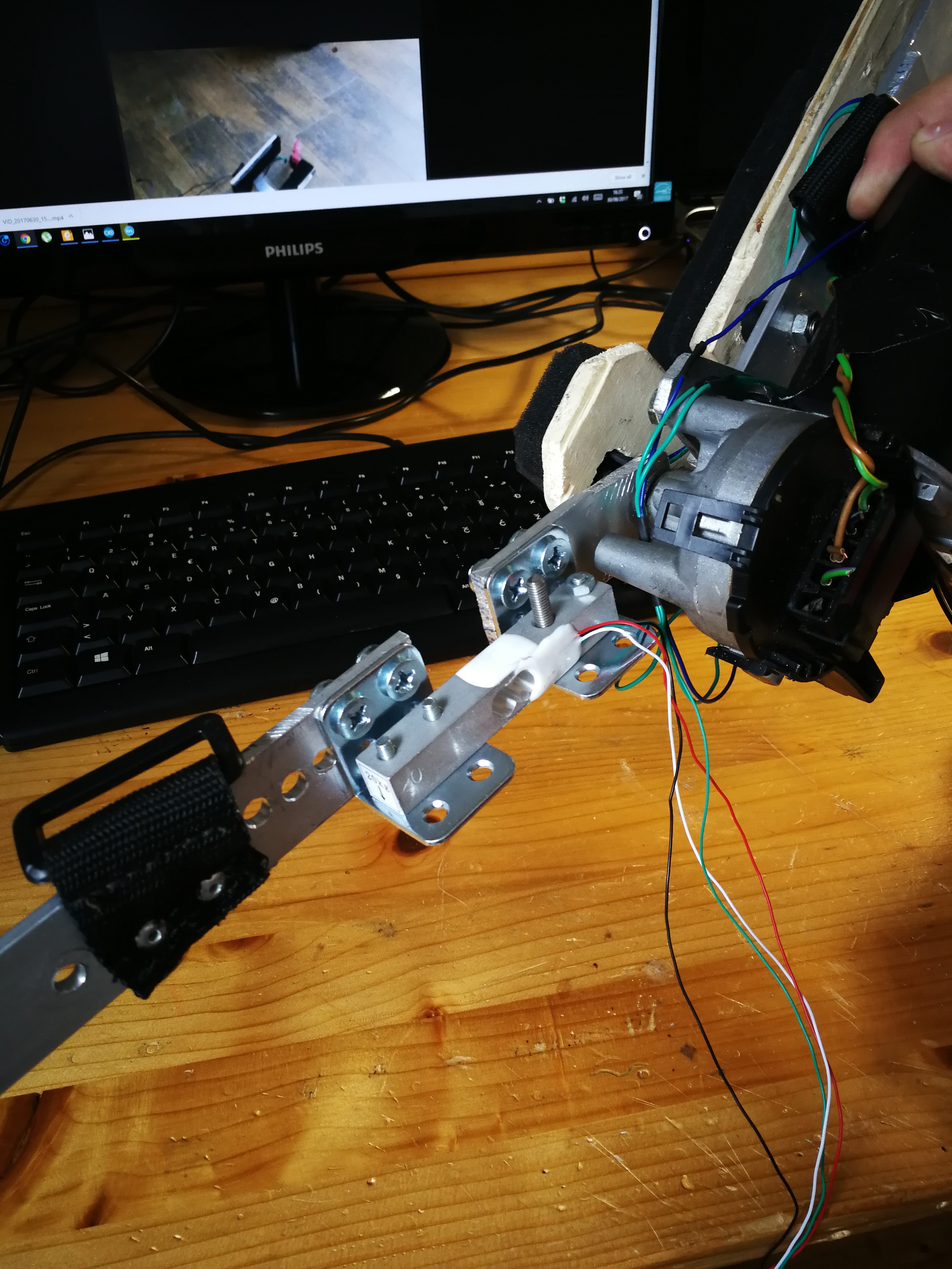

HARDware

10/21/2017 at 10:18 • 0 comments![]()

This are all the wooden and aluminum parts you'll need, minus the mounts that hold wood plates (check out the videos). Please keep in mind that there are no holes. But why Kristjan? Because I'm 99.9999% sure that every motor you'll find has different geometry, every arm is different and it goes on. So in order to make this arm, you'll need to be creative. You can follow my instructions as far as you can, but I can promise you that you'll have to figure things on your own too. But hey! That's all part of experience and that is the most valuable thing in life next to health and knowledge.

-

PID control

10/20/2017 at 15:33 • 1 commentHere is a little test with PID control. As you can see it can hold a position pretty well. The PID is not tuned. That's why you can hear that beeping sound coming from the motor.

Now all I have to do is to join PID control with intuitive movement, so that I can actually lift something.

This video is without any regulator/power:

Here you can see PID regulator in action. It is designed so that it holds a setpoint (angle), and tries to do that no matter whether there is a force on it or not)

-

What YOU should do if you make one, or what I should have done

10/19/2017 at 12:50 • 0 commentsLet's start off with the MOTOR. I'm using windshield wiper motor, but it is a stupid idea. Well not stupid but a beginners mistake. It's heavy. So heavy in fact that it pulls the whole ExoArm from your arm. I used it because I had ideas of using this ExoArm to lift 10kg and more. What I did not account for was that this ExoArm needs back support if one would wish to lift this kind of loads. But then it wouldn't cost $100 but more like $200.

So if you are going to make this arm, I suggest you try the motor that lifts and lowers the car glass window. It's lighter, it has lower torque, but for our applications it's good enough.

Something like this: https://www.ebay.com/itm/Power-Window-Motor-Front-Left-ACI-MAXAIR-83098-fits-98-11-Lincoln-Town-Car-/253215691421?epid=75818760&hash=item3af4d4d29d:g:DrgAAOSwno1ZpYq8&vxp=mtr

But I strongly suggest that you visit a local car junkyard and buy one there. Who would spend $50 on a new motor if you can get used one for $20.

Second, how to fix your arm to the ExoArm. If you look at my design, you will see that the only supports that I used are on the bottom and on the side (wood plates and foam). I encourage you that you place a support on the upper part as well. It will make your arm fit tighter to the ExoArm and therefore make it more intuitive.

-

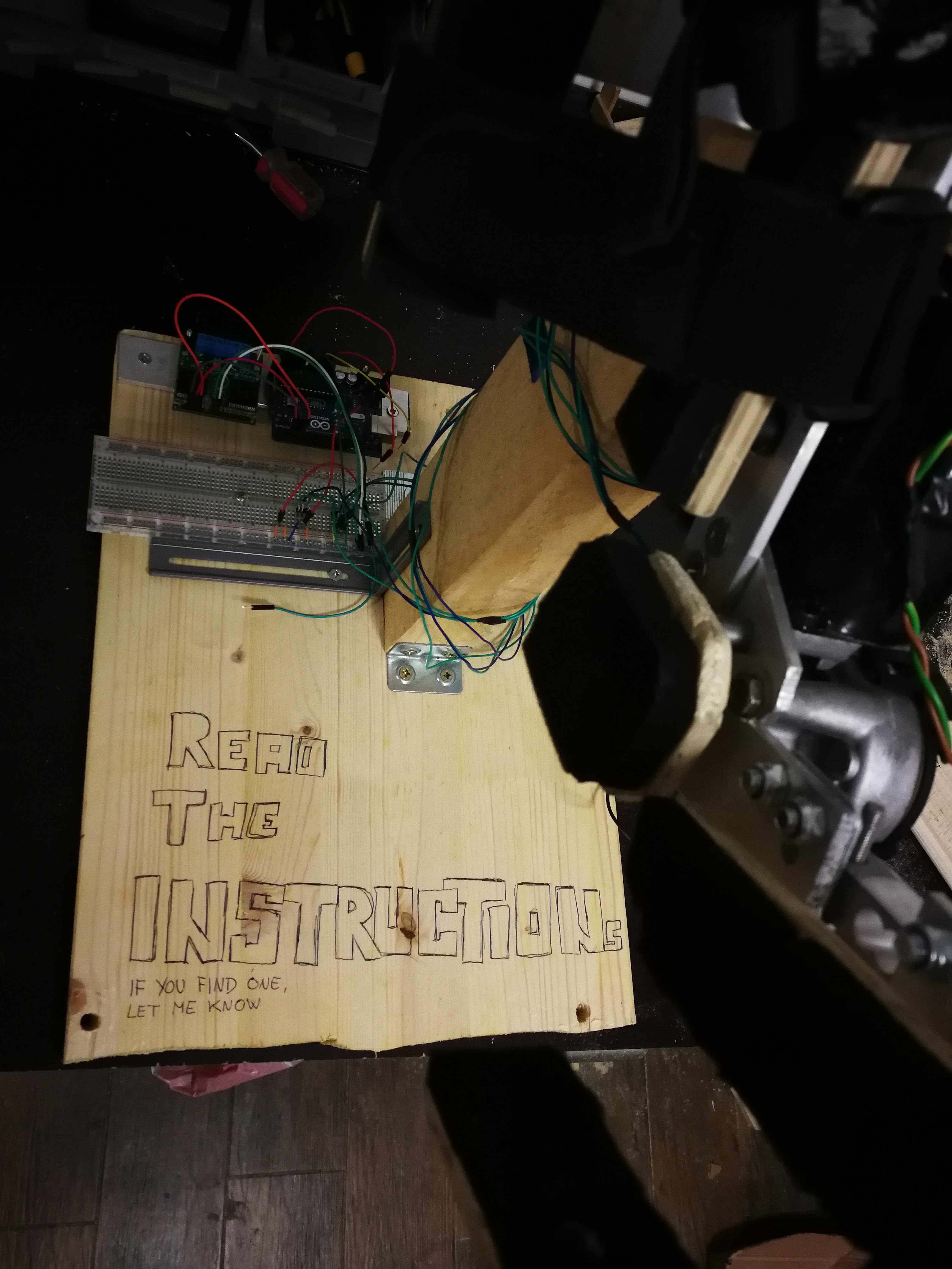

19 October (I'm back)

10/19/2017 at 12:02 • 0 commentsI'm back and it's two days until the deadline. Which is funny. This summer was hectic and I honestly didn't have much time to sit behind computer and stare in the code while sipping 6th cup of coffee. What little time I had I've been experimenting with arm and I'm getting better and better responses from it. I also resorted to 3D printing because I'm at collage and don't have access to a workshop. All the parts will be designed in a way that they can also be made from wood or any other material.

To keep this short, in the time of making this project I came to few conclusions and what should be done to make this ExoArm better. I will make another Project Log where I'll talk about that.

-

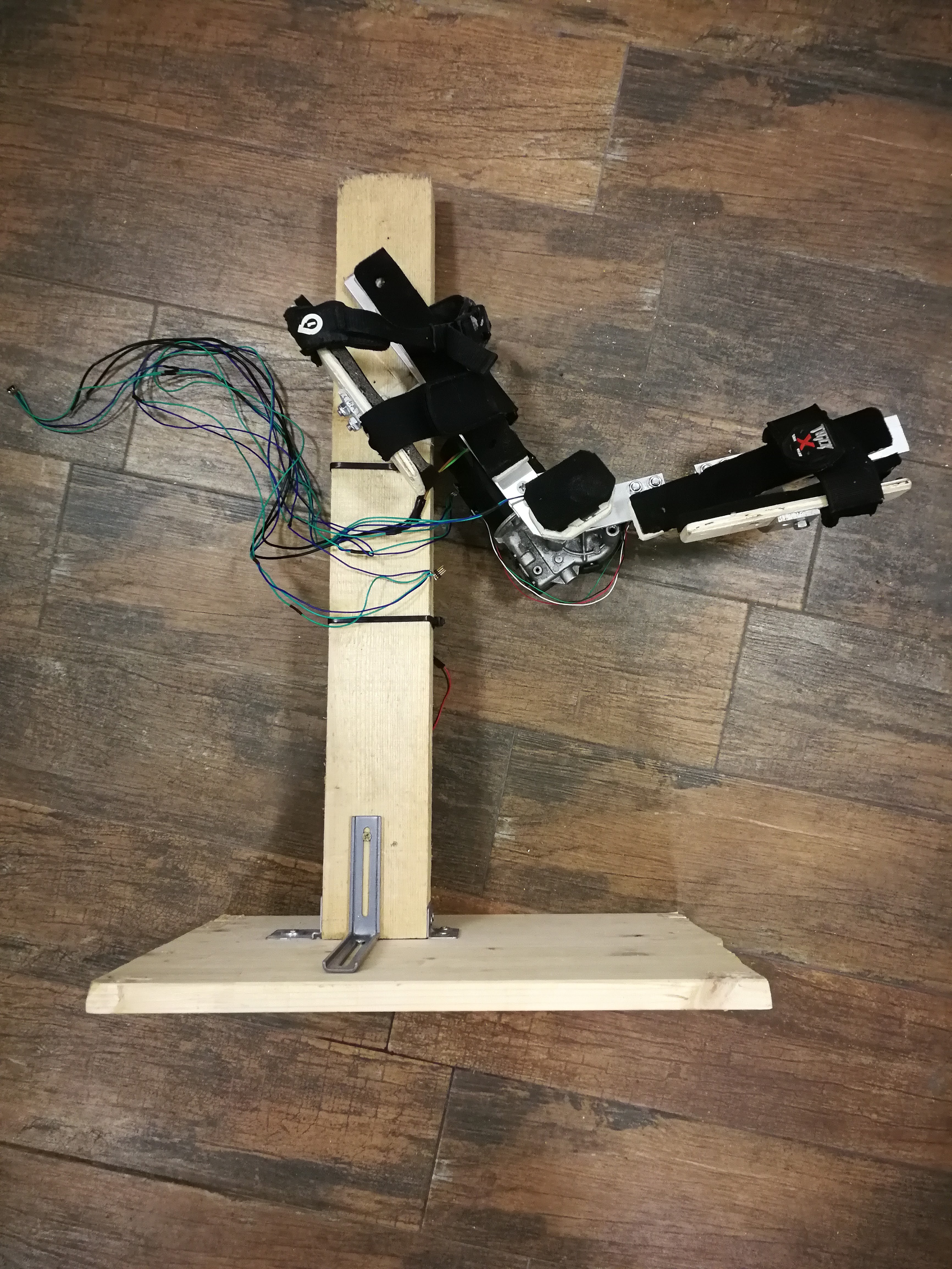

july 9, 2017

07/09/2017 at 13:17 • 0 commentsDecided to make the stand little more functional.

Not much going on at the moment regarding the ExoArm. I'm still throwing my time out of the windows trying to make it work with a weight attached to it and I can say with all of my heart that it's a lot harder than it might look.

Stay tuned for updates, it is bound to happen anytime now! :)

![]()

![]()

-

july 3, 2017

07/03/2017 at 14:18 • 0 commentsThe idea turned to reality! It actually works, and I'm super hyped!

Next thing is to make it useful for lifting heavier things and to somehow detect when something is suspended on it.

-

june 30, 2017

06/30/2017 at 14:44 • 1 commentThe SG (strain gauge) is mounted on the forearm. I placed 2.5kg weight on the arm, the SG did the job and everyone is happy forever. Well not really. Not yet. When I applied pressure upwards, the sensor value decreased, which is a good sign so big props to the theory from june 20 log. The battle is on!

Next step is to create a holder for the arm, so that I can further test it (putting it on and off from my arm is agonizing especially if I do it 40 times a day).

![]()

![]()

-

june 20, 2017

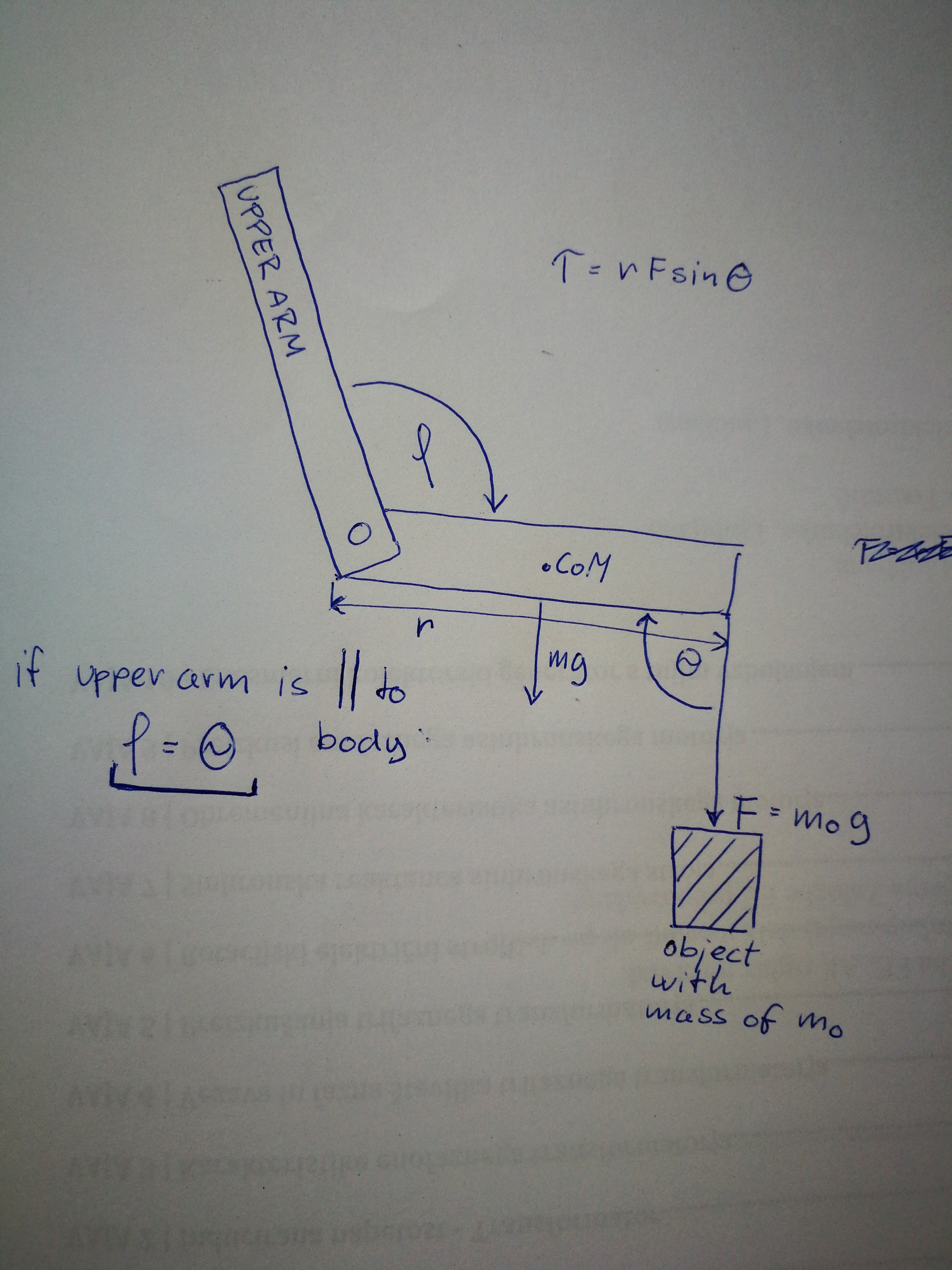

06/20/2017 at 17:47 • 0 commentsI'm still waiting to receive the strain gauge that will be placed in the middle of fore arm. It will be used to determine if there is any object suspended on the ExoArm.

So far my idea is as following (it's just the idea and may have big flaws, but until I receive the part I can't be sure)

- There is no weight on the ExoArm:

This one is simple. Strain gauge will deflect when my arm is moved up or down, so controlling this movement shouldn't be so hard.

- An object is suspended on the ExoArm:

The strain gauge sensor will detect a mass of the object, therefore we know the force and also torque. Torque changes with the angle (theta) of the object but if we say that the upper arm is parallel to the body, then the Phi angle is the same as -Theta angle.

So now we have a good estimate of the torque. Here is the part where I lose my "insight" into the mechanics. If an object is suspended on the ExoArm when I try to move my arm up, the torque on the ExoArm changes. And if torque changes, the output of strain gauge also changes, therefore the ExoArm will follow your arm depending whether the strain gauge output it bigger or smaller. So this could maybe be an effective way to control the ExoArm. I'm still thinking and trying to come up with a 100% effective way, but at the moment this is as furthest as I am.

Would love to hear your ideas and suggestions!

![]()

Affordable Exoskeleton Arm (ExoArm)

An affordable Exoskeleton Arm (ExoArm), that will help elderly, disabled people and workers complete everyday tasks with less exhaustion.

Kristjan Berce

Kristjan Berce