STM32L0 Watch

PCB design, software development, STM32 learning... The watch is just a bonus for me. ;)

PCB design, software development, STM32 learning... The watch is just a bonus for me. ;)

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Watch1.2_BOM.pdfBill of materials (includes Mouser order codes and link to assembly instructions)application/pdf - 60.00 kB - 06/03/2017 at 14:32 |

|

|

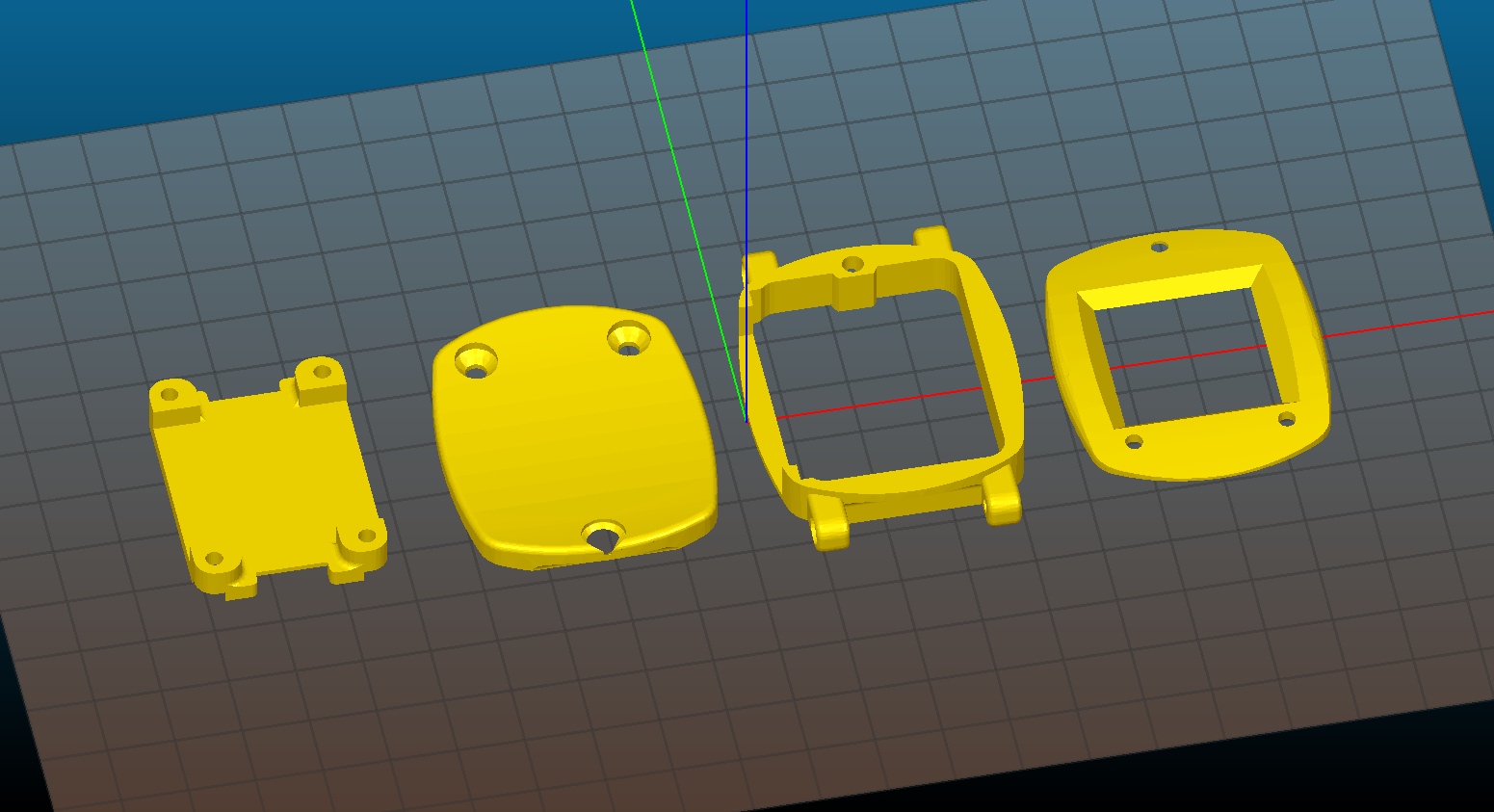

Watch_3D_v2.zipSTL filesZip Archive - 247.35 kB - 04/14/2017 at 02:35 |

|

|

Watch_FreeCAD.zipFreeCAD projectZip Archive - 6.77 MB - 03/30/2017 at 16:41 |

|

|

Watch_KiCAD.zipKiCAD projectZip Archive - 2.70 MB - 03/30/2017 at 16:39 |

|

|

L051_Watch.zipSW4STM32 projectZip Archive - 5.28 MB - 03/30/2017 at 16:37 |

|

|

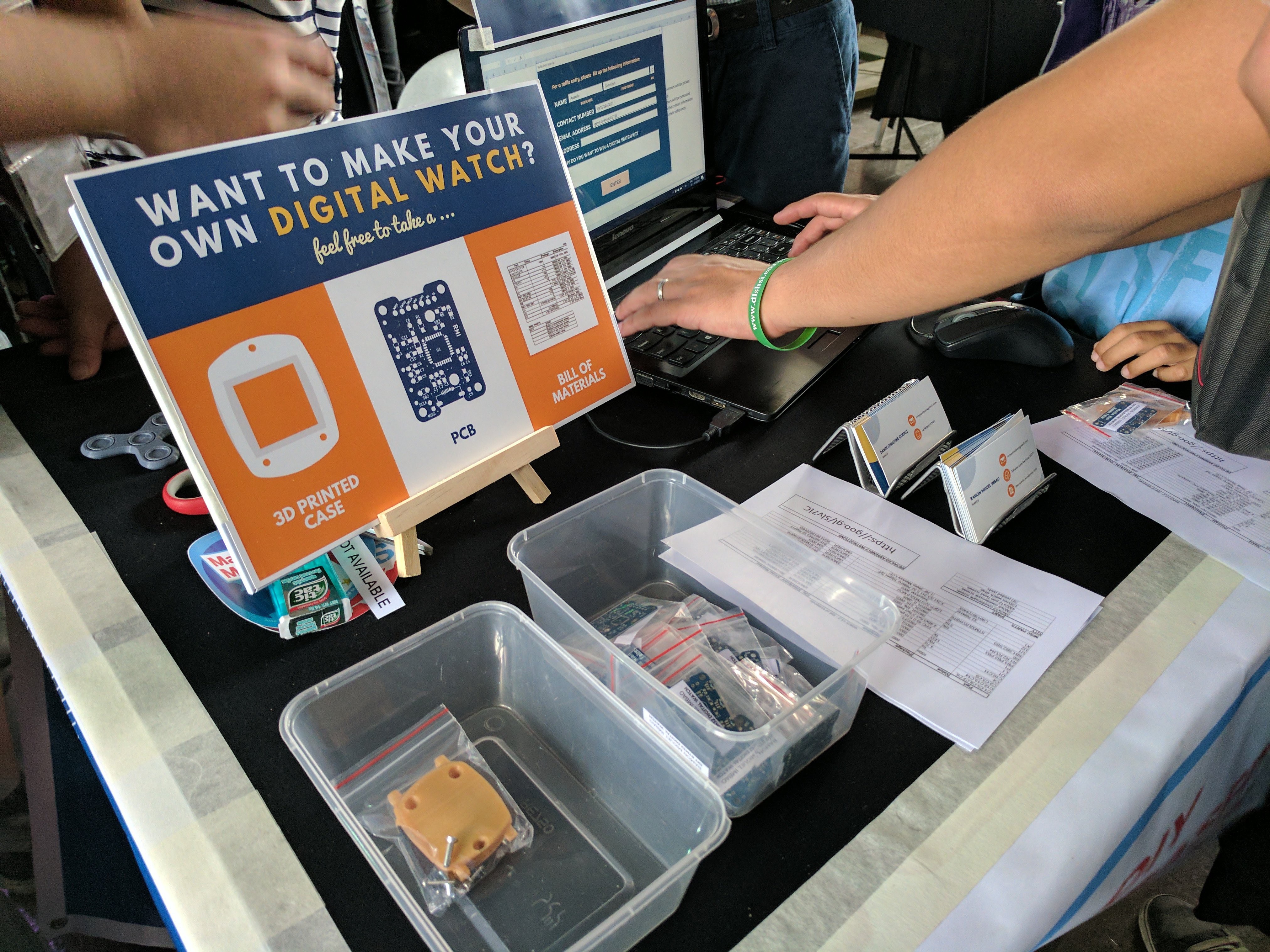

Thanks to everyone who came by our booth at the Manila Mini Maker Faire 2017!

I've already emailed the winners of the raffle for the two watch kits we'll be giving away.

See you guys next year hopefully? :D

(Thanks to Chris Bermejo for the photos)

Below, I detail how to properly assemble the watch from bare board to finished product.

--- Tools used

Have the BOM handy to easily identify which part goes where!

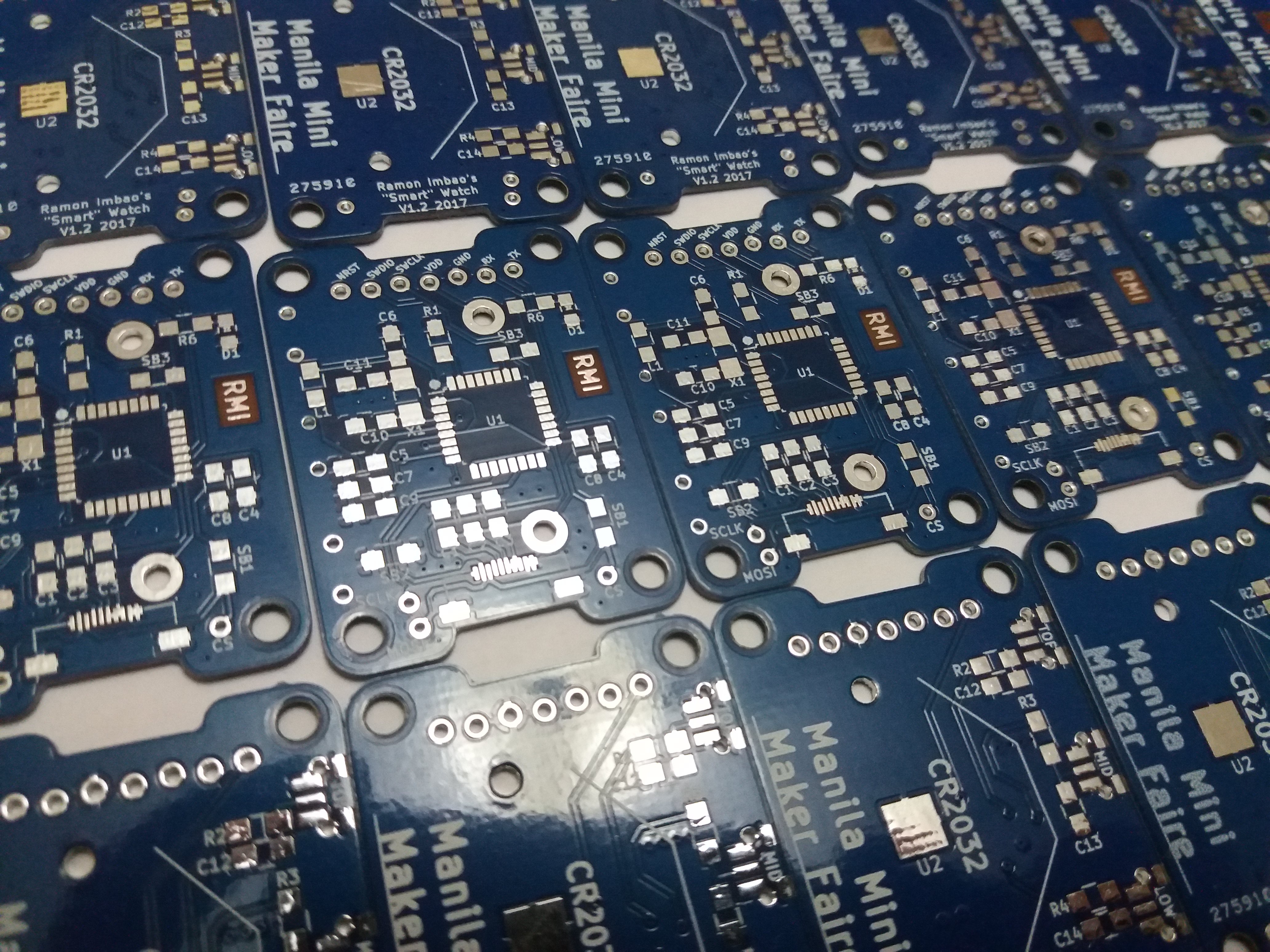

--- Bare board

Firstly, we'll work on the top part of the board. Specifically, the first thing I like soldering would be the FPC connector. It's the most difficult one to solder with a 0.5 mm pin pitch.

--- FPC connector

Don't worry about shorting pins 1 and 2, or shorting pins 3, 4, 5, and 6. Those are GND and VBAT respectively. The rest of the pins must be isolated from each other however.

--- Passives

Solder all the passives on the top board. Just go through the BOM, and take your time. Make sure to do a better job than I did as seen in the photo.

--- Crystal

I read somewhere that you shouldn't heat up the crystal too much or you'll damage it, so take care in soldering this.

--- STM32 IC

Align the IC on all the pads. Make sure that the dot on the package matches the dot on the board.

Here it is all soldered up. As you can see, I was very liberal with my flux.

--- Passives (back)

Now you can flip the board around and solder the rest of the passives at the back. All of these are just 100n capacitors and 10k resistors.

--- Buttons

Place the buttons and align them using the holes located on the board. It's a bit more difficult to solder these since the leads don't extend outward. A hot air station might be better suited for this.

--- Solder pad

Don't forget to add a tiny bit of solder to the big square pad. This helps create a tighter fit on the battery and ensures a good connection. This should create a small bump, like maybe 1 mm thick or less.

--- Battery holder

Finally, solder the battery holder on. It's the only through-hole part in the build.

--- Connect STLink

I used a Chinese ST-Link clone. Just connect the five relevant pins from the programmer to the board: SWCLK, SWDIO, NRST, VCC, and GND.

--- OpenOCD

Open up a CLI. Type in the following command to start up the OpenOCD debugger.

(I used Linux for this part. There should be tutorials online about how to set up OpenOCD for Windows. Actually programming the part is OS-agnostic, so just search for that one specific tutorial to get OpenOCD set up)

openocd -f interface/stlink-v2.cfg -f target/stm32l0.cfgThe output should be something like this:Open On-Chip Debugger 0.10.0-dev-00399-g19df456 (2016-11-04-15:40)

Licensed under GNU GPL v2

For bug reports, read

http://openocd.org/doc/doxygen/bugs.html

Info : auto-selecting first available session transport "hla_swd". To override use 'transport select <transport>'.

adapter speed: 300 kHz

adapter_nsrst_delay: 100

Info : The selected transport took over low-level target control. The results might differ compared to plain JTAG/SWD

none separate

Info : Unable to match requested speed 300 kHz, using 240 kHz

Info : Unable to match requested speed 300 kHz, using 240 kHz

Info : clock speed 240 kHz

Info : STLINK v2 JTAG v27 API v2 SWIM v6 VID 0x0483 PID 0x3748

Info : using stlink api v2

Info : Target voltage: 3.216787

Info : stm32l0.cpu: hardware has 4 breakpoints, 2 watchpoints--- Programming with SW4STM32Fire up System Workbench for STM32 (SW4STM32), load the project, and flash it to the board by hitting Run.

--- Connect screen

--- Test buttons

Press the buttons. The top and bottom buttons should move the minute hand forwards and backwards respectively. The middle button should reset the second hand. The previous picture doesn't have a second hand so this will have to be manually tested. You could also uncomment the lines in the code to enable the second hand.

Anyway, if...

Read more »

I'll be going to the Manila Mini Maker Faire this June 10 - 11. I'll have 100 blank PCBs and 50 3D printed cases to give away to any interested makers there, along with the chance for two people to win a complete watch kit each. See you guys there!

I accidentally uploaded an earlier version of the back face. It's supposed to have this thin cutout for the PCB. Anyway, it's fixed now!

Here's how I printed the parts for the watch. I used Slic3r to slice these. Find out more below.

Finally took the time to take a picture of the internals. Lots of photos below!

Read more »

Currently, I would say the hardware is complete. I'd like to perhaps get the watch printed in a clear resin so people can see the inner workings of it. Black is still the sexiest.

My files are a mess. My code is a mess as well. There are some FreeRTOS things in the code right now, but I've commented out the main thread creation portion. FreeRTOS isn't needed in this sort of thing? Well, it's still a good learning experience for me.

I've removed the second hand to reduce power consumption. Measuring it shows it's around 0.31 mA most of the time. That would give me around a month(?) of battery life. I still need to read through and try to understand the low-power modes of the STM32L0. I think that's too big considering I'm running at 2MHz in (supposedly) low-power run mode and being in low-power sleep mode the rest of the time. Maybe I still need to reduce clock speed during sleep mode?

Would love to implement a digital clock face, but still need to implement fonts (ongoing). I specifically chose the STM32L051 version so I have more flash memory available.

3D print parts

I printed everything except the buttons with black PLA at 0.025 (!!!) mm layer height. The buttons were printed with black TPE.

Populate PCB

I started with the FPC connector since it's the most difficult one to work with and I don't have a hot air gun.

Insert LCD on connector

Create an account to leave a comment. Already have an account? Log In.

I made it a wristwatch because I like wristwatches more than pocket watches. Since the files are available, you can turn it into a pocket watch yourself. :)

I don't understand your second question, sorry.

watch show 2d barcode (matrix or qrcode) and camera can read it, computer screen show 2d code and camera read it, alternative to wifi

Displaying things on the watch is easy enough. As for the camera, I have no experience interfacing with one, but there are loads of free pins on the micro I'm using so it should be relatively straightforward. You'd have to process the image you capture though since the display is just either black or white.

Yay STM32L0! I've had great luck with libopencm3, although some of the L0 stuff isn't finished (compared to the F0). If you go this route, don't forget your can easily set registers using the MMIO32(address) macro..

Thanks for the tip! I'll definitely try libopencm3 out. The only reason I went with the CubeHAL is I found a book (Mastering STM32) that contained lots of examples for it.

Become a member to follow this project and never miss any updates

why this is hand watch?

why not http://2.bp.blogspot.com/-22MbZTN9GQQ/TVeL0dCU-aI/AAAAAAAAAOE/YxsXid32EFs/s200/PocketWatch_Face.jpg

second question is lora or 2Dbarcode send (secren) and recive (camera)