-

Fresh project pages

12/21/2017 at 10:04 • 0 commentsThis is a redirect to a new project page as I feel this project has diverged significantly from the original idea.

'Bird of Prey II' Super Long Range VTOL UAV

-

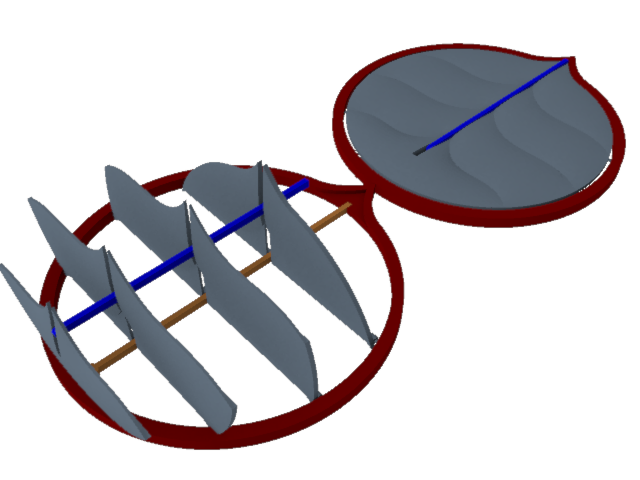

Louvered port covers

12/12/2017 at 09:36 • 0 commentsOne piece port covers are unwieldly and hard to actuate. This louvered port design makes the cover lower profile and easier to actuate. This reduces the clearance for the landing gear. Plus it looks super deadly.

Louvred port detail

The root of each louvre section as well as the central fixed spar are attached to the hard plastic porthole sleeve that passes through and reinforces the porthole where the vertical thrusting axial pair are mounted. A moving spar is actuated by a servo to open and close the louvre.

Port covers on the top of the UAV wing are open or closed.

Port covers on the bottom of the wing are controlled using the pitch and yaw signals while in VTOL mode, and are closed in forward flight mode. The pitch control in VTOL mode will help accelerate the UAV to the necessary forward flight speed, while maintaining adequate lift and yaw manuevering through vertical thrust vectoring.

-

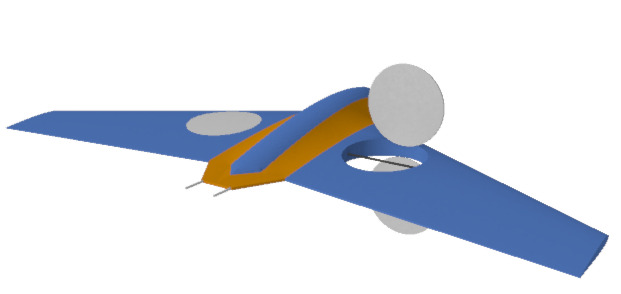

Transition from Vertical Take Off to Forward Flight

12/03/2017 at 23:02 • 0 commentsTo transition from VTO to FF, a few things need to happen:

1. Forward motion must be initiated.

2. Rear pusher prop must transition from thrusting downwards, ~90 to rear pusher position.

3. Vertical thruster coaxial pairs must shut down.

4. Port covers must close.

Ideas for transition:

Once altitude suitable for transition is reached, use servos to set the bottom port covers to an angle that would deflect the thrust of the vertical thruster rearward, gradually increasing angle until closed. At the same time, gradually increase the angle of deflection of the rear pusher unit until proper airfoil lift is achieved. During this transitory phase, the ailerons would be in max up position, gradually descending until stable forward flight is achieved.

All this can be done either manually or programmed directly into the flight controller, or an ancillary device (onboard or at base station). (Yawing while in VTOL mode can be accomplished by changing the deflective angle of the port covers as well)

Louvred port detail

Another completely seperate idea for this transition is the stop-and-drop method, where once a suitable altitude is reached, vertical thrusting units stop and rear pusher unit pivots to rear-thrust postion. The vehicle drops, nose first, rear thrust pushes it to nominal forward flight speed. Vehicle then levels out for forward flight via ailerons.

-

More design...

12/02/2017 at 22:09 • 0 comments -

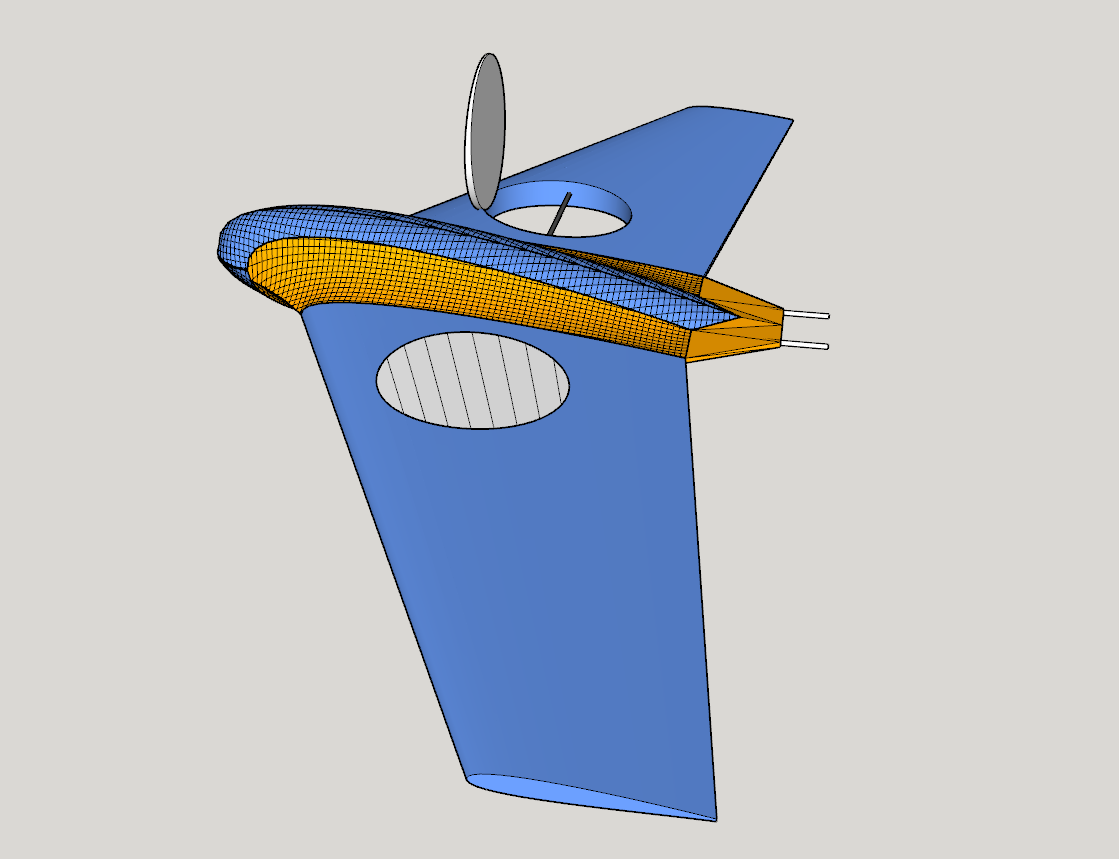

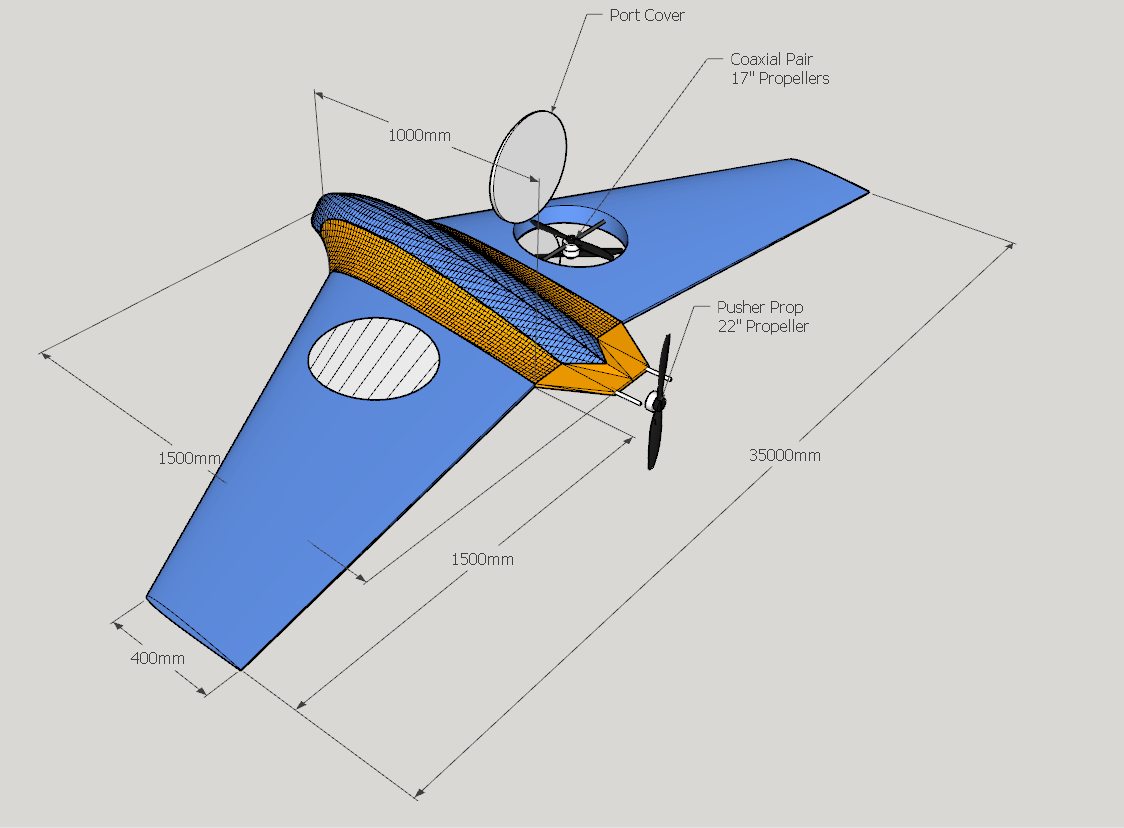

Reconsideration of Motivational Apparatus

11/28/2017 at 19:53 • 0 commentsIn reconsidering how this drone is going to move, I have come up with a different idea. Eight BLDCs is a lot of weight, and four coaxial sets means four ports in the airframe; that is a lot of lost wing area, and therefore lift.

The new idea is to make the VTOL component more like a bi-copter, using two coaxial pairs of drive units. These components will be in two ports. A third single drive unit will be mount rear and center. This unit will have the tilt component and be located just off the extreme back end of the airframe.

On vertical liftoff, the bicopter pair will provide the bulk of lifting thrust while the lone unit at the back will be pointed vertically groundward and provide only levelling stability.

At a predetermined altitude, the lone unit tilts in steps to provide pushing thrust until forward flight is established. At this point, the lifting coaxial pairs disengage. The ports through the airframe would then be covered, either with a sliding door, or a hinged door attached fore-ward.

Control of forward flight will be maintained through a combined aileron/flap actuated by servos.

-

Frame Construction - Part 1

09/03/2017 at 02:18 • 0 commentsMy almost-complete project, Mostly Printed CNC Build, will allow frame creation from a variety of materials. The three that interest me the most however are:

Aluminum

Graphene-based 3D printing filament

Reinforced carbon fibre

Aluminum - The frame can be milled from a soft aluminum. The main shape of the frame, biomorphic or purely structural, can be cut out and then channeled out to reduce weight but maintain structural integrity. Wire routing may also be improved in this way.

Graphene 3D filament - although lighter than other filaments will be a heavy option because it will take more material to achieve the structural integrity required. The entire frame will fit within the extents of the print bed.

Carbon fibre - can be milled to the correct shape, but will be floppy until reinforced by either another layer of carbon fibre or carbon fibre tubing. This will also add to the weight.

I would like to try at least two of these materials for frame creation.

-

Softwares

07/09/2017 at 04:04 • 0 commentsThe software to run the BOP will consist of flight control that can switch between VTOL and Forward Flight, OpenAero-VTOL in CleanFlight or similar. The software must be able to take data gathered from motors, telemetry sensors, and power systems and use this data to manage flight systems to manipulate component variables, including number of motors in use, stabilization, low battery auto return, efficiency, etc. Other software details may include autonomous collision avoidance, automated takeoff and landing sequences, and flight planning. Future development of softwares may include recognition of thermal updrafts and adjustment of flight path to coincide with these updrafts to maximize loft and efficiency.

-

Drive Considerations

07/09/2017 at 04:03 • 0 commentsDue to the extremely different thrust requirements for vertical take-off/landing and forward flight modes, the BOP is equipped with eight drive units. In VTOL mode, all eight are engaged. When the BOP is switched to forward flight mode, four to six of the drive units disengage, allowing greater motor efficiency and thus substantially extending battery discharge time and therefore flight times. These motor/propeller drive units are arranged in a coaxial orientation, with two drive units being stacked together to minimize the number of holes through the body. The top/forward drive units will consist of a 2808 series motor running at 2400 kV and a standard 7 inch carbon fibre propeller. The bottom/rearward drive unit will consist of the same motor as top/forward, but the propellers will be folding props (like those used on gliders) and will fold back when drive unit is not engaged, reducing drag coefficients and increasing thrust effectiveness by a considerable amount. In instances where extreme amounts of power are needed, two or four of these drive units can be engaged (ie steep vertical climb, burst of speed).

-

Frame and body interaction

04/20/2017 at 21:29 • 0 commentsFor a lot of my projects (Raptor V-tail, Laser Rifle, RasPi SmartZoom, etc.) aesthetics are important. In some circumstances, I place form above function, but mostly I try to find a happy fusion of these two aspects of design.

For the Bird of Prey, I think this fusion is easily achievable. Some of my design ideas:

- biomorphic frame design

- translucent skin on wings to provide a view of frame/internals

- frame can be flown as multicopter without skin in high wind conditions

- streamlined cover of sensor payload (camera, LIDAR, etc)

-

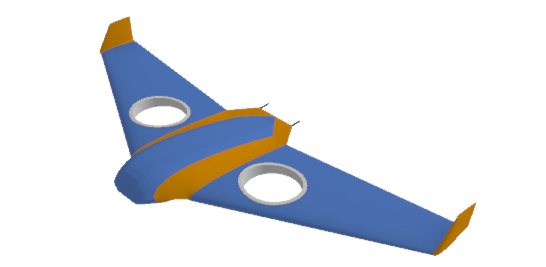

Overall Design

04/06/2017 at 23:17 • 0 comments- Form: The 'Bird of Prey' is a multi-use long range, long duration, vertical take-off/landing aerial robotic platform that incorporates the versatility of a multirotor with the efficiency of a fixed wing. The fixed wing aspect of the BOP is in a hybrid delta/flying-wing configuration. The BOP has a max AUW of 6kg with the current configuration of motors.

- Usage: This VTOL will be used for:

- airborne visual photo/videography

- airborne thermal photo/videograpy

- airborne radio repeater

- airborne network node

- airborne visual/laser/spectrum mapping

- Design: As mentioned above, the hybrid body of the BOP lends itself to VTOL as well as sustained Forward Flight. The BOP transitions from VTOL to Forward Flight by tilting the drive units. All shock sensitive electronics are enclosed and frame/body support structures are in place to allow takeoff and landing directly on the body without inclusion of landing gear. Body will be sealed for dust-proofing and partial or full waterproofing, allowing for inclement weather operations as well as water take-off, landing and below-surface camera work. The skin is seperate and removable from the frame, allowing pure multirotor operation.

'Bird of Prey' VTOL UAV drone

Flight time and versatility will be vastly extended using a combination of multirotor and blended wing technologies.

ken.do

ken.do