All files for this project can be downloaded from dropbox, Download link to files

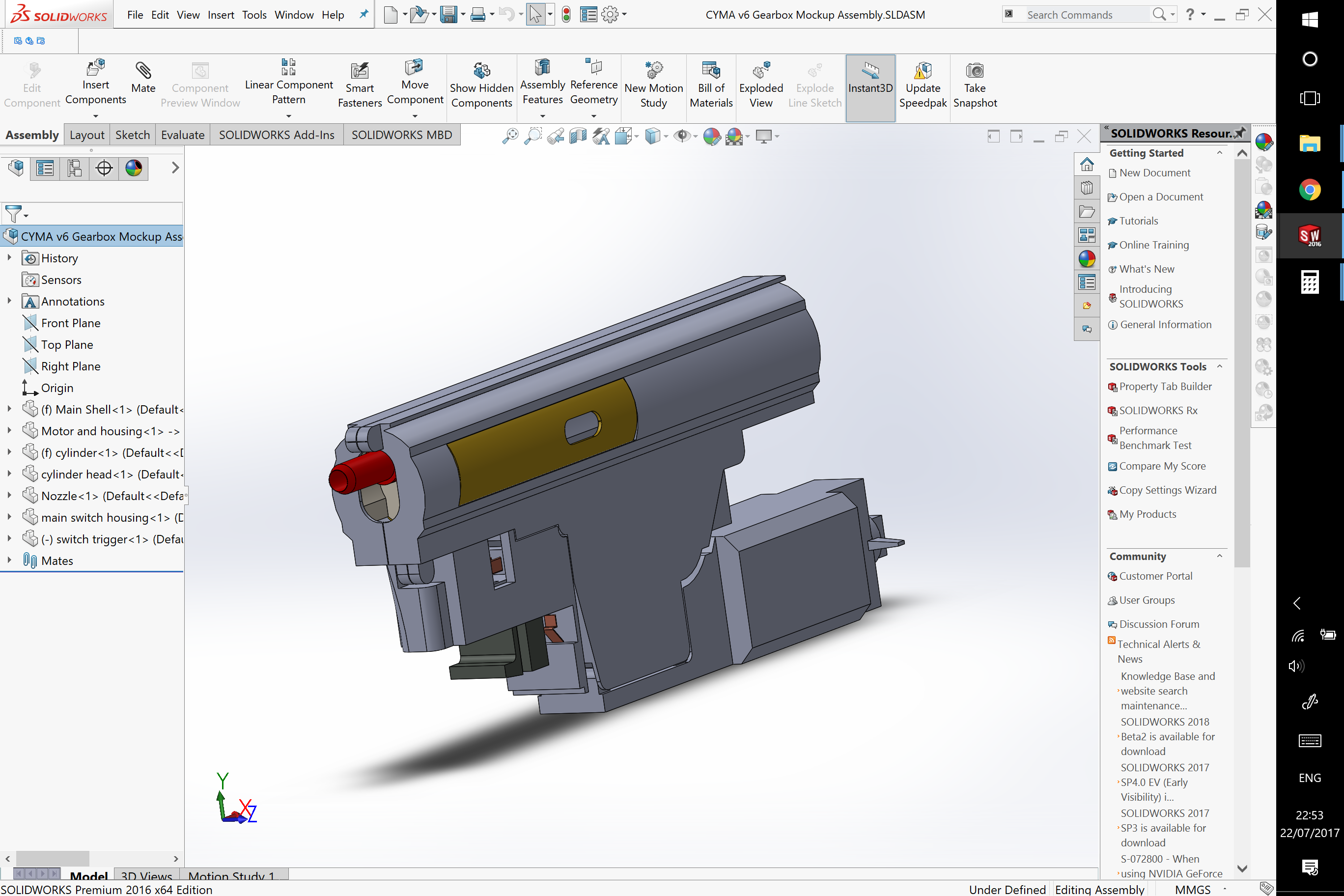

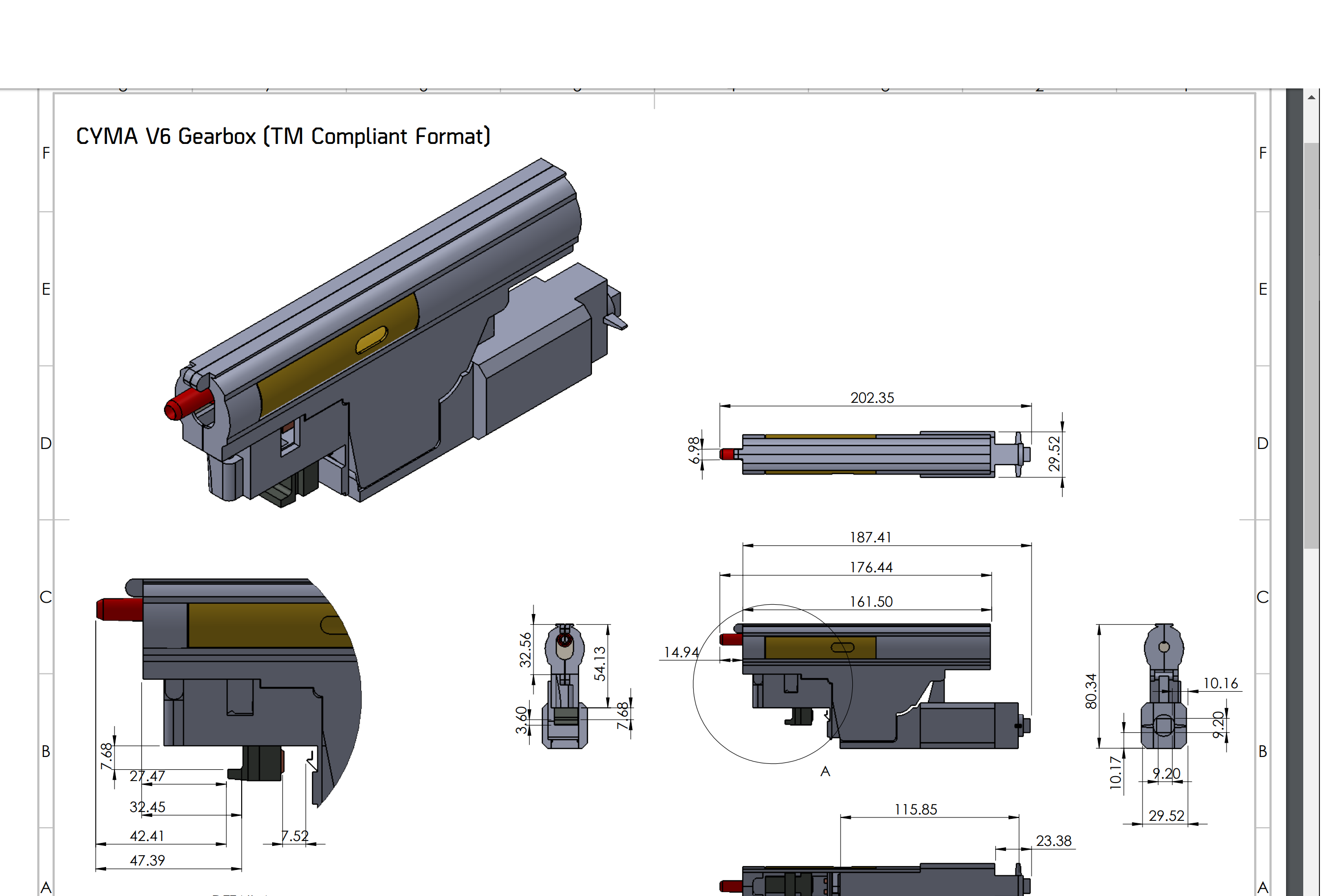

Production of Airsoft CAD files for community use

AIM: to design accurate cad files of all popular AEG gear boxes and part to allow for easy design of shells for custom made airsoft guns

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Des Reverteg

Des Reverteg

ben.brochtrup

ben.brochtrup

Jaime García

Jaime García

Josh Starnes

Josh Starnes

when is the files coming